The global handrail system market is experiencing steady expansion, driven by rising construction activities and increasing emphasis on safety in residential, commercial, and industrial buildings. According to Grand View Research, the global railing systems market size was valued at USD 23.8 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.4% from 2023 to 2030. This growth is fueled by stringent building codes, urbanization, and demand for durable, aesthetically pleasing architectural components—particularly in staircase and balcony safety systems. As round handrails remain a preferred choice for their ergonomic design and versatility, the demand for compatible handrail brackets has surged. With manufacturers increasingly focusing on corrosion-resistant materials like stainless steel and adjustable designs for ease of installation, selecting the right bracket provider is critical for quality and compliance. Based on performance, material innovation, and market reach, the following nine manufacturers have emerged as leaders in producing high-quality handrail brackets for round handrails.

Top 9 Handrail Brackets For Round Handrails Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

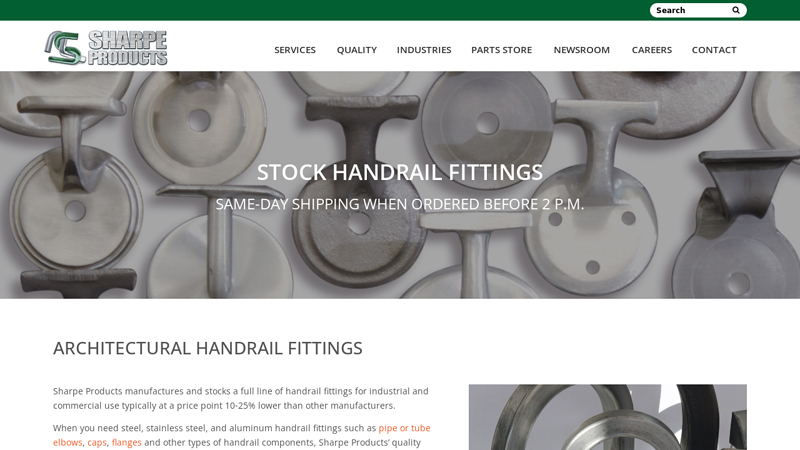

#1 Stock Handrail Fittings

Domain Est. 1999

Website: sharpeproducts.com

Key Highlights: Sharpe Products manufactures and stocks a full line of handrail fittings for industrial and commercial use typically at a price point 10-25% lower than other ……

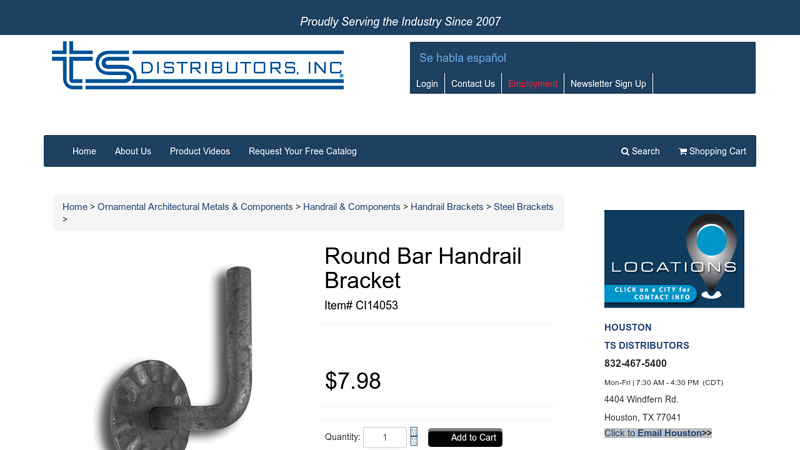

#2 Round Bar Handrail Bracket

Domain Est. 2006

Website: tsdistributors.com

Key Highlights: In stockThree hole base plate; Material: 5/8″ round, distressed; Base Size: 3-1/4″; Wall to Center of Handrail: 2-3/4″. Related Items: Hammered Handrail Bracket …Missing: handra…

#3 Handrail Brackets & Accessories

Domain Est. 1995

Website: crlaurence.com

Key Highlights: 30-day returnsHandrail Brackets & Accessories. Coastal Series Handrail Brackets. La Jolla Series Handrail Brackets. Blumcraft® Pacific Series Handrail Brackets….

