The global steel market continues to expand, driven by rising infrastructure development, urbanization, and industrial construction—particularly in emerging economies. According to Mordor Intelligence, the global construction steel market was valued at approximately USD 1.3 trillion in 2023 and is projected to grow at a CAGR of over 5.8% from 2024 to 2029. Reinforcing this trend, Grand View Research estimates that the reinforced steel market alone will witness steady growth, fueled by increased demand for high-strength deformed bars in both residential and commercial projects. Within this landscape, Grade 60 steel—known for its minimum yield strength of 60,000 psi and excellent ductility—has become a preferred choice for structural applications. As a result, leading manufacturers have ramped up production capacity and adopted advanced thermo-mechanical processing to meet rigorous international standards. The following list highlights the top 10 Grade 60 steel manufacturers shaping the industry through scale, innovation, and consistent product quality.

Top 10 Grade 60 Steel Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Rebar

Domain Est. 1990

Website: cmc.com

Key Highlights: CMC Steel operates nine state-of-the-art EAF mini and micro mills across the U.S., and is the largest producer of rebar in the nation….

#2 Leeco Steel, LLC

Domain Est. 1996

Website: leecosteel.com

Key Highlights: For over 130 years, Leeco Steel has been a leading steel plate distributor of AR steel plate, heavy steel plate, HSLA steel plate & more. Call for a quote!…

#3 Alton Steel

Domain Est. 2002

Website: altonsteel.com

Key Highlights: Our bars are made to ASTM specifications and to our customer’s unique chemistries for high strength carbon and alloy steels. ; SBQ. Diameters: 0.750″ to 3.9″…

#4 FF Steel

Domain Est. 2008

Website: ff.com.pk

Key Highlights: FF Steel is an exclusive manufacturer of Grade 60 Steel Bars in pakistan. Exclusively produces Grade-60 Steel Bars to make Stronger and Safer Pakistan….

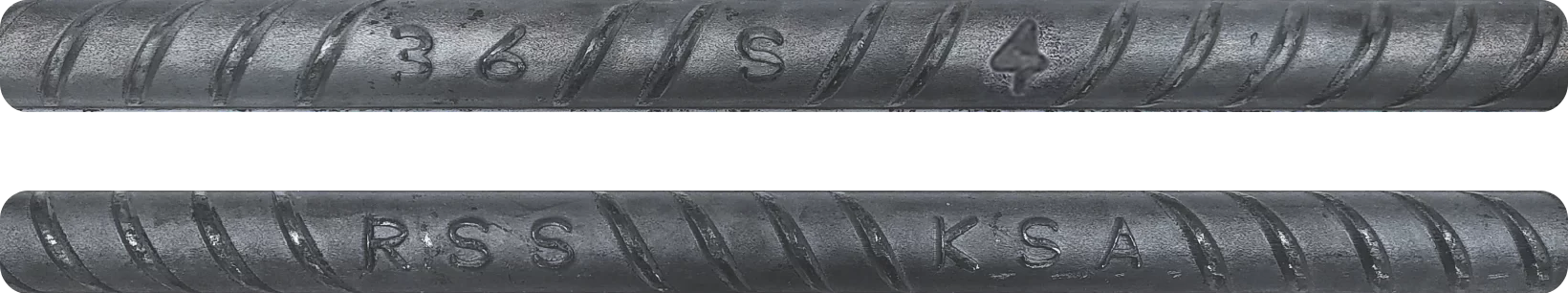

#5 Red Sea Steel

Website: redseasteel.sa

Key Highlights: Red Sea Steel provides top-tier rebar steel from ASTM A615 Grade 60 and Grade 80, ensuring superior strength, durability, and compliance with international ……

#6 Structural Steel Rebar

Domain Est. 1997

Website: metalsusa.com

Key Highlights: Metals USA carries carbon steel rebar in grades 40 and 60 both bare and also epoxy coated, along with A706 weldable rebar for any of your construction needs….

