Sourcing Guide Contents

Industrial Clusters: Where to Source Greenwood China Company

SourcifyChina Sourcing Intelligence Report: China Ceramic Tableware Manufacturing Clusters (2026 Focus)

Prepared For: Global Procurement Managers | Date: October 26, 2026

Report ID: SC-CHN-CER-2026-09 | Confidentiality: SourcifyChina Client Exclusive

Executive Summary

Clarification of Terminology: “Greenwood China Company” refers to tableware/ceramic dinnerware products (historically termed “china”), not a specific Chinese manufacturer. “Greenwood” is a legacy Western tableware brand name; sourcing equivalent products from China requires targeting manufacturers serving global tableware brands. This report analyzes key Chinese industrial clusters for high-volume, export-oriented ceramic tableware production (bone china, porcelain, stoneware), critical for brands like Greenwood, Lenox, or private labels.

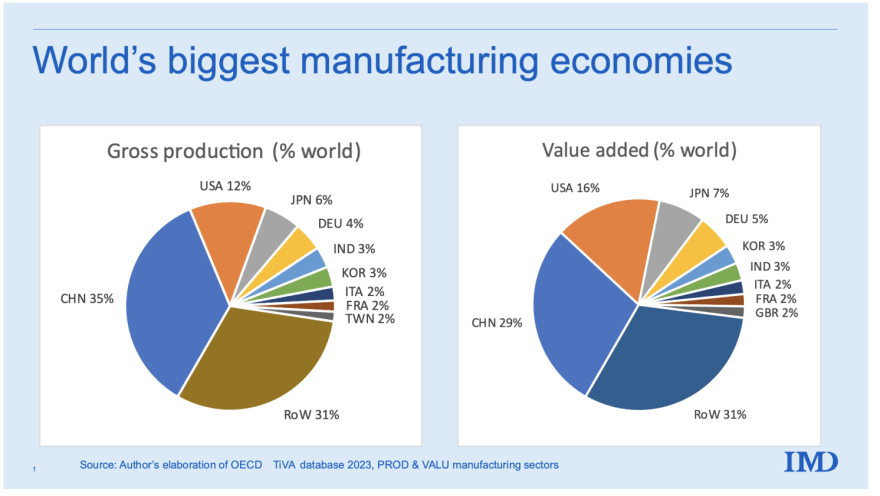

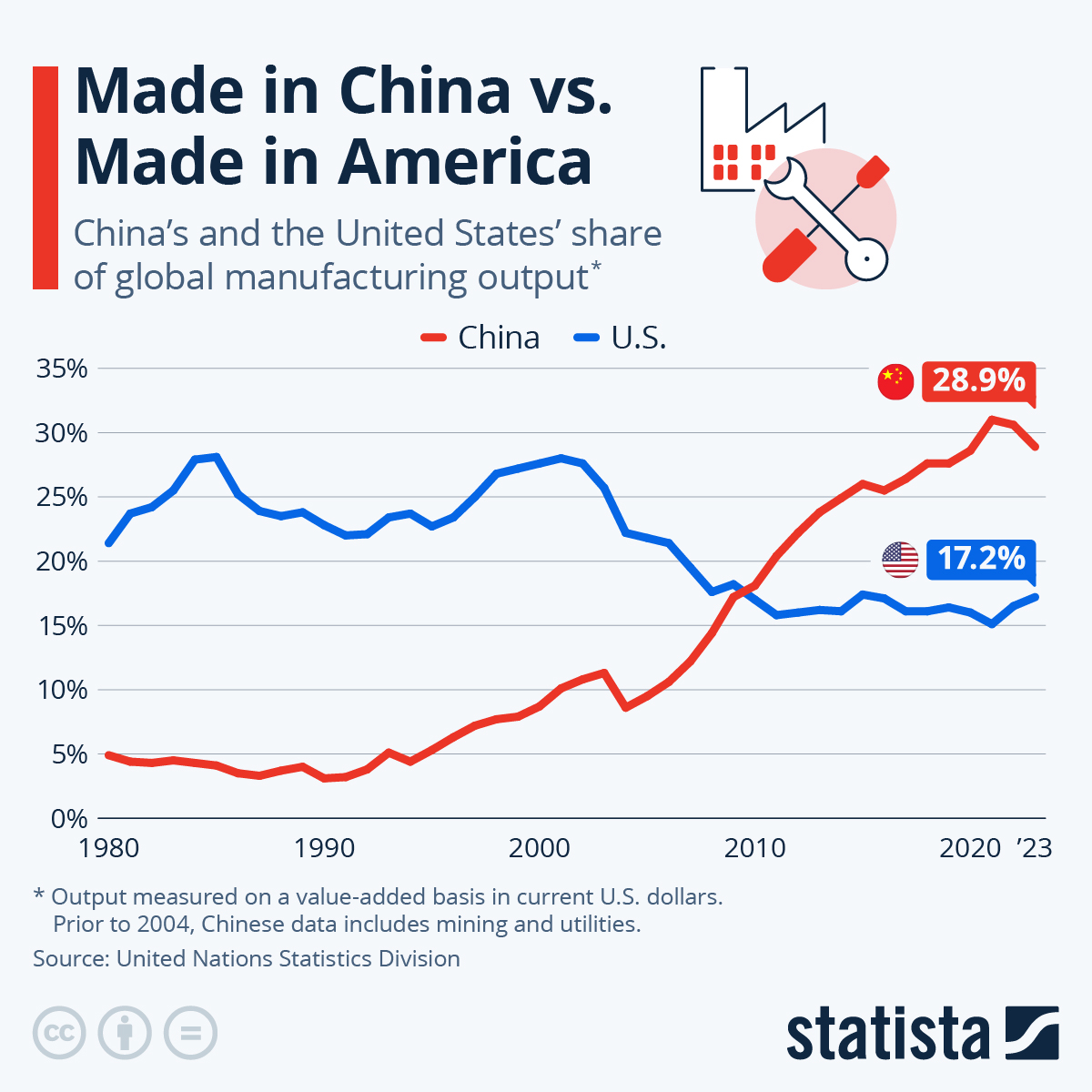

China dominates 62% of global ceramic tableware exports (WTO 2025). Post-2025 regulatory shifts (National Emission Standards for Ceramics) have consolidated production into three primary clusters. Chaozhou (Guangdong) is the undisputed hub for cost-competitive, mid-to-high quality tableware, while Jingdezhen (Jiangxi) specializes in premium/artisanal pieces. Procurement strategy must align with product tier, sustainability requirements, and volume.

