Introduction: Navigating the Global Market for Hardware for Outdoor Furniture

Outdoor furniture buyers face a persistent problem: hardware fails silently. Corrosion, inconsistent threads, and loose certifications undermine product safety, brand trust, and margin in retail, hospitality, contract, and consumer channels across the USA and Europe.

This guide helps you standardize specifications, ensure compliance, and source confidently across markets. You’ll see how premium materials, especially 316 stainless steel for coastal and high-UV environments, prevent premature failure and protect your brand.

What’s inside:

– Market landscape (USA/EU)

– Materials and finishes (316 vs 304 stainless steel, zinc/nickel plating)

– Standards and testing (ASTM A240/A480, ISO 3506 torque, ASTM B117/ISO 9227 salt spray)

– Compliance (RoHS/REACH, Proposition 65 for USA)

– Global supply chains (US/EU stock, lead times, MOQs)

– Specifications (thread/coarse/fine, washers, locknuts, socket cap screws, hex bolts)

– Quality assurance (CMTRs, QC checklists, PPAP basics)

– Cost management (TCO, lifecycle, warranty claims)

– Sustainability (recycled content, traceable materials)

– Case examples (patio furniture projects and lessons learned)

Use the reference section and practical checklists to specify correctly, verify quality, and reduce total cost of ownership—without fluff.

Article Navigation

- Top 10 Hardware For Outdoor Furniture Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for hardware for outdoor furniture

- Understanding hardware for outdoor furniture Types and Variations

- Key Industrial Applications of hardware for outdoor furniture

- 3 Common User Pain Points for ‘hardware for outdoor furniture’ & Their Solutions

- Strategic Material Selection Guide for hardware for outdoor furniture

- In-depth Look: Manufacturing Processes and Quality Assurance for hardware for outdoor furniture

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘hardware for outdoor furniture’

- Comprehensive Cost and Pricing Analysis for hardware for outdoor furniture Sourcing

- Alternatives Analysis: Comparing hardware for outdoor furniture With Other Solutions

- Essential Technical Properties and Trade Terminology for hardware for outdoor furniture

- Navigating Market Dynamics and Sourcing Trends in the hardware for outdoor furniture Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of hardware for outdoor furniture

- Strategic Sourcing Conclusion and Outlook for hardware for outdoor furniture

- Important Disclaimer & Terms of Use

Top 10 Hardware For Outdoor Furniture Manufacturers & Suppliers List

1. Outdoor Furniture Hardware – Rockler

Domain: rockler.com

Registered: 1997 (28 years)

Introduction: 1–2 day delivery · 90-day returnsBuild Something Extraordinary With Our Large Selection of Quality Exterior Hardware at Rockler Woodworking and Hardware….

2. Premium Stainless Steel Hardware for Patio Furniture

Domain: hauserspatio.com

Registered: 2007 (18 years)

Introduction: Free delivery over $1,399 · 30-day returnsExplore our selection of stainless steel hardware for patio furniture, including 5/16″-18 and 1/4″-20 sizes. Perfect for repairs and upgrades, our hardware …Missing: top suppliers…

3. Furniture Hardware, Supplies & Parts | Van Dyke’s Restorers

Domain: vandykes.com

Registered: 1997 (28 years)

Introduction: Free delivery 60-day returns At Van Dyke’s Restorers, we offer furniture hardware and parts that can help you complete chairs, trunks, desks, cabinets and beds….

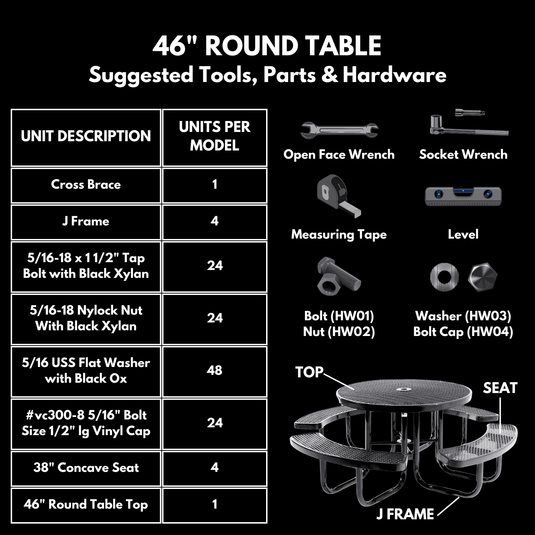

Illustrative Image (Source: Google Search)

4. Patio Furniture Supplies, Vinyl Straps, and replacement Plastic …

Domain: patiofurnituresupplies.com

Registered: 2003 (22 years)

Introduction: We manufacture replacement slings for chairs, chaises, barstools, love seats, adjustable chairs, glider rockers, swivel rocker patio chairs and ottomans….

5. Reliable Brands for Outdoor/Patio Furniture. Mid-to-High End. Direct …

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: I’ve got the rundown of pros/cons of everything from tube and cast aluminum, to oiling wood, to polywood/HDPE and wrought iron and steel with ……

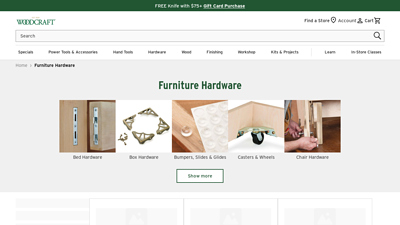

6. Furniture Hardware | Woodcraft

7. Caps, Glides, Inserts, & Parts Archives – Patio Products

Domain: patioproducts.com

Registered: 1999 (26 years)

Introduction: We stock nylon inserts, snap rivets, caps, glides, stem bumpers, metal clips, umbrella parts, sled runners, tire extrusions, wheels, aluminum wheel hubs, ……

Illustrative Image (Source: Google Search)

8. Industrial Furniture Components

Domain: superiorcomponents.com

Registered: 2001 (24 years)

Introduction: Superior Components is the world’s largest stocking distributor of industrial furniture components, fasteners, and parts….

Understanding hardware for outdoor furniture Types and Variations

Understanding Hardware for Outdoor Furniture: Types and Variations

The following analysis focuses on five commonly used hardware types in outdoor furniture assembly and maintenance. All five are available in premium 316 stainless steel, providing excellent corrosion resistance and long service life in coastal and fully exposed environments.

Illustrative Image (Source: Google Search)

At-a-glance comparison

| Type | Features | Applications | Pros | Cons |

|---|---|---|---|---|

| Bolts (hex, socket cap, machine screws) | 316 stainless; coarse threads (e.g., 1/4″-20, 5/16″-18); hex and socket drives; range of lengths (commonly 3/4″ to 3-1/2″) | Chair frames, table bases, umbrella mounts, joint connections needing disassembly/repair | High strength; repeatable assembly; robust corrosion resistance | Requires access for driving/nut capture; thread locking (nylock) recommended for vibration |

| Screws (self-tapping, wood/deck screws) | 316 stainless; pointed or machine tips; coarse or fine threads; Phillips or hex drive | Secondary bracing, trim, canopy hardware, sling rails; component-to-frame attachments | Fast installation; creates own threads; fewer parts | Lower clamp force than bolts; pilot drilling often required in hard metals |

| Nuts & Washers (hex, nylon lock; flat washers) | 316 stainless; 1/4″ and 5/16″ common sizes; nylon insert locking nuts; flat washers for load distribution | Pair with bolts/screws; protect surfaces; prevent loosening under motion | Secure assemblies; surface protection; standard sizes simplify stocking | Locking nuts can seize if overtightened; ensure correct torque |

| Rivets (blind/pop rivets) | 316 stainless rivet body and pin; single-sided installation; permanent fastener | Aluminum frames, sling rails, end caps, panels; one-side access only | No nut/washer required; strong shear; high production speed | Not ideal for frequent disassembly; requires correct rivet length and hole size |

| Glides (adjustable, stem, vinyl) | Stem, threaded adjustable, flat or conical; vinyl/rubber options; stainless components | Tables, chairs, umbrellas; leveling and surface protection; sling rail protection | Stability, floor protection, vibration dampening; easy leveling | Threaded glides can seize in harsh environments if not 316 stainless |

Bolts (hex bolts, socket cap screws, machine screws)

- Materials: 316 stainless steel recommended for coastal and chlorinated environments.

- Sizes: Common imperial sizes for patio furniture include 1/4″-20 and 5/16″-18. Lengths often range from 3/4″ to 3-1/2″ in catalog offerings.

- Drive styles: Hex head for wrench assembly; socket cap (allen) for low-profile joints and clean aesthetics.

- Finish/performance: 316 stainless resists rust and staining; suitable for all-weather exposure; polished or passivated finishes are typical.

- Thread tolerance: Coarse threads reduce stripping in soft metals and enable quick assembly.

- Notes:

- Use flat washers under heads and nuts to distribute load and protect powder-coated or soft surfaces.

- Pair with hex nylon locking nuts (nylock) to reduce loosening from chair rock/rocker motion.

- For swivel/rocker assemblies, standard hex bolts with lock nuts are common in replacement kits.

- Socket cap screws are useful where low-profile heads prevent snagging and maintain clean lines.

Screws (self-tapping, wood/deck screws)

- Materials: 316 stainless steel where corrosion and UV exposure are concerns.

- Drive styles: Phillips or hex. Hex drives reduce cam-out and speed installation with tools.

- Threads: Coarse threads for wood/fasteners in softer substrates; fine threads for metal-to-metal.

- Tips: Self-tapping tips can eliminate pilot holes in aluminum; pointed tips aid wood penetration.

- Typical uses:

- Secondary bracing and trims.

- Canopy and umbrella hardware mounting.

- Attaching sling rails or vinyl components to frames.

- Reinforcing components that are accessible but not subject to frequent disassembly.

- Pros:

- Faster, fewer components.

- Good pull-out resistance when correctly piloted.

- Cons:

- Lower clamping force than properly torqued bolts.

- Not optimal where frequent disassembly is expected.

