The global soil pH testing equipment market is experiencing steady growth, driven by increasing demand for precision agriculture, rising awareness of soil health, and the need for sustainable farming practices. According to Grand View Research, the global soil testing market size was valued at USD 2.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 9.4% from 2023 to 2030. This growth is fueled by technological advancements in portable testing devices, government initiatives promoting soil health management, and the expanding adoption of smart farming techniques. As farmers and agricultural professionals seek accurate, real-time soil analysis to optimize crop yields and minimize environmental impact, the role of reliable ground pH testers has become increasingly critical. In this evolving landscape, a select group of manufacturers have emerged as leaders, combining innovation, accuracy, and scalability to meet growing global demand. Here are the top 9 ground pH tester manufacturers shaping the future of soil health diagnostics.

Top 9 Ground Ph Tester Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 pH Pen Meter, Range: 0 to 14pH

Domain Est. 1995

Website: globalgilson.com

Key Highlights: 30-day returnspH Pen Meters have a LCD display and provide accurate results with easy operation at an affordable price for field or lab testing of soil or other …Missing: ground…

#2 pH Products & Information

Domain Est. 1996

#3 pH Probes & Sensors

Domain Est. 2007

Website: atlas-scientific.com

Key Highlights: 5-day delivery 15-day returnsAtlas Scientific’s embedded pH technology offers precision and accuracy equal to or greater than any brand of bench top laboratory pH measuring equipme…

#4 pH Measurement

Domain Est. 1995

Website: hach.com

Key Highlights: Simple and affordable pH measurement for home, school, and hobbyist use. Hach’s pH testers deliver quick and easy measurements with accurate and reliable ……

#5 pH Meters

Domain Est. 1996

#6 pH

Domain Est. 1999

Website: draminski.com

Key Highlights: pH Meter for Soil. A soil pH meter is a device designed for quick and accurate pH measurements in soil, which is essential for effective crop management….

#7 Milwaukee pH Meters

Domain Est. 2010

Website: milwaukeeinstruments.com

Key Highlights: Free delivery over $50 14-day returns…

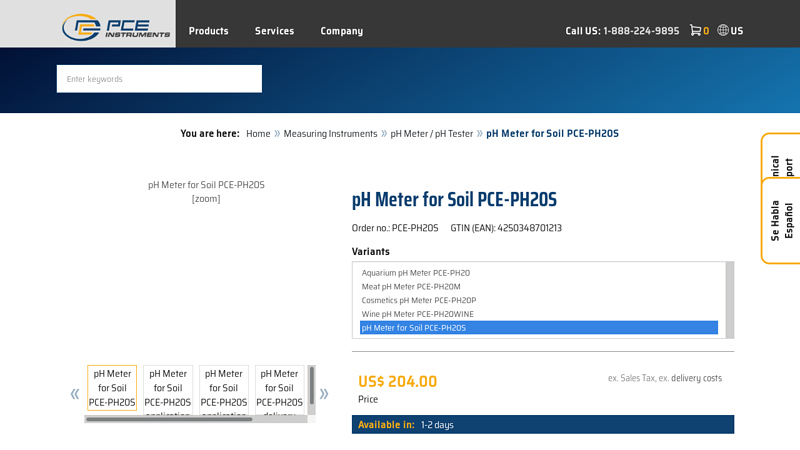

#8 pH Meter for Soil PCE

Domain Est. 2010

Website: pce-instruments.com

Key Highlights: In stock $15 deliverypH Meter for Soil. Easy to use, for determining the pH value of soil, with external pH electrode, can be recalibrated and is waterproof (IP67)….

#9 pH

Website: milwaukeeinstruments.eu

Key Highlights: Get Better Results. Upgrade to Milwaukee for accurate quick digital testing. Test pH, TDS, ORP and more with easy to use testers and meters. Expert support….

Expert Sourcing Insights for Ground Ph Tester

H2: 2026 Market Trends for Ground pH Testers

The market for ground pH testers is poised for significant evolution by 2026, driven by technological advancements, sustainability imperatives, and shifting agricultural and environmental priorities. Key trends shaping the landscape include:

H2: Rise of Smart, Connected Soil pH Monitoring Systems

The most transformative trend will be the widespread adoption of IoT-integrated, real-time soil pH monitoring solutions. Standalone handheld testers will increasingly be supplemented or replaced by networks of wireless sensors embedded in fields, orchards, and green spaces. These systems will offer continuous pH data streaming to cloud platforms, enabling predictive analytics and automated irrigation/fertilization adjustments. By 2026, integration with broader precision agriculture platforms (combining pH with moisture, NPK, temperature data) will be standard, moving beyond simple spot-checks to dynamic, data-driven soil management. Expect significant growth in subscription-based models for data analytics and remote monitoring services.

