The global sandblasting equipment market is experiencing steady growth, driven by increasing demand for surface preparation and finishing solutions across industries such as automotive, aerospace, construction, and manufacturing. According to Grand View Research, the global abrasive blasting equipment market size was valued at USD 3.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.6% from 2023 to 2030. This growth is fueled by rising industrial maintenance activities, stringent regulatory standards for surface cleanliness, and the growing adoption of automated blasting systems to improve efficiency and worker safety. As grit blast cabinets—key tools in precision surface treatment—become increasingly integral to production and refurbishment processes, selecting reliable manufacturers is more critical than ever. In this data-driven landscape, identifying top-tier grit blast cabinet manufacturers involves evaluating innovation, production capacity, global reach, and adherence to safety and environmental standards. Based on market presence, product range, and technological advancements, the following ten manufacturers stand out in 2024.

Top 10 Grit Blast Cabinet Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

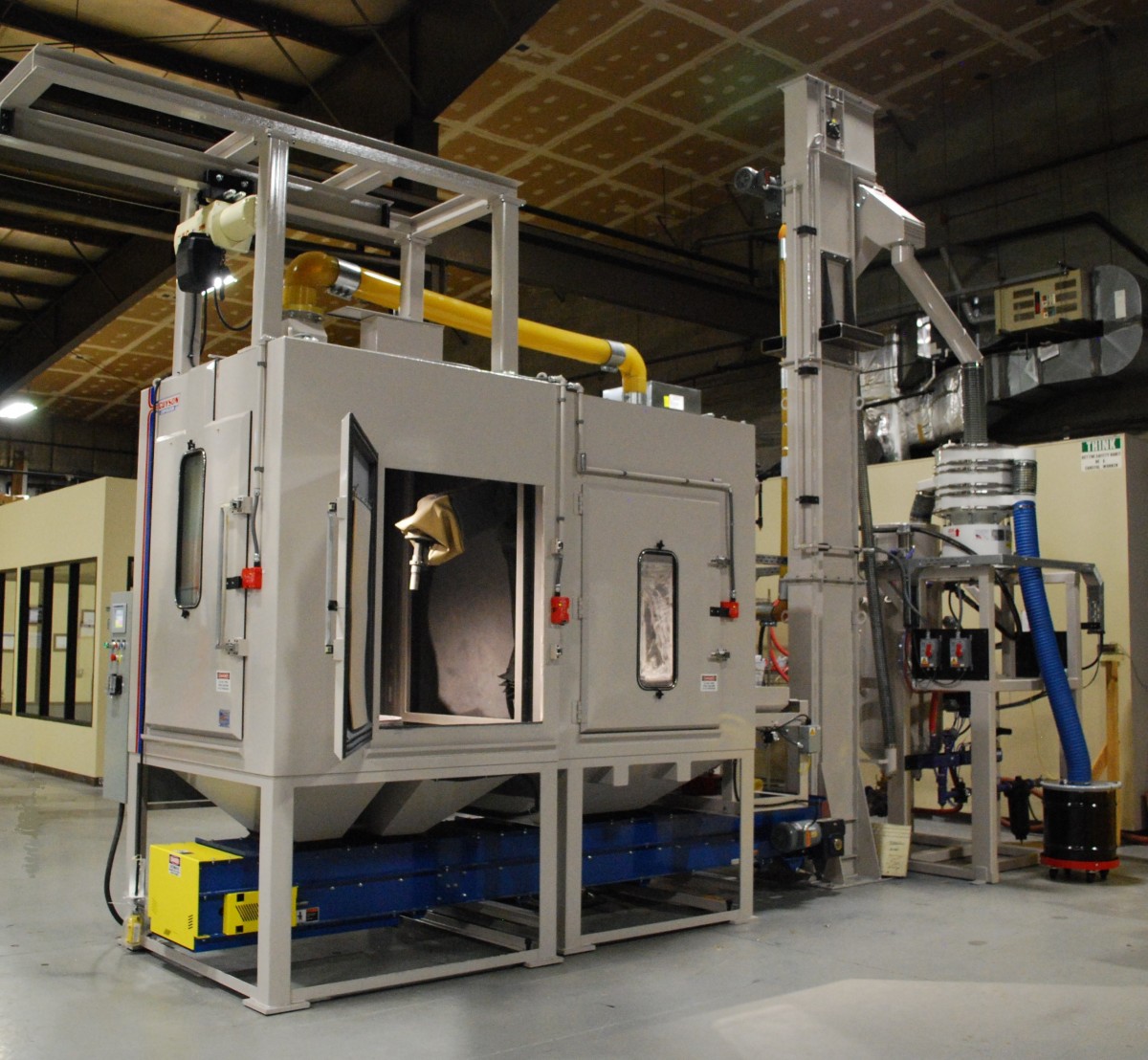

#1 Quality Abrasive Blasting Cabinets

Domain Est. 1998 | Founded: 1978

Website: skatblast.com

Key Highlights: America’s leading manufacturer of affordable Made in USA abrasive sandblasting cabinets since 1978! Remove rust, paint & scale in minutes. View Blast Cabinets….