Nuts & Washers (hex nuts, nylon locking nuts, flat washers)

- Materials: 316 stainless steel.

- Sizes: 1/4″-20 and 5/16″-18 are common in patio furniture.

- Nut types:

- Hex nuts: standard assemblies; pair with washers for surface protection.

- Nylon locking nuts (nylock): create prevailing torque to resist loosening.

- Washers:

- Flat washers spread clamping loads and protect coatings (e.g., powder coat) from embedding marks.

- Recommended under both bolt heads and nuts.

- Pros:

- Secure, reversible assembly.

- Straightforward, standardized components.

- Cons:

- Over-torqued lock nuts can gall threads; follow recommended torque values.

- Ensure hardware is clean and dry before assembly.

Rivets (blind/pop rivets)

- Materials: 316 stainless rivet and pin (metal pop rivet) for outdoor durability.

- Installation: Single-sided access; expand the rivet shank to create a permanent joint.

- Pros:

- Fast, repeatable installations in production or repair.

- No nut/washer set required.

- Cons:

- Removal is destructive in many cases; not suited to frequent disassembly.

- Hole sizing and rivet length are critical for correct clamp and strength.

- Typical applications:

- Aluminum frame joints, sling rails, panels, and end caps where only one side is reachable.

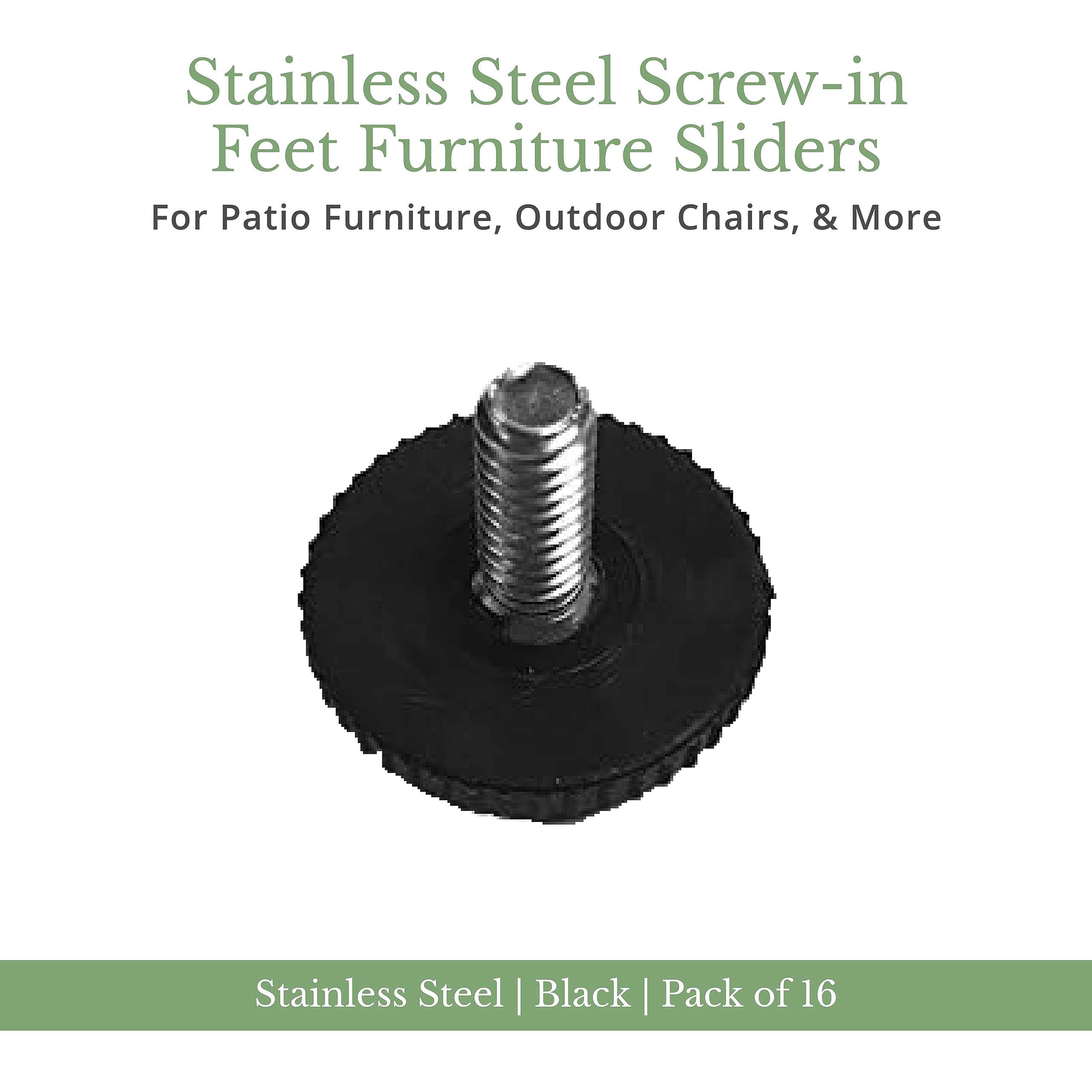

Glides (adjustable glides, stem glides, vinyl end caps)

- Types:

- Threaded adjustable glides: allow height and level compensation for tables and chairs.

- Stem glides and bumpers: insert into tubular legs to reduce noise and protect floors.

- Vinyl end caps/sling rail end caps: protect tubular ends and sling rails from wear and moisture ingress.

- Materials:

- 316 stainless steel or plated hardware for stems/bases.

- Vinyl/rubber for contact surfaces and end caps.

- Applications:

- Tables and chairs needing floor protection and stability.

- Umbrella poles and leg bottoms.

- Sling rails and tubular frames for edge protection.

- Pros:

- Leveling and stability on uneven surfaces.

- Reduced vibration, floor damage, and rail abrasion.

- Cons:

- Threaded glides may seize in corrosive environments; 316 stainless minimizes this risk.

- Vinyl/rubber components degrade over time in UV; periodic replacement is common.

Selection guidance: For high-exposure environments (coastal, pools, rooftop installations), standardize on 316 stainless for all steel hardware and specify 1/4″-20 or 5/16″-18 coarse threads to simplify stocking. Combine hex bolts and socket cap screws with flat washers and nylon locking nuts for repeatable, vibration-resistant assemblies. Use blind rivets for permanent joints and one-sided access. Add adjustable/stem glides and vinyl end caps for stability and surface protection in commercial and residential collections.

Key Industrial Applications of hardware for outdoor furniture

Key Industrial Applications of Hardware for Outdoor Furniture

Industries and Applications with Detailed Benefits

| Industry/Application | Primary Hardware Needs | Key Benefits of 316 Stainless Steel Hardware |

|---|---|---|

| Hospitality (Hotels, Resorts, Restaurants) | Chair assembly bolts, umbrella base mounts, table connectors, foot glides | Maintains professional appearance in high-traffic areas; resists salt air in coastal properties; minimizes maintenance downtime; supports year-round outdoor operations |

| Commercial/Municipal (Parks, Public Spaces, Government Buildings) | Bench hardware kits, picnic table assemblies, public seating components | Withstands vandalism and heavy usage; corrosion resistance for year-round outdoor exposure; reduced replacement frequency lowers maintenance budgets |

| Healthcare/Senior Living Facilities | Outdoor furniture assembly hardware, patient area seating components, garden furniture | Hygienic smooth surfaces resist bacteria accumulation; reliable operation for accessibility compliance; minimal maintenance preserves staff resources |

| Educational Institutions (Schools, Universities) | Outdoor classroom furniture, cafeteria seating, recreational equipment | Supports high student usage volumes; safe operation reduces liability concerns; cost-effective over multi-year academic cycles |

| Retail/Shopping Centers | Store display outdoor furniture, customer seating, landscaping elements | Maintains brand appearance standards; withstands constant customer interaction; quick replacement minimizes business disruption |

| Corporate/Office Parks | Executive outdoor furniture, employee break area seating, conference furniture | Professional aesthetic for business image; durability supports year-round utilization; minimal maintenance maintains workplace efficiency |

| Property Management/HOAs | Community pool furniture, clubhouse seating, common area furnishing | Long service life reduces replacement costs; weather resistance minimizes seasonal replacement cycles; aesthetic consistency maintains property values |

| Recreational/Entertainment Venues | Pool furniture hardware, outdoor entertainment area components, stadium/venue seating | Heavy-duty construction supports crowd loads; chemical resistance for pool environments; reliable performance for safety-critical applications |

Critical Selection Factors

Material Grade Priority: 316 stainless steel provides superior corrosion resistance compared to 304 or coated alternatives, particularly in coastal or industrial environments with higher chloride exposure.

Thread Compatibility: Standard threads (1/4″-20, 5/16″-18, 10-24) ensure cross-platform compatibility and simplified inventory management.

Assembly Efficiency: Pre-packaged hardware kits reduce procurement complexity and installation time for commercial-scale deployments.

Illustrative Image (Source: Google Search)

Longevity Economics: While premium hardware represents higher initial investment, the extended service life and reduced maintenance requirements deliver superior total cost of ownership in commercial applications.

3 Common User Pain Points for ‘hardware for outdoor furniture’ & Their Solutions

3 Common User Pain Points for Hardware for Outdoor Furniture — and Their Solutions

Below are the most frequent issues procurement, operations, and facility teams report when sourcing and assembling outdoor furniture hardware in the USA and Europe, with practical fixes that reduce returns, field callbacks, and assembly time.

Pain Point 1: Rust, Corrosion, and Aesthetic Deterioration

Scenario: After a single coastal or de-icing season, bolts and nuts show corrosion, and chair slings rattle because components have degraded.

Problem: Inferior steel corrodes quickly in salt spray, chlorine splash, UV, and freeze-thaw, leading to seized hardware, stained cushions, and warranty claims.

