The global HVAC market is experiencing robust expansion, driven by increasing demand for energy-efficient cooling systems and rising infrastructure development across residential and commercial sectors. According to Mordor Intelligence, the HVAC market is projected to grow at a CAGR of over 7.5% from 2024 to 2029, with significant ripple effects on component-level demand—particularly for reliability-enhancing solutions like hard start compressor kits. These kits, which improve compressor longevity and startup efficiency, have become essential in both new installations and system retrofits. As the need for dependable HVAC performance rises—especially in extreme climates and aging equipment—the market for hard start solutions is expanding in parallel. This growing demand has spurred innovation and competition among manufacturers, leading to a surge in high-performance, technologically advanced kits. Based on industry trends and market data, we’ve identified the top 8 hard start compressor kit manufacturers shaping the landscape through quality, scalability, and engineering excellence.

Top 8 Hard Start Compressor Kit Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Compressor Hard Start Kits

Domain Est. 1994

Website: grainger.com

Key Highlights: Hard-start kits integrate with a compressor or other high-power refrigeration components and provide a surge of energy to help start components….

#2 HARD START KITS

Domain Est. 2006

Website: store.arsnet.com

Key Highlights: Wiring, Plugs, Terminals, Nuts, etc. Our Leading Brands. JOHNSON CONTROLS INC. CLIPLIGHT MANUFACTURING CO….

#3 5

Domain Est. 1996

Website: cpsproducts.com

Key Highlights: A 5-2-1 Compressor Saver protects these expensive components by significantly reducing the amount of time required for your compressor to start….

#4 Hard Start Kits

Domain Est. 1996

Website: diversitech.com

Key Highlights: Equipment Mounting · Pads · Equipment Stands · Wall Brackets · Mounting Blocks, Feet, and Risers · Hanging Brackets · Mounting Accessories · Tools ……

#5 5

Domain Est. 1998

Website: ecmdi.com

Key Highlights: This Hard Start Kit significantly reduces the amount of time it takes for your compressor to start. This means it reduces the stress, strain, and heat each ……

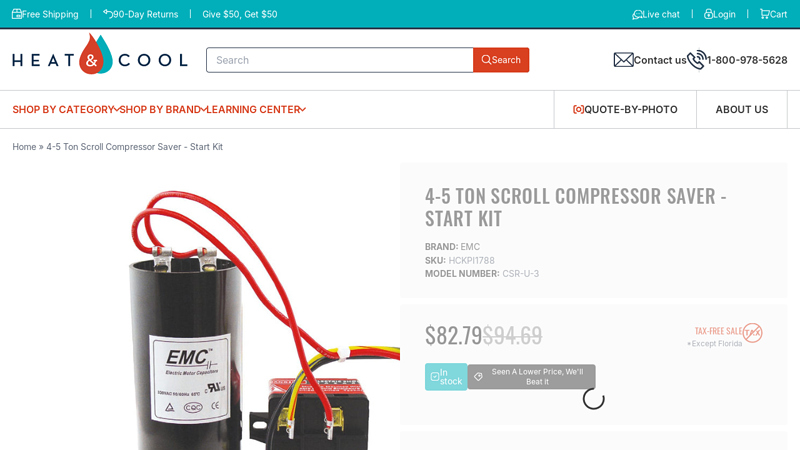

#6 4

Domain Est. 2003

Website: heatandcool.com

Key Highlights: In stock Rating 5.0 10 The compressor saver uses a powerful multi-layer starting capacitor with a smart switch to give a sufficient boost to reduce startup time and draws less po…

#7 Hard Start

Domain Est. 2004

Website: five-two-one.com

Key Highlights: The video below demonstrates how the 5-2-1 Compressor Saver® (aka Hard Start Kit) works conceptually. The video is a non-technical representation on how the ……

#8 Compressor Saver Buy Hard Kit From Leading Electronic …

Domain Est. 2020

Website: navigatepa.com

Key Highlights: Buy Hard Start Capacitor Kit From Leading Electronic Component … Get it delivered as soon as today. Schedule your delivery in checkout. More delivery methods in ……

