The global high-definition (HD) door market is experiencing robust expansion, driven by rising consumer demand for durable, aesthetically refined, and technologically advanced building materials. According to a 2023 report by Mordor Intelligence, the global interior doors market—of which HD doors are a premium segment—is projected to grow at a CAGR of over 6.8% from 2023 to 2028. This growth is fueled by increasing residential and commercial construction activity, especially in emerging economies, alongside a shift toward modular and sustainable building solutions. HD doors, known for their high-density fiberboard (HDF) core, moisture resistance, and superior surface finish, are gaining traction among architects and homeowners alike. As innovation continues to redefine performance standards in door manufacturing, a select group of industry leaders stands out for their material quality, design versatility, and large-scale production capabilities. The following list highlights the top eight HD door manufacturers shaping the future of modern interiors worldwide.

Top 8 Hd Door Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

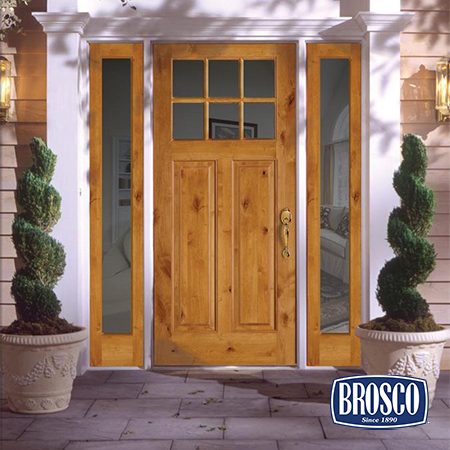

#1 Crafting Quality

Domain Est. 2018

Website: hddoor.com.sg

Key Highlights: As one of Singapore’s leading door manufacturers, HDDoor strives to elevate standards in the industry by focusing on quality, precision ……

#2 Masonite Residential

Domain Est. 1995

Website: masonite.com

Key Highlights: Explore the best selection of interior and exterior doors for your home. Masonite doors are crafted from the highest quality materials for every home style….

#3 Therma

Domain Est. 1995

Website: thermatru.com

Key Highlights: The Therma-Tru retractable screen door allows fresh air and natural light inside while keeping debris and insects out….

#4 C.H.I Overhead Doors

Domain Est. 1998

Website: chiohd.com

Key Highlights: C.H.I Overhead Doors provide high-quality garage doors for homes and businesses in a variety of styles and colors. Learn more….

#5

Domain Est. 2002

Website: hormann.us

Key Highlights: Hörmann – Innovative Door Systems For All Your Residential, High Performance, and Commercial Door Needs….

#6 Doors & Molding

Domain Est. 2006

Website: hdsupplysolutions.com

Key Highlights: In need of home or commercial door supply? Shop HD Supply’s wide variety of custom cut doors, door molding, and hardwares including door knobs and handles….

#7 Heavy Duty Pocket Door Frames

Domain Est. 2011

Website: heavydutypocketdoorframes.com

Key Highlights: HDPOCKETDOORS is our specialty division dedicated to manufacturing heavy-duty pocket door frame kits, featuring innovative designs that prioritize strength, ……

#8 Garage Doors Suppliers Company

Domain Est. 2023

Website: hddoors.co.uk

Key Highlights: HD Doors is a leading garage door supplier company in the UK. We supply, install, & repair secure, stylish garage doors with expert service you can trust….

Expert Sourcing Insights for Hd Door

H2: 2026 Market Trends for HD Door

As we approach 2026, the market for HD Door—presumably a manufacturer or provider of high-definition, high-design, or high-performance doors (including interior, exterior, smart, and luxury residential/commercial entry systems)—is expected to evolve significantly due to technological advancements, shifting consumer preferences, sustainability demands, and integration with smart home ecosystems. Below is an analysis of key market trends shaping the HD Door industry in 2026:

-

Growth in Smart and Connected Door Systems

By 2026, smart door technology is projected to dominate the premium segment. HD Door is likely to see increased demand for products integrated with IoT (Internet of Things), including fingerprint scanners, facial recognition, Wi-Fi-enabled locks, and mobile app control. These features enhance security, convenience, and home automation compatibility—key drivers in both residential and commercial markets. -

Sustainable and Eco-Friendly Materials

Sustainability remains a top priority for consumers and regulators alike. HD Door is expected to shift toward using recycled composites, FSC-certified wood, low-VOC finishes, and energy-efficient designs (e.g., improved insulation for thermal performance). In 2026, eco-conscious branding and carbon-neutral manufacturing processes will differentiate market leaders. -