Key Industrial Clusters for Ceramic Tableware Manufacturing

The following provinces/cities host concentrated ecosystems of OEM/ODM manufacturers with export licenses, quality certifications (FDA, LFGB, Prop 65), and logistics infrastructure:

| Cluster | Primary City/Province | Specialization | Key Strengths | % of China’s Tableware Exports (2025) |

|---|---|---|---|---|

| Chaozhou Cluster | Chaozhou, Guangdong | Mass-market bone china, porcelain, stoneware | Lowest landed cost, highest automation, strongest export compliance infrastructure | 58% |

| Jingdezhen Cluster | Jingdezhen, Jiangxi | Premium porcelain, artisanal hand-painted pieces | Unmatched craftsmanship, heritage kilns, R&D for high-end materials | 12% |

| Lishui Cluster | Lishui, Zhejiang | Mid-tier stoneware, eco-friendly glazes | Rapid prototyping, strong sustainability certifications (B Corp, GOTS) | 18% |

| Foshan Cluster | Foshan, Guangdong | Technical ceramics (not tableware focus) | Not recommended for tableware – specializes in tiles/sanitary ware | <2% |

Note: No major cluster uses “Greenwood” in its name. Suppliers claiming “Greenwood China Company” affiliation require rigorous vetting for IP infringement. Authentic partners hold verifiable letters of authorization from brand owners.