Solution: Standardize on 316 stainless steel (marine-grade) for all load-bearing fasteners and contact points; pair with 316 washers and nylon-insert locknuts to maintain clamp load and minimize galvanic corrosion. For bases and feet, choose stainless steel glides and base components rated for outdoor use.

Examples:

– Use 316 stainless steel socket cap screws and hex bolts for arm-to-seat and frame assemblies.

– Add 316 flat washers and nylon-insert locknuts to protect the finish and keep joints tight through thermal cycles.

Simple example: Replacing two corroded hex bolts in a patio chair with 316 stainless equivalents and adding nylon locknuts often stops the chair from wobbling after a heavy rain or a salty seaside weekend.

Illustrative Image (Source: Google Search)

Recommended parts (verify exact sizes per build):

– Hex Bolt 5/16″-18 x 2-1/4″ (316 Stainless Steel)

– Hex Bolt 5/16″-18 x 2-3/4″ (316 Stainless Steel)

– Socket Cap Screw 1/4″-20 x 2″ (316 Stainless Steel)

– Socket Cap Screw 1/4″-20 x 3/4″ (316 Stainless Steel)

– Flat Washer 5/16″ (316 Stainless Steel)

– Flat Washer 1/4″ (316 Stainless Steel)

– Hex Nylon Locking Nut 5/16″-18 (316 Stainless Steel)

– Hex Nylon Locking Nut 1/4″-20 (316 Stainless Steel)

Pain Point 2: Joint Looseness, Wobble, and Inconsistent Clamp Force

Scenario: Chairs feel “loose” after a few months; tables wobble under load; sling rails shift.

Problem: Vibration, thermal expansion, and poor assembly practices reduce clamp force; basic nuts back out; threads gall; and slings stretch or misalign.

Solution: Use torque-stable fasteners, add flat washers to distribute load, and employ nylon-insert locknuts to retain preload. Where applicable, replace or supplement worn sling rail end caps and check rail attachment hardware for proper engagement.

Simple example: Adding a locknut to a 2-inch hex bolt on a dining chair base often eliminates the small wobble felt when someone leans back at the table.

Recommended parts (select per frame geometry):

– Hex Bolt 5/16″-18 x 1-1/2″ (316 Stainless Steel)

– Hex Bolt 5/16″-18 x 2-1/2″ (316 Stainless Steel)

– Hex Nylon Locking Nut 5/16″-18 (316 Stainless Steel)

– Hex Nylon Locking Nut 1/4″-20 (316 Stainless Steel)

– Flat Washer 5/16″ (316 Stainless Steel)

– Flat Washer 1/4″ (316 Stainless Steel)

Pain Point 3: Mismatched Threads, Fitment Delays, and Assembly Bottlenecks

Scenario: New hardware doesn’t fit existing frames; holes won’t align; threads are wrong for the region (imperial vs metric).

Problem: Heterogeneous inventories and mixed thread families create downtime on the shop floor and at the job site.

Solution: Map one part number per joint function across SKUs, standardize on two core thread sizes (e.g., 1/4″-20 and 5/16″-18) and stock matched fasteners in lengths that cover most chairs and tables. Create kits with bolts, washers, and locknuts for quick assembly and fewer pick errors. Keep popular metric equivalents available where applicable for European customers.

Simple example: A “frame kit” containing one 1/4″-20 hex bolt, a flat washer, and a nylon locknut per attachment point cuts assembly time in half compared to picking pieces from three different bins.

Illustrative Image (Source: Google Search)

Recommended parts for kits:

– Hex Bolt 5/16″-18 x 2-1/4″ (316 Stainless Steel)

– Hex Bolt 5/16″-18 x 1-3/4″ (316 Stainless Steel)

– Hex Bolt 5/16″-18 x 2″ (316 Stainless Steel)

– Socket Cap Screw 1/4″-20 x 2″ (316 Stainless Steel)

– Socket Cap Screw 1/4″-20 x 3/4″ (316 Stainless Steel)

– Flat Washer 1/4″ (316 Stainless Steel)

– Flat Washer 5/16″ (316 Stainless Steel)

– Hex Nylon Locking Nut 1/4″-20 (316 Stainless Steel)

– Hex Nylon Locking Nut 5/16″-18 (316 Stainless Steel)

Quick reference (select per application)

| Hardware Type | Example (316 Stainless Steel) | Best Use |

|---|---|---|

| Fastener (arm-to-seat) | Hex Bolt 5/16″-18 x 2-1/4″ | Chair arm pivot; mid-to-high load |

| Fastener (frame-to-base) | Hex Bolt 5/16″-18 x 2-1/2″ | Table base; rail-to-leg attachments |

| Fastener (compact) | Socket Cap Screw 1/4″-20 x 3/4″ | Tight clearances; low profile |

| Fastener (long reach) | Socket Cap Screw 1/4″-20 x 2″ | Through-thickness assemblies |

| Washer | Flat Washer 5/16″ or 1/4″ | Distribute load; protect finish |

| Locknut | Hex Nylon Locking Nut 5/16″-18 / 1/4″-20 | Maintain preload; reduce loosening |

| Foot/glide | Metal Pop Rivet Glide (as needed) | Protects floors; adjusts height |

Note: When specifying for Europe, confirm compatibility with local frame standards and use equivalent metric fasteners where applicable.

Strategic Material Selection Guide for hardware for outdoor furniture

Strategic Material Selection Guide for Hardware for Outdoor Furniture

Key performance drivers

- Corrosion exposure (coastal salt spray, chlorinated water, acid rain, humidity, UV) defines the base material and protective finish.

- Load and fatigue (swing hardware, rockers, umbrella canopies, heavy table bases) drive head style and thread requirements.

- Assembly method (manual torque vs. automation, accessibility) affects the choice of head, drive, and securing features (e.g., nyloc).

When to choose 316 stainless steel (A4; EU A4 = 316)

- Coastal/marine, poolside, and high-chlorine or de-icing salt environments.

- Long-service outdoor furniture (commercial and residential) where replacement costs are high and warranties matter.

- When the product may sit damp for extended periods or experience UV cycling.

Reference example (316): Socket cap screws 1/4″-20, hex bolts 5/16″-18 in various lengths, nylon lock nuts, flat washers, and rivets.

When 304 stainless steel (A2) may be acceptable

- Inland, low-chlorine, sheltered applications with good drainage and regular cleaning.

- Lower-cost replacement parts where full 316 is not justified.

Protective finishes and plated steels (non-stainless)

- Hot-dip galvanized carbon steel: good outdoor protection for inland/urban use; not recommended for coastal or chlorinated areas without heavy zinc and regular inspection.

- Electrogalvanized/Zn-plated carbon steel: entry-level; indoors or short-lived outdoor components only.

- E-coat or powder coat over carbon steel: acceptable for non-structural, visually critical parts; requires vented drainage to avoid underfilm corrosion.

Aluminum

- Lightweight and corrosion-resistant; good for low-stress, aesthetic parts; strength and thread stripping risk increase with smaller diameters. Do not use with stainless in galvanic couples without isolation.

Brass

- Excellent corrosion resistance and finish; lower strength and thread integrity; best for decorative, low-load applications. Avoid heavy swinging or high-load joints.

Thread forms and fasteners

- Coarse threads (e.g., 1/4″-20, 5/16″-18 UNC) provide robust stripping resistance and fast assembly for wood/ phenolic components commonly found in outdoor furniture.

- Locking features (nylon lock nuts) reduce loosening from vibration (rockers, swing bases, umbrella canopies).

- Flat washers distribute load and protect soft substrates (wood/ phenolic).

EU/US terminology alignment (procurement)

- Grade 316 ≈ EU A4-80; Grade 304 ≈ EU A2-70.

- Property class 8.8 and above are common in structural hardware; specify grade/class on drawings and POs.

Sourcing and QC checklist

- Specify material grade (316/A4 or 304/A2), property class (e.g., A2-70, A4-80), and finish.

- Verify head/drive (hex, socket cap) and length for fit and clearance.

- Ensure fasteners come with compatible washers and lock nuts where specified.

- Confirm corrosion test claims with supplier documentation (salt spray, chlorine exposure).

- Maintain isolation between dissimilar metals (e.g., stainless fasteners on aluminum bases) using washers/gaskets to prevent galvanic corrosion.

Example components (316 stainless)

- Socket cap screws 1/4″-20 x 3/4″ and 2″ (316).

- Hex bolts 5/16″-18 from 3/4″ to 2-3/4″ (316).

- Hex nylon lock nuts 1/4″-20 and 5/16″-18 (316).

- Hex nuts and flat washers 1/4″ and 5/16″ (316).

- Metal pop rivet glides.

