The global ground leveling machinery market is experiencing robust growth, driven by increasing infrastructure development, urbanization, and rising investments in agricultural mechanization. According to a report by Grand View Research, the global construction machinery market—under which ground leveling equipment falls—was valued at USD 147.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. Similarly, Mordor Intelligence projects a CAGR of over 5.2% for construction equipment during the forecast period of 2024–2029, citing Asia-Pacific’s rapid infrastructure expansion as a key growth driver. With demand surging for precision grading and efficient land preparation in construction, agriculture, and mining sectors, manufacturers are focusing on innovation in laser-guided, GPS-equipped, and automated leveling systems. As competition intensifies, seven manufacturers have emerged as industry leaders, combining technological advancement, global reach, and reliable performance to dominate the ground leveling machinery landscape.

Top 7 Ground Leveling Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

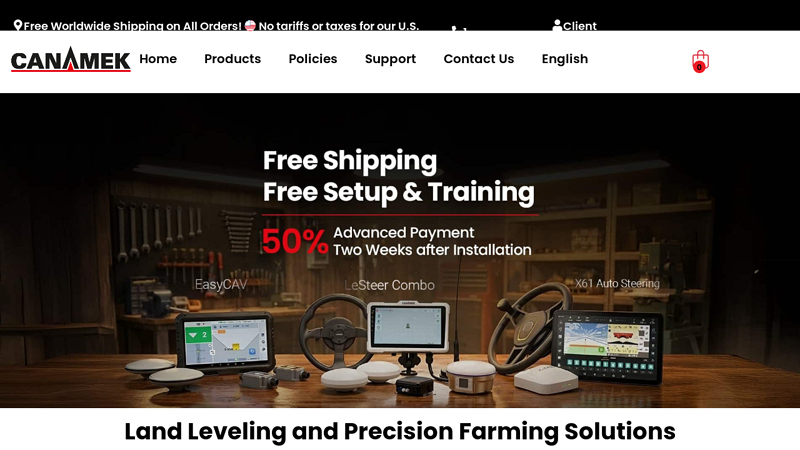

#1

Domain Est. 2013

Website: canamek.ca

Key Highlights: CANAMEK Systems is a company specializing in the development and manufacturing of advanced agricultural machinery and technology solutions….

#2 Altec Inc

Domain Est. 1996

Website: altec.com

Key Highlights: Altec is a leading equipment and service provider for the electric utility, telecommunications, contractor, lights and signs, and tree care markets….

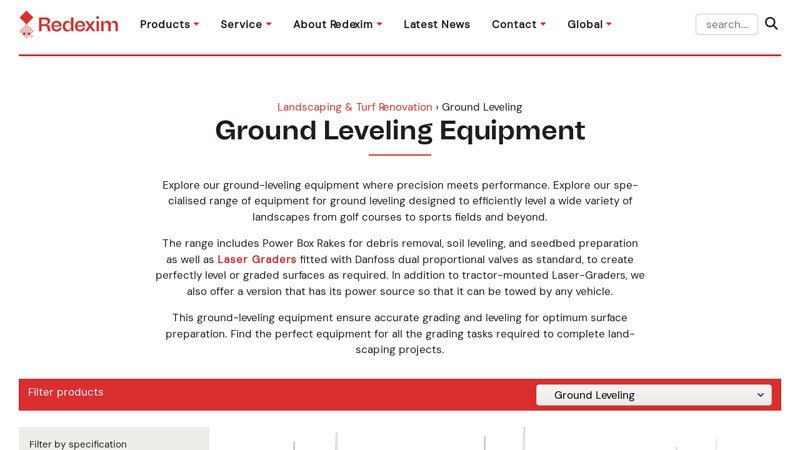

#3 Ground Leveling Equipment

Domain Est. 1997

Website: redexim.com

Key Highlights: Explore our specialised range of equipment for ground leveling designed to efficiently level a wide variety of landscapes from golf courses to sports fields ……

#4 Land forming

Domain Est. 2000

Website: topconpositioning.com

Key Highlights: Easily survey, design, and execute. Our 2D land leveling and 3D land forming solutions set the foundation for you to get the most out of your fields ……

#5 Ground Level Services

Domain Est. 2001

Website: groundlevel.com

Key Highlights: Ground Level Services delivers comprehensive solutions for the construction, maintenance, and modernization of mission-critical telecommunications and data ……

#6 FieldLevel™ II System

Domain Est. 2024

Website: ptxtrimble.com

Key Highlights: Trimble’s FieldLevel™ II system is a comprehensive land forming solution for streamlining your surveying, design and leveling activities….

#7 Somero

Domain Est. 1996

Website: somero.com

Key Highlights: Somero Enterprises manufactures laser-guided and technologically innovative machinery used in horizontal concrete placement….

