The global handbag market continues to expand, driven by rising disposable incomes, evolving fashion trends, and increasing demand for luxury and sustainable accessories. According to Grand View Research, the global luxury handbag market size was valued at USD 56.5 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. With handbags serving as both functional items and status symbols, the demand for high-quality components—particularly durable and stylish handles—has surged. As brands prioritize craftsmanship and material innovation, handbag handle manufacturers play an increasingly critical role in the supply chain. From premium leather to eco-conscious alternatives and hardware engineering, specialized suppliers are shaping the functionality and aesthetics of today’s most sought-after bags. In this landscape of growth and innovation, we spotlight the top seven handbag handle manufacturers leveraging design expertise, scalable production, and sustainable practices to meet the demands of a dynamic market.

Top 7 Handbag Handles Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

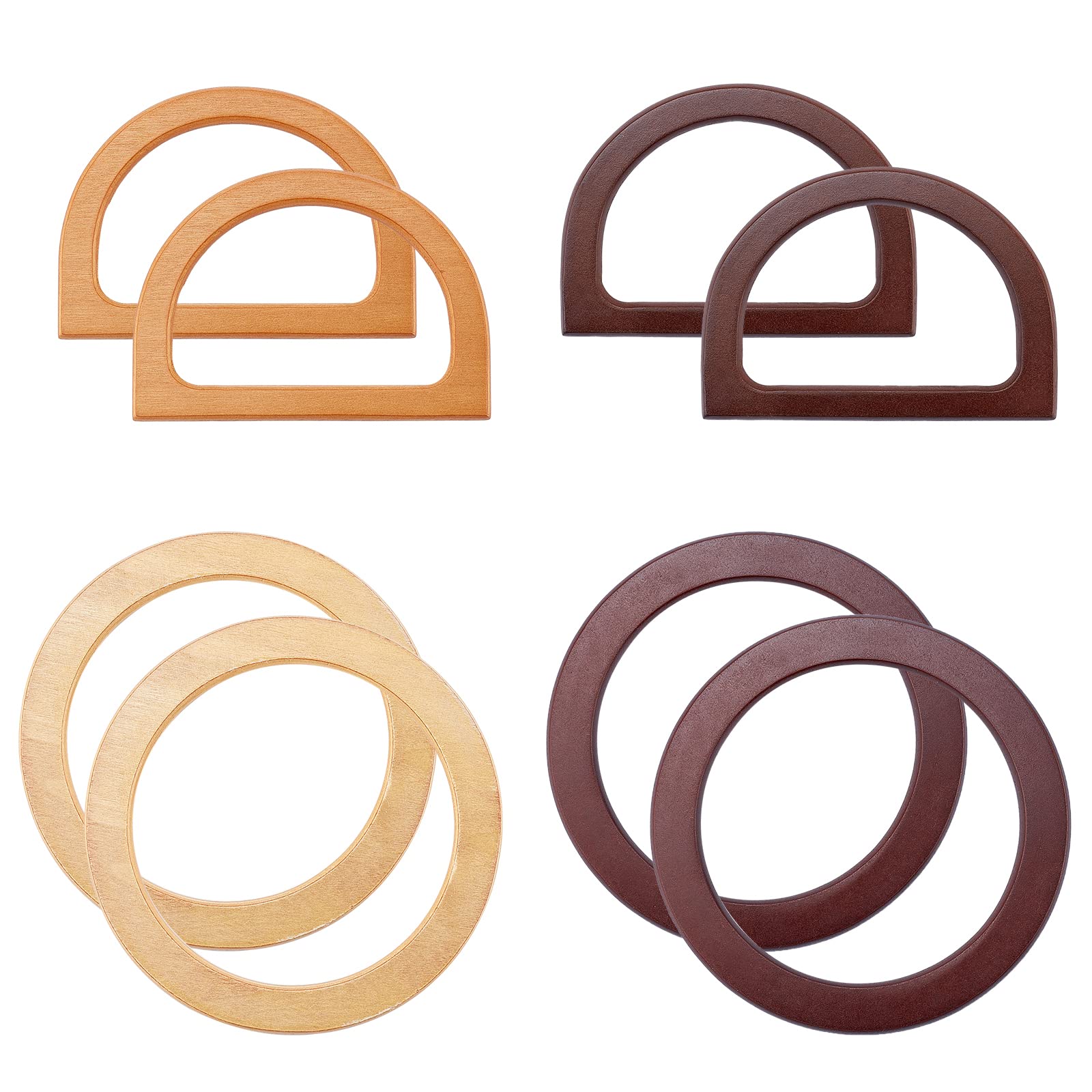

#1 Wooden Bag Handles Manufacturing

Domain Est. 2023

Website: lesondi.com

Key Highlights: Discover an exclusive range of bag handles, expertly crafted to meet the highest standards. OEM & ODM services let you customize design for your business ……