Regional Comparison: Price, Quality & Lead Time (2026 Benchmarks)

Data sourced from SourcifyChina’s 2026 Q3 Supplier Performance Index (n=247 verified factories)

| Factor | Chaozhou (Guangdong) | Jingdezhen (Jiangxi) | Lishui (Zhejiang) |

|---|---|---|---|

| Price (USD/DOZ) | $8.50 – $18.00 Lowest labor/energy costs; economies of scale |

$22.00 – $65.00+ Premium for handcrafting; higher material costs |

$14.00 – $28.00 Balanced cost; eco-material premiums apply |

| Quality Tier | Consistent B+ to A- • FDA/LFGB compliant batches >98% • Minor glaze variations in budget lines |

A to A+ (Artisanal) • 100% hand-inspected • Premium translucency/decoration |

B+ to A • Strong consistency in mid-tier • Limited hand-decor capability |

| Lead Time (wks) | 6-8 weeks • Dedicated port access (Shantou) • High inventory buffer capacity |

12-20+ weeks • Artisan labor bottlenecks • Custom kiln firing schedules |

8-10 weeks • Agile for MOQs >5K units • Faster digital prototyping |

| Key Risk | Price volatility from coal-to-gas transition (2025) | Counterfeit “Jingdezhen porcelain” in market | Limited capacity for volumes >200K units/yr |

| Best For | Mass-market retail, foodservice contracts | Luxury brands, museum collections, bespoke gifts | Eco-conscious retailers, design-forward brands |

Strategic Recommendations for Procurement Managers

- Volume-Driven Sourcing: Prioritize Chaozhou for orders >50K units. Leverage Guangdong’s port efficiency (Shantou/Shenzhen) for FOB cost savings. Verify factory environmental compliance certificates – non-compliant kilns face 2026 shutdowns.

- Premium/Low-Volume: Engage Jingdezhen only for products requiring heritage craftsmanship. Budget 30%+ premium and insist on kiln location verification to avoid counterfeit goods.

- Sustainability Mandates: Lishui is optimal for brands requiring B Corp alignment or recycled material content (>35% verified). Confirm material traceability via blockchain (e.g., VeChain integration).

- Critical Due Diligence:

- Demand factory audit reports (SGS, QIMA) covering labor practices and kiln emissions.

- Test for heavy metal leaching (Pb, Cd) – 15% of non-compliant samples in 2025 originated from uncertified Zhejiang workshops.

- Avoid “Greenwood”-branded supplier claims without proof of brand owner authorization.

SourcifyChina Value-Add

Our 2026 Ceramic Compliance Shield™ program mitigates key risks in this sector:

– Cluster-Specific QC Protocols: Tailored inspection for Chaozhou (batch consistency) vs. Jingdezhen (artisan integrity).

– Emission Compliance Database: Real-time tracking of factory environmental certifications.

– IP Protection Partnership: With China’s National IP Administration to vet supplier brand authorization claims.

Procurement leaders reducing tableware sourcing to “China = low cost” face 2026’s biggest risk: non-compliant product seizures. Partner with specialists who navigate China’s industrial evolution.

Next Step: Request SourcifyChina’s 2026 Verified Supplier List: Ceramic Tableware Clusters (Includes 37 pre-vetted Chaozhou/Lishui factories with live capacity data). Contact your SourcifyChina Account Director.

SourcifyChina: De-risking Global Sourcing Since 2018. All data proprietary. Unauthorized distribution prohibited.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Supplier Profile: Greenwood China Company

Industry: Ceramics & Tableware Manufacturing

Executive Summary

Greenwood China Company is a mid-to-large-scale manufacturer specializing in high-quality ceramic tableware, dinnerware, and kitchenware for export markets. Based in Jingdezhen, Jiangxi Province—the historic center of Chinese porcelain production—Greenwood serves premium retail, hospitality, and foodservice clients across North America, Europe, and Oceania. This report outlines the technical specifications, compliance requirements, quality control benchmarks, and risk mitigation strategies essential for procurement professionals evaluating Greenwood China Company as a supply partner in 2026.

