The global hazmat suits market, driven by rising industrial safety regulations and increasing nuclear energy applications, is projected to grow at a CAGR of 7.2% from 2023 to 2028, according to Mordor Intelligence. With growing concerns over radiological hazards in healthcare, defense, and nuclear power sectors, demand for high-performance radiation-protective hazmat suits has intensified. Technological advancements in material science—such as lead-free composites and lightweight laminates—are enabling manufacturers to improve protection while enhancing wearer mobility. In this evolving landscape, a select group of eight manufacturers have emerged as leaders, combining innovation, regulatory compliance, and global reach to dominate the radiation-specific segment of the hazmat suit market.

Top 8 Hazmat Suit Radiation Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Demron

Domain Est. 2001

Website: radshield.com

Key Highlights: Demron is specifically engineered to combine radiation protection with “ease of use” in order to maximize effective radiological defense.Missing: hazmat manufacturer…

#2 DuPont™ Tychem® Hazmat Suits

Domain Est. 1987

Website: dupont.com

Key Highlights: DuPont has developed hazmat garments and biohazard suits to help protect against the chemical and biological hazards they face at work….

#3 Hazmat suits

Domain Est. 1994

Website: draeger.com

Key Highlights: Chemical protection suits (CPS). Our hazmat suits (type 1) protect your workers from a variety of hazardous substances in gaseous, liquid, aerosol and solid ……

#4 Hazmat Suit

Domain Est. 1995

Website: ansell.com

Key Highlights: Stay safe with Ansell’s top-quality hazmat suits, designed to provide comprehensive protection in hazardous environments….

#5 Kappler

Domain Est. 1996

Website: kappler.com

Key Highlights: With patented fabrics, innovative seaming and unique designs, your Kappler garment has you prepared for hazardous materials. Know what you’re getting into….

#6 Radiation Protection Products. Radiation Shield by StemRad

Domain Est. 2011

Website: stemrad.com

Key Highlights: StemRad has made personal radiation protection possible, making the lives of Physicians, Astronauts, First Responders, and Nuclear Industry Workers safer….

#7 About Hazmat Resource

Domain Est. 2018

Website: hazmatresource.com

Key Highlights: 6-day delivery 30-day returnsWe provide a wide range of personal protective equipment (PPE), testing devices, and technical reference materials, to name a few….

#8 Hazmat Supplies & Professional Protective Gear

Domain Est. 2018

Expert Sourcing Insights for Hazmat Suit Radiation

H2: Projected 2026 Market Trends for Hazmat Suits in Radiation Protection

The global market for hazmat suits designed for radiation protection is poised for significant transformation by 2026, driven by rising nuclear energy investments, heightened focus on emergency preparedness, technological innovation, and regulatory advancements. These factors are converging to reshape demand, product development, and regional market dynamics.

-

Increased Demand from Nuclear Energy Expansion

As countries pursue low-carbon energy alternatives, nuclear power is experiencing a resurgence. Nations such as China, India, the United Kingdom, and several Eastern European countries are investing in new reactor construction and life extensions for existing plants. This expansion increases the need for radiation-protective personal protective equipment (PPE), including advanced hazmat suits, for routine operations, maintenance, and decommissioning activities. -

