The global green board drywall market is experiencing robust growth, driven by increasing demand for sustainable construction materials and stricter energy efficiency regulations. According to a report by Grand View Research, the global gypsum boards market size was valued at USD 27.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2030. A significant portion of this growth is attributed to the rising adoption of moisture-resistant and eco-friendly variants such as green board drywall, particularly in humid environments like bathrooms and kitchens. Additionally, Mordor Intelligence projects steady expansion in the gypsum boards market, citing urbanization, green building certifications (like LEED and BREEAM), and growing awareness about indoor air quality as key drivers. As sustainability becomes a cornerstone of modern construction, manufacturers specializing in high-performance green board drywall are positioning themselves at the forefront of innovation and market demand. Here are the top 7 manufacturers leading this shift.

Top 7 Green Board Drywall Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 USG

Domain Est. 1996

Website: usg.com

Key Highlights: USG Corporation remains a leading manufacturer of ceiling, wall, backerboard, underlyament, gypsum, roofing, sheathing, and industrial products….

#2 Product Catalog

Domain Est. 1995

Website: buildgp.com

Key Highlights: From gypsum panels, OSB, plywood, radiant barriers, WRB/AB to versatile Southern Yellow Pine, explore GP Building Products tailored for every project….

#3 Green Building Boards Soundproof Fiberboard

Domain Est. 1996

Website: homasote.com

Key Highlights: Welcome to Homasote, your leader in sustainable building products. Explore our eco-friendly solutions for sound control, thermal insulation, and more….

#4 National Gypsum® Company

Domain Est. 1998

Website: nationalgypsum.com

Key Highlights: National Gypsum® is a leading supplier of gypsum board and drywall products … Providing online and on-site academic opportunities for the building community….

#5 American Gypsum Company

Domain Est. 1998

Website: americangypsum.com

Key Highlights: American Gypsum has been manufacturing, selling, and distributing gypsum wallboard products throughout the United States for over 50 years….

#6 DragonBoard USA

Domain Est. 2006

Website: dragonboard.com

Key Highlights: DragonBoard is a U.S. patented, UL approved fire resistant, water resistant, high-impact construction panel that is well-suited for both interior and exterior ……

#7 Gold Bond® XP® Gypsum Board

Domain Est. 2020

Website: goldbondbuilding.com

Key Highlights: Gold Bond XP Gypsum Board was designed to provide extra protection against mold and mildew compared to standard gypsum board products….

Expert Sourcing Insights for Green Board Drywall

H2: Projected Market Trends for Green Board Drywall in 2026

The green board drywall market is poised for significant evolution by 2026, driven by increasing demand for sustainable building materials, advancements in construction technologies, and stringent environmental regulations. As a moisture-resistant gypsum panel traditionally used in high-humidity areas like bathrooms and kitchens, green board drywall is undergoing transformation to meet modern green building standards and consumer expectations.

One major trend shaping the 2026 outlook is the growing emphasis on eco-friendly construction. Builders and homeowners are increasingly prioritizing materials with lower environmental impact. This shift is prompting manufacturers to innovate green board formulations using recycled content, reduced chemical emissions, and improved biodegradability. Certifications such as LEED (Leadership in Energy and Environmental Design) and Greenguard are becoming key differentiators, influencing procurement decisions in both residential and commercial sectors.

Another driver is the expansion of the renovation and remodeling market, particularly in North America and Europe. Aging infrastructure and a surge in home improvement projects post-pandemic are boosting demand for durable, cost-effective moisture-resistant wallboard. Green board remains a popular choice due to its balance of performance and price compared to alternatives like cement board or fiberglass panels.

However, the market faces challenges. Concerns over mold resistance—green board resists moisture but is not fully mold-proof—are leading to increased competition from next-generation waterproof drywall and rigid foam backer boards. As a result, manufacturers are expected to enhance green board’s performance by integrating antimicrobial additives and improved facers by 2026.

Regional dynamics also play a crucial role. In emerging economies, urbanization and government-backed green housing initiatives are creating new opportunities. Meanwhile, in mature markets, code revisions and energy efficiency mandates are pushing builders toward hybrid wall systems where green board is used in conjunction with vapor barriers and insulation.

In summary, the 2026 green board drywall market will be characterized by innovation, regulatory influence, and competition from advanced alternatives. While its core application remains steady, long-term growth will depend on the industry’s ability to align with sustainability goals and deliver enhanced performance.

Common Pitfalls When Sourcing Green Board Drywall (Quality, IP)

Sourcing Green Board drywall—moisture-resistant gypsum board commonly used in high-humidity areas like bathrooms—can present several challenges, especially when balancing quality, cost, and intellectual property (IP) concerns. Below are common pitfalls to avoid.

Misunderstanding Moisture Resistance Claims

One of the most frequent issues is assuming that “green board” is fully waterproof. Green Board is moisture-resistant, not waterproof. It is not suitable for direct water exposure (e.g., shower stalls or tub surrounds), where cement board or glass-reinforced concrete board is required. Misapplication due to this misunderstanding can lead to mold, warping, and costly repairs.