H2: Demand for Affordability and Accessibility in Developing Markets

While high-end smart systems grow, there will be a parallel surge in demand for low-cost, durable, and user-friendly pH testers in emerging agricultural economies. Innovations in materials (e.g., robust polymer electrodes) and simplified digital interfaces will make basic digital testers more accessible to smallholder farmers. Government and NGO-led soil health initiatives will drive bulk procurement, making affordability a critical competitive factor. Expect major players to launch budget-focused product lines and partnerships with local distributors to capture this expanding segment.

H2: Integration with Regenerative Agriculture and Carbon Farming

Ground pH testing will become intrinsically linked to regenerative agriculture and soil carbon sequestration projects. Accurate, frequent pH monitoring will be essential for optimizing soil health practices (cover cropping, reduced tillage, compost application) that enhance carbon storage. By 2026, pH data will be a key input for carbon credit verification, requiring standardized testing protocols and potentially certified sensor networks. Testers capable of logging GPS-tagged data for audit trails will gain prominence.

H2: Advancements in Sensor Technology and Durability

Electrode technology will see notable improvements, focusing on longer lifespan, faster response times, and reduced calibration needs. Research into solid-state sensors and ion-selective field-effect transistors (ISFETs) will yield more robust probes resistant to clogging and harsh field conditions. Self-cleaning mechanisms and improved reference electrode stability will reduce maintenance. This enhances reliability for both consumer-grade kits and professional in-situ sensors, lowering the total cost of ownership.

H2: Expansion Beyond Agriculture into Environmental Monitoring

The application of ground pH testers will broaden significantly into urban planning, ecological restoration, and pollution control. Monitoring soil pH will be crucial for phytoremediation projects, landfill management, brownfield redevelopment, and assessing the impact of acid rain or industrial runoff. Municipalities and environmental agencies will increase procurement, demanding testers with high accuracy and data logging capabilities suitable for compliance reporting. Consumer interest in urban gardening and compost monitoring will also sustain demand for simple home-use testers.

These converging trends point towards a 2026 market characterized by technological sophistication, deeper data integration, and a broader application scope, while simultaneously emphasizing accessibility and affordability to meet diverse global needs.

Common Pitfalls When Sourcing a Ground pH Tester (Quality and IP Protection)

Sourcing a ground pH tester—especially for agricultural, environmental, or industrial applications—requires careful evaluation to ensure both product quality and intellectual property (IP) integrity. Failing to address these aspects can lead to inaccurate measurements, equipment failure, legal disputes, or reputational damage. Below are key pitfalls to avoid:

1. Compromising on Sensor Accuracy and Durability

One of the most frequent issues is selecting low-cost pH testers that lack precision or long-term stability. Inaccurate readings can lead to poor soil management decisions, affecting crop yields or environmental monitoring efforts. Look for:

– Calibrated sensors with documented accuracy (e.g., ±0.1 pH)

– Electrodes resistant to clogging or fouling in soil matrices

– Rugged construction suitable for field conditions (moisture, temperature extremes)

Avoid generic or unbranded devices without traceable calibration certificates.

2. Overlooking Waterproof and Ingress Protection (IP) Ratings

Ground pH testers are often used in wet or muddy environments, making ingress protection critical. A common mistake is assuming “water-resistant” means fully protected. Always verify:

– Minimum IP67 rating (dust-tight and submersible up to 1m for 30 minutes)

– Sealed electrode junctions and cable entry points

– Corrosion-resistant housing materials (e.g., ABS or stainless steel)

Units without proper IP certification risk internal damage, sensor drift, or electrical hazards.

3. Ignoring Calibration and Maintenance Requirements

Some sourced testers require frequent calibration or electrolyte refills, which may not be practical in remote or large-scale applications. Pitfalls include:

– Purchasing testers with non-replaceable or proprietary electrodes

– Lack of access to calibration buffers or technical support

– Inadequate documentation for maintenance procedures

Ensure the supplier provides clear maintenance guidelines and ongoing support.

4. Falling for Misrepresented Specifications or Fake Certifications

Unverified suppliers may exaggerate IP ratings, accuracy, or durability. Red flags include:

– Missing or falsified CE, RoHS, or ISO certifications

– Vague technical documentation

– No traceable manufacturer or test reports

Always request third-party test reports and verify certifications through official databases.