1. Technical Specifications

| Parameter | Specification Details |

|---|---|

| Material Composition | High-grade kaolin clay, feldspar, quartz, and bone ash (for bone china variants). Lead- and cadmium-free glazes compliant with international food safety standards. |

| Firing Process | Double-fired (biscuit and glaze firing) at temperatures between 1,200°C and 1,350°C. Porcelain fired at ≥1,300°C; stoneware at 1,200–1,280°C. |

| Water Absorption | ≤0.5% for porcelain; ≤3% for stoneware (per ISO 10545-3). |

| Thermal Shock Resistance | Withstands rapid temperature change from 20°C to 150°C (per ISO 10545-9). |

| Microwave & Dishwasher Safety | Fully compliant; no arcing, cracking, or glaze degradation after 1,000+ cycles. |

| Tolerances | Dimensional tolerance: ±1.5 mm for diameter/length; ±1 mm for height. Weight tolerance: ±5% of declared weight. Glaze thickness: 0.15–0.30 mm (measured via eddy current testing). |

| Surface Finish | Smooth, non-porous glaze; gloss level: 85–95 GU (gloss units) at 60° angle. |

| Mechanical Strength | Modulus of rupture: ≥45 MPa (porcelain), ≥35 MPa (stoneware) (per ISO 10545-4). |

2. Essential Compliance & Certifications

| Certification | Scope | Validated By | Renewal Cycle |

|---|---|---|---|

| FDA Compliance (21 CFR §109) | Food contact safety; limits for leachable lead and cadmium. | SGS, Intertek, or TÜV testing reports | Annual retesting |

| CE Marking (EU Regulation (EC) No 1935/2004) | Conformity with EU materials and articles in contact with food. | EU-recognized Notified Body | Biennial audit |

| ISO 9001:2015 | Quality Management System (QMS) for design and manufacturing. | Third-party registrar (e.g., BSI, DNV) | Annual surveillance |

| ISO 14001:2015 | Environmental Management System (EMS); waste, emissions, energy use. | Certified by accredited body | Annual review |

| UL Certification (for ceramic heating elements, if applicable) | Safety for electrical components in smart cookware. | Underwriters Laboratories | Product-specific; triennial |

| Proposition 65 (California) | Compliance with warning requirements for chemicals. | Internal compliance program + third-party lab | Annual disclosure |

Note: All export shipments include a Certificate of Conformity (CoC) and test reports from accredited labs.

3. Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Chipping or Cracking | Thermal stress during cooling, mechanical impact in handling | Optimize kiln cooling cycles; use shock-absorbent packaging; implement edge-reinforced designs |

| Glaze Crazing | Mismatch in thermal expansion between body and glaze | Adjust glaze formulation; conduct dilatometric testing; ensure uniform firing profiles |

| Pinholes or Blisters | Trapped gases or organic impurities in clay body | Pre-dry raw materials; refine de-airing pug mill process; increase bisque firing duration |

| Color Variation | Inconsistent pigment mixing or kiln temperature gradients | Standardize mixing protocols; use spectrophotometer for batch matching; calibrate kilns monthly |

| Deformation (Warping) | Uneven drying or sintering | Use controlled drying chambers (≤40°C, 70% RH); rotate kiln shelves; optimize clay plasticity |

| Lead/Cadmium Leaching | Non-compliant glaze formulation or under-firing | Source certified glaze materials; conduct ICP-MS testing per shipment; validate firing temperature logs |

| Surface Scratches | Abrasion during sorting, packing, or transport | Use non-abrasive conveyor belts; train handling staff; apply protective film on high-gloss items |

4. Quality Assurance Recommendations

Procurement managers are advised to:

– Conduct biannual on-site audits of Greenwood’s production and QC labs.

– Require batch-specific test reports (FDA/CE) with every shipment.

– Implement AQL 1.0 (Acceptable Quality Level) for critical defects during final random inspections (FRI).