Expert Sourcing Insights for Hard Start Compressor Kit

H2: 2026 Market Trends for Hard Start Compressor Kits

The global market for hard start compressor kits is projected to experience steady growth by 2026, driven by rising demand for energy-efficient HVAC systems, increasing equipment reliability needs, and expanding residential and commercial cooling applications. Key trends shaping the 2026 landscape include:

-

Growing HVAC System Installations

The continued urbanization and expansion of infrastructure in emerging economies, coupled with rising consumer demand for comfort cooling in residential and commercial buildings, are fueling HVAC system installations. Hard start kits are increasingly integrated as standard or recommended add-ons to improve compressor longevity and startup efficiency, particularly in regions with unstable power supplies. -

Focus on Energy Efficiency and Equipment Longevity

As energy costs rise and sustainability becomes a priority, end-users and HVAC professionals are adopting hard start kits to reduce inrush current and minimize mechanical stress on compressors. This trend is reinforced by government and industry initiatives promoting energy-efficient appliances and systems, indirectly supporting demand for auxiliary components like hard start kits. -

Technological Advancements and Smart Integration

By 2026, advancements in capacitor technology and solid-state relays are enhancing the performance of hard start kits. Some manufacturers are introducing smart versions compatible with IoT-enabled HVAC systems, allowing remote diagnostics and predictive maintenance. These innovations are expected to increase product value and appeal, especially in premium and commercial HVAC segments. -

Replacement and Retrofit Market Expansion

A significant portion of demand stems from the retrofit and repair market. Aging HVAC units, particularly in North America and Europe, are being upgraded with hard start kits to extend operational life and avoid costly compressor replacements. This cost-effective solution is gaining traction among homeowners and service technicians alike. -

Regional Market Dynamics

North America remains a dominant market due to high HVAC penetration and a mature service industry. However, Asia-Pacific is expected to witness the highest growth rate, driven by rapid construction, industrialization, and increasing adoption of air conditioning in countries like India and Southeast Asia. Government-led initiatives for cooling efficiency may further accelerate adoption. -

Supply Chain and Material Considerations

The market is sensitive to fluctuations in raw material costs, particularly electrolytic capacitors and electronic components. By 2026, manufacturers are anticipated to adopt localized production and alternative materials to mitigate supply chain risks and maintain competitive pricing. -

Regulatory and Environmental Standards

Stricter regulations on HVAC efficiency and refrigerant management are prompting system upgrades. While hard start kits are not directly regulated, their role in improving system performance aligns with broader environmental goals, thus supporting market acceptance.

In summary, the 2026 hard start compressor kit market is poised for moderate but sustained growth, underpinned by technological innovation, energy efficiency demands, and a strong after-sales service ecosystem. Companies that invest in product differentiation, regional expansion, and compatibility with modern HVAC systems are likely to gain a competitive advantage.

Common Pitfalls When Sourcing a Hard Start Compressor Kit (Quality & IP)

When sourcing a Hard Start Compressor Kit, especially for HVAC systems, overlooking quality and intellectual property (IP) considerations can lead to significant operational, legal, and financial risks. Being aware of these common pitfalls helps ensure reliable performance and legal compliance.

Poor Component Quality Leading to Premature Failure

One of the most frequent issues is selecting kits with substandard components. Low-quality capacitors, relays, or wiring may not meet required electrical specifications or environmental tolerances. These components are often prone to overheating, short cycling, or outright failure, potentially causing damage to the compressor or other system parts. Look for kits that use UL-listed or ETL-certified components and verify manufacturer specifications for voltage, current, and temperature ratings.

Lack of Proper Certifications and Compliance

Many inexpensive or counterfeit kits lack essential safety certifications such as UL, CSA, or CE. Using non-compliant kits can void equipment warranties, violate building codes, and create safety hazards like fire or electrical shock. Always verify that the kit and its individual components carry recognized third-party certifications appropriate for your region.

Misrepresentation of Compatibility and Specifications

Some suppliers falsely advertise universal compatibility or exaggerate performance claims. A kit that doesn’t match the compressor’s start requirements (e.g., wrong microfarad rating or voltage) can cause inefficient starts or even mechanical stress. Always cross-reference the kit’s specs with the compressor manufacturer’s guidelines or consult technical datasheets before purchasing.