#4 Handrail Brackets

Domain Est. 1999

Website: rockymountainhardware.com

Key Highlights: Our Rocky Mountain Hardware handrail brackets are handcrafted from premium bronze and turn your stairways into standout features of your home….

#5 Round Handrail

Domain Est. 2008

Website: ezhandrail.com

Key Highlights: Available in kit form or full length extrusions, each system is carefully designed and packaged to arrive at your build site within 5 days of order placement….

#6 Handrail Brackets

Domain Est. 2010

Website: bedfordreinforced.com

Key Highlights: Crafted from sturdy 3/16″ thick 316 stainless steel, Bedford’s handrail brackets offer robust support for your handrails, ensuring lasting performance, even in ……

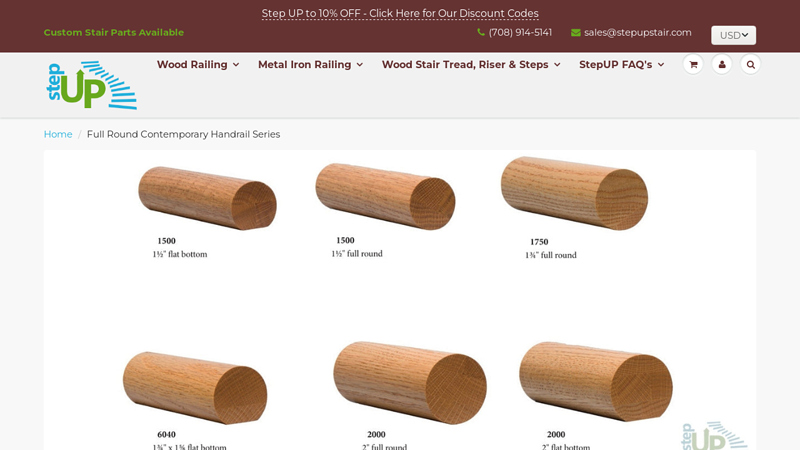

#7 Full Round Contemporary Handrail Series

Domain Est. 2014

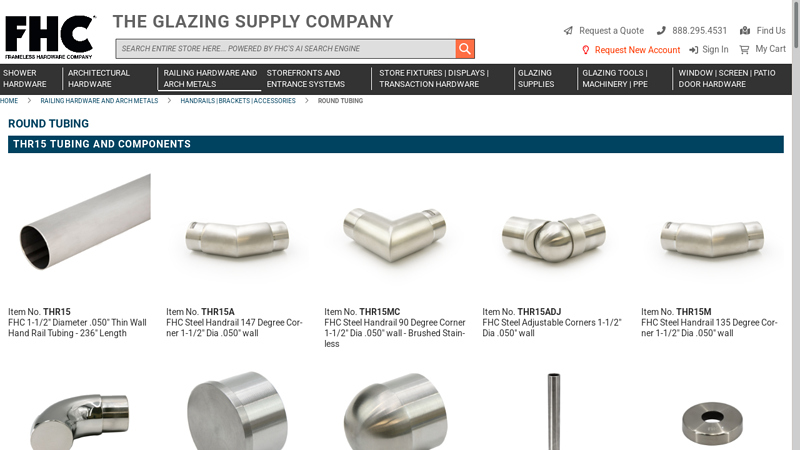

#8 Round Tubing – Handrails

Domain Est. 2019

Website: fhc-usa.com

Key Highlights: Handrail Brackets and Components · Metal Bonding Cements | Threadlocker … FHC Round Handrail Fitting Round 1.9″ Diameter Connor Sleeves 304SS. Item No ……

#9 Round Steel Handrail Bracket

Domain Est. 2021

Expert Sourcing Insights for Handrail Brackets For Round Handrails

H2: 2026 Market Trends for Handrail Brackets for Round Handrails

The global market for handrail brackets designed specifically for round handrails is poised for steady growth and notable transformation by 2026, driven by advancements in construction technology, evolving safety regulations, and shifting consumer preferences. This analysis explores the key trends shaping the market landscape over the coming years.