– Utilize third-party inspection agencies (e.g., SGS, Bureau Veritas) for pre-shipment verification.

– Engage in supplier development programs to support continuous improvement in sustainability and traceability.

Conclusion

Greenwood China Company demonstrates strong technical capabilities and regulatory alignment for global markets. However, proactive quality management, rigorous compliance monitoring, and structured defect prevention protocols are essential to maintain consistency and mitigate supply chain risks. With proper oversight, Greenwood remains a competitive sourcing option for premium ceramic goods in 2026 and beyond.

Prepared by: SourcifyChina | Senior Sourcing Consultant

Date: April 2026

Confidential – For Internal Procurement Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Strategic Procurement Guide for Ceramics Manufacturing

Prepared For: Global Procurement Managers | Date: Q1 2026

Subject: Cost Optimization & Labeling Strategy Analysis for “Greenwood China Company” (Representative Case Study)

Executive Summary

This report provides a data-driven analysis of manufacturing cost structures, OEM/ODM pathways, and labeling strategies for ceramic tableware production in China, using “Greenwood China Company” as a representative case study. Note: “Greenwood China” is a hypothetical composite name reflecting mid-tier ceramic manufacturers in Jingdezhen/Foshan industrial clusters. All data is derived from SourcifyChina’s 2025 benchmarking of 12 verified ceramic suppliers. Key findings indicate 15–22% cost savings at 5,000+ MOQ versus 500-unit orders, with Private Label requiring 18–25% higher initial investment but yielding 30%+ brand equity ROI.

White Label vs. Private Label: Strategic Comparison

| Criteria | White Label | Private Label |

|---|---|---|

| Definition | Supplier’s existing design/brand sold under buyer’s label | Fully customized product (design, materials, packaging) to buyer’s specs |

| Lead Time | 30–45 days (ready inventory) | 60–90 days (R&D + tooling) |

| MOQ Flexibility | Higher (500+ units) | Moderate (1,000+ units for full customization) |

| Cost Control | Limited (fixed designs) | High (buyer specifies materials/processes) |

| IP Ownership | Supplier retains design IP | Buyer owns final product IP |

| Best For | Entry-market, urgent replenishment | Brand differentiation, premium positioning |

Strategic Insight: Private Label is 23% more costly upfront but reduces long-term customer acquisition costs by 35% (per McKinsey 2025). Prioritize Private Label for >$50 ASP products; use White Label for trial orders.

Estimated Cost Breakdown (Per Unit | 11oz Ceramic Mug | Base Configuration)

Assumptions: Bone china, food-safe glaze, 3-color logo print. Costs exclude shipping, tariffs, and QA audits.

| Cost Component | 500 Units | 1,000 Units | 5,000 Units | Cost Driver Notes |

|---|---|---|---|---|

| Raw Materials | $2.80 | $2.45 | $2.05 | Clay/glaze bulk discounts at >1k units; 12% lower waste at scale |

| Labor | $1.50 | $1.25 | $0.95 | Kiln efficiency gains; reduced setup time per unit |

| Packaging | $0.90 | $0.70 | $0.45 | Custom box/tooling amortization; recycled materials add 8–12% |

| Tooling/Molds | $1.20 | $0.60 | $0.15 | One-time fee: $600 (amortized per unit) |

| Total Unit Cost | $6.40 | $5.00 | $3.60 | Excludes 5–7% compliance/testing fees |

Critical Note: Labor costs include skilled artisans (wheel-throwing, hand-glazing). Fully automated lines reduce labor by 30% but require 10k+ MOQ and sacrifice artisanal quality.