#2 Straps & Handles

Domain Est. 2011

#3 Women’s Top Handle Bags

Domain Est. 1989

Website: bally.com

Key Highlights: Free delivery 7-day returnsOur designer handbags are crafted from fine leather with sleek top handles, distinctive Bally Emblems or lock-effect clasps for understated elegance to m…

#4 Specialty Handles

Domain Est. 1997

Website: allenfield.com

Key Highlights: We offer a variety of unique plastic handles, from bag & bucket handles to self-adhesive handles. All of our specialty handles are designed to enhance the look ……

#5 Elegant Designer Leather Totes

Domain Est. 2001

Website: us.loropiana.com

Key Highlights: Free delivery 30-day returnsExplore the Loro Piana collection of women’s totes and top handle bags in luxury leathers, featuring Italian craftsmanship, and elegant design….

#6 Gianni Chiarini Firenze Bags and Accessories

Domain Est. 2006

Website: giannichiarini.com

Key Highlights: Gianni Chiarini Firenze official website. Bags, Handbags, Shoulder Bags, Pochette and Accessories for women….

#7 Bag hardware webshop in Budapest.

Website: baghardwareshop.eu

Key Highlights: All you need for bag making. High quality bag hardwares, worldwide shipping from Hungary, Europe….

Expert Sourcing Insights for Handbag Handles

H2: 2026 Market Trends for Handbag Handles

The handbag handle market in 2026 is poised for significant evolution, driven by shifting consumer values, technological innovation, and sustainability imperatives. Key trends shaping the landscape include:

1. Sustainability as a Core Design Principle:

Environmental consciousness will dominate handle choices. Expect widespread adoption of recycled materials (e.g., ocean-bound plastics, recycled metals, upcycled textiles) and bio-based alternatives (cork, Piñatex, mycelium leather, algae-based polymers). Traceability and certifications (e.g., GRS, FSC) will become essential for consumer trust. Brands will prioritize circularity, designing handles for disassembly and recycling.

2. Material Innovation and Hybrid Solutions:

Beyond traditional leather and metal, 2026 will see advanced composites offering superior strength-to-weight ratios, enhanced durability, and unique textures. Hybrid handles—combining recycled metals with sustainable textiles or bioplastics with natural fibers—will gain traction, balancing aesthetics, function, and eco-credentials. 3D-printed custom handles using sustainable filaments will emerge for niche, high-end markets.

3. Ergonomic and Adaptive Functionality:

Comfort and versatility will be paramount. Handles will feature advanced ergonomic shaping, padded grips using recycled foams or natural latex, and adjustable mechanisms (telescoping, modular attachments). Convertible designs—effortlessly switching from top-handle to shoulder or crossbody—will meet demands for multifunctional bags. Lightweight, high-strength materials will reduce strain.

4. Aesthetic Minimalism Meets Bold Statement Pieces:

Two contrasting trends will coexist:

* Quiet Luxury: Clean lines, subtle hardware, and natural material textures (brushed recycled metals, woven organic cotton) emphasizing understated quality.

* Maximalist Expression: Oversized, sculptural handles in vibrant recycled plastics, translucent biopolymers, or intricately braided sustainable yarns serving as key fashion statements. Color and texture will be used strategically for impact.

5. Technology Integration:

Smart features will begin appearing in premium handles, including:

* Embedded NFC chips for authentication and brand engagement.

* Woven conductive threads enabling wireless charging or device connectivity (early adoption).

* Sensors monitoring weight distribution for ergonomic feedback (niche applications).

6. Supply Chain Transparency and Localization:

Consumers will demand proof of ethical sourcing and manufacturing. Blockchain tracking for materials and increased regional production (nearshoring) will reduce carbon footprints and enhance supply chain resilience, impacting handle component sourcing.