#2 Titan Abrasive Blast Cabinets

Domain Est. 1998

Website: titanabrasive.com

Key Highlights: Titan’s heavy-duty, industrial blast cabinets deliver high performance, reduced operating costs, and improved productivity — all in a user-friendly design….

#3 Blast Cleaning Technologies

Domain Est. 2012

Website: bct-us.com

Key Highlights: We’re the most advanced shotblast manufacturer of heavy-duty equipment, blast wheels, high-quality shotblast parts, and engineered upgrades….

#4 Grit Blasting Cabinet Manufacturer

Domain Est. 2019

Website: gritblast.co.in

Key Highlights: GritBlast is the finest Grit Blasting Cabinet Manufacturer & Supplier. We also provide surface preparation solutions & spraying techniques….

#5 Sand, Abrasive, Wet and Vapor Blaster Cabinets

Domain Est. 1996

Website: mediablast.com

Key Highlights: Media Blast & Abrasives is the go-to source for top-quality sandblasting cabinets, abrasive blasting cabinets, and wet vapor blasting solutions made in the USA….

#6 Econoline

Domain Est. 1997

Website: sandblasting.com

Key Highlights: Econoline Abrasive Products is the leader in sandblasting equipment, abrasive blast equipment, blast cabinets, and sandblast dust collectors….

#7 Manual Sandblast Cabinets

Domain Est. 1997

Website: empire-airblast.com

Key Highlights: These rugged, easy-to-use cabinets are available in five standard sizes with your choice of a dust bag or dust collector and can be ordered as either suction ……

#8 Blast

Domain Est. 1997 | Founded: 1971

Website: blast-it-all.com

Key Highlights: BLAST-IT-ALL was founded in 1971 by Larry and Tom Hess. Our first cabinet, a Model 4426, was fabricated by a local company, painted and assembled at our first ……

#9 Clemco Industries

Domain Est. 1999

Website: clemcoindustries.com

Key Highlights: Clemco is a global leader in abrasive blasting, cleaning, shot peening, and surface preparation solutions, serving industries from aerospace and energy to ……

#10 Schmidt Abrasive Blasting Equipment

Domain Est. 2010

Website: schmidtabrasiveblasting.com

Key Highlights: Lightweight and most portable in the AmphiBlast family. Wet or dry blast with a single unit. Minimal water usage. Set and forget switching between machine ……

Expert Sourcing Insights for Grit Blast Cabinet

H2: 2026 Market Trends for Grit Blast Cabinets

The global grit blast cabinet market is poised for steady growth through 2026, driven by increasing demand across industrial manufacturing, automotive restoration, aerospace, and metal fabrication sectors. As industries prioritize surface preparation for coating, corrosion control, and material longevity, grit blast cabinets remain essential tools in efficient and environmentally controlled abrasive blasting operations.