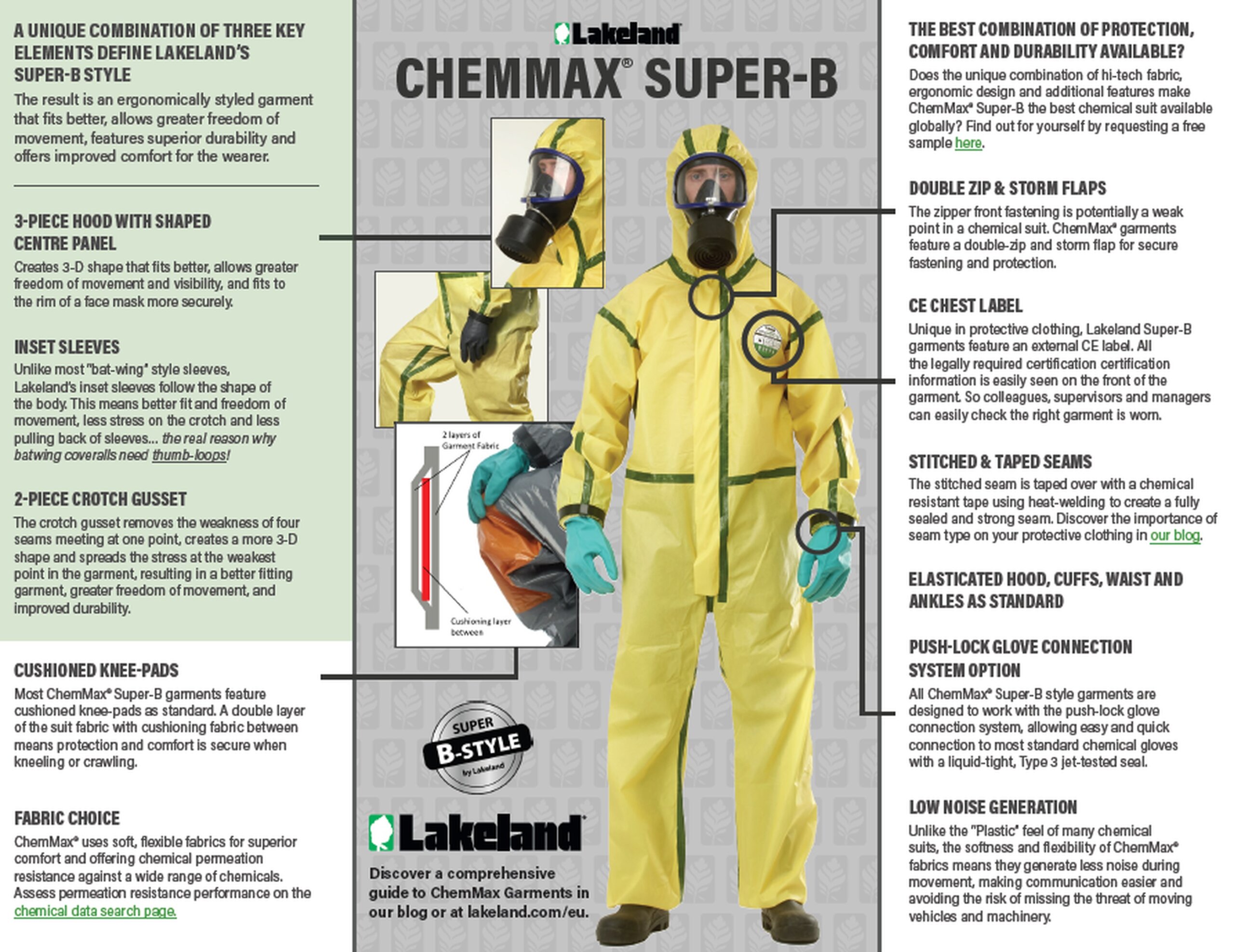

Technological Advancements in Material Science

By 2026, next-generation hazmat suits are expected to integrate lightweight, multi-threat shielding materials that offer improved protection against both ionizing radiation and chemical/biological hazards. Innovations include nano-coated fabrics, lead-free radiation shielding polymers, and breathable laminates that enhance wearer comfort during prolonged use. Smart textile integration—such as embedded dosimeters and real-time health monitoring sensors—is anticipated to become standard in premium protective suits. -

Focus on Reusability and Sustainability

Environmental concerns and cost-efficiency are driving a shift from single-use to reusable, decontaminable hazmat suits in radiation applications. Manufacturers are responding with durable, sterilizable suit designs that maintain integrity after multiple uses. This trend aligns with sustainability goals in both public and private sectors and is expected to influence procurement policies. -

Regulatory and Standardization Developments

Regulatory bodies such as the International Atomic Energy Agency (IAEA), OSHA, and the European Committee for Standardization (CEN) are expected to tighten performance standards for radiation PPE by 2026. These updates will likely mandate higher levels of protection, improved labeling, and traceability, which will impact design, certification, and market entry for new products. -