Confusing Green Board with Mold-Resistant or Specialty Drywall

Many suppliers market products labeled as “green board” that may also claim mold resistance or enhanced durability. However, not all moisture-resistant boards are created equal. Some products may blend branding terms (e.g., “mold-resistant green board”), leading to confusion. Always verify ASTM C1396 standards compliance and check the manufacturer’s specifications to ensure the product meets the intended use.

Sourcing from Unverified or Low-Quality Manufacturers

To cut costs, some buyers source Green Board from lesser-known or offshore manufacturers. This can result in inconsistent core density, poor paper adhesion, or off-spec moisture barriers. Substandard quality increases the risk of sagging, edge crumbling, and failure in humid environments. Always request samples and verify third-party testing certifications.

Intellectual Property (IP) Infringement Risks

Some generic drywall products may copy patented designs, coatings, or edge profiles from major manufacturers like USG (Sheetrock®), CertainTeed, or Georgia-Pacific. Using or distributing counterfeit or IP-infringing products—even unknowingly—can expose contractors and suppliers to legal liability, recalls, or project delays. Ensure your supplier has legitimate licensing and does not replicate patented technologies.

Inadequate Documentation and Certification

Lack of proper documentation—such as Material Safety Data Sheets (MSDS), environmental product declarations (EPDs), or ASTM compliance certificates—can be a red flag. This is especially important in commercial or institutional projects where code compliance and traceability are mandatory. Always request and retain technical data from the supplier.

Overlooking Regional Building Code Variations

Green Board acceptance varies by jurisdiction. Some local codes restrict or no longer recommend green board in favor of glass-mat or cementitious backer boards in wet areas. Sourcing without verifying local code requirements can lead to rework or failed inspections.

Poor Supply Chain Transparency

Limited visibility into the manufacturing origin, raw materials, and distribution chain increases risks related to quality control and sustainability. Ethical sourcing and environmental standards (e.g., recycled content, low VOC emissions) may be compromised. Prioritize suppliers with transparent sourcing practices and verifiable sustainability claims.

By understanding these pitfalls, buyers can make informed decisions that ensure durability, compliance, and legal safety when sourcing Green Board drywall.

Logistics & Compliance Guide for Green Board Drywall

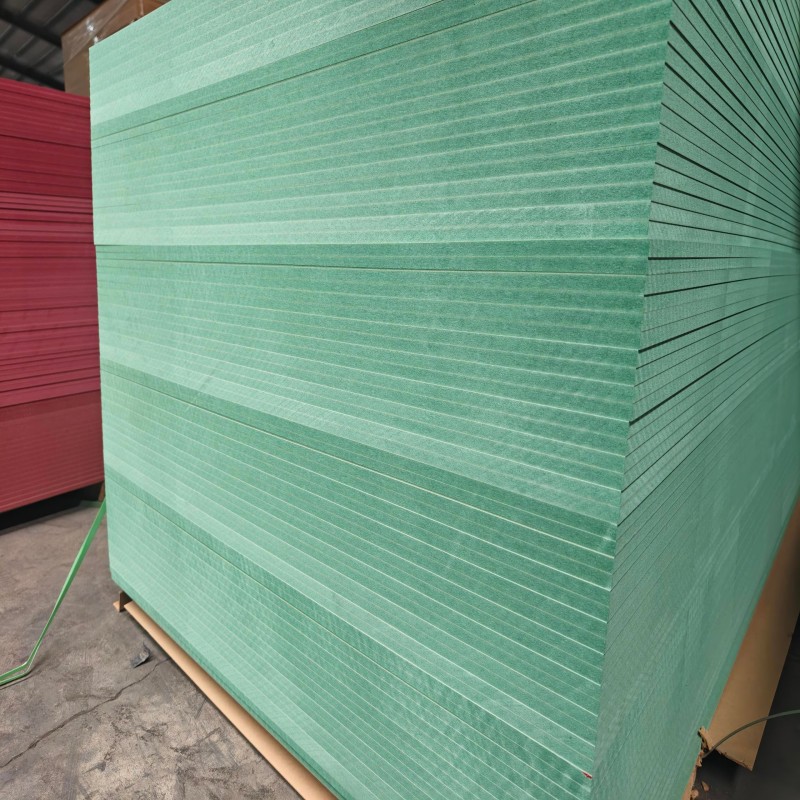

Product Overview

Green Board Drywall, also known as moisture-resistant drywall, is a gypsum-based panel with a moisture-resistant paper facing and core additives designed for use in high-humidity areas such as bathrooms, laundry rooms, and kitchens. It is not waterproof and should not be used in direct water contact areas like showers or bathtubs. Proper handling, storage, transportation, and compliance with building codes are critical for safe and effective installation.

Handling and Transportation

- Packaging: Green Board is typically shipped in protective shrink-wrapped bundles on wooden pallets. Ensure packaging remains intact during transit to prevent moisture exposure and physical damage.