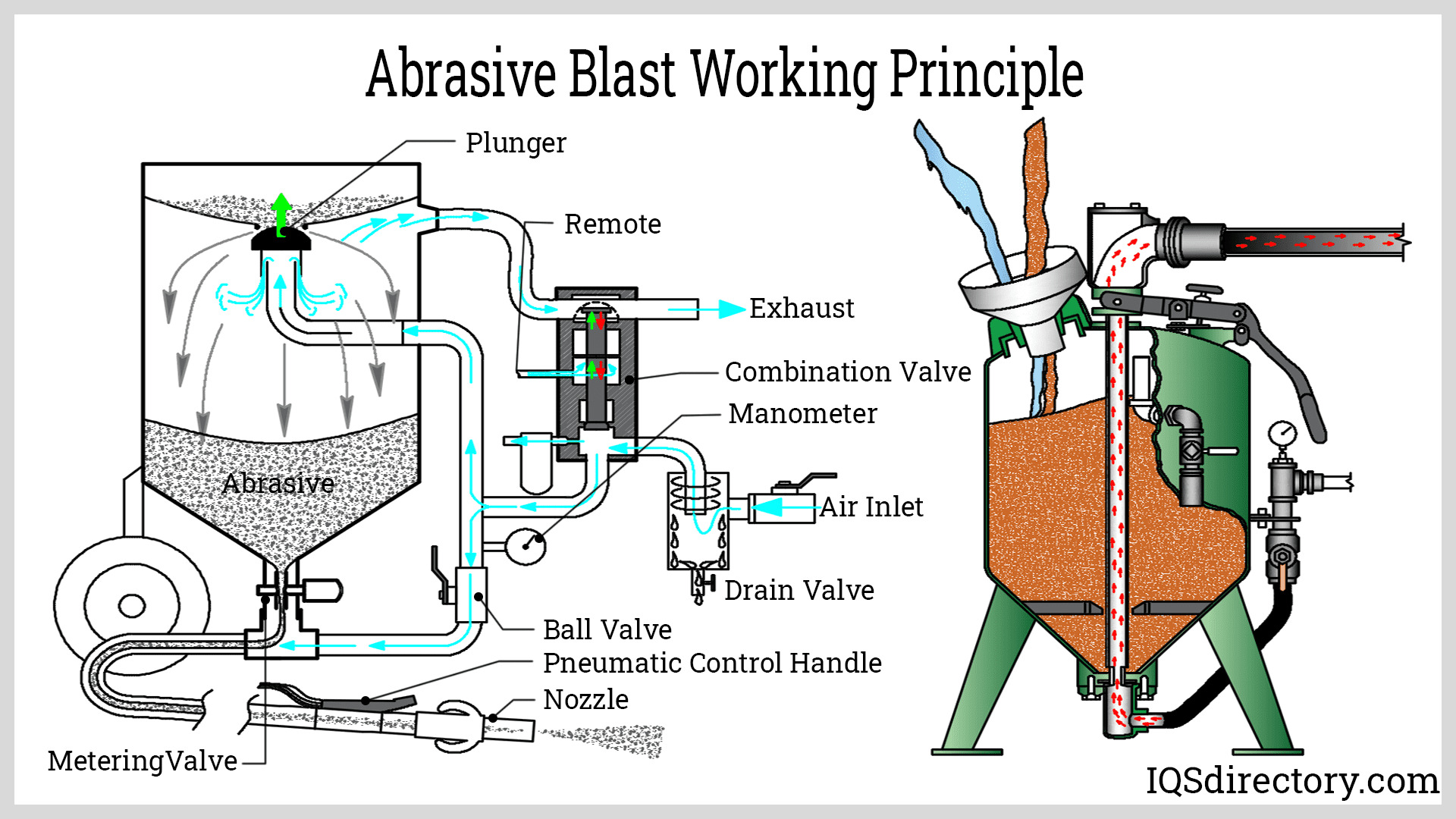

One of the key trends shaping the 2026 market is technological advancements in cabinet design and automation. Manufacturers are increasingly integrating features such as dust collection systems compliant with OSHA and EPA regulations, automated blast cycles, and improved ergonomic designs to enhance operator safety and productivity. Closed-loop recycling systems for abrasives are also gaining traction, reducing waste and operational costs—appealing to sustainability-minded industries.

Another significant trend is the rising adoption of modular and portable grit blast cabinets. Small and medium-sized enterprises (SMEs), particularly in automotive and custom fabrication, prefer compact, mobile units that offer flexibility without sacrificing performance. This shift supports the growth of mid-tier cabinet models equipped with digital controls and interchangeable media options.

Regionally, North America and Europe are expected to maintain strong market shares due to stringent industrial safety standards and high levels of automation in manufacturing. Meanwhile, the Asia-Pacific region—especially China, India, and Southeast Asia—is projected to witness the fastest growth, fueled by expanding infrastructure projects, rising industrialization, and government initiatives to modernize manufacturing capabilities.

Additionally, the integration of Industry 4.0 principles is influencing product development. Smart grit blast cabinets with IoT-enabled monitoring systems allow for real-time performance tracking, predictive maintenance, and remote diagnostics. By 2026, such connected systems are anticipated to become more mainstream, particularly in high-volume production environments.

Lastly, environmental regulations are pushing innovation in alternative blasting media and energy-efficient cabinet systems. Water-based or wet blasting cabinets are gaining attention as eco-friendly alternatives to traditional dry blasting, reducing airborne particulates and improving workplace air quality.