-

Increased Demand in Residential and Commercial Construction

Urbanization and infrastructure development, particularly in emerging economies, are fueling demand for accessible and safe architectural features. Handrail brackets for round handrails are increasingly being integrated into residential buildings, multi-family housing, commercial complexes, and public facilities. The emphasis on universal design and aging-in-place solutions is significantly contributing to the adoption of ergonomic and aesthetically pleasing handrail systems. -

Material Innovation and Sustainability Focus

By 2026, manufacturers are expected to prioritize sustainable materials such as recycled stainless steel, aluminum alloys, and eco-friendly powder-coated finishes. These materials not only enhance corrosion resistance and durability but also align with green building certifications like LEED and BREEAM. Consumers and contractors are showing a growing preference for brackets that combine longevity with environmental responsibility. -

Design Customization and Aesthetic Integration

Architectural trends are shifting toward minimalist and modern designs, prompting demand for handrail brackets that offer sleek profiles and seamless integration with round handrails. Customizable options—such as finishes (brushed nickel, matte black, satin chrome), adjustable angles, and concealed mounting systems—are gaining traction. Designers are seeking brackets that serve both functional and decorative purposes. -

Rise of Smart and Modular Systems

The integration of smart building technologies is beginning to influence handrail hardware. While still in early stages, modular bracket systems that allow for easy installation, reconfiguration, and compatibility with sensor-based safety features (e.g., motion-activated lighting) are emerging. These innovations cater to adaptive building environments and smart home ecosystems. -

Stringent Safety and Regulatory Compliance

Regulatory bodies worldwide are tightening building codes related to fall prevention and accessibility. Standards such as the International Building Code (IBC) and the Americans with Disabilities Act (ADA) mandate specific load-bearing capacities, spacing, and installation heights for handrails. As a result, manufacturers are focusing on producing brackets that meet or exceed these requirements, ensuring reliability and compliance across markets. -

E-Commerce and Direct-to-Consumer Sales Growth

Online distribution channels are expanding rapidly, enabling consumers and contractors to access a wide variety of handrail brackets with detailed specifications, 3D models, and installation guides. By 2026, e-commerce platforms are expected to account for a significant share of sales, particularly for DIY and renovation projects. Brands investing in digital marketing and augmented reality (AR) tools for product visualization will gain a competitive edge. -

Regional Market Diversification

While North America and Europe remain dominant markets due to strict safety codes and high construction activity, the Asia-Pacific region—especially China, India, and Southeast Asia—is anticipated to witness the fastest growth. Government investments in public infrastructure and rising middle-class housing demand are key drivers in these regions.

In conclusion, the 2026 market for handrail brackets for round handrails will be shaped by innovation in materials and design, regulatory pressures, and digital transformation in distribution. Companies that embrace sustainability, customization, and compliance will be best positioned to capture market share in this evolving sector.

Common Pitfalls When Sourcing Handrail Brackets for Round Handrails (Quality & IP)

Sourcing the right handrail brackets for round handrails involves more than just matching diameters. Overlooking key quality and intellectual property (IP) considerations can lead to safety hazards, costly replacements, or legal complications. Here are critical pitfalls to avoid:

Choosing Inadequate Material Quality or Finish

Selecting brackets made from substandard materials—such as low-grade steel or poorly coated metals—can result in premature corrosion, rust, or structural failure, especially in outdoor or high-moisture environments. Always verify material specifications (e.g., 304 or 316 stainless steel for corrosion resistance) and finish durability (e.g., powder coating or anodizing). Inadequate finishes not only degrade appearance but also compromise long-term performance.