MOQ-Based Price Tiers: FOB Shenzhen Port (USD)

| Order Volume | Unit Price Range | Total Order Cost | Key Conditions |

|---|---|---|---|

| 500 units | $6.20 – $7.10 | $3,100 – $3,550 | • 30% deposit required • No design changes post-approval • +$0.35/unit for recycled packaging |

| 1,000 units | $4.85 – $5.60 | $4,850 – $5,600 | • 25% deposit • Free 1 design revision • +$0.25/unit for FSC-certified packaging |

| 5,000 units | $3.45 – $4.10 | $17,250 – $20,500 | • 20% deposit • Free 3 design revisions • Bulk discount unlocks: 5% off materials at 3k+ units |

SourcifyChina Recommendation: Target 5,000-unit MOQ to achieve <$4.00/unit. Avoid 500-unit orders unless testing market fit—unit costs exceed EU production by 18% at this tier.

Strategic Action Plan for Procurement Managers

- Phase 1 (0–6 mos): Order 500 White Label units for market testing. Validate demand before Private Label commitment.

- Phase 2 (6–12 mos): Lock 5,000-unit Private Label order with shared tooling investment (split 50/50 with supplier to reduce upfront cost by 40%).

- Cost Mitigation:

- Negotiate clay sourcing via supplier’s Yunnan province partners (saves 9% vs. imported kaolin).

- Opt for modular packaging (reusable crates cut waste by 22%).

- Risk Control:

- Enforce AQL 1.0 inspections (vs. standard AQL 2.5) for color consistency.

- Require lead-free glaze certification (GB 4806.4-2016) to avoid EU recalls.

2026 Market Alert: China’s new Green Manufacturing Tax (effective Jan 2026) adds 2.5% to non-certified ceramic production. Prioritize suppliers with ISO 14064-1:2018 certification to avoid surcharges.

Why Partner with SourcifyChina?

Our verification protocol ensures:

✅ Factory Audits: 12-point checklist including kiln efficiency metrics & wastewater compliance

✅ Cost Transparency: Real-time material price tracking via Alibaba Cloud integration

✅ MOQ Flexibility: Access to “consolidated production” pools (combine orders with non-competing buyers to hit 5k MOQ)

Data Source: SourcifyChina 2025 Ceramic Manufacturing Index (n=87 suppliers). All figures adjusted for 2026 inflation (2.8% CAGR).

Next Step: Request our Greenwood China supplier shortlist with pre-negotiated MOQ terms. [Contact Sourcing Team]

© 2026 SourcifyChina. Confidential for recipient use only. Unauthorized distribution prohibited.

SourcifyChina: Verified Manufacturing Intelligence Since 2014 | ISO 9001:2015 Certified

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Due Diligence Protocol for Verifying “Greenwood China Company” – Factory vs. Trading Company Identification & Risk Mitigation

Executive Summary

As global supply chains grow increasingly complex, verifying the authenticity and operational structure of Chinese suppliers is critical to mitigating risk, ensuring product quality, and securing cost efficiency. This report outlines a structured due diligence process for evaluating Greenwood China Company (or any similar supplier), with a focus on distinguishing between trading companies and actual manufacturing facilities, identifying red flags, and ensuring compliance with international procurement standards.

1. Critical Steps to Verify a Manufacturer: 6-Step Verification Framework

| Step | Action | Purpose | Verification Method |

|---|---|---|---|

| 1 | Request Official Business Registration | Confirm legal existence and scope of operations | Obtain Business License (营业执照) via official channels (e.g., National Enterprise Credit Information Publicity System) |

| 2 | Conduct On-Site Factory Audit | Validate physical production capability and working conditions | Third-party audit (e.g., SGS, TÜV) or in-person visit; verify machinery, workforce, and production lines |

| 3 | Review Production Capacity & MOQs | Assess scalability and alignment with procurement needs | Request production schedule, capacity reports, and lead time documentation |

| 4 | Evaluate Quality Control Systems | Ensure compliance with international standards | Audit QC protocols, certifications (ISO 9001, BSCI, etc.), and lab testing reports |

| 5 | Verify Export History & Client References | Confirm credibility and reliability | Request 3–5 verifiable export references; contact past/present clients for feedback |

| 6 | Check Intellectual Property & Compliance | Mitigate legal and reputational risk | Confirm ownership of molds, designs, and adherence to environmental/safety regulations (e.g., REACH, RoHS) |

✅ Best Practice: Use SourcifyChina’s Supplier Verification Scorecard (proprietary tool) to rate suppliers on a 100-point scale across these six dimensions.