In summary, the 2026 grit blast cabinet market will be shaped by technological innovation, regulatory compliance, sustainability efforts, and regional industrial expansion. As end-user industries demand higher efficiency, safety, and environmental responsibility, manufacturers of grit blast cabinets must continue evolving to meet these dynamic market needs.

Common Pitfalls When Sourcing a Grit Blast Cabinet (Quality, IP)

Sourcing a grit blast cabinet involves more than just selecting a model and placing an order. Overlooking key factors related to quality and intellectual property (IP) can lead to operational inefficiencies, safety risks, and legal complications. Below are critical pitfalls to avoid:

Poor Build Quality and Substandard Materials

One of the most frequent issues is selecting a cabinet made with inferior materials or poor craftsmanship. Thin-gauge steel, weak welds, or inadequate sealing can compromise the cabinet’s durability and safety. Low-quality viewports may cloud or crack quickly, reducing visibility and increasing maintenance costs. Always verify the use of abrasion-resistant steel, proper reinforcements, and robust filtration systems to ensure longevity and operator safety.

Inadequate Ingress Protection (IP) Rating

The IP rating indicates the cabinet’s protection against dust and moisture. A common mistake is assuming all cabinets meet high environmental protection standards. Using a cabinet with a low IP rating (e.g., IP54 instead of IP65) in dusty industrial environments can lead to internal component failure, especially in the electrical or control systems. Ensure the cabinet meets or exceeds the required IP rating for your working environment to prevent downtime and equipment damage.

Misrepresentation of Specifications by Suppliers

Some suppliers may exaggerate performance metrics such as airflow capacity, dust collection efficiency, or blast pressure. This misrepresentation can result in underperforming equipment that fails to meet production demands. Always request third-party test reports or certification documents and consider conducting site visits or requesting live demonstrations before finalizing a purchase.

Lack of Intellectual Property Due Diligence

When sourcing from lesser-known or overseas manufacturers, there’s a risk of purchasing cabinets that infringe on patented designs or proprietary technology. Using such equipment may expose your business to legal liability, especially in regions with strict IP enforcement. Conduct due diligence by verifying the supplier’s design rights, requesting proof of IP ownership, or ensuring the product is licensed for use in your market.

Skipping Compliance and Certification Verification

Grit blast cabinets must comply with regional safety and environmental regulations (e.g., OSHA, CE, ATEX). A major pitfall is assuming compliance based on supplier claims without verifying certifications. Non-compliant cabinets may lack essential safety features like emergency stops, proper grounding, or explosion-proof components, putting operators at risk and exposing your company to fines or shutdowns.

Overlooking After-Sales Support and Spare Parts Availability

Even high-quality cabinets require maintenance. Sourcing from suppliers with poor after-sales support or limited spare parts availability can lead to extended downtimes. Ensure the supplier offers a clear service network, readily available replacement components, and technical documentation—especially important when dealing with IP-protected systems that may require authorized servicing.

Avoiding these pitfalls requires thorough vetting of suppliers, clear specification requirements, and attention to both technical quality and legal safeguards. Investing time upfront ensures long-term operational reliability and compliance.

Logistics & Compliance Guide for Grit Blast Cabinet

This guide outlines the key logistics considerations and compliance requirements for the safe and legal handling, transportation, installation, and operation of a grit blast cabinet.

Product Classification and Shipping Documentation

Grit blast cabinets are typically classified as industrial machinery for shipping purposes. Accurate classification ensures proper handling and regulatory compliance. Required documentation includes a commercial invoice, packing list, and bill of lading or air waybill. If shipping internationally, additional documentation such as a certificate of origin and export declaration may be required. Properly declare the item as “Industrial Abrasive Blasting Cabinet” with the correct HS (Harmonized System) code, commonly 8479.89 in many jurisdictions.

Packaging and Handling Requirements

The grit blast cabinet must be securely packaged to prevent damage during transit. Use a robust wooden crate or heavy-duty pallet with corner protectors and waterproof wrapping. Interior components, such as the viewing window, gloves, and pressure pot, should be individually padded or removed and packed separately if possible. Clearly label the package with “Fragile,” “This Side Up,” and “Do Not Stack” indicators. Forklift or pallet jack access points should be clearly marked for safe handling.

Import/Export Regulations

Verify export controls based on the country of origin and destination. Some components (e.g., high-pressure systems or electronic controls) may be subject to export restrictions. Ensure compliance with the destination country’s import regulations, including customs duties, import permits, and conformity assessment requirements. For shipments to the EU, adherence to CE marking directives is mandatory. Shipments to the U.S. must comply with EPA and OSHA standards upon arrival.