#7 Specifications

Domain Est. 1997

Website: steelwarehouse.com

Key Highlights: Steel grades are classified using a 4-digit series of numbers. The first two digits specify the type of steel, and the second two digits specify the percentage ……

#8 Rajhi Steel High-Tensile Rebar

Domain Est. 2001

Website: madar.com

Key Highlights: In stockHigh-quality Rajhi Steel rebar, conforming to ASTM A615 Grade 60. SASO & ISO 9001 certified for ultimate strength and reliability in all construction projects….

#9 Harris Supply Solutions: Steel Rebar Distributor

Domain Est. 2005

Website: harrissupplysolutions.com

Key Highlights: Harris Supply Solutions is the largest steel rebar distributor in the U.S., offering high-quality concrete reinforcing bar for any application. Call today!…

#10 Djibouti Steel

Domain Est. 2015 | Founded: 2018

Website: djiboutisteel.com

Key Highlights: Djibouti’s First Steel Company manufacturing reinforcement steel bars Grade 60 ASTM 615A. Djibouti steel was established in 2018 for manufacture of ……

Expert Sourcing Insights for Grade 60 Steel

H2: Projected Market Trends for Grade 60 Steel in 2026

The global market for Grade 60 steel, a widely used deformed steel bar in reinforced concrete construction, is expected to experience steady growth and structural shifts by 2026, driven by infrastructure development, urbanization, and evolving regulatory standards. This analysis explores key trends shaping the Grade 60 steel market in 2026 under the H2 framework, focusing on demand drivers, regional dynamics, technological advancements, and sustainability pressures.

1. Infrastructure-Led Demand Growth

By 2026, government-led infrastructure initiatives—particularly in emerging economies—will remain the primary driver of Grade 60 steel demand. Countries in Southeast Asia, India, Africa, and Latin America are expected to expand transportation networks, affordable housing, and urban development projects, all of which rely heavily on reinforced concrete. In the United States, continued investment under the Bipartisan Infrastructure Law will also sustain demand for rebar, including Grade 60, for bridge and highway rehabilitation.

2. Regional Market Shifts

Asia-Pacific will continue to dominate the Grade 60 steel market, with China and India as key consumers. However, market maturation in China may lead to slower growth, while India’s “Housing for All” and Smart Cities Mission programs are expected to fuel double-digit demand increases. In North America, demand will be stable but influenced by construction cycles and interest rates. Meanwhile, the Middle East’s giga-projects (e.g., NEOM, Qiddiya) will contribute to rising regional consumption.

3. Price Volatility and Supply Chain Adjustments

Steel prices in 2026 will remain sensitive to raw material costs (iron ore, scrap, and energy), geopolitical tensions, and trade policies. Recycling rates for scrap steel are expected to rise, supporting electric arc furnace (EAF) production—a cleaner method increasingly used for rebar. This shift may improve cost predictability and reduce carbon intensity, but supply chain resilience will remain a concern, prompting manufacturers to diversify sourcing and localize production.

4. Technological and Quality Enhancements

Manufacturers are investing in advanced rolling technologies and quality control systems to meet tighter tolerances and higher performance standards. By 2026, digital twin technology and IoT-enabled monitoring in steel plants are expected to improve consistency in Grade 60 rebar production, reducing defects and enhancing weldability and ductility.

5. Sustainability and Regulatory Pressures

Environmental regulations will increasingly influence the Grade 60 steel market. Green building certifications (e.g., LEED, BREEAM) and low-carbon construction mandates may push contractors toward rebar with verified Environmental Product Declarations (EPDs). While Grade 60 is not as high-strength as newer grades (e.g., Grade 80), its widespread availability and lower cost maintain its relevance—especially as producers adopt cleaner production methods to reduce its carbon footprint.

6. Competition from Higher-Grade Alternatives

Though Grade 60 will remain dominant due to its cost-effectiveness and code acceptance, it will face growing competition from higher-strength steels (e.g., ASTM A706 Grade 80) in seismic zones and tall buildings, where material efficiency is critical. However, the higher cost and limited availability of Grade 80 will constrain its market penetration, preserving Grade 60’s role in mainstream construction.