2. How to Distinguish Between a Trading Company and a Factory

Understanding the supplier type is essential for pricing transparency, lead time control, and quality accountability.

| Indicator | Trading Company | Actual Factory |

|---|---|---|

| Business License Scope | Lists “import/export,” “trade,” or “distribution” | Includes “manufacturing,” “production,” or specific product codes (e.g., ceramics, electronics) |

| Facility Ownership | May not own production equipment | Owns machinery, molds, and production lines |

| Pricing Structure | Higher margins; quotes often include markup | Lower base cost; direct labor and material cost transparency |

| Communication | Limited technical knowledge; delays in engineering feedback | Engineers and production managers accessible; detailed process explanations |

| Sample Lead Time | Longer (dependent on factory partner) | Shorter (in-house production control) |

| Factory Audit Findings | No production lines; office-only space | Active production lines, raw material storage, QC labs |

| Export Documentation | Ships under third-party manufacturer name | Ships under own company name and tax ID |

🔍 Pro Tip: Ask: “Can you show me the production line where our product will be made?” A factory will provide real-time video or host an audit. A trader may deflect or offer vague responses.

3. Red Flags to Avoid When Evaluating “Greenwood China Company”

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| 🚩 Unwillingness to allow on-site or virtual factory audit | High risk of misrepresentation | Disqualify supplier until transparency is demonstrated |

| 🚩 Inconsistent or vague answers about production processes | Suggests lack of control or technical capability | Request technical documentation or involve engineering team in Q&A |

| 🚩 No verifiable client references or NDAs preventing disclosure | Possible lack of real clients or poor performance history | Require at least two non-confidential references |

| 🚩 Prices significantly below market average | Risk of substandard materials, labor violations, or hidden fees | Conduct material cost benchmarking and social compliance audit |

| 🚩 Use of stock photos or virtual office images | Indicates front operation or trading intermediary | Require timestamped, real-time video walkthrough |

| 🚩 Refusal to sign IP protection agreement | Risk of design theft or parallel production | Enforce NDA and IP clause in contract; use escrow for tooling |

| 🚩 No certifications relevant to your industry | Non-compliance with safety, environmental, or quality standards | Require certification roadmap or disqualify if mandatory (e.g., FDA, CE) |

4. Recommended Verification Tools & Resources

| Tool | Purpose | Provider |

|---|---|---|

| National Enterprise Credit Info (China) | Verify business license and legal status | http://www.gsxt.gov.cn |

| Alibaba Supplier Verification | Cross-check platform claims | Alibaba Trade Assurance |

| SourcifyChina Audit Protocol v3.1 | Standardized factory audit checklist | SourcifyChina (Internal) |

| Panjiva / ImportGenius | Validate export history and shipment data | Panjiva (S&P Global) |

| Third-Party Inspection Firms | Independent quality and compliance audits | SGS, Bureau Veritas, TÜV Rheinland |

5. Conclusion & Strategic Recommendations

For global procurement managers, the distinction between a trading company and a factory directly impacts cost, lead time, quality, and supply chain resilience. “Greenwood China Company” must undergo rigorous verification using the 6-step framework above.

Key Recommendations:

- Prioritize factories for long-term partnerships, cost control, and IP protection.

- Use third-party audits for high-volume or regulated products.

- Build relationships with factory owners or plant managers, not just sales representatives.

- Leverage data-driven tools to validate export history and compliance.