Customization and Aesthetic Innovation

Homeowners and architects are increasingly seeking personalized design solutions. HD Door will benefit from offering customizable finishes, textures, colors, and architectural styles (e.g., minimalist, industrial, farmhouse). Advances in digital rendering and augmented reality (AR) tools will allow customers to visualize door designs in their spaces pre-purchase, boosting conversion rates. -

Integration with Home Security Ecosystems

Doors are becoming central access points in home security networks. By 2026, HD Door products are likely to be co-developed or certified with major security platforms like Ring, Google Nest, and ADT. This interoperability enhances consumer trust and increases product value. -

Rise in Multifunctional and Space-Saving Designs

Urbanization and smaller living spaces are driving demand for multifunctional doors—such as sliding, folding, and acoustic partition doors. HD Door can capitalize on this trend by offering space-efficient, soundproof, and thermally insulated solutions tailored to apartments, ADUs (Accessory Dwelling Units), and mixed-use buildings. -

Expansion in Commercial and Institutional Applications

Beyond residential use, HD Door is positioned to grow in commercial markets, including offices, healthcare facilities, and educational institutions. These sectors demand doors with enhanced durability, fire resistance, hygiene coatings, and accessibility compliance—areas where HD Door can leverage innovation. -

Regional Market Diversification

In 2026, emerging markets in Asia-Pacific, Latin America, and the Middle East will show rising demand for premium door solutions due to urban development and increasing disposable incomes. HD Door may expand distribution channels and form regional partnerships to tap into these growing economies. -

Supply Chain Resilience and Localized Manufacturing

Post-pandemic lessons have emphasized the need for agile supply chains. By 2026, HD Door is expected to invest in nearshoring, automation, and digital inventory management to reduce lead times and respond quickly to market fluctuations.

Conclusion

The 2026 market for HD Door will be defined by technological integration, sustainability, and design personalization. Companies that embrace smart features, eco-conscious production, and customer-centric innovation will lead the industry. HD Door’s success will depend on its ability to anticipate consumer needs, adapt to regulatory environments, and maintain a competitive edge through R&D and strategic market positioning.

Common Pitfalls When Sourcing HD Doors (Quality and IP)

Sourcing high-definition (HD) doors—especially those incorporating advanced technology such as smart access controls, surveillance integration, or data transmission—presents unique challenges. While “HD” can refer to high-definition finishes or high-density materials, in modern contexts it often implies doors with integrated digital or networked components. Two critical areas where procurement pitfalls commonly arise are quality and intellectual property (IP). Overlooking these can lead to product failures, legal exposure, and reputational damage.

Quality-Related Pitfalls

Inadequate Material and Finish Specifications

One of the most frequent sourcing issues is a lack of clearly defined quality standards for materials and surface finishes. HD doors may be marketed based on aesthetics (e.g., photorealistic wood grain or metallic finishes), but suppliers may use low-grade laminates or coatings that degrade quickly under UV exposure or physical wear. Buyers often fail to specify performance criteria such as scratch resistance, color fastness, or moisture tolerance, leading to premature failure and customer dissatisfaction.

Poor Manufacturing Tolerances and Workmanship

Even with high-quality materials, inconsistent manufacturing processes can compromise the final product. Warped frames, misaligned hardware, or uneven seams are common when production oversight is lax. This is especially critical for doors requiring tight seals (e.g., fire-rated or soundproof doors) or those integrating electronic components like sensors and access controls.

Lack of Performance Testing and Certification

Many suppliers claim compliance with industry standards (e.g., fire ratings, thermal insulation, or durability benchmarks) without providing verifiable test reports. Sourcing without demanding third-party certifications (such as UL, CE, or ISO) exposes buyers to liability. For HD doors with electronic features, electromagnetic compatibility (EMC) and environmental protection (IP ratings) testing are often overlooked.

Inconsistent Integration of Electronic Components

For smart HD doors, the integration of HD cameras, access control systems, or IoT features must be seamless. Poor wiring, incompatible protocols, or substandard electronics can lead to system failures. Sourcing from suppliers without proven experience in electromechanical integration increases the risk of malfunction and maintenance issues post-installation.

Intellectual Property (IP)-Related Pitfalls

Unlicensed Use of Design or Technology

Many HD door designs—especially those with distinctive finishes or embedded tech—are protected by design patents, copyrights, or trademarks. Sourcing from manufacturers who copy high-end designs without authorization exposes the buyer to legal action for contributory infringement. This is particularly common in markets where aesthetic replication is widespread.