Counterfeit or IP-Infringing Products

A major concern in the HVAC aftermarket is the proliferation of counterfeit hard start kits that copy patented designs or branding from reputable manufacturers (e.g., Supco, HVACParts4U). These clones often infringe on intellectual property rights and may not undergo the same quality control. Sourcing such products exposes buyers to legal liability and risks poor performance. Always purchase from authorized distributors or directly from the IP holder to ensure authenticity and support innovation.

Inadequate Technical Support and Documentation

Low-cost kits often come with minimal or incorrect installation instructions and no access to technical support. This can lead to improper installation, miswiring, or incorrect troubleshooting. Reputable brands provide detailed documentation, wiring diagrams, and customer support—critical factors when dealing with high-voltage components.

Short-Term Savings vs. Long-Term Costs

Choosing a cheaper kit to save upfront costs often results in higher long-term expenses due to repeated failures, compressor damage, or service calls. Investing in a high-quality, IP-compliant kit from a trusted manufacturer reduces downtime and extends the life of the HVAC system.

Conclusion

To avoid these pitfalls, prioritize suppliers that offer certified, genuine products with transparent specifications and proper IP compliance. Conduct due diligence by checking reviews, verifying certifications, and confirming distributor authorization. This approach ensures system reliability, safety, and adherence to legal standards.

H2: Logistics & Compliance Guide for Hard Start Compressor Kit

This guide outlines the critical logistics and compliance considerations for the storage, transportation, handling, import/export, and regulatory adherence of Hard Start Compressor Kits. Adherence ensures product integrity, safety, and legal operation across supply chains and markets.

H3: 1. Product Classification & Identification

- Commodity Code: Determine the appropriate HS (Harmonized System) code. Common classifications include:

- 8504.40: Electrical transformers, static converters (like capacitors) & inductors.

- 8536.30: Switches for voltages ≤ 1,000 V (if the kit includes a relay/PTC).

- 8537.10: Boards, panels, etc. for electrical control (if integrated on a PCB).

- Action: Confirm the exact HS code(s) with a customs broker or trade authority based on the specific kit components (capacitor type, relay, wiring harness).

- UN Number: Hard Start Kits typically contain no hazardous materials (e.g., no PCBs, no significant amounts of hazardous chemicals). They are generally non-hazardous for transport. Verify this for all components (e.g., capacitor electrolyte).

- ECCN (Export Control Classification Number): Generally EAR99 (items not specifically listed on the CCL) for standard kits. Confirm no advanced microcontrollers or dual-use technology is present.

H3: 2. Packaging & Labeling Requirements

- Primary Packaging: Kits must be securely packaged to prevent damage:

- Capacitors: Protected from physical impact, moisture, and shorting (terminals insulated).

- Wiring Harnesses/Relays: Prevented from tangling or wire damage.

- Use anti-static bags if components are ESD-sensitive.

- Shipping Packaging: Use sturdy corrugated cardboard boxes with adequate cushioning (bubble wrap, foam inserts). Ensure boxes meet ISTA or ASTM standards for drop and vibration resistance.

- Labeling (External Box):

- Product Name & SKU/Part Number.

- Net & Gross Weight.

- “Fragile” and “This Side Up” indicators.

- Manufacturer/Seller Name & Address.

- Country of Origin (Critical for tariffs and consumer labeling laws).

- Handling symbols (e.g., moisture-sensitive, temperature limits).

- Compliance Marks: Display required certification marks (e.g., UL, cUL, ETL, CE, RoHS – see Section 4).

- Hazard Symbols: None required for non-hazardous kits, but clearly mark if any component is restricted (rare).

H3: 3. Storage & Handling

- Environment:

- Temperature: Store between 5°C (41°F) and 35°C (95°F). Avoid freezing and extreme heat.

- Humidity: Maintain low humidity (<60% RH) to prevent corrosion and capacitor degradation. Use desiccants if necessary.

- Ventilation: Store in a well-ventilated, dry area.

- Handling:

- Avoid dropping or impacting packages.

- Prevent exposure to water, solvents, or corrosive atmospheres.

- Handle capacitors carefully; do not short terminals.

- Shelf Life: Monitor capacitor shelf life. Electrolytic capacitors have limited shelf life (typically 2-5 years). Implement FIFO (First-In, First-Out) inventory management. Test capacitors approaching end-of-life if possible.