In summary, the 2026 handbag handle market will be defined by a fusion of radical sustainability, intelligent functionality, and design innovation, transforming the handle from a simple functional component into a central element of a bag’s environmental story, user experience, and fashion identity.

Common Pitfalls Sourcing Handbag Handles: Quality and Intellectual Property

Sourcing handbag handles may seem straightforward, but brands and manufacturers often encounter significant challenges related to quality consistency and intellectual property (IP) risks. Overlooking these pitfalls can lead to product failures, customer dissatisfaction, legal disputes, and reputational damage.

Quality-Related Pitfalls

Inconsistent Material Composition

One of the most frequent quality issues is variability in the materials used. Suppliers may substitute lower-grade metals, plastics, or leathers to cut costs, resulting in handles that are weaker, discolored, or prone to cracking. Without strict material specifications and third-party testing, inconsistencies can slip through, especially across production batches.

Poor Craftsmanship and Structural Integrity

Handles must endure repeated stress and weight. Poorly welded metal joints, weak stitching on leather straps, or inadequate reinforcement can lead to premature breakage. Insufficient quality control at the factory level often results in handles failing under normal use, damaging brand credibility.

Inadequate Finish and Durability

Scratches, uneven plating, peeling coatings, or color mismatches can compromise aesthetics and longevity. For example, chrome-plated handles may corrode if not properly sealed, especially in humid environments. Overlooking finish durability during sampling can result in widespread post-delivery complaints.

Lack of Standardized Testing

Many suppliers do not conduct or provide data from standardized durability tests (e.g., tensile strength, abrasion resistance, cycle testing). Without verified test results, brands risk sourcing components that fail under real-world conditions.

Intellectual Property-Related Pitfalls

Unintentional Design Infringement

Handbag handles—especially distinctive shapes, logos, or hardware designs—can be protected under design patents or trademarks. Sourcing handles that mimic luxury brand elements (e.g., interlocking letters, signature shapes) without authorization exposes the buyer to cease-and-desist letters, customs seizures, or litigation.

Supplier Use of Counterfeit or IP-Infringing Molds

Some manufacturers use molds or designs copied from established brands. Even if a buyer is unaware, purchasing such handles constitutes contributory infringement. This risk is heightened when dealing with low-cost suppliers in regions with lax IP enforcement.

Lack of IP Warranty or Indemnification

Many supply agreements fail to include clauses where the supplier guarantees that the handles do not infringe on third-party IP or agrees to indemnify the buyer in case of a legal claim. Without such protection, the brand bears full liability for IP violations.

Ambiguous Ownership of Custom Designs

When a brand provides a unique handle design for production, unclear contracts may lead to disputes over ownership. Suppliers might reuse or resell the design to competitors unless intellectual property rights are explicitly assigned to the buyer in writing.

Mitigation Strategies

To avoid these pitfalls, buyers should:

– Conduct thorough supplier vetting and factory audits.

– Require material certifications and third-party testing reports.

– Implement clear technical specifications and quality checkpoints.

– Perform IP clearance searches on handle designs.

– Secure written agreements that include IP warranties, indemnification, and design ownership clauses.

Proactively addressing quality and IP concerns ensures reliable, legally compliant handbag components that uphold brand integrity.

Logistics & Compliance Guide for Handbag Handles

When sourcing, manufacturing, or distributing handbag handles—whether made from leather, metal, plastic, fabric, or composite materials—it’s essential to adhere to global logistics standards and regulatory compliance requirements. This guide outlines key considerations to ensure smooth operations, legal conformity, and product safety.

Product Classification & Tariff Codes

Accurate classification of handbag handles is critical for customs clearance and duty assessment. Handles may be classified under different Harmonized System (HS) codes depending on material, design, and intended use. Common classifications include:

- 4205.00: Leather or composition leather handbag components

- 7326.20: Iron or steel mountings, fittings, and similar articles

- 3926.30: Articles of plastics, for handbags or luggage

- 5808.00: Braids, tassels, and ornamental trimmings

Always consult local customs authorities or a licensed customs broker to confirm the correct HS code, as misclassification can lead to delays, fines, or shipment seizures.