Materials comparison (outdoor hardware)

| Material | Composition/grade | Corrosion resistance (outdoor) | Strength (typical) | Weight | Cost (relative) | Finish durability | Sustainability notes | Thread density compatibility | Primary applications |

|---|---|---|---|---|---|---|---|---|---|

| 316 stainless (A4) | 18% Cr, 8–10% Ni, 2–3% Mo | Excellent (coastal/chlorine resistant) | High | Medium | Higher | Excellent (no coating needed) | Fully recyclable; long service life | Compatible with coarse UNC/UNF | Swivel bases, rockers, umbrella canopies, exposed frames |

| 304 stainless (A2) | 18% Cr, 8–10% Ni (no Mo) | Good inland; poor coastal/chlorine | High | Medium | Medium–high | Good | Recyclable; strong corrosion with proper care | Compatible with coarse UNC/UNF | Sheltered outdoor frames, internal assemblies |

| Hot-dip galvanized steel (class 8.8+) | Carbon steel + thick Zn coating | Good inland; moderate coastal | Very high | Heavy | Low–medium | Good initially; can white-rust if damaged | Less recyclable than stainless; finite Zn lifecycle | Compatible with coarse UNC/UNF | Structural joints; inland installations; budget-sensitive |

| Electrogalvanized/Zn-plated steel | Carbon steel + thin Zn | Poor outdoors; rusts in wet cycles | Very high | Heavy | Low | Fair–poor | Coatings reduce corrosion, risk of white rust | Compatible with coarse UNC/UNF | Low-cost, non-critical; indoor or temporary |

| Aluminum (6xxx series) | Al-Mg-Si | Very good; susceptible to galvanic corrosion | Medium–high (size-dependent) | Very light | Medium | Good anodized; otherwise protective oxide layer | High recyclability; low weight logistics | Generally compatible; avoid fine threads with small diameters | Lightweight frames, aesthetic parts; avoid heavy loading |

| Brass (low-lead/no-lead) | Cu-Zn | Excellent | Low | Heavy | Medium–high | Excellent | Fully recyclable | Fine threads okay; limited for high-load joints | Decorative caps, low-load hardware |

| E-coat/Powder coat over carbon steel | Coated steel | Good when intact; rusts if chips occur | High (steel core) | Heavy | Medium | Good if maintained; risk of underfilm corrosion | Coatings add lifecycle maintenance | Compatible with coarse UNC/UNF | Visual/frame elements; non-structural use |

In-depth Look: Manufacturing Processes and Quality Assurance for hardware for outdoor furniture

In-depth Look: Manufacturing Processes and Quality Assurance for Outdoor Furniture Hardware

Overview

This section covers how premium outdoor hardware—typically 316/316L stainless steel—is manufactured and quality-assured for patio and garden furniture in USA and Europe. It focuses on three principal steps—Prep, Forming, and Assembly—plus a documented quality system aligned with ISO standards to ensure corrosion resistance, dimensional accuracy, and consistency. It also provides an overview of the ISO-based quality framework that governs material, performance, inspection, environmental testing, traceability, and packaging.

Illustrative Image (Source: Google Search)

Materials and Prep

To ensure outdoor performance, base alloy selection is the first decision. 316/316L austenitic stainless steel is standard for commercial-grade outdoor furniture hardware due to its corrosion resistance, ductility, and balance of strength with cost compared with 904L. Material certification is verified through supplier documentation in line with ISO 10474 (Inspection Documents).

The primary pre-processing steps include:

– Cold sawing or cutting-to-length of bar/rod stock; deburring to remove burrs and sharp edges that can act as initiation sites for corrosion and cause handling risks.

– Degreasing and cleaning to remove oils and machining coolants—chlorinated solvents are avoided; alkaline or aqueous cleaners with a verified water break test are used prior to passivation.

– Surface enhancement via grinding or centerless polishing for high-visibility parts; matte finish for most fasteners to match furniture aesthetics.

– Passivation per ASTM A967 and ASTM A380 to remove free iron and restore the chromium oxide surface layer for corrosion resistance. The cycle uses alkaline detergent cleaning, nitric or citric acid, water rinse, and drying; the solution concentration, time, and temperature are controlled.

– Optional electro-polishing for certain visual parts to reduce surface roughness and improve cleanability.

– Controlled handling and packaging to avoid moisture, contamination, and cosmetic damage during transport.

Forming

For fasteners and joints, 316L stainless is normally used to avoid sensitization and intergranular corrosion risk. The forming route depends on the hardware’s function:

– Cold forming for thread-forming and thread-cutting screws and bolts; it minimizes material waste, creates a work-hardened surface, and supports consistent head geometry.

– Hot forging may be applied to high-strength fasteners or to form complex shapes; if used, the process maintains appropriate die filling and flash management, followed by thermal processing that prevents sensitization.

– Machining operations produce custom features (e.g., shoulder bolts, socket cap heads, specialty washers); tight tolerances are held per drawing and industry norms.

– Thread production is monitored for thread form, pitch diameter, and runout to ensure engagement, clamp load, and assembly fit. Lubrication during threading reduces galling tendency in stainless steel.

– Surface finish is controlled after forming by polishing or tumbled deburring; surface roughness is used as a practical control for corrosion and cleanability.

Assembly

Where hardware is shipped as kits or sub-assemblies:

– Torque/tension verification ensures specified assembly clamp force and preload; fasteners are installed with proper lubrication or anti-seize if required to reduce thread friction and galling.

– Final quality control includes dimensional inspection, functional tests (e.g., rotation for swivel parts), and a clean-room wipe or visual inspection to verify surfaces are free from particulate contamination.

– Packaging protects against moisture and abrasion—often with VCI paper or desiccants, cushioning, and anti-scratch materials. Labels include batch code and material grade to support traceability and reverse logistics.

Illustrative Image (Source: Google Search)

Quality Assurance (ISO-based framework)

An ISO 9001-compliant quality system governs the entire manufacturing and test process. Documentation includes process instructions (SOPs), inspection and test plans (ITPs), nonconformance (NCR) procedures, and corrective/preventive actions (CAPA). Acceptance criteria are defined in drawings or product specifications, with calibration per ISO/IEC 17025 where applicable. Product traceability relies on batch marking and inspection documents aligned with ISO 10474.

For materials and process control:

– ISO 683-13 covers heat treatment of steels where applicable; ISO 6892-1 governs tensile testing for bar stock and finished parts.

– ASTM/ASME standards for stainless (A240/A182/A276) may be used to characterize plate, forged components, and bars; properties are recorded in the ITP and verified against certificates.

– Passivation and surface treatments follow ASTM A967 (passivation), with surface preparation referenced in ASTM A380; surface roughness is controlled to improve corrosion resistance and cleanability.

For fasteners and joining hardware:

– ISO 898-1 specifies mechanical properties for carbon and alloy steel fasteners but serves as a benchmark for establishing performance targets (e.g., proof load, ultimate tensile strength, ductility); stainless fasteners are qualified via equivalent methods even when graded differently (e.g., ISO 3506).

– Hardness testing is used to verify mechanical properties; methods and equipment are calibrated per ISO/IEC 17025 and include Rockwell, Brinell, or Vickers tests as appropriate.

– Mechanical verification may include torque-tension testing, clamp load calculations, and endurance tests for rotating parts (e.g., swivels), with fixtures and protocols documented in the ITP.

For corrosion resistance and environmental performance:

– ASTM B117 is the standard salt spray test used to compare corrosion resistance; typical acceptance for stainless outdoor hardware is no red rust after 72–168 hours (acceptance window is set in the product specification based on intended use).

– ASTM G85 Annex A2 (cyclic salt fog/dry/wet) is recommended where the specification requires an accelerated corrosion test closer to outdoor UV, wet/dry cycles, and chloride exposure.

– Cyclic corrosion testing (e.g., ASTM G85, SAE J2334) may be used for severe outdoor conditions or warranty programs.

Illustrative Image (Source: Google Search)

Inspection and verification:

– Incoming inspection verifies material certificates, geometry, and corrosion performance of selected batches; acceptance per product spec and ISO 10474 requirements.

– In-process inspection covers dimensions, thread fit, surface defects, and cleanliness; nonconformance is dispositioned per ISO 9001 procedures with corrective action as needed.

– Final inspection verifies mechanical performance (e.g., proof load or torque), appearance (no visible corrosion or contamination), and packaging integrity.

Process and product standards for stainless hardware:

– ASTM A276 covers stainless steel bars and shapes; ASTM A276/A276M provides material and property specifications.

– ASTM A314 standardizes raw materials for remelting (billets, blooms, and bars).

– ASME B18.2.1/B18.3.1 (US) and ISO/DIN fasteners (EN standards) establish dimensional conformity for hex bolts, socket cap screws, washers, and nuts used on outdoor furniture.

– REACH/RoHS compliance is documented where non-stainless materials (e.g., plating, vinyl) are included; this is maintained to support EU market requirements and corporate procurement policies.

– ISO 12944 is used to define coating and corrosion requirements where stainless hardware is combined with coated steel or aluminum frames.

Documentation and packaging:

– Certificates include grade (316/316L), heat/lot numbers, and mechanical/corrosion test results; traceability is maintained per ISO 10474.

– Packaging is designed to limit moisture exposure and mechanical damage; components are labeled with grade, batch, and inspection status for USA/Europe distribution and warranty support.

This manufacturing and QA approach provides outdoor furniture buyers and installers with confidence in corrosion performance, mechanical reliability, and compliance with ISO-based quality standards.

Illustrative Image (Source: Google Search)

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hardware for outdoor furniture’

Practical Sourcing Guide: A Step-by-Step Checklist for Hardware for Outdoor Furniture

Audience: USA, Europe

Step 1: Define product and structural requirements

- Map each joint and load path in the frame and articulating points (seats, backs, arms, recliners, rockers, swivel bases).

- Identify tension/compression and shear loads; include impact and fatigue (rockers/swivels).

- Choose grade/finish accordingly:

- Coastal/marine or chemically aggressive environments: Type 316 (A4) stainless steel.

- Urban/rural inland: Type 304/304L (A2) stainless steel or 18‑8 equivalent.

- Specify if material should be weldable (e.g., 304/304L); if not, use compatible assemblies or non-welded stainless hardware.

- Note any REACH/RoHS constraints and regional restrictions (EU/US CA SB 253, EUDR) for coatings or lubricants in contact surfaces.

Step 2: Standardize fasteners and compatible parts

- Use common sizes and threads:

- Coarse thread (UNC) in US: 1/4‑20 and 5/16‑18 are typical for chair/sling assemblies.

- Fine thread (UNF) acceptable where specified or available.

- Standardize bolt lengths to minimize SKU sprawl; match hardware to available stock lengths to reduce cost and lead time.

- Select hardware types aligned with your assembly method:

- Hex cap screws/bolts for general structural assemblies.

- Socket cap screws for clean appearance and compact joints.

- Nylon‑locking nuts to mitigate loosening from vibration; use stainless nylocs.

- Flat washers to distribute load and protect soft substrates (e.g., aluminum extrusions).

- Include rivets or pins where permanent attachments are required (e.g., sling rail end caps).

Step 3: Specify material, grade, and finish

- Material certification: Request mill certs (Type 304/304L, 316/316L).