Expert Sourcing Insights for Ground Leveling Machine

2026 Market Trends for Ground Leveling Machines

The global ground leveling machine market is poised for significant transformation by 2026, driven by technological advancements, infrastructure development, and a growing emphasis on precision agriculture and smart construction. As industries increasingly prioritize efficiency, automation, and sustainability, ground leveling machines are evolving to meet these demands. This analysis explores key market trends shaping the industry through 2026.

Rising Demand in Construction and Infrastructure

One of the primary drivers of the ground leveling machine market is the surge in global infrastructure development. Governments across Asia-Pacific, the Middle East, and Africa are investing heavily in urbanization, transportation networks, and smart city projects. These initiatives are fueling demand for efficient earthmoving and site preparation equipment. Ground leveling machines, particularly laser-guided and GPS-enabled models, are becoming essential tools for ensuring foundation accuracy and reducing rework in large-scale construction projects.

Adoption of Automation and Smart Technologies

By 2026, automation and digital integration are expected to redefine ground leveling operations. Machine control systems that utilize real-time kinematic (RTK) GPS, 3D modeling, and laser guidance are gaining widespread adoption. These technologies allow for millimeter-level precision, reducing labor costs and material waste. Autonomous or semi-autonomous leveling machines are beginning to enter the market, particularly in developed regions like North America and Western Europe, where labor shortages and rising operational costs are pressing concerns.

Growth in Precision Agriculture

Agriculture remains a core application sector for ground leveling machines, especially in regions with large-scale farming operations such as North America, Australia, and parts of South America. As farmers adopt precision farming techniques to optimize irrigation and crop yields, laser land leveling has become critical. The push for water conservation and improved farm productivity is accelerating the adoption of automated leveling solutions, contributing significantly to market growth through 2026.

Sustainability and Fuel Efficiency

Environmental regulations and the global shift toward sustainability are influencing equipment design. Manufacturers are increasingly offering electric and hybrid ground leveling machines to reduce carbon emissions and operational costs. While diesel-powered models still dominate, the market share of eco-friendly alternatives is expected to grow steadily by 2026, particularly in regions with strict emissions standards such as the European Union.

Regional Market Dynamics

Asia-Pacific is anticipated to lead market growth due to rapid industrialization, expanding agricultural land, and government-backed infrastructure programs in countries like India and China. Latin America and the Middle East are also emerging as key markets, driven by agricultural modernization and construction booms. In contrast, North America and Europe will focus more on technological upgrades and fleet modernization rather than volume growth.

Competitive Landscape and Innovation

The competitive landscape is becoming increasingly consolidated, with major players such as Caterpillar, John Deere, Topcon, and Trimble investing in R&D to enhance machine intelligence and connectivity. Partnerships between equipment manufacturers and tech firms are accelerating the integration of IoT, data analytics, and cloud-based fleet management systems. Smaller manufacturers are focusing on cost-effective, niche solutions for local markets, fostering innovation across the value chain.

Challenges and Opportunities

Despite positive trends, the market faces challenges including high initial equipment costs, skilled operator shortages, and supply chain disruptions. However, opportunities abound in after-sales services, equipment leasing models, and digital service platforms that offer remote diagnostics and predictive maintenance.

In conclusion, the ground leveling machine market in 2026 will be characterized by intelligent automation, sustainability, and regional diversification. Companies that embrace innovation and adapt to evolving end-user needs will be well-positioned to capitalize on this dynamic landscape.

Common Pitfalls When Sourcing a Ground Leveling Machine (Quality and Intellectual Property)

Sourcing a ground leveling machine—especially from overseas or new suppliers—can be fraught with risks related to both product quality and intellectual property (IP) protection. Avoiding these pitfalls is critical to ensuring performance, longevity, and legal safety. Below are key areas to watch:

Poor Build Quality and Material Standards

One of the most frequent issues is receiving machines constructed with substandard materials or inadequate workmanship. Low-cost suppliers may use thinner steel, inferior bearings, or low-grade hydraulics to cut costs, leading to premature wear, breakdowns, and safety hazards. Always verify material specifications and request third-party inspection reports before shipment.

Inadequate or Missing Quality Certifications

Reputable ground leveling machines should comply with international standards such as CE, ISO 9001, or ANSI. Suppliers who cannot provide valid certifications may be cutting corners. Lack of certification increases the risk of non-compliance with local regulations and can void insurance or operational permits.

Misrepresentation of Technical Specifications

Some suppliers exaggerate machine capabilities—such as leveling accuracy, operating speed, or load capacity—to close sales. This can result in equipment that underperforms in real-world conditions. Always validate specs with independent testing or ask for on-site demonstrations.

Copycat or Counterfeit Designs (IP Infringement Risk)

Many low-cost machines are direct copies of patented designs from established brands. Sourcing such equipment exposes buyers to intellectual property litigation, especially when importing into regions with strong IP enforcement (e.g., the U.S. or EU). Customs seizures and legal penalties can result in significant financial losses.