5. Neglecting Intellectual Property (IP) Risks

Sourcing from manufacturers in regions with weak IP enforcement can expose your business to legal and ethical risks:

– Risk of purchasing counterfeit or cloned devices infringing on patented designs

– Liability if your branded product uses copied technology

– Lack of innovation or proprietary features in generic models

Due diligence includes:

– Verifying the manufacturer’s original design and IP ownership

– Signing NDAs and IP assignment agreements

– Conducting patent landscape searches before finalizing suppliers

6. Poor After-Sales Support and Warranty Coverage

Low-cost suppliers often lack reliable technical support or warranty services. This becomes critical when field instruments fail. Avoid vendors who:

– Offer no or limited warranty (e.g., less than 1 year)

– Do not provide replacement parts or repair services

– Have slow or unresponsive customer service

Choose suppliers with a proven track record of post-purchase support.

Conclusion

To avoid these pitfalls, prioritize suppliers with transparent specifications, verifiable certifications, strong IP practices, and robust customer support. Investing time in due diligence ensures you source a reliable, accurate, and legally sound ground pH tester tailored to your operational needs.

H2: Logistics & Compliance Guide for Ground pH Tester

This guide outlines the essential logistics and compliance considerations for the safe, legal, and efficient handling, transportation, storage, and disposal of Ground pH Testers. Adherence ensures product integrity, personnel safety, environmental protection, and regulatory compliance.

H3: Product Classification & Regulatory Framework

- Chemical Classification: Ground pH Testers typically contain dilute aqueous solutions of buffer salts (e.g., pH 4.0, 7.0) and sometimes indicators. Classify based on SDS:

- Generally Non-Hazardous for transport under major regulations (ADR/RID, IMDG, IATA) if concentrations are low and no significant hazards exist.

- Always consult the Safety Data Sheet (SDS) to confirm classification. Potential minor hazards could include slight irritation (Skin/Eye Irrit. 2, H315, H319) or aquatic toxicity (Aquatic Chronic 3, H412).

- Key Regulations:

- Transport: ADR (Road, Europe), IMDG Code (Sea), IATA DGR (Air), 49 CFR (USA). Classification determines packaging, labeling, and documentation requirements.

- Storage: Local fire codes (e.g., NFPA 30, NFPA 1), OSHA Hazard Communication Standard (HCS), REACH (EU), TSCA (USA).

- Disposal: RCRA (USA), Waste Framework Directive (EU), local municipal hazardous waste regulations.

- General: GHS (Globally Harmonized System) for labeling and SDS.

H3: Packaging & Labeling Requirements

- Primary Container: Leak-proof vials, bottles, or sachets made of compatible plastic (e.g., HDPE, LDPE) or glass. Ensure secure seals (screw caps, induction seals).

- Secondary Packaging: Rigid outer box (e.g., corrugated cardboard) providing cushioning and containment for primary containers. Must withstand normal handling.

- Labeling:

- Product Label: Clear product name (“Ground pH Tester Solution”), concentration(s), hazard pictograms (if applicable per SDS), signal word (“Warning” or “Danger”), hazard statements (H-phrases), precautionary statements (P-phrases), first aid instructions, supplier contact info, batch/lot number, expiry date.

- Transport Label (if hazardous): UN number (e.g., UN3082, Environmentally Hazardous Substance, liquid, n.o.s.), Proper Shipping Name, Class 9 label (if applicable), orientation arrows.

- GHS Pictograms: Use only if hazards require it (e.g., GHS07 for Irritant, GHS09 for Environmental Hazard). Most dilute testers won’t require transport pictograms.

- Inner Packing: Use absorbent material (e.g., vermiculite, absorbent pads) inside the secondary packaging to contain leaks from primary containers.

H3: Storage Requirements

- Location: Well-ventilated, dry, cool area. Protect from direct sunlight, heat sources, and freezing temperatures. Store below 25°C (77°F) unless specified otherwise.

- Segregation: Store away from incompatible materials:

- Strong acids and bases.

- Oxidizing agents.

- Flammable materials.

- Containers: Keep in original, tightly sealed containers. Store upright.

- Spill Containment: Use secondary containment (e.g., spill pallets, trays) capable of holding the volume of the largest container plus freeboard. Clearly label containment.

- Shelving: Use stable, non-combustible shelving. Ensure adequate aisle space for access and fire safety.