- Mechanical requirements (if applicable): Property class (e.g., A2‑70/A4‑70) or equivalent tensile strength; verify hardness ranges to avoid thread galling.

- Corrosion category: A2 or A4 per ISO 3506 (A4 recommended for coastal).

- Finish options:

- Passivated stainless for baseline corrosion resistance.

- Electropolish for enhanced corrosion resistance and cleaner surface; specify when aesthetics and hygiene matter (food‑service, resort pools).

- Avoid zinc plating/galvanized hardware for outdoor commercial use unless life cycle is short and maintenance is controlled; they typically exhibit white/rust staining and coating failure.

Step 4: Specify joining components and articulating hardware

- Structural joints: Hex bolts/cap screws with washers and nuts; specify torque ranges in spec drawings.

- Locking elements: Nylon‑locking nuts, spring washers, thread lockers where compatible with stainless; ensure chemical compatibility and temperature ratings.

- Rockers/swivels: Specify bearing type, lubrication (marine‑grade grease), corrosion‑resistant materials; require salt spray testing (ASTM B117/ISO 9227) thresholds appropriate to the environment.

- Glides: Threaded adjustable glides for height and leveling; wrap‑on or screw‑in types; include material (stainless, UHMW/PP, rubber) and weight capacity per glide.

- Sling rails: End caps, pins/rivets, and tensioning hardware compatible with commercial sling fabrics (Sunbrella, Phifertex); specify secure attachment and easy replacement.

Step 5: Define mechanical and environmental compliance

- Standards: Use ANSI/BIFMA X5.1 and EN 581 as guidance for test loads and durability expectations; align design spec to the most stringent requirements (especially for commercial/contract use).

- Durability: Require minimum hours for salt spray testing:

- A2: typically 1,000 hours as baseline.

- A4/A4‑70: target 2,000–5,000 hours depending on design risk (coastal).

- Chemical resistance: Document exposure to chlorides, sunscreen/suntan oils, cleaners; specify passivation/ep for better performance where relevant.

- Temperature range: Verify hardware performance at operating conditions (e.g., swingers, sun exposure, freeze–thaw cycles).

Step 6: Sourcing and supplier selection

- Supplier vetting:

- Confirm material traceability and certifications (REACH, RoHS, REACH‑SVHC, Prop 65 as applicable).

- Request 3.1 mill test certificates for each batch.

- Verify salt spray test reports or perform in‑house testing on samples.

- Production QA:

- Define inspection plan and AQL levels for incoming QC (e.g., sampling per ISO 2859‑1).

- Verify torque values, finish quality, thread fit, and cleanliness.

- Include passivation or electropolish checks (surface residue/contamination).

- MOQs and lead time: Confirm volume pricing, reorder points, and inventory safety stock aligned to seasonal demand.

- Documentation: Secure full BOMs, CAD/2D drawings, assembly PDFs, and torque charts.

Step 7: Sampling, prototyping, and field testing

- Request samples for critical assemblies (e.g., sling rails, rocker mechanisms).

- Validate fit and clearance against existing furniture components and replacement slings.

- Conduct torque‑to‑yield tests for critical joints; record data for manufacturing SOPs.

- Perform salt spray verification or external lab testing on a pilot set if possible.

- Assemble prototypes and conduct user testing (e.g., rocking, recline, swivel cycles) to catch early failure modes.

Step 8: Packaging, handling, and assembly documentation

- Packaging:

- Use compartmentalized bins or labeled kits to avoid mix‑ups of coarse/fine thread components.

- Moisture‑resistant packaging; include desiccant for coastal shipments.

- Hardware staging: Provide assembly kits per chair/table with torque instructions and torque tool specs.

- Marking: Include clear SKU/lot identification and inspection stamps for traceability.

- Assembly documentation: Provide step‑by‑step instructions with recommended torque ranges (e.g., stainless threaded fasteners typically require lubrication or specific torque values to avoid thread galling; specify per product family).

- Spare parts: Offer kits with additional washers, nylocs, and rivets for field replacements.

Step 9: Cost modeling and inventory planning

- Benchmark price ranges for 316 stainless steel hardware (indicative, volume‑dependent):

- Socket cap screws 1/4‑20: $1.20–$1.90 each.

- Hex bolts 5/16‑18: $1.10–$2.30 each (varies by length).

- Hex nylon locking nuts 5/16‑18: $0.70–$0.80 each.

- Hex nuts 1/4‑20: $0.20–$0.30 each.

- Flat washers: $0.25–$0.35 each.

- Rivets/glides (commercial options): $0.30–$2.00+ depending on style and material.

- Create a landed cost model including freight, customs, packaging, QC, and warranty provisions.

- Set reorder points for seasonally volatile components (e.g., rocker/swivel kits, glides).

Step 10: Ongoing quality, traceability, and warranty

- Maintain lot traceability and batch records; archive test certificates.

- Establish a defect trending process and supplier performance scorecard.

- Define warranty periods by hardware type and environment; A4 generally carries longer warranties in coastal conditions.

- Provide a field service kit (tools, fasteners, replacement glides) and an RMA process to expedite commercial repairs.

Notes:

– US (UNC) and Europe (metric) fastener standards coexist in global supply chains; align to the standard used in your production location or ensure dual‑spec sourcing.

– For replacement slings and umbrella parts, verify attachment hardware compatibility with commercial fabrics and canopy mounting standards; ensure secure, repeatable mounting hardware and clearly documented assembly steps.

Comprehensive Cost and Pricing Analysis for hardware for outdoor furniture Sourcing

Comprehensive Cost and Pricing Analysis for Outdoor Furniture Hardware

Audience: USA, Europe

Scope: Stainless steel fasteners and connectors for commercial and residential outdoor furniture

What Drives Cost in Outdoor Furniture Hardware

Outdoor furniture hardware operates in harsh environments (humidity, salt spray, UV, freeze–thaw cycles), and costs reflect the materials, processes, and logistics needed to keep assemblies secure and corrosion-free over years of service.

Illustrative Image (Source: Google Search)

- Material choices and grade

- Finish and quality assurance

- Fastener geometry and tolerances

- Assembly and packaging labor

- Logistics and regional delivery requirements

- Warranty and returns (corrosion, defects)

Material Costs: Stainless Steel Grade and Finish

In real catalogs from a U.S. retailer (Hauser’s Patio), stainless steel fasteners are priced by type, size, and grade. Representative prices (USD, online retail):

| Item (316 SS, as shown) | Size | Price (USD) |

|---|---|---|

| Socket Cap Screw | 1/4″-20 x 2″ | $1.90 |

| Socket Cap Screw | 1/4″-20 x 3/4″ | $1.22 |

| Hex Bolt | 5/16″-18 x 1-1/2″ | $1.52 |

| Hex Bolt | 5/16″-18 x 2-1/4″ | $1.92 |

| Hex Bolt | 5/16″-18 x 3/4″ | $1.08 |

| Hex Bolt (longer lengths scale up) | up to 2-3/4″ | $2.22 |

| Hex Nut | 5/16″-18 | $0.32 |

| Hex Nut | 1/4″-20 | $0.24 |

| Nylon Locking Nut (hex) | 5/16″-18 | $0.74 |

| Nylon Locking Nut (hex) | 1/4″-20 | $0.52 |

| Flat Washer | 5/16″ | $0.34 |

| Flat Washer | 1/4″ | $0.28 |

| Bolt w/ Lock Nut (10/24) | 2-1/2″ | $1.17 |

| Bolt w/ Lock Nut (10/24) | 3-1/2″ | $1.29 |

Grade differentials observed in market quotes (indicative; actuals vary by supplier):

– 304 vs. 316: 316 is typically 15–35% higher due to molybdenum content

– 316 vs. Super Duplex (e.g., 2507): 316 is typically 30–60% lower than super duplex

– Ferrite/oxide scale vs. passivated: passivation adds ~1–3% to material cost, often included in “316 SS” pricing in catalogs

Material–performance mapping (salt spray life, relative):

– 304 SS: 72–168 hours to first red rust (per ASTM B117), suitable for most inland applications

– 316 SS: 240–1000+ hours depending on finish and part geometry; preferred near coasts and with UV/salt exposure

– Super Duplex: >1000 hours and superior pitting resistance; used where cost justifies performance (marine/coastal, harsh climates)

Decision Guidelines

- Use 316 SS for structural joints, chair rockers, swivel bases, and any outdoor assembly exposed to salt air or persistent moisture.

- Consider 304 SS for purely decorative or interior-facing parts; specify passivation and washers to limit galvanic coupling with aluminum or zinc coatings.

- Specify cap heads or socket screws for visibility and reduced snagging; hex bolts are cost-effective for hidden structural assemblies.

Labor and Assembly Costs

Assembly cost drivers include piece count per unit, fastener type (tool access), and packaging requirements.

Illustrative Image (Source: Google Search)

| Task | Typical Cost Driver | Impact Summary |

|---|---|---|

| Fastener installation | Thread fit, torque spec | 25–50¢ per fastener on automated lines; 60–120¢ per fastener in bench assembly |

| Torque verification (batch testing) | Torque-tension checks | 2–5¢ per fastener (sampled) |

| Passivation and QA checks | Documentation and testing | 3–5¢ per part (batch-level) |

| Bagging/packaging per SKU | Bag, label, barcode | 5–10¢ per SKU (unitized or retail bagging) |

| Kitting and labeling for OEMs | BOM-level kitting | $0.20–0.40 per BOM for multi-SKU kits |

Typical per-SKU assembly cost (labor + tooling + QA) ranges from 6–15% of landed material cost, depending on complexity and volume.