Ignoring Load Capacity and Structural Integrity

Not all brackets are engineered to support the same loads. Using undersized or poorly designed brackets can lead to sagging, loosening, or catastrophic failure under stress. Always confirm that brackets meet relevant building codes (e.g., IBC, ADA) and have been tested for required load ratings. Avoid generic or untested products lacking third-party certification.

Poor Fit Due to Inaccurate Diameter Compatibility

Even slight mismatches between the bracket’s clamping range and the handrail’s outer diameter can result in insecure fittings or damage to the rail. Ensure precise compatibility by measuring the actual handrail diameter and selecting brackets with an appropriate tolerance range. Avoid one-size-fits-all solutions unless verified for your specific rail size.

Overlooking IP Rights and Design Infringement

Sourcing from manufacturers or suppliers that replicate patented bracket designs can expose your project or company to intellectual property litigation. Always verify that the product designs are either licensed, in the public domain, or original. Request documentation or certification of IP compliance, especially when sourcing from overseas suppliers with less stringent IP enforcement.

Compromising on Installation and Adjustability Features

Brackets that lack proper adjustability (e.g., for angle alignment or rail positioning) can make installation difficult and lead to misaligned or wobbly handrails. Poor design may also require specialized tools or additional hardware not included. Prioritize brackets with user-friendly installation features and clear instructions.

Failing to Verify Certifications and Compliance

Reputable brackets should comply with industry standards such as ISO, ASTM, or EN specifications. Lack of verifiable certifications may indicate non-compliance with safety or quality benchmarks. Always request test reports or compliance documentation before procurement, particularly for commercial or public installations.

Relying on Unverified Suppliers or Counterfeit Products

Sourcing from unknown or unvetted suppliers increases the risk of receiving counterfeit or misrepresented products. These may look identical to genuine parts but fail under load or degrade quickly. Conduct due diligence: check supplier credentials, read reviews, request samples, and verify authenticity through traceable manufacturing details.

Avoiding these pitfalls ensures the handrail system is not only safe and durable but also legally and aesthetically sound. Prioritize quality verification, proper specifications, and IP integrity throughout the sourcing process.

Logistics & Compliance Guide for Handrail Brackets For Round Handrails

Product Classification & HS Code

Handrail brackets for round handrails are typically categorized under construction hardware or architectural metal components. The appropriate Harmonized System (HS) code may vary by country, but a common classification is:

HS Code: 7326.90 – Other articles of iron or steel (specific subcategory may vary by design and material).

Note: Always verify with local customs authorities, as classification can depend on material (e.g., stainless steel, carbon steel, aluminum), finish, and intended use.

Packaging & Labeling Requirements

- Packaging: Brackets should be packed in sturdy, moisture-resistant cartons or palletized bundles with protective wrapping to prevent scratches and corrosion during transit.

- Labeling: Each package must include:

- Product name and model number

- Quantity per package

- Net and gross weight

- Country of origin

- Handling instructions (e.g., “Fragile,” “Do Not Stack”)

- Supplier/manufacturer details

Ensure labels comply with destination country requirements, including bilingual labeling where applicable (e.g., English and French in Canada).

Import/Export Documentation

Standard documentation required for international shipping includes:

- Commercial Invoice

- Packing List

- Bill of Lading (B/L) or Air Waybill (AWB)

- Certificate of Origin (may be required for preferential tariffs)

- Material Test Reports (if applicable, especially for stainless steel)

- Import Declaration (completed by importer)

For exports from the EU or imports into regulated markets (e.g., USA, EU, UK), ensure compliance with local product safety and documentation standards.