Lack of Original Design Documentation

Suppliers may be unable to provide engineering drawings, CAD files, or proof of design ownership. This not only raises red flags about IP infringement but also complicates future maintenance, spare parts sourcing, or modifications. Ensure the supplier can legally transfer or license design documentation if needed.

No Warranty or After-Sales Support

Low-priced machines often come with limited or no warranty, and suppliers may disappear after delivery. Without technical support, spare parts, or service networks, downtime can be costly. Confirm warranty terms and the availability of local service before purchasing.

Hidden Costs from Re-Work or Replacement

Initially low prices can be misleading. Poor quality may necessitate repairs, retrofitting, or early replacement—eroding any initial savings. Factor in lifecycle costs, not just the purchase price, when evaluating suppliers.

Failure to Conduct Factory Audits or Prototype Testing

Skipping on-site audits or sample testing increases the likelihood of quality surprises. Always visit the manufacturing facility or hire a third-party inspector to evaluate production processes and assess prototype units before placing bulk orders.

By proactively addressing these pitfalls—especially through due diligence on quality assurance and IP legitimacy—buyers can mitigate risks and ensure reliable, legally compliant ground leveling equipment.

Logistics & Compliance Guide for Ground Leveling Machine

Shipping and Transportation

Ensure the ground leveling machine is securely fastened to the transport vehicle using rated straps or chains. Use wooden blocks or rubber padding to prevent movement and protect the machine’s surface. Cover the machine with a weather-resistant tarp to shield it from rain, dust, and debris during transit. Confirm that the transport vehicle has the appropriate weight capacity and dimensions to accommodate the machine safely. For international shipments, comply with Incoterms (e.g., FOB, CIF) as defined in the sales contract.

Packaging Requirements

Package all loose components, including blades, sensors, and control panels, in labeled, shock-resistant containers. Use anti-corrosion wrapping for metal parts and include desiccants if shipping through humid environments. Clearly mark packages with “Fragile,” “This Side Up,” and handling instructions. Attach a packing list detailing all included items and serial numbers. For export, ensure packaging meets ISPM 15 standards for wood materials.

Import and Export Compliance

Verify that the ground leveling machine complies with destination country regulations, including electrical standards (e.g., CE, UKCA, EAC) and machinery safety directives (e.g., EU Machinery Directive 2006/42/EC). Obtain necessary export licenses if required by the country of origin. Prepare a commercial invoice, bill of lading, packing list, and certificate of origin. For U.S. exports, screen end-users against denied party lists (e.g., BIS, OFAC).

Customs Documentation

Submit accurate customs documentation to avoid delays. Include a detailed product description, HS (Harmonized System) code—typically under 8429.51 or 8429.52 for graders and leveling machinery—declared value, country of origin, and weight. Declare any included electronics or engines separately if subject to different tariffs. Retain records for a minimum of five years for audit purposes.

Safety and Certification Standards

Ensure the machine meets relevant safety standards such as ISO 2867 (earth-moving machinery—access systems), ISO 12100 (safety of machinery), and local electrical codes. Provide a Declaration of Conformity (DoC) and CE marking for European markets. Include multilingual safety labels and operating manuals. Conduct periodic audits to maintain compliance with evolving regulations.

On-Site Handling and Installation

Use certified lifting equipment and trained personnel when unloading the machine. Follow manufacturer-recommended procedures for setup, including leveling, hydraulic system checks, and sensor calibration. Conduct a pre-operation safety inspection and provide site-specific training to operators. Document installation and inspection results for compliance records.

Environmental and Disposal Compliance

Adhere to local and international environmental regulations regarding noise emissions, fluid leaks, and exhaust (if engine-powered). Dispose of packaging materials in accordance with local recycling or waste management laws. For end-of-life disposal, follow WEEE (Waste Electrical and Electronic Equipment) directives where applicable and ensure proper recycling of batteries and hydraulic components.

Conclusion for Sourcing a Ground Leveling Machine:

After a thorough evaluation of available options, technical requirements, budget considerations, and long-term operational needs, sourcing a ground leveling machine is a strategic investment that will significantly enhance efficiency, precision, and productivity in land preparation activities. Whether opting for a motor grader, laser-guided leveling system, or a compact grading attachment, the selected machine should align with the scale of operations, terrain conditions, and intended applications.

Key factors such as durability, ease of maintenance, operator comfort, and available technical support must be prioritized to ensure optimal performance and return on investment. Additionally, considering suppliers with strong reputations, warranty offerings, and after-sales service will contribute to sustained machine uptime and operational success.

In conclusion, procuring the right ground leveling machine—tailored to specific project demands—will not only improve grading accuracy and reduce labor costs but also support timely project completion and high-quality outcomes. A well-informed sourcing decision today lays the foundation for long-term agricultural or construction efficiency.