Logistics and Landed Cost (USA and Europe)

Domestic shipments (USA, EU) benefit from shorter lead times and simplified regulatory pathways.

| Mode & Region | Typical Lead Time | Freight % of Landed | Notes |

|---|---|---|---|

| USA domestic parcel (0–20 lbs) | 1–3 business days | 2–8% | Small-batch replenishment; zone pricing affects cost |

| USA domestic LTL (pallet) | 2–5 business days | 3–6% | Lower per-unit freight at volume |

| EU domestic road (pallet) | 2–7 business days | 3–10% | Distance and country-specific surcharges vary |

| Overseas container (20’/40’) | 30–60 days port-to-door | 8–20% | Lower per-unit freight; inventory and finance costs increase landed cost |

Insurance is typically 0.1–0.3% of invoice; customs brokerage and handling add $50–$250 per shipment. Duty is not applicable for stainless fasteners exported between USA and EU; however, regional VAT and handling apply. Include 1–2% finance cost on inventory tied up during extended transit.

Packaging and Storage

- Bulk poly bags: $0.05–0.12 per unit for fasteners; label cost $0.01–0.03 per unit

- Retail clamshells or retail bins: $0.20–0.50 per unit (higher visual appeal, higher handling cost)

- Pallet load optimization can reduce outbound freight by 5–15%.

Warranty and Returns

- Corrosion-related failures cluster around coastal exposures and salt pools; plan for 0.2–0.8% annual warranty/returns for 316 SS hardware in such environments.

- Manufacturing defects (under-torque, burrs, stripped threads) typically track at 0.1–0.3%; QA and sampling reduce this further.

- Include 0.2–0.5% of revenue in a quality reserve for outdoor deployments.

Pricing: Unit, Set, and Retail Benchmarks

Example Benchmark: 316 SS Fasteners

Based on U.S. retail prices:

| Component (316 SS) | Size | Unit Price (USD) |

|---|---|---|

| Socket Cap Screw | 1/4″-20 x 2″ | $1.90 |

| Socket Cap Screw | 1/4″-20 x 3/4″ | $1.22 |

| Hex Bolt | 5/16″-18 x 2-1/4″ | $1.92 |

| Nylon Locking Nut | 5/16″-18 | $0.74 |

| Flat Washer | 5/16″ | $0.34 |

Assembled Set Cost (material only)

Set A: 1/4″-20 socket cap screw (3/4″) + flat washer + nut

– Material cost: $1.22 + $0.28 + $0.24 = $1.74

Set B: 5/16″-18 hex bolt (2-1/4″) + nylon locking nut + washer

– Material cost: $1.92 + $0.74 + $0.34 = $3.00

Add labor (6–15% of material), packaging (5–10¢ per SKU), QA (2–5¢ per fastener), and freight (3–10% landed, depending on mode/region) to derive retail or OEM pricing.

Cost Build-up Example (landing price)

| Cost Component | % or $Add-on | Explanation |

|---|---|---|

| Material (316 SS) | 100% | Base fastener cost (per table above) |

| Labor + Assembly | +6–15% | Install, torque sampling, QA, packaging |

| Packaging + Labeling | +$0.06–0.12 per unit | Bags, labels, barcode |

| Logistics (domestic) | +3–10% | Freight, insurance, handling |

| Quality Reserve | +0.2–0.5% | Warranty and returns |

| Gross Margin Target | +25–60% | Depends on channel and volume |

| List Price | Result | Total per unit |

How to Cut Costs Without Risking Performance

- Select 316 SS only where needed: Use 304 SS for decorative or interior-facing parts; specify passivation and washers to mitigate galvanic issues.

- Standardize threads and lengths across products: Two thread sizes (1/4″-20 and 5/16″-18) plus 2–3 lengths often cover most assemblies.

- Buy in bulk: Shift from small retail packs (25–50 units) to 500–1000 unit bulk bags; savings often land at 10–20% on material, plus lower per-unit freight.

- Optimize packaging: Use poly bags with labels instead of retail clamshells for secondary markets; reserve retail packaging for end-user SKUs.

- Bundle fasteners into kitted BOMs: Reduce pick/pack labor and errors; target $0.20–$0.40 per BOM kitting overhead.

- Contract and procurement leverage:

- Multi-year agreements for top SKUs; volume-based tiers.

- Quarterly spot buys for market peaks (spring/summer) to capture price dips.

- Dual sourcing: Maintain one regional (USA/EU) distributor for replenishment and one contract manufacturer for bulk (container) buys to manage lead time vs. cost.

- Use nylon-insert locking nuts selectively: They reduce re-torque and squeaks in moving joints (rockers, chairs). Consider hex nuts in static joints to cut cost.

- Finish and QA discipline: Don’t sacrifice passivation or packaging; savings rarely exceed 1–3% and failures are costly in the field.

- Freight optimization: Ship on pallets rather than parcel for >20 lb orders; consolidate SKUs to lower per-unit freight. Add insurance for high-value shipments.

- Product design alignment:

- Choose cap heads for exposed hardware; hex for hidden structure.

- Standardize washer usage to minimize variety (e.g., two washer sizes: 1/4″ and 5/16″).

- Prefer socket screws with 2–3 common lengths for most fixtures.

Actionable Pricing and Sourcing Checklist

- Map fasteners to deployment zones (coastal/interior) and assign 316 vs. 304 by use case.

- Standardize threads and lengths to two main sizes; reduce BOM complexity.

- Convert frequent SKUs to bulk bags (500–1000 units) and apply labels/barcodes.

- Define torque and sampling protocols; include QA cost in landed pricing.

- Negotiate tiered contracts with annual volume commitments and spot buys for seasonal peaks.

- Maintain one USA/EU regional distributor for quick-turn and one contract manufacturer for container freight.

- Target landed pricing by mode: aim for <10% freight share in domestic (USA/EU) shipments and <20% in container imports.

- Include 0.2–0.5% quality reserve in outdoor deployments.

- Use nylon-insert locking nuts for moving assemblies; standard hex nuts elsewhere.

This structured cost and pricing framework lets you balance material performance (316 vs. 304) with logistics, labor, and warranty realities—ensuring competitive pricing while keeping assemblies secure in outdoor environments across the USA and Europe.

Illustrative Image (Source: Google Search)

Alternatives Analysis: Comparing hardware for outdoor furniture With Other Solutions

Alternatives Analysis: Comparing hardware for outdoor furniture with other solutions

Premium stainless steel hardware for patio furniture is not a one-size-fits-all choice. Buyers in the USA and Europe often weigh it against coated carbon steel and aluminum hardware. The right decision hinges on coastal exposure, load requirements, inspection cycles, and TCO. The table below summarizes three common options and is followed by an analysis.

Comparative overview

| Attribute | Premium 316/304 Stainless Steel (e.g., socket cap screws, hex bolts, washers, nylon locknuts) | Powder-coated carbon steel (zinc/galvanized base with polyester/epoxy powder coat) | Aluminum hardware (e.g., 6061-T6, 5052; anodized) |

|---|---|---|---|

| Initial material cost (illustrative) | Higher baseline; e.g., 316 bolts/nuts/washers often $0.24–$2.22 per component on commercial catalogs | Lower initial unit cost; can be 30–50%+ less at small diameters before coating | Mid-range; generally higher than coated steel, often below 316 SS at equivalent sizes |

| Corrosion resistance (outdoor) | 316 SS: excellent coastal; 304: good inland; minimal red rust; good pitting/chloride resistance | Variable; zinc + powder coat reduces corrosion but fails at chip/scratch sites; higher rust risk over time | Generally good inland; may show white oxidation; less robust than 316 in salt spray/coastal |

| Expected service life (commercial) | 7–15+ years depending on grade, finish, exposure, cleaning; coastal 316 outperforms | 3–6 years with proper coating; earlier failures at cut edges, torque abrasion, UV-induced chalking | 5–10 years depending on alloy, anodizing, and load; weaker than 316 at high torques |

| Typical failure modes | Loosening, thread wear, galling without lubrication; rare corrosion failure (316) | Corrosion at coating defects, rust bleed-through, underfilm corrosion, coating delamination, weld/heat-affected zone (HAZ) corrosion | Creep/relaxation at joints, galvanic corrosion if coupled with dissimilar metals; cracking at stress risers |

| Strength and torque | High tensile/shear; recommended torque values per manufacturer; 316 holds loads well | Adequate initial strength; pre-load loss from corrosion products; lower performance when pitted | Lower strength vs. steel at equal diameters; acceptable for many furniture joints; limited under high torque |

| Maintenance | Low; periodic cleaning; re-torque checks; thread lubricants reduce galling | Moderate; touch-up paint, rust remediation, replace failed parts; tighter inspection cadence | Low to moderate; monitor anodized surfaces; avoid dissimilar metal pairs |

| Availability and lead time | High; broad catalog availability in standard threads (US/Metric); consistent across USA and EU | High; widely available; coating lead times vary; some sizes often in stock | High; widely available; anodized finishes add modest lead time |

| Compliance and certificates | Stainless steel inert to many REACH and RoHS substances; safe for food-contact areas (typical grades) | Coatings may include solvents; ensure RoHS/REACH compliance; avoid hexavalent chromium (Cr6+) in zinc processes | Anodized alloys compliant; avoid cadmium in hardware; ensure coating compliance |

| Warranty and lifecycle cost (TCO) | Longer service life reduces lifecycle spend; better suited for commercial settings | Lower upfront cost, but maintenance and replacements raise TCO over time | Balanced mid-range TCO; replacement frequency higher than 316 in harsh exposures |

| Coastal/salt-spray suitability | Strong: 316 resists pitting/chlorides; 304 acceptable in low-salt exposure | Weak to moderate: coating defects cause rapid corrosion near marine environments | Moderate: performs better than coated steel but generally less than 316; monitor anodizing integrity |

| Sustainability | Recyclable and durable; lower replacement cadence reduces waste | Lower durability increases replacement cycle; more packaging waste | Recyclable; lighter shipping weight; overall footprint depends on alloy and finish |

Analysis

-

Initial cost versus lifecycle: Premium stainless steel carries a higher baseline price (e.g., $0.24–$2.22 for washers, nuts, and bolts on a typical commercial catalog), but its longer service life—especially in coastal and UV-exposed environments—reduces lifecycle costs. Coated carbon steel undercuts upfront costs but typically demands earlier replacement and touch-up maintenance. Aluminum sits in the middle, with acceptable longevity inland and moderate risk near coasts.