H3: 4. Regulatory Compliance & Certifications

- Electrical Safety:

- North America: Must be certified by a Nationally Recognized Testing Laboratory (NRTL) such as UL (Underwriters Laboratories) or ETL (Intertek) to standards like UL 810 (Capacitors) and UL 508 (Industrial Control Equipment). cUL required for Canada. Certification must cover the entire kit or its critical components.

- Europe: Requires CE Marking demonstrating conformity with relevant EU Directives:

- Low Voltage Directive (LVD) 2014/35/EU: Ensures electrical safety.

- EMC Directive 2014/30/EU: Ensures electromagnetic compatibility (prevents interference).

- RoHS Directive 2011/65/EU: Restricts hazardous substances (Lead, Mercury, Cadmium, etc.). Requires material declarations and testing.

- Environmental:

- RoHS (EU & similar global regulations): Mandatory. Ensure all components are RoHS compliant. Maintain Supplier Declarations of Conformity (SDoC).

- REACH (EU): Register and communicate information on Substances of Very High Concern (SVHCs). Requires SDoC from suppliers.

- WEEE (EU): Producers are responsible for end-of-life recycling. Register with national WEEE schemes.

- Country-Specific:

- UK: UKCA marking (replacing CE for Great Britain, though CE often still accepted) + UK RoHS/REACH.

- Australia/NZ: RCM (Regulatory Compliance Mark) + AS/NZS standards.

- China: CCC (China Compulsory Certification) may be required for certain electrical components.

- Korea: KC Mark required.

- Action: Verify specific requirements for each target market.

H3: 5. Transportation & Shipping

- Mode: Typically shipped via standard parcel (air/ground) or LTL (Less-Than-Truckload) freight.

- Hazardous Materials: As confirmed in Section 1, standard kits are non-hazardous. No HAZMAT declaration or special handling required.

- Documentation:

- Commercial Invoice (accurate description, value, HS code, origin).

- Packing List (detailed contents, weights, dimensions).

- Bill of Lading (BOL) or Air Waybill (AWB).

- Certificate of Conformity (CoC): Required by many countries (e.g., for CE, UKCA, KC). Must be issued by the manufacturer/importer, stating compliance with relevant standards.

- RoHS/REACH Declarations: May be requested by customs or end customers.

- Import Duties & Taxes: Determine applicable tariffs (based on HS code and origin) and VAT/GST requirements in the destination country. Utilize trade agreements (e.g., USMCA, CPTPP) where applicable.

H3: 6. Import/Export Procedures (Key Considerations)

- Importer of Record (IoR): Clearly identify the legal entity responsible for customs clearance and compliance in the destination country. This could be the seller, buyer, or a third-party logistics provider.

- Customs Broker: Engage a licensed customs broker in the destination country to ensure accurate tariff classification, duty calculation, and document submission.

- Product Registration: Some countries require pre-registration of electrical products (e.g., SIRIM in Malaysia, INMETRO in Brazil). Research requirements early.

- Labeling on Product: Ensure permanent labels on the kit itself or its primary packaging include:

- Manufacturer/Seller Name & Address.

- Part Number & Model.

- Electrical Ratings (Voltage, Capacitance, Current – if applicable).

- Required Compliance Marks (UL, CE, etc.).

- Country of Origin.

- Warnings (e.g., “Disconnect Power Before Installation”).

Disclaimer: This guide provides general information. Regulations vary significantly by country and are subject to change. Always consult with legal counsel, regulatory experts, and customs brokers for definitive advice tailored to your specific product configuration and target markets before shipment.

Conclusion for Sourcing Hard Start Compressor Kit:

Sourcing a hard start compressor kit is a cost-effective and efficient solution to address common issues related to compressor startup in refrigeration and air conditioning systems. These kits help reduce the initial surge of current, extend the lifespan of compressors, and prevent frequent breaker trips or system failures—particularly in older units or regions with unstable power supply. When sourcing hard start kits, it is essential to consider compatibility with the compressor’s specifications, reputable suppliers, product quality, and adherence to safety standards. Opting for kits with proven reliability and proper certification ensures optimal performance and long-term savings. Ultimately, investing in a high-quality hard start compressor kit not only enhances system reliability but also reduces maintenance costs and downtime, making it a strategic choice for both residential and commercial HVAC applications.