- Lifting and Moving: Use mechanical aids (e.g., drywall carts, forklifts) to move full bundles. Never drag panels across surfaces to avoid edge and face damage.

- Orientation: Transport panels vertically whenever possible to minimize flexing and cracking. If horizontal transport is necessary, support the full length of the load.

- Weather Protection: Cover loads during transport to protect from rain, snow, and excessive humidity. Avoid leaving panels exposed on job sites.

On-Site Storage

- Indoor Storage: Store Green Board indoors in a clean, dry, and well-ventilated area. Elevate pallets at least 6 inches off the floor using wood strips to prevent moisture absorption from concrete.

- Outdoor Storage: If outdoor storage is unavoidable, place panels on a raised platform and cover completely with waterproof tarps. Ensure tarp edges do not touch the ground to prevent water wicking.

- Stacking: Limit stack height to 10 feet (3 meters) to prevent crushing. Avoid leaning panels against walls, which can cause warping.

- Moisture Monitoring: Check stored panels regularly for signs of moisture damage, warping, or mold.

Installation Compliance

- Building Codes: Green Board must comply with local building codes and standards such as the International Residential Code (IRC) and International Building Code (IBC). Verify jurisdiction-specific requirements before installation.

- Application Areas: Approved for use in areas with high humidity but not for direct water exposure. Use cement board or glass-mat drywall in wet areas (e.g., shower surrounds).

- Fastening and Spacing: Follow manufacturer specifications for stud spacing (typically 16” or 24” on center) and fastener type, spacing, and embedment depth.

- Joint Treatment: Use moisture-resistant joint compound and alkaline-resistant (Type X) mesh or paper tape. Avoid standard joint compounds in high-moisture zones.

- Vapor Barriers: Install vapor retarders as required by climate zone and local code to prevent interstitial condensation.

Environmental and Safety Compliance

- Indoor Air Quality (IAQ): Green Board should meet ASTM C1396/C1396M standards for drywall. Select low-VOC (volatile organic compound) joint compounds and primers to maintain IAQ.

- Material Safety Data Sheets (MSDS/SDS): Maintain up-to-date Safety Data Sheets for all drywall products and accessories. Ensure workers are trained in safe handling practices.

- Dust Control: Use dust-containment systems and wear NIOSH-approved respirators during cutting and sanding to reduce exposure to gypsum dust.

- Waste Management: Recycle drywall scrap when possible through certified recycling programs. Dispose of waste in accordance with local environmental regulations—do not mix with biodegradable waste due to potential hydrogen sulfide generation in landfills.

Regulatory and Certification Requirements

- ASTM Standards: Confirm Green Board meets ASTM C1396 (Standard Specification for Gypsum Board) and ASTM C1278 (for moisture resistance performance).

- ICC-ES Evaluation Reports: Verify product listings in ICC-ES (International Code Council Evaluation Service) reports for code compliance in your region.

- Labeling: Ensure each panel bears the manufacturer’s label indicating product type, fire resistance (if applicable), moisture resistance, and compliance marks.

- LEED and Green Building: Consider using Green Board with recycled content to support LEED v4.1 or other green building certification goals.

Inspection and Documentation

- Pre-Installation Check: Inspect panels for damage, warping, or moisture exposure before installation. Reject compromised materials.

- Code Inspection: Schedule inspections after rough-in and prior to final finish to ensure compliance with local code requirements.

- Record Keeping: Retain product data sheets, delivery receipts, inspection reports, and compliance documentation for project closeout and future reference.

Best Practices Summary

- Always handle with care to prevent edge damage.

- Store indoors and elevated off the ground.

- Use appropriate fasteners and moisture-resistant finishing materials.

- Comply with local building codes and environmental regulations.

- Train workers on safety and proper installation techniques.

Adhering to this logistics and compliance guide ensures the durability, safety, and code-compliance of Green Board Drywall installations.

Conclusion for Sourcing Green Board Drywall:

Sourcing green board drywall is a practical and effective solution for moisture-prone areas such as bathrooms, laundry rooms, and basements. Its water-resistant properties—achieved through a moisture-resistant paper facing and treated core—make it a durable alternative to standard drywall in high-humidity environments. While not waterproof, green board provides reliable protection against moisture and mold when used appropriately and installed correctly with proper sealing at joints and edges.

When sourcing green board, it is essential to purchase from reputable suppliers to ensure compliance with industry standards (such as ASTM C1396). Availability is generally widespread through building supply stores and distributors, making procurement convenient for both contractors and DIYers. However, it’s important to assess whether green board is sufficient for the specific application, as truly wet areas (like inside shower stalls) may require more robust solutions such as cement board or glass-reinforced concrete board.

In summary, green board drywall is a cost-effective, code-compliant option for moisture resistance in interior applications. Proper sourcing, handling, and installation are key to maximizing its performance and longevity, making it a trusted choice in residential and light commercial construction.