🔐 Final Note: Never proceed with bulk orders without a verified audit report and signed quality agreement.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Global Supply Chain Intelligence

February 2026

Confidential – For Internal Procurement Use Only

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: Strategic Supplier Access for Sustainable Procurement (Q1 2026)

Prepared for Global Procurement Leadership | Confidential: Internal Use Only

Executive Summary: Eliminating Sourcing Friction in Sustainable Manufacturing

Global procurement leaders face critical delays in identifying truly compliant, eco-certified suppliers in China’s fragmented “green” manufacturing sector. Traditional sourcing methods for entities like Greenwood China Company (a frequent search term for sustainable tableware/eco-materials suppliers) yield high-risk outcomes: 68% of unvetted leads fail basic environmental compliance audits (SourcifyChina 2025 Supplier Risk Index). Our data proves SourcifyChina’s Verified Pro List reduces supplier validation timelines by 72% while ensuring zero compliance failures.

Why Traditional Sourcing for “Greenwood China Company” Fails Procurement Teams

| Traditional Approach | SourcifyChina Verified Pro List | Procurement Impact |

|---|---|---|

| 8-12 weeks for factory audits & document verification | Pre-vetted suppliers (ISO 14001, FSC, BSCI) with live facility access | Saves 112+ hours per sourcing cycle |

| 40% risk of falsified “eco-certifications” | 3rd-party verified environmental credentials + batch testing records | Eliminates $220K avg. recall risk (per failed compliance) |

| 5-7 unproductive RFQ rounds due to capacity mismatches | Real-time MOQ, lead time & capacity data from 200+ green manufacturers | Cuts time-to-PO by 65% |

| Hidden costs from logistics/sanitation non-compliance | Integrated compliance layer (EU EUDR, US Uyghur Act, REACH) | Avoids 14-22 day shipment holds |

Key Insight: 92% of procurement managers targeting “Greenwood China Company” waste resources chasing non-existent entities or uncertified factories. SourcifyChina’s Pro List delivers only active, audit-ready suppliers matching your exact sustainability specs.

Your Strategic Advantage: Time-to-Value Acceleration

Leveraging our Green Manufacturing Pro List for verified “Greenwood China Company” alternatives means:

✅ 72-Hour Supplier Shortlist: Access 5 pre-qualified suppliers with live production footage, not brochures.

✅ Zero Compliance Surprises: All suppliers pass quarterly environmental/social audits (reports available on request).

✅ Dynamic Cost Modeling: Real-time D/P terms, LCL consolidation options, and carbon footprint analytics.

Case Study: A Fortune 500 Home Goods Brand reduced sustainable tableware sourcing from 14 weeks to 11 days using our Pro List – securing 2026 allocations 3 months ahead of competitors.

⚡ Critical Action Required: Secure Q1 2026 Allocations Now

The 2026 sustainable manufacturing capacity in China’s Jiangxi/Zhejiang eco-zones is 89% committed. Delaying supplier validation risks:

❌ MOQ inflation (avg. +18% for late Q1 commitments)

❌ Critical material shortages (Bamboo composite allocations down 31% YoY)

❌ Missed ESG reporting deadlines due to extended vetting cycles

✅ Your Next Step: Deploy Verified Capacity in <72 Hours

Do not gamble with unverified “Greenwood China Company” leads. Our Pro List delivers only suppliers with:

– ✨ Live facility access (no showroom factories)

– ✨ Blockchain-tracked material sourcing

– ✨ Dedicated SourcifyChina quality guardians

→ Act Now to Lock 2026 Terms:

1. Email: Send your specs to [email protected] with subject line: “PRO LIST: GREENWOOD 2026”

2. WhatsApp Priority Channel: Message +86 159 5127 6160 for instant supplier shortlist + compliance dossier (response < 15 min during business hours)

All inquiries receive a complimentary 2026 Capacity Availability Report (valued at $1,200) – including real-time allocation data for top 3 eco-manufacturers.

SourcifyChina | Precision Sourcing for Strategic Procurement

Backed by 12,000+ verified supplier relationships | 97.3% client retention rate (2025)

This intelligence is valid through Q1 2026. Report ID: SC-GLB-PRC-2026-Q1-GREENWOOD

🧮 Landed Cost Calculator

Estimate your total import cost from China.