H3: Transportation Guidelines

- Classification: Confirm non-hazardous status using SDS. If hazardous (rare), follow full regulations for Class 9 or relevant class.

- Packaging: Use UN-certified packaging tested for the intended mode(s) of transport (if hazardous). For non-hazardous, ensure robust, leak-proof packaging with adequate cushioning and secondary containment.

- Documentation:

- Non-Hazardous: Commercial invoice, packing list. Mark packages “Fragile” and “This Way Up”.

- Hazardous: Full transport document (e.g., Dangerous Goods Note – DGN) with UN number, PSN, class, packing group, quantity, emergency contact. Shipper’s declaration for dangerous goods (IATA/IMDG).

- Handling: Train personnel on safe manual handling. Use appropriate equipment (trolleys, forklifts). Avoid dropping or crushing packages. Protect from weather during loading/unloading.

H3: Handling & Use Procedures

- Personal Protective Equipment (PPE): Minimum: Safety glasses, nitrile gloves. Lab coat/apron recommended. Consult SDS for specific requirements.

- Procedure: Use in well-ventilated areas. Avoid contact with skin, eyes, and clothing. Do not ingest. Wash hands thoroughly after handling.

- Spill Response:

- Small Spills: Contain with absorbent material (spill kit). Wear PPE. Wipe area with water. Dispose of absorbent as chemical waste (check local regs).

- Large Spills: Evacuate area. Ventilate. Contain spill if safe. Consult SDS and emergency services if needed. Report per company policy.

- First Aid: Refer to Section 4 of the SDS. Typically:

- Eye Contact: Rinse immediately with plenty of water for at least 15 minutes. Seek medical advice.

- Skin Contact: Wash with soap and water. Remove contaminated clothing.

- Ingestion: Rinse mouth. Do NOT induce vomiting. Seek medical attention immediately.

H3: Disposal & Waste Management

- Waste Classification: Consult SDS and local regulations. Dilute buffer solutions are often non-hazardous waste but may have specific disposal requirements (e.g., pH neutralization before drain disposal where permitted).

- Disposal Methods:

- Liquid Waste: May be neutralized (pH 6-9) and disposed of down the sanitary sewer only if permitted by local wastewater authority and company policy. Otherwise, collect as chemical waste.

- Contaminated Materials: Absorbents, gloves, packaging. Dispose of as non-hazardous or hazardous waste based on contamination level and local rules.

- Empty Containers: Rinse thoroughly (triple rinse with water). Dispose of plastic/glass as non-hazardous waste or recyclables per local rules. Never reuse containers.

- Documentation: Maintain records of waste disposal (manifests, certificates) as required by law (e.g., RCRA manifests in the USA).

H3: Documentation & Record Keeping

- Mandatory:

- Current Safety Data Sheet (SDS) – Readily accessible.

- Transport Documents (if hazardous).

- Waste Disposal Records (manifests, certificates).

- Training Records (handling, emergency procedures).

- Recommended:

- Inventory logs (batch numbers, quantities, storage locations).

- Spill/incident reports.

- Inspection records (storage areas, containment).

H3: Training & Responsibilities

- All Personnel: Trained on SDS content, safe handling, PPE, spill response, and emergency procedures.

- Storage Personnel: Trained on segregation, labeling, inspection, and inventory management.

- Shipping Personnel: Trained on classification, packaging, labeling, documentation (if handling hazardous goods).

- Waste Handlers: Trained on proper segregation, containerization, labeling, and disposal procedures.

- Supervisors/Managers: Responsible for ensuring compliance, providing resources (PPE, spill kits), and maintaining records.

Disclaimer: This guide provides general information. Always consult the specific Safety Data Sheet (SDS) for the exact Ground pH Tester product, applicable national and local regulations, and your organization’s specific safety policies. Regulations vary significantly by jurisdiction.

In conclusion, sourcing a ground pH tester requires careful consideration of accuracy, durability, ease of use, and cost-effectiveness. It is essential to select a reliable supplier offering tested, calibrated instruments suitable for the intended application—whether for agricultural, gardening, landscaping, or environmental monitoring purposes. Evaluating features such as digital vs. analog models, probe quality, portability, and battery life will ensure long-term performance and user satisfaction. Additionally, choosing a supplier with good customer support, warranties, and compliance with industry standards enhances confidence in the purchase. By conducting thorough research and comparing options, businesses and individuals can source a high-quality ground pH tester that delivers consistent, accurate results and supports informed soil management decisions.