Material Compliance & Restrictions

Handbag handles must comply with international regulations governing materials, especially concerning sustainability and hazardous substances:

- REACH (EU): Restricts the use of Substances of Very High Concern (SVHC) in chemical components (e.g., phthalates in plastics, chromium VI in leather).

- RoHS (EU): Applies to electronic or metallic components, limiting lead, cadmium, mercury, and other hazardous elements.

- CPSIA (USA): Ensures lead and phthalate content in children’s products is within permissible limits—relevant if handles are used in kids’ bags.

- Proposition 65 (California): Requires warnings if products contain chemicals known to cause cancer or reproductive harm.

Suppliers must provide compliance documentation such as Certificates of Conformity (CoC), test reports (e.g., from SGS, Intertek), and material declarations.

Packaging & Labeling Requirements

Proper packaging and labeling ensure product integrity and regulatory adherence:

- Country of Origin Labeling: Required in most markets (e.g., “Made in China” or “Product of Italy”).

- Material Content Labeling: Some regions require disclosure of material composition (e.g., “100% Genuine Leather”).

- Sustainable Packaging: Increasingly mandated; avoid excessive plastic and use recyclable materials where possible.

- Barcodes & SKU Labels: Facilitate inventory management and traceability in logistics systems.

Ensure labels are durable and affixed securely to packaging or product tags.

Import/Export Documentation

Complete and accurate documentation is essential for cross-border shipments:

- Commercial Invoice

- Packing List

- Bill of Lading or Air Waybill

- Certificate of Origin (may be required for preferential tariffs under trade agreements)

- Test Reports and Compliance Certificates

- Import Licenses (if applicable, depending on destination and materials)

Maintain digital and physical copies for audit purposes.

Transportation & Handling

Handbag handles—especially fragile or high-end components—require careful handling:

- Fragile Items: Use padded internal packaging for delicate finishes or plated metals.

- Climate Control: Leather and certain composites may degrade in extreme temperatures or humidity; consider climate-controlled transport.

- Theft & Tamper Prevention: Use sealed containers and tamper-evident packaging for high-value shipments.

- Freight Mode Selection: Air freight for urgency; sea freight for bulk. Balance cost, time, and environmental impact.

Partner with logistics providers experienced in fashion accessories to minimize damage and delays.

Environmental & Ethical Compliance

Growing consumer and regulatory focus on sustainability impacts sourcing and logistics:

- Conflict Minerals: If using metals like tin or tungsten, ensure supply chains comply with OECD Due Diligence Guidance.

- Deforestation Regulations (e.g., EU EUDR): If using leather or plant-based materials, verify sustainable sourcing and traceability.

- Carbon Footprint Reporting: Some markets or retailers require emissions data for transportation and production.

Consider third-party certifications such as ISO 14001 (Environmental Management) or BSCI (Business Social Compliance Initiative) for added credibility.

Quality Control & Inspection

Implement quality checks at multiple stages:

- Pre-Production: Sample approval and material verification

- During Production: In-line inspections for consistency and defects

- Pre-Shipment: Final random sampling (e.g., AQL Level II) to verify compliance with specifications

Document all QC activities and address non-conformities before shipping.

Conclusion

Successfully managing the logistics and compliance of handbag handles requires attention to detail across classification, materials, documentation, and sustainability. By proactively addressing regulatory requirements and partnering with compliant suppliers and logistics providers, businesses can reduce risks, enhance brand reputation, and ensure timely delivery to market.

Conclusion for Sourcing Handbag Handles

Sourcing high-quality handbag handles is a critical step in ensuring the durability, functionality, and aesthetic appeal of handbag designs. Through careful evaluation of materials—such as leather, metal, wood, or synthetic options—designers and manufacturers can align their sourcing decisions with brand values, target market preferences, and production goals. Factors such as strength, ergonomics, style, cost-efficiency, and ethical sourcing must be balanced to achieve optimal results.

Building strong relationships with reliable suppliers, conducting thorough quality assessments, and staying informed about emerging trends and sustainable practices further enhance sourcing success. Whether producing luxury fashion pieces or affordable accessories, the right handbag handle not only contributes to product performance but also elevates the overall customer experience.

In conclusion, a strategic and well-researched approach to sourcing handbag handles supports product excellence, brand integrity, and long-term business growth in the competitive fashion industry.