Geopolitical and Emergency Preparedness Drivers

Rising geopolitical tensions and the persistent threat of radiological incidents (e.g., dirty bombs, nuclear accidents) are prompting governments to bolster civil defense and first responder capabilities. This is increasing public sector procurement of radiation-rated hazmat suits, particularly in North America, Europe, and parts of Asia-Pacific. Stockpiling initiatives and disaster response drills are further stimulating market growth. -

Regional Market Shifts

The Asia-Pacific region is projected to be the fastest-growing market by 2026, led by China and India’s nuclear ambitions and expanding industrial safety regulations. North America will maintain a strong market share due to advanced emergency response infrastructure and federal funding for homeland security. Meanwhile, the Middle East is emerging as a new growth area, with countries like the UAE and Saudi Arabia launching nuclear energy programs. -

Supply Chain Resilience and Localization

Lessons from recent global crises have emphasized the need for resilient PPE supply chains. By 2026, there will be a greater push toward localized manufacturing of hazmat suits, especially in radiation-grade variants, to reduce dependency on imports and ensure rapid deployment during emergencies.

In conclusion, the 2026 market for radiation-specific hazmat suits will be characterized by innovation, stricter regulations, and rising demand across civil, industrial, and defense sectors. Companies that invest in advanced materials, comply with evolving standards, and adapt to regional needs will be best positioned to capture growth in this specialized segment of the protective equipment industry.

H2: Common Pitfalls When Sourcing Hazmat Suits for Radiation Protection (Quality and IP Considerations)

Sourcing hazmat suits designed for radiation protection involves critical considerations around quality assurance and intellectual property (IP) rights. Failure to address these aspects can lead to safety risks, legal exposure, and procurement inefficiencies. Below are common pitfalls to avoid:

1. Overlooking Certification and Compliance Standards

A major quality pitfall is sourcing suits that lack proper certification for radiation protection, such as compliance with NFPA 1994 (Class 4 for radiological environments), EN 1073-2 (European standard for radioactive contamination), or NIOSH/OSHA regulations. Procuring non-compliant suits jeopardizes user safety and may violate workplace safety laws.

2. Confusing Chemical Protection with Radiation Protection

Many hazmat suits are designed for chemical hazards but not for particulate radioactive contamination. Buyers often assume all protective suits offer radiation shielding, which is incorrect. Radiation-specific suits require sealed seams, anti-static properties, and materials resistant to alpha/beta particles—features not always present in standard chemical suits.

3. Inadequate Quality Control from Suppliers

Sourcing from low-cost manufacturers, particularly in regions with lax regulatory oversight, increases the risk of substandard materials and inconsistent manufacturing. Without third-party testing reports or batch traceability, it’s difficult to verify that each suit meets required protection levels.

4. Neglecting Durability and Usability Testing

High-quality radiation hazmat suits must balance protection with mobility and durability. Pitfalls include purchasing suits that tear easily, fog up visors, or restrict movement—compromising both safety and operational effectiveness. Field testing and user feedback should be part of the evaluation process.

5. Ignoring Intellectual Property (IP) Risks

Some suppliers may offer suits that mimic designs or branding of established, patented models (e.g., Tyvek® or DuPont™). Sourcing counterfeit or IP-infringing products exposes organizations to legal liability, supply chain disruptions, and reputational damage. Always verify trademarks, patents, and authenticity documentation.

6. Lack of Transparency in Material Sourcing

IP concerns also extend to proprietary material technologies (e.g., specialized laminates or filtration layers). Suppliers may not disclose full material specifications, making it difficult to assess innovation legitimacy or ensure consistency. This lack of transparency can mask IP violations or performance shortcomings.

7. Failure to Verify Supplier Credentials

Procurement teams may overlook the importance of vetting suppliers for IP compliance and manufacturing legitimacy. Engaging with unauthorized distributors or gray-market vendors increases the risk of receiving imitation products lacking proper performance validation.

8. Not Securing Licensing for Custom or Branded Equipment

If custom hazmat suits are developed using proprietary technology, failing to secure proper IP licenses or usage rights can result in infringement claims. Ensure contracts include clear IP ownership clauses, especially when co-developing or modifying existing designs.

By proactively addressing these quality and IP-related pitfalls, organizations can ensure they source radiation-appropriate hazmat suits that are safe, compliant, and legally sound.