Conclusion

By 2026, the Grade 60 steel market will be shaped by sustained infrastructure demand, regional growth imbalances, and a push toward sustainability. While technological improvements and environmental regulations will influence production and procurement practices, Grade 60 is expected to retain its position as the most widely used rebar grade globally, particularly in cost-sensitive and large-scale construction projects. Market stakeholders should prepare for moderate growth, price volatility, and increasing emphasis on low-carbon steel solutions.

Common Pitfalls When Sourcing Grade 60 Steel (Quality and Intellectual Property)

Quality-Related Pitfalls

Sourcing Grade 60 steel, commonly used in reinforced concrete construction, requires careful attention to quality standards. Poor quality can compromise structural integrity and lead to costly failures.

1. Inconsistent Mechanical Properties

One of the most common issues is inconsistent yield strength and tensile strength. Grade 60 steel must meet ASTM A615 or equivalent standards, with a minimum yield strength of 60,000 psi. However, some suppliers—particularly in regions with lax quality control—may provide rebar that fails to meet these specifications. This can result from improper heat treatment, incorrect alloy composition, or substandard manufacturing processes.

2. Poor Surface Quality and Corrosion Resistance

Defects such as scale, cracks, or excessive rust can weaken the steel or reduce bond strength with concrete. Sourcing from unverified mills may result in rebar with surface imperfections that are not immediately visible but compromise long-term durability, especially in corrosive environments.

3. Non-Compliance with Certification and Traceability

Reputable suppliers provide mill test certificates (MTCs) that verify compliance with standards. A frequent pitfall is accepting rebar without proper documentation or receiving falsified certificates. Without traceability, it is difficult to verify chemical composition, mechanical testing results, or production batch details.

4. Use of Re-rolled or Re-melted Steel

Some low-cost suppliers use recycled scrap steel that is re-rolled into rebar. While not inherently problematic, poor reprocessing can introduce impurities, inconsistent dimensions, and weak structural performance. Re-rolled steel may not meet ductility or bend requirements, posing serious risks in seismic zones.

Intellectual Property and Compliance Risks

Beyond physical quality, sourcing Grade 60 steel can involve legal and intellectual property (IP) concerns, particularly when dealing with proprietary manufacturing processes or counterfeit materials.

1. Misrepresentation of Brand or Origin

Counterfeit materials may carry fake logos or branding of well-known steel producers. This misrepresentation not only violates trademark laws but also deceives buyers into believing they are purchasing high-quality, certified products. Such practices constitute IP infringement and undermine trust in supply chains.

2. Use of Proprietary Manufacturing Techniques Without Licensing

Some advanced Grade 60 steel variants—such as those with enhanced corrosion resistance or seismic performance—involve patented production methods (e.g., thermomechanical treatment). Unauthorized use of these techniques by third-party manufacturers can result in IP violations, exposing buyers to legal risk if the steel is later found to be illegally produced.

3. Lack of Due Diligence in International Sourcing

When sourcing from overseas, especially from jurisdictions with weak IP enforcement, there is an increased risk of inadvertently obtaining steel produced through IP violations. Buyers may face reputational damage or legal challenges if their projects are found to use materials linked to intellectual property theft.

4. Inadequate Contractual Safeguards

Many procurement agreements fail to include clear clauses on IP compliance, quality warranties, or liability for counterfeit goods. Without these protections, buyers have limited recourse if substandard or infringing materials are delivered.

In summary, sourcing Grade 60 steel involves navigating both technical quality challenges and legal risks related to intellectual property. Ensuring supplier credibility, demanding full certification, and implementing robust procurement contracts are essential to avoid these common pitfalls.

Logistics & Compliance Guide for Grade 60 Steel

Grade 60 steel, commonly known as ASTM A615 Grade 60, is a deformed steel reinforcing bar widely used in concrete construction due to its high yield strength (60,000 psi or 420 MPa). Proper logistics and compliance are essential to ensure quality, safety, and adherence to regulatory standards throughout the supply chain.

Material Specifications and Standards

Grade 60 steel must conform to specific material standards to ensure structural integrity. The primary reference standard is:

– ASTM A615/A615M: Standard Specification for Deformed and Plain Carbon-Steel Bars for Concrete Reinforcement.