Regulatory Compliance

United States

- ADA (Americans with Disabilities Act): Handrail brackets must support installations that comply with ADA height, clearance, and continuity requirements (typically 34”–38” above walking surface).

- IBC (International Building Code): Brackets must support handrails capable of withstanding a 50 lb/ft uniform load and a 200 lb concentrated load.

- OSHA: Relevant for workplace installations; fixed industrial stairs require compliant guardrails.

European Union

- EN 1090-1: Execution of steel structures – CE marking required if brackets are part of a structural component.

- Construction Products Regulation (CPR) 305/2011: Brackets used in construction may require CE marking, indicating conformity with essential requirements (e.g., mechanical resistance, stability).

- REACH & RoHS: Ensure materials are free from restricted substances (e.g., lead, cadmium).

United Kingdom

- Post-Brexit, UKCA marking may be required for construction products placed on the UK market. CE marking is still accepted until further notice.

- Compliance with BS 8300 and Approved Document K of the Building Regulations for accessibility and safety.

Canada

- Must comply with National Building Code of Canada (NBCC) and CSA B651 for accessibility.

- Use of bilingual labeling (English/French) required under the Consumer Packaging and Labelling Act.

Shipping & Handling Considerations

- Weight & Dimensions: Optimize packaging to reduce dimensional weight for air freight. Standard export pallet size: 48” x 40” (1200mm x 1000mm).

- Mode of Transport: Sea freight recommended for bulk orders; air freight for urgent or sample shipments.

- Incoterms: Clearly define responsibility using standard Incoterms (e.g., FOB, CIF, DDP). Recommended: FOB for exporter control; DDP for full-service delivery.

- Insurance: Always insure shipments for replacement value, especially for high-value stainless steel or custom-finished brackets.

Quality & Testing Standards

- Load Testing: Brackets should be tested to support at least 200 lbs (90 kg) per mounting point, in line with IBC and similar codes.

- Corrosion Resistance: Salt spray testing (ASTM B117) recommended for outdoor or marine-grade brackets.

- Finish Inspection: Powder-coated, galvanized, or stainless steel finishes must be free of defects and meet specified thickness standards.

Environmental & Sustainability Compliance

- Recyclability: Steel and aluminum brackets are highly recyclable; include recycling symbols on packaging where possible.

- Carbon Footprint: Consider use of low-emission shipping and local sourcing to meet ESG (Environmental, Social, Governance) goals.

- Packaging Waste: Use recyclable or biodegradable materials to comply with EU Packaging Waste Directive and similar regulations.

After-Sales & Warranty Support

- Provide clear installation instructions and torque specifications.

- Offer minimum 1-year warranty against manufacturing defects.

- Maintain traceability via batch/lot numbers for recall readiness.

Conclusion

Handrail brackets for round handrails must meet rigorous logistics and compliance standards to ensure safety, durability, and legal market access. Adherence to international shipping protocols, building codes, and environmental regulations is essential for global distribution. Always consult with legal and customs experts in the destination market to ensure full compliance.

In conclusion, sourcing handrail brackets for round handrails requires careful consideration of several key factors to ensure safety, durability, and aesthetic compatibility. It is essential to accurately measure the diameter of the handrail and match it with appropriately sized brackets to guarantee a secure fit. Materials such as stainless steel, aluminum, or wrought iron should be selected based on the environment—indoors or outdoors—and the desired level of corrosion resistance and strength.

Additionally, attention should be given to the mounting surface and load requirements to ensure structural integrity, especially in commercial or high-traffic areas. A variety of bracket styles—including wall-mounted, flange, or surface-mounted options—offer flexibility depending on installation needs and design preferences.

Sourcing from reputable suppliers who provide certified, code-compliant products ensures adherence to building regulations and safety standards. Comparing pricing, lead times, and warranty options can further optimize the procurement process. Ultimately, selecting the right handrail brackets enhances both the functionality and visual appeal of the handrail system, contributing to long-term user safety and satisfaction.