Logistics & Compliance Guide for Hazmat Suits Designed for Radiation Protection

This guide outlines the essential logistics and compliance considerations for the procurement, storage, transportation, use, and disposal of hazmat suits specifically designed to protect against radiological hazards. Strict adherence is critical for personnel safety, regulatory compliance, and environmental protection.

Procurement & Specification

- Verify Protection Level: Ensure the suit is explicitly rated for the specific type(s) of radiation (alpha, beta, gamma, neutron) and contamination levels expected in your operational environment. Check the manufacturer’s certification and test data (e.g., attenuation factors).

- Regulatory Compliance: Confirm the suit meets relevant standards such as ANSI N42.17, ISO 13688 (general protective clothing), and any specific national regulations (e.g., NRC, EPA, OSHA guidelines in the US).

- Material Compatibility: Select suits made from materials resistant to the specific radioactive contaminants and potential decontamination agents used (e.g., Tyvek, butyl rubber, specific laminates). Avoid materials that become brittle or degrade when irradiated.

- Integration & Accessories: Procure necessary compatible accessories: appropriate respiratory protection (PAPR, SCBA), double-gloving systems (compatible inner/outer gloves), boot covers, tape, and communication devices.

- Supplier Qualification: Source from reputable suppliers with documented quality control processes and traceability.

Storage & Inventory Management

- Controlled Environment: Store suits in a clean, dry, cool, and dark area. Avoid exposure to direct sunlight, extreme temperatures, humidity, ozone, and chemical fumes, as these can degrade materials.

- Original Packaging: Keep suits in their original, sealed packaging until ready for use to prevent contamination and physical damage.

- Shelf Life Monitoring: Implement a strict inventory system tracking manufacturing dates and expiration dates. Rotate stock using a First-Expired-First-Out (FEFO) system. Do not use expired suits.

- Segregation: Store new, unused suits separately from used or potentially contaminated suits. Clearly label storage areas.

- Accessibility: Ensure storage locations allow for rapid access during emergencies while maintaining security.

Transportation (Inbound & Outbound)

- New Suits (Inbound): Transport in original, undamaged packaging. Protect from physical damage, moisture, and temperature extremes during transit. Maintain temperature logs if required by the manufacturer.

- Used/Contaminated Suits (Outbound – Waste): THIS IS HIGHLY REGULATED.

- Characterization: Accurately characterize the waste (isotopes, activity levels, physical/chemical form) according to regulations (e.g., DOT 49 CFR, IATA/ICAO for air, ADR for road in Europe).

- Packaging: Use only approved, certified Type A or Type B packaging (depending on activity) designed for radioactive waste. Packaging must be leak-tight, impact-resistant, and properly labeled.

- Labeling & Documentation: Apply correct radioactive placards and labels (e.g., Radioactive Yellow-II or III). Complete all required shipping papers, including a Radioactive Materials Shipping Manifest and Waste Shipment Documents, accurately detailing contents, activity, and emergency contacts.

- Carrier: Use only carriers licensed and trained to transport radioactive materials. Provide them with full emergency response information.

- Recordkeeping: Maintain detailed, auditable records of all waste shipments for the required period (often decades).

On-Site Handling & Donning/Doffing

- Contamination Control Zones: Establish clearly marked zones: Support Zone (clean), Contamination Reduction Zone (CRZ – controlled), Exclusion Zone (hot). Control movement and material transfer between zones.

- Trained Personnel: Only personnel certified in radiological work practices, PPE use, and emergency procedures should handle or wear these suits.

- Supervised Donning: Perform donning in the designated clean area (Support Zone or clean end of CRZ) under the supervision of a trained monitor. Follow a strict, documented procedure including:

- Pre-donning inspection (suit integrity, seal checks).

- Sequential layering (undergarments, suit, gloves taped, boot covers taped, respiratory protection, hood).

- Seal verification (tape seals, respirator fit check).

- Strict Doffing: Perform doffing in the CRZ using a meticulous, supervised procedure to prevent self-contamination:

- Initial survey and decontamination (if possible) before entering the CRZ.

- Step-by-step removal starting from the outside, turning garments inside out as removed.