Lack of IP Ownership Clarity in Custom Designs

When commissioning custom HD doors, buyers often assume they automatically own the design rights. However, without a clear contract stating IP ownership, the manufacturer may retain rights to the design, allowing them to sell identical products to competitors. This undermines exclusivity and brand differentiation.

Use of Proprietary Technologies Without Licensing

Smart HD doors may incorporate patented technologies (e.g., facial recognition algorithms, encrypted communication protocols, or motorized locking systems). If the supplier uses licensed components without proper authorization, the end buyer may face legal challenges or be forced to discontinue use. Always verify that embedded technologies are legally licensed and compliant with regional regulations.

Inadequate Documentation and Traceability

IP risks are compounded when suppliers fail to provide documentation proving the legitimacy of designs, software, or components. Without bills of materials, software licenses, or design registrations, buyers have no defense in case of IP disputes. This also hampers compliance with procurement regulations in public or corporate sectors.

Mitigation Strategies

To avoid these pitfalls:

– Define detailed technical specifications and quality benchmarks upfront.

– Require third-party test reports and compliance certifications.

– Conduct factory audits and sample testing before bulk orders.

– Include explicit IP clauses in supplier contracts, ensuring transfer of rights where needed.

– Perform due diligence on design originality and technology licensing.

By addressing both quality and IP concerns proactively, organizations can ensure reliable, legally compliant HD door sourcing that supports long-term performance and brand integrity.

Logistics & Compliance Guide for HD Door

This guide outlines the essential logistics procedures and compliance requirements for HD Door to ensure efficient operations, regulatory adherence, and customer satisfaction.

Supply Chain Management

Establish a robust supply chain network by partnering with reliable suppliers for raw materials such as hardwood, hardware, and finishes. Implement vendor evaluation protocols, maintain inventory safety stock levels, and use demand forecasting tools to minimize delays and production bottlenecks.

Transportation & Distribution

Coordinate inbound and outbound logistics using certified freight carriers experienced in handling large, fragile goods. Utilize protective packaging and secure loading techniques to prevent damage during transit. Optimize delivery routes to reduce lead times and fuel consumption, and provide customers with real-time shipment tracking.

Warehousing & Inventory Control

Maintain organized, climate-controlled warehouse facilities to preserve wood quality and prevent warping or moisture damage. Employ barcode or RFID systems for accurate inventory tracking, regular stock audits, and FIFO (First In, First Out) rotation to ensure material freshness and reduce waste.

Import/Export Compliance

For international operations, ensure all shipments comply with destination country regulations. Prepare accurate commercial invoices, packing lists, and certificates of origin. Adhere to ISPM-15 standards for wooden packaging and stay updated on tariff classifications and customs documentation requirements.

Product Safety & Certification

Ensure all doors meet relevant building codes and safety standards, such as ANSI, ASTM, or local fire and egress regulations. Maintain up-to-date product testing certifications and provide technical documentation to distributors and end-users upon request.

Environmental & Sustainability Compliance

Comply with environmental regulations regarding emissions, waste disposal, and chemical use (e.g., VOC limits in finishes). Source FSC or PEFC-certified wood to support sustainable forestry practices and enhance brand reputation.

Regulatory Documentation & Recordkeeping

Maintain comprehensive records of supplier agreements, shipment logs, compliance certifications, and quality control inspections. Retain documentation for a minimum of seven years to support audits and regulatory inquiries.

Incident Management & Corrective Actions

Establish procedures for handling logistics disruptions, product damage, or compliance violations. Implement corrective and preventive actions (CAPA) to address root causes and improve operational resilience.

Training & Continuous Improvement

Conduct regular training for logistics and operations staff on compliance updates, safety protocols, and new technologies. Monitor key performance indicators (KPIs) such as on-time delivery rates and error frequencies to drive continuous improvement.

In conclusion, sourcing HD (high-definition) doors requires a strategic approach that balances quality, durability, design, cost, and supplier reliability. By clearly defining project requirements—such as material type, finish, dimensions, acoustic or fire ratings, and sustainability standards—buyers can effectively evaluate potential suppliers and ensure compliance with industry specifications. Conducting thorough market research, comparing quotes, and performing due diligence on supplier credentials, lead times, and after-sales service are critical steps in the sourcing process. Additionally, considering long-term value over initial cost, especially for commercial or high-traffic applications, can lead to enhanced performance and reduced maintenance expenses. Ultimately, successful sourcing of HD doors hinges on collaboration with trusted manufacturers or distributors who offer innovation, consistency, and customization to meet exact project demands.