Installation Site Preparation

Ensure the installation site meets the following criteria:

– Adequate floor space with reinforced flooring to support cabinet weight (typically 500–1,500 lbs depending on model).

– Proper ventilation or connection to an exhaust/dust collection system compliant with local air quality regulations.

– Access to required utilities: compressed air supply (minimum 80–120 psi), electrical power (if motorized), and adequate lighting.

– Clear emergency exit paths and sufficient clearance for operator access and maintenance.

Regulatory Compliance Standards

The grit blast cabinet must comply with applicable safety and environmental regulations, including:

– OSHA 29 CFR 1910 (U.S.): General requirements for respiratory protection, machine guarding, and hazard communication.

– ANSI B7.1: Safety requirements for the use of abrasive blast cleaning equipment.

– ISO 8518: Safety of abrasive blast-cleaning machines.

– EU Machinery Directive 2006/42/EC: Requires CE marking, risk assessment, and technical file documentation.

– REACH and RoHS (if applicable): For material compliance in the EU.

Personal Protective Equipment (PPE) Requirements

Operators must use appropriate PPE to mitigate health risks from dust, noise, and flying particles. Required PPE includes:

– NIOSH-approved respirator (e.g., N95 or P100) or supplied-air hood.

– Hearing protection (earmuffs or plugs) due to high noise levels.

– Safety goggles or face shield in addition to the cabinet viewport.

– Durable gloves (integrated into cabinet or worn underneath) and flame-resistant clothing.

– Steel-toed safety boots.

Environmental and Waste Disposal Compliance

Spent abrasive media and removed surface contaminants (e.g., paint, rust, heavy metals) are often classified as hazardous waste. Comply with local environmental regulations (e.g., EPA regulations under RCRA in the U.S.) for containment, labeling, storage, and disposal. Use HEPA-filtered dust collectors to minimize airborne particulate emissions. Conduct waste characterization testing if contamination is suspected. Maintain records of waste manifests and disposal certifications.

Operator Training and Documentation

Provide comprehensive training for all users covering:

– Safe operation procedures and emergency shutdown.

– PPE usage and maintenance.

– Inspection and maintenance protocols.

– Hazard recognition (e.g., silica dust, noise exposure).

Maintain training records and ensure operators are certified. Provide a user manual, safety data sheets (SDS) for abrasive media, and compliance documentation on-site.

Maintenance and Inspection Schedule

Implement a routine maintenance program to ensure safe and compliant operation:

– Inspect gloves, viewing window, and seals weekly for wear or damage.

– Check filters and dust collector efficiency monthly.

– Test pressure relief valves and air hoses annually.

– Keep a maintenance log to demonstrate compliance during audits or inspections.

Emergency Preparedness

Establish emergency procedures for incidents such as:

– Abrasive media leaks or hose failures.

– Fire (due to static or flammable materials).

– Operator injury or respiratory exposure.

Ensure emergency shut-off valves are accessible, first aid kits are available, and emergency contacts are posted. Conduct periodic drills and review response plans annually.

Recordkeeping and Audits

Maintain detailed records for compliance verification, including:

– Equipment certifications (CE, UL, etc.).

– Operator training logs.

– Maintenance and inspection reports.

– Waste disposal manifests.

– Incident reports and corrective actions.

These records should be retained for a minimum of 3–5 years, or as required by local regulations.

Conclusion for Sourcing a Grit Blast Cabinet

After thorough evaluation of available options, sourcing a grit blast cabinet should focus on balancing performance, durability, safety, and cost-effectiveness. Key factors such as cabinet size, abrasive recovery system (whether manual or automated), visibility and lighting, dust collection efficiency, and ease of maintenance must align with the specific requirements of the operation—whether for small-scale restoration or high-volume industrial use.

Investing in a high-quality grit blast cabinet from a reputable supplier ensures long-term reliability, operator safety, and consistent surface preparation results. While initial costs may vary, selecting a cabinet with robust construction, regulatory compliance (e.g., OSHA, CE standards), and strong technical support provides significant return on investment through reduced downtime and improved productivity.

Ultimately, the right grit blast cabinet enhances workflow efficiency and surface treatment quality, making it a critical component in fabrication, automotive, aerospace, and metal finishing applications. Prioritizing vendor reputation, warranty, and after-sales service will further support successful integration and operation.