Additional relevant standards may include:

– ASTM A706: For low-alloy steel bars with enhanced weldability and ductility, often used in seismic zones.

– AASHTO M31: Used in transportation infrastructure projects in the United States.

Compliance requires mill test reports (MTRs) or certificates of conformance (CoC) for each heat or batch, verifying chemical composition and mechanical properties.

Handling and Storage

Proper handling and storage prevent damage and corrosion:

– Segregation: Store Grade 60 bars separately from other grades to avoid mix-ups.

– Elevation: Keep bars off the ground using wooden sleepers or pallets to prevent moisture contact.

– Covering: Use waterproof tarps or store indoors to minimize rust and surface degradation.

– Stacking: Limit stack height to prevent bending or deformation; follow manufacturer recommendations.

– Labeling: Clearly mark bundles with bar size, grade, heat number, and ASTM specification.

Transportation Requirements

Transporting Grade 60 steel bars requires careful planning to maintain integrity:

– Securing Loads: Use chains, straps, or binders to secure bundles on flatbed trucks or railcars, preventing shifting during transit.

– Protection: Shield bars from extreme weather, especially saltwater spray in coastal regions, to reduce corrosion risk.

– Documentation: Include shipping manifests, CoC, and purchase order details with the shipment.

– Weight Compliance: Adhere to local and federal weight limits for trucks and transport vehicles.

Import/Export and Regulatory Compliance

International shipments must meet trade and safety regulations:

– Customs Documentation: Prepare commercial invoices, packing lists, bills of lading, and certificates of origin.

– HS Code: Typically classified under 7214.20 (non-alloy steel bars and rods, hot-rolled, deformed) for customs purposes.

– Import Regulations: Verify country-specific standards (e.g., BS 4449 in the UK, IS 1786 in India) if ASTM A615 is not accepted.

– Duties and Tariffs: Check applicable trade agreements and anti-dumping regulations, especially for steel products.

– Environmental and Safety: Comply with OSHA (USA), WHMIS (Canada), or other regional safety standards during loading/unloading.

Quality Assurance and Testing

Ensure compliance through regular quality checks:

– Tensile Testing: Verify yield strength, tensile strength, and elongation per ASTM A370.

– Bend and Re-bend Tests: Confirm ductility and performance under stress.

– Dimensional Checks: Measure deformations, diameter, and length accuracy.

– Third-Party Inspection: Use certified labs or inspectors for independent verification, especially on large contracts.

Traceability and Documentation

Maintain full traceability from mill to construction site:

– Heat Number Tracking: Each bar batch must be traceable to its production heat.

– Record Retention: Keep MTRs, test results, delivery receipts, and inspection reports for at least 5–10 years, depending on project requirements.

– Digital Systems: Use barcoding or RFID tags for efficient inventory management and audit trails.

Environmental and Safety Considerations

Adhere to environmental and worker safety protocols:

– Spill Prevention: Prevent oil or rust runoff during storage that could contaminate soil or water.

– Worker Safety: Provide PPE (gloves, eye protection, steel-toe boots) during handling; train personnel on safe lifting practices.

– Recycling: Promote scrap metal recycling; Grade 60 steel is fully recyclable and often contains recycled content.

By following this guide, stakeholders can ensure that Grade 60 steel is handled, transported, and documented in full compliance with industry standards and regulatory requirements, supporting safe and durable construction projects.

In conclusion, sourcing Grade 60 steel offers a reliable and cost-effective solution for construction and structural applications requiring high strength, durability, and good weldability. Its minimum yield strength of 60,000 psi makes it suitable for reinforcing concrete in buildings, bridges, and other infrastructure projects. When sourcing Grade 60 steel, it is essential to ensure compliance with relevant standards such as ASTM A615 or ASTM A706, particularly when seismic performance or ductility is a concern. Additionally, evaluating suppliers based on quality assurance, certification, delivery timelines, and cost competitiveness will help secure material that meets project specifications and regulatory requirements. Overall, with proper sourcing practices, Grade 60 steel remains a preferred choice for enhancing structural integrity and long-term performance in modern construction.