-

Corrosion performance: In marine or de-icing salt exposure, 316 stainless steel is the most reliable (pitting/chloride resistance). 304 is suitable inland with lower salt exposure. Coated carbon steel resists rust when intact but is vulnerable at scratches and contact points. Aluminum may exhibit oxidation and perform inconsistently depending on alloy, anodizing quality, and exposure.

-

Strength and torque capacity: Stainless steel components maintain pre-load well and hold mechanical joints through many seasons. Coated carbon steel loses pre-load as corrosion products form. Aluminum is adequate for lighter joints but may deform or relax over time under load.

Illustrative Image (Source: Google Search)

-

Maintenance and inspection: Stainless steel requires minimal maintenance—periodic cleaning and torque checks. Coated steel requires routine inspection for chipping and rust, plus touch-ups. Aluminum requires inspections of anodic coatings and control of galvanic pairs.

-

Compliance and sourcing: Stainless steel is generally straightforward for REACH and RoHS compliance. Coated steels need diligence on coating chemistry and suppliers’ documentation to avoid restricted substances. Aluminum alloys and anodized finishes are commonly compliant; ensure documentation and avoid cadmium-bearing materials.

Practical procurement guidance

-

Coastal hotels, resorts, and municipal parks: Favor 316 stainless steel for bolts, washers, and lock nuts. Use appropriate lubricants to minimize galling and follow torque specs.

-

Inland venues with moderate budgets: Coated carbon steel can work if inspection cycles and touch-up programs are well managed, though expect earlier part replacement.

Illustrative Image (Source: Google Search)

-

Lightweight designs and decorative elements: Aluminum hardware is viable when joint loads are modest and exposure is not marine. Keep material pairs compatible to avoid galvanic corrosion.

-

Thread standards: Standardize on US (e.g., 1/4″-20, 5/16″-18) or Metric (M6, M8) per your market to simplify inventory and avoid mixed fastener standards across USA and EU deployments.

-

Warranty and sourcing: Favor suppliers offering commercial-grade hardware, clear grade specifications (e.g., 316/304 SS), and consistent stock in USA/EU warehouses. Ensure coating compliance for non-stainless alternatives.

Bottom line: For durable, low-maintenance performance—especially in coastal conditions—premium stainless steel hardware delivers superior lifecycle value. Coated carbon steel offers lower upfront cost but requires higher maintenance. Aluminum is a practical mid-ground option for lighter-duty applications and inland environments.

Illustrative Image (Source: Google Search)

Essential Technical Properties and Trade Terminology for hardware for outdoor furniture

Essential Technical Properties and Trade Terminology for hardware for outdoor furniture

Key points overview

– Material grade and specification: Prefer 316 austenitic stainless (A4) for coastal/marine exposure; 304 (A2) acceptable inland; select 316 fasteners like 5/16″-18 hex bolts and 1/4″-20 socket cap screws for high-corrosion zones.

– Mechanical properties: Use property classes A2-70 / A4-70 for general service; A4-80 for higher loads; ensure washers and nuts match bolt grade and finish.

– Standards and compliance: Align with ASTM (A193, A574, F593, F594, F146) or ISO (3506 A2/A4; 4032/4035; 4034; 7089/7090; 7089) depending on market; mark parts per standard where possible.

– Corrosion and surface finish: 316 (A4) resists chlorides better than 304 (A2); passivation and electropolish improve corrosion resistance; avoid carbon steel zinc for coastal use; PTFE or nylon patches can secure bolted joints without lubrication.

– Thread and fit: Use UNC (imperial) coarse threads for furniture brackets and frames; maintain proper thread engagement and clamped thickness; specify underhead and body diameter tolerances for repeatability.

– Packaging and QC: Specify MOQ, lead time, packaging (bulk, polybags with separators, labeled cartons), 100% torque-proof if required, and batch traceability.

– Marking and documentation: Specify DIN 912 (socket cap), DIN 933 (full thread hex), DIN 934 (hex nut), ISO 7089 (flat washers); provide test certificates (magnetic/surface passivation), COA, RoHS and REACH declarations on request.

– Trade terms and logistics: Define Incoterms (EXW, FOB, CIF, DDP), US/EU ports, POs, HS codes, and payment terms; provide SDS for any finishes or lubricants.

Material grades, corrosion behavior, and mechanical properties

Stainless grade selection is the most important technical driver in outdoor furniture hardware. Austenitic stainless steels are standard for exposed assemblies.

- 316 stainless (A4; Cr–Ni–Mo): Stronger pitting and crevice corrosion resistance than 304; preferred for coastal/marine areas and high-chloride environments. Examples in the reference set: 5/16″-18 hex bolts and 1/4″-20 socket cap screws.

- 304 stainless (A2; Cr–Ni): Suitable inland or low-chloride outdoor use; may show surface tea-staining in humid coastal climates.

Mechanical property classes:

– A2-70 / A4-70: Typical for general outdoor furniture load paths; sufficient for chair frames, slat connectors, and bracket assemblies.

– A4-80: Higher strength; use sparingly with 316 fasteners where preload or dynamic loads demand higher allowable tension.

Surface and finish:

– Passivation per ASTM A967 removes free iron and improves corrosion resistance; optional electropolish for a smoother, more corrosion-resistant surface.

– Avoid carbon steel zinc plating for coastal use; zinc corrodes quickly and stains adjacent stainless parts.

– Optional thread-locking: Thread seal PTFE tape or nylon patch (e.g., on socket cap screws) to avoid thread-locking compounds in marine environments; for more robust locking, specify nylon insert (lock) nuts or prevailing torque nuts, all in matching stainless grade.

Illustrative Image (Source: Google Search)

Fastener standards and property class mappings (US/EU aligned)

| Fastener type | US standard(s) | Property class/mark | EU/ISO standard(s) | Notes |

|---|---|---|---|---|

| Socket cap screw (hex socket) | ASTM A574 (alloy steel), ASTM F739 for stainless | 316 stainless (A4-70); label “A4-70” on head | DIN 912; ISO 4762 | Use 316 for coastal; 304 (A2) inland; mark per standard where feasible. |

| Hex bolt / cap screw (full thread) | ASTM F593 (bolts/screws/studs) | A2-70 (304), A4-70 (316); A4-80 available | DIN 933; ISO 4017 | Common furniture sizes: 1/4″-20 and 5/16″-18 (imperial coarse). |

| Hex nut | ASTM F594 (nuts) | Match to bolt class: A2-70 → A2 nut; A4-70 → A4 nut | DIN 934; ISO 4034/4032 | Specify prevailing torque (nylon insert) when vibration resistance is needed. |

| Flat washer | ASTM F146; ASTM F436 for hardened steel washers (do not use in stainless assemblies) | Stainless steel flat washer, A2/A4 per application | ISO 7089 (series A) | Use stainless washers to match fastener grade; prevents galvanic staining. |

| Locking elements | Various | Nylon insert lock nut; prevailing torque nut | DIN 982; ISO 7040 (nylon insert) | Specify stainless to match grade; avoid non-stainless lock washers in coastal zones. |

Common hardware families in outdoor furniture (reference-set examples)

| Product name | Likely function | Key spec to define | Grade/class | Cross-reference |

|---|---|---|---|---|

| Socket Cap Screw 1/4″-20 × 2″ (316 SS) | Fastening brackets, cross-braces, bases | Length, coarse UNC thread, hex socket tolerance | A4-70 (316) | ASTM A574; DIN 912 |

| Socket Cap Screw 1/4″-20 × 3/4″ (316 SS) | Compact assemblies, leg-to-beam joints | Length, head height | A4-70 | DIN 912 |

| Hex Bolt 5/16″-18 × varied lengths (1/2″–2-3/4″) (316 SS) | Chair frames, table bases, armrests | Full-thread lengths, head height, wrench size | A4-70 | ASTM F593; DIN 933 |

| Hex Bolt 1/4″-20 × 2-1/2″ (10/24) with lock nut | Swing/rocker mechanisms, sliding joints | Thread (10/24 or UNC 1/4″-20), lock nut type | A4-70 + A4 lock nut | ASTM F593/F594; DIN 933/934 |

| Hex Nut 1/4″-20 (316 SS) | General assembly; matches 1/4″ bolts | Nut height, thread class 2B | A4 | ASTM F594; DIN 934 |

| Hex Nylon Locking Nut 5/16″-18 (316 SS) | Vibrated joints, chair rockers | Nylon insert type, torque prevailing | A4 | ASTM F594; ISO 7040 |

| Flat Washer 1/4″ / 5/16″ (316 SS) | Distributes load; protects finish | Washer series, diameter tolerance | A4 | ASTM F146; ISO 7089 |

| Metal Pop Rivet Glide | Foot caps for glides/furniture feet | Rivet material (stainless), load rating | Stainless | Specify per manufacturer standard |

Technical specifications to include in B2B RFQs

- Material grade: 316 stainless (A4) or 304 (A2); specify Mo-bearing 316 if coastal/marine.

- Standards and property class: ASTM F593 for bolts/screws; ASTM F594 for nuts; ISO 3506 for metric (if applicable); property class A2-70/A4-70 or A4-80 as required.

- Thread system and fit: Imperial UNC coarse threads (1/4″-20, 5/16″-18) for North America; metric where needed; specify thread tolerance 2A/2B (external/internal).

- Mechanicals: Specify minimum tensile/yield per property class or ask supplier for certificates; for stainless, align expected preload with torque guidance.

- Surface finish: Passivation; electropolish optional; specify cleanliness (no rust, no oil); no zinc plating.