- Each removed item is immediately placed into designated radioactive waste containers.

- Final survey of personnel and inner clothing.

- NEVER re-enter a contaminated area in a previously worn suit.

Use & Operational Procedures

- Time, Distance, Shielding: Adhere to ALARA principles. Minimize time in radiation fields, maximize distance from sources, and use physical shielding whenever possible, even when wearing a suit.

- Monitoring: Personnel must wear appropriate dosimeters (e.g., TLD, OSL, electronic dosimeters) and use survey meters (e.g., Geiger counters, alpha scintillators) to monitor contamination levels and dose rates.

- Buddy System: Always work in pairs for safety, monitoring, and assistance with emergencies or doffing.

- Limitations: Understand that most suits primarily protect against contamination (loose radioactive particles). They offer limited shielding against penetrating radiation (gamma, neutron). Rely on time, distance, and engineered shielding for dose reduction.

- Integrity Checks: Perform regular suit integrity checks during use (e.g., visual inspection for tears, checking seals) if feasible and safe.

Decontamination & Disposal

- Decontamination Attempt: Attempt decontamination only if permitted by procedure, safe for personnel, and likely to be effective. Use approved methods and decontamination agents. Monitor effectiveness.

- Waste Classification: Accurately classify the suit as radioactive waste (e.g., Low-Level Waste – LLW, Mixed Waste if hazardous chemicals are also present) based on activity and regulations.

- Segregation: Segregate waste by isotope, half-life, activity level, and physical form (e.g., dry vs. liquid-soaked) as required.

- Packaging: Package waste in approved, labeled containers (drums, bags within boxes) suitable for the waste type and final disposal pathway. Ensure containers are secure and leak-tight.

- Final Disposal: Dispose of only through authorized, licensed radioactive waste disposal facilities following all regulatory requirements. Landfill disposal of radioactive waste is strictly prohibited.

Training & Documentation

- Comprehensive Training: Provide initial and recurrent training covering radiation hazards, ALARA, specific suit use (donning/doffing), monitoring, emergency procedures, waste handling, and all relevant regulations.

- Procedure Documentation: Maintain up-to-date, written procedures for all aspects: procurement, storage, transportation, donning, doffing, use, decontamination, waste handling, and emergency response.

- Records: Keep detailed records of training, dosimetry, waste shipments, inventory, inspections, and any incidents involving the suits or radiation exposure.

Emergency Response

- Spill/Contamination: Follow established emergency procedures. Isolate the area, notify radiation safety officer (RSO), assess hazards, provide medical aid if needed, and initiate decontamination under controlled conditions.

- Suit Breach: If a suit is torn or compromised, personnel must immediately cease work, retreat to the nearest safe decontamination area following emergency doffing procedures, and notify the RSO. Monitor for contamination and dose.

- Transportation Incident: In case of an accident during transport of waste, follow emergency response plans, secure the scene if safe, notify authorities (including carrier emergency contacts and radiation regulators), and provide shipping papers.

Conclusion: Sourcing Hazmat Suits for Radiation Protection

Sourcing hazmat suits for radiation protection requires careful consideration of material composition, certification standards, intended use, and compliance with regulatory guidelines. Given the potentially life-threatening nature of radiation exposure, it is essential to procure protective gear from reputable suppliers who adhere to international safety standards such as NFPA 1994, NFPA 1991, or ASTM F2702. These suits must offer effective shielding against alpha, beta, and in some cases, gamma radiation, while also ensuring wearer mobility, thermal comfort, and durability.

A successful sourcing strategy involves evaluating the specific hazards present—whether in nuclear facilities, medical environments, or emergency response scenarios—and selecting suits with appropriate levels of protection, such as fully encapsulated vapor- or pressure-resistant suits. Additionally, integration with other personal protective equipment (PPE), including respirators and dosimeters, is crucial for comprehensive safety.

Ultimately, investing in high-quality, certified radiation-resistant hazmat suits from reliable vendors not only ensures regulatory compliance but also safeguarding the health and lives of frontline personnel. Regular training, proper maintenance, and adherence to decontamination protocols further enhance the effectiveness of these critical protective measures.