- Fastener head and nut forms: Socket cap (DIN 912/ISO 4762), hex head (DIN 933/ISO 4017), hex nut (DIN 934/ISO 4034); washer series per ISO 7089.

- Optional features: Nylon insert (prevailing torque) lock nuts; thread-locking via PTFE tape or nylon patch; specify “no oil or compound” for food-adjacent or marine use if applicable.

- Packaging and labeling: Bulk packaging or segmented polybags; include lot/batch codes and barcodes; export labeling per market.

- Documentation: Mill test certificates; RoHS/REACH compliance statements; SDS if any finishes/lubricants are used.

Corrosion guidance by environment

| Environment | Recommended grade/class | Notes |

|---|---|---|

| Coastal/marine (salt mist, chlorides) | 316 (A4-70/80) | Avoid carbon steel washers/zinc; confirm passivation; consider electropolish for exposed hardware. |

| Inland urban/suburban | 304 (A2-70) acceptable | May show tea-staining; keep parts dry where possible; stainless washers to prevent galvanic staining. |

| Poolside/hard water | 316 (A4) | High chlorination; prioritize 316 fasteners and washers. |

| High-vibration seating/rockers | 316 (A4) with lock nuts | Use nylon insert or prevailing torque nuts; match to bolt grade. |

Trade terminology for procurement (MOQ, OEM, Incoterms, etc.)

| Term | Meaning | Why it matters | Example specification |

|---|---|---|---|

| MOQ (Minimum Order Quantity) | Smallest order size supplier will accept | Influences stocking and lead time | “MOQ: 500 pcs per SKU; mixed SKUs allowed.” |

| OEM (Original Equipment Manufacturer) | Supplier produces to your design/drawing | Required for custom dimensions, head markings | “OEM custom socket cap screw per supplied drawing; material A4-70.” |

| Lead time | Production plus dispatch time | Drives project schedule | “Lead time: 6–8 weeks for standard stock sizes; 10–12 weeks for OEM.” |

| Incoterms | Shipping responsibility and risk transfer | Clarifies cost allocation | “FOB US West Coast or FOB Hamburg.” |

| Test certificates / MTC | Mill test/certificates confirming chemistry and mechanicals | Traceability and compliance | “Include MTC per lot; submit PDF and signed originals.” |

| Packaging | Inner/outer packaging and labeling | Prevents damage; enables customs clearance | “Polybag inner; 25 pcs per bag; labeled carton; barcode SKU/lot.” |

| Lot/batch traceability | Unique lot codes for each batch | Recall support; quality investigations | “Lot code printed on label; include PO and date.” |

| Country of origin (COO) | Manufacturing location | Tariff, compliance, lead time | “COO: CN or TW; indicate in CO.” |

| HS codes | Harmonized tariff codes | Customs declarations | “Socket cap screw: 7318.15; washer: 7318.22.” |

| SDS | Safety Data Sheet | Required if finishes/lubricants used | “Provide SDS for passivation and any lubricants.” |

| REACH/RoHS | EU chemical compliance | Market access | “Declaration of compliance on request.” |

| QC and AQL | Acceptance quality limit and inspection | Controls defect rate | “QC plan with AQL 2.5 for major defects.” |

| Payment terms | Net days, LC, deposit, etc. | Cash flow | “Net 30 upon delivery; 30% deposit for first order.” |

How to specify common items (reference-set aligned)

- Hex Bolt 5/16″-18 × 1–2.75″ (316 SS): Specify full-thread lengths where clamping thicknesses vary; choose socket cap or hex head per assembly; specify A4-70; require washers and nuts in matching grade.

- Socket Cap Screw 1/4″-20 × 3/4″–2″ (316 SS): Use for compact brackets; specify DIN 912 marking; provide torque guidance; indicate nylon patch if thread-seal is required but no oil is allowed.

- Lock nuts: Specify “prevailing torque nylon insert” (316 SS) for chair rockers or swing mechanisms; avoid stainless flat washers that are too small (under head) to prevent bite-through of soft aluminum or thin steel.

- Glides and foot caps: Specify stainless or corrosion-resistant materials; where rivet glides are used, specify stainless rivets and compatible foot material (e.g., UHMW or TPR) for durability.

QA checklist before PO release

- Confirm grade/class matches environment (A4-70/80 for coastal; A2 inland).

- Verify standards and head markings are per ASTM/ISO/DIN; ensure nuts/washers match fastener grade.

- Specify passivation; request SDS if any finishes used; confirm no oil for marine-adjacent assemblies.

- Include packaging, labeling, lot traceability, and test certificates in the spec.

- Lock in Incoterms, ports, and HS codes; define MOQ, lead time, and payment terms.

- Provide drawings or tables for clamped thicknesses and thread engagement where critical.

Quick reference tables

Grade-class summary:

– A2-70 (304 SS): General indoor/outdoor (inland).

– A4-70 (316 SS): Coastal/marine; poolside.

– A4-80 (316 SS): Higher strength, same corrosion resistance as A4-70.

Standards quick map:

– Socket cap screws: ASTM A574; DIN 912; ISO 4762.

– Hex bolts: ASTM F593; DIN 933; ISO 4017.

– Hex nuts: ASTM F594; DIN 934; ISO 4034/4032.

– Flat washers: ASTM F146; ISO 7089 (series A).

– Lock nuts: ASTM F594; ISO 7040 (nylon insert).

Summary

Use 316 stainless (A4) for high-corrosion environments and 304 (A2) for milder settings; specify A2-70/A4-70 property classes and match bolts, nuts, and washers; align with ASTM/ISO/DIN standards, passivate parts, and define MOQ, lead time, packaging, Incoterms, and documentation requirements to ensure repeatable procurement and assembly quality.

Navigating Market Dynamics and Sourcing Trends in the hardware for outdoor furniture Sector

Navigating Market Dynamics and Sourcing Trends in the Hardware for Outdoor Furniture Sector

Structural shifts shaping the market

- Post‑pandemic normalization in outdoor furnishing: Demand shifted from home‑driven spikes in 2020–2022 toward commercial hospitality recovery and institutional refresh cycles. The market splits between commercial projects (durable, serviceable, corrosion‑resistant hardware) and Do‑It‑Yourself/home improvement (repair and refresh parts).

- Supply volatility in stainless steel inputs: Stainless hardware for outdoor furniture relies on nickel‑bearing stainless grades (notably 316/304). Periods of volatility in nickel and stainless scrap flows (e.g., 2022–2023) can create pricing and lead‑time whiplash, especially for specialized fasteners and components.

- Freight normalization vs. episodic disruptions: Ocean freight availability is generally improved, yet Red Sea and regional bottlenecks can periodically shorten capacity and extend transit times.

- Retail/e‑commerce influence on parts pricing: SKU‑level price visibility (e.g., small lot pricing for cap screws, bolts, washers) enables rapid market intelligence and competitor benchmarking across the U.S. and EU.

Regulatory and sustainability drivers

- RoHS/REACH and restricted substances: Fastener and metal finishing inputs are increasingly scrutinized for hexavalent chromium and other restricted substances. Even “stainless‑only” assemblies may require documentation for coatings, lock nuts with inserts, and adhesive/compound components.

- EUPP/EUDR traceability: New EU measures for product passports (e.g., batteries/WEEE) and due‑diligence on deforestation risk are expanding expectations for supplier transparency and material traceability, signaling tighter standards across categories.

- Packaging and shipping requirements: Regulations targeting microplastics (e.g., certain polymer beads), single‑use plastics, and plastic additives increase scrutiny of packaging materials, films, and hardware liners or wraps.

Sourcing trends and procurement strategies

- Grade selection anchored in corrosion performance:

- 316 stainless for marine/coastal exposure and high‑end commercial frames.

- 304 stainless for standard outdoor use or interiors.

- Consolidate on fewer suppliers, broaden the SKU set: A tiered‑supplier model (primary plus regional backups) reduces disruption risk while maintaining consistent specifications. Expand the component set (bolts, cap screws, washers, lock nuts, rivets, glides, rail end caps) to streamline assembly and service.

- Negotiate with price/margin transparency: Use live SKU‑level pricing as a benchmark in negotiations (e.g., 316 stainless hex bolts and cap screws within a published range). Tie price reviews to nickel/stainless indices and freight baselines to manage volatility.

- Lead‑time and MOQ management:

- Set MOQs that support multi‑month builds, but plan buffer lead times for specialty threads/coatings.

- Favor suppliers with rapid SKU throughput, especially for repair markets needing quick turns.

- Quality and spec discipline:

- Confirm thread form (e.g., 1/4″‑20, 5/16″‑18) and head styles (hex, socket cap), finish and edge conditions.

- Validate assembly fit with real hardware sets (bolt‑lock nut‑washer combinations) to avoid rework.

- ESG and documentation:

- Request material traceability (melt source when possible) and compliance attestations (RoHS/REACH/Prop 65 as applicable).

- Align packaging with evolving restrictions (polymer beads, microplastics, single‑use plastics).

Historical perspective and product availability

- Evolution of stainless in outdoor furniture: Stainless steel hardware gained share due to superior strength‑to‑weight and corrosion resistance compared to plated carbon steel. Grade 316 became the default for coastal and commercial projects; 304 remained standard for mild outdoor use.

- Price/product example (U.S. market): Published pricing in recent years illustrates the working range for common sizes: 1/4″‑20 socket cap screws (316) around $1.2–$1.9; 5/16″‑18 hex bolts (316) in common lengths ~$1.1–$2.3; nylon lock nuts ~$0.5; flat washers ~$0.28–$0.34. These reference points support procurement benchmarking across suppliers.

Risk checklist for sourcing stainless hardware

- Nickel/stainless index sensitivity and pass‑through clauses in contracts.

- Freight disruption from Red Sea/alternative routing, with impacts on West/East Coast U.S. and EU ports.

- Supplier capacity swings when residential demand softens and commercial cycles surge.

- Documentation gaps on coatings, plastics, and finishes amid expanding regulation.