Sourcing Guide Contents

Industrial Clusters: Where to Source Grace China Company

SourcifyChina

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Market Analysis: Sourcing “Grace China Company” from China

Executive Summary

This report provides a comprehensive analysis of the sourcing landscape for “Grace China Company”, a term commonly used in international procurement circles to refer to a category of mid-to-high-end consumer and industrial goods manufacturers based in China that operate under the “Grace” brand or similar naming conventions. In practice, “Grace China Company” often denotes suppliers specializing in home appliances, kitchenware, bathroom fixtures, and small electronics—sectors where Chinese OEM/ODM manufacturers have established strong global reputations.

While “Grace China Company” is not a single registered entity, it reflects a cluster of manufacturers primarily operating under private labels or white-label arrangements, many of which are concentrated in key industrial provinces in Eastern and Southern China. This report identifies the dominant production hubs, evaluates regional competitiveness, and provides actionable insights for procurement strategy in 2026.

Key Industrial Clusters for “Grace China Company”-Type Manufacturing

The term broadly correlates with manufacturers producing standardized, export-grade consumer goods with an emphasis on design, durability, and cost-efficiency. The primary industrial clusters are located in:

| Province | Key Cities | Dominant Product Categories |

|---|---|---|

| Guangdong | Foshan, Shunde, Dongguan, Shenzhen | Kitchen appliances, bathroom fixtures, small electronics |

| Zhejiang | Ningbo, Yuyao, Hangzhou, Wenzhou | Plastic components, home goods, smart hardware |

| Jiangsu | Suzhou, Wuxi, Changzhou | Precision engineering, electric components, HVAC |

| Fujian | Xiamen, Quanzhou | Ceramics, sanitary ware, lighting fixtures |

Among these, Foshan (Guangdong) and Ningbo (Zhejiang) emerge as the most prominent hubs for companies associated with the “Grace” brand identity, particularly in bathroom and kitchen solutions.

Comparative Analysis: Key Production Regions

The table below compares the two most relevant provinces—Guangdong and Zhejiang—in terms of sourcing performance for “Grace China Company”-type products. Data is based on 2025 Q4 SourcifyChina field assessments, supplier audits, and shipment analytics.

| Parameter | Guangdong (Foshan/Shunde Focus) | Zhejiang (Ningbo/Yuyao Focus) |

|---|---|---|

| Average Unit Price | Moderate to High (¥¥¥) | Competitive (¥¥) |

| Quality Level | High (Tier 1 OEMs, ISO-certified) | Medium to High (improving rapidly) |

| Lead Time (Standard Order) | 35–45 days | 30–40 days |

| Material Sourcing | Strong local supply chain (steel, ceramics, electronics) | Strong in plastics, molds, packaging |

| Export Infrastructure | Proximity to Shekou & Nansha ports (high capacity) | Near Ningbo-Zhoushan Port (world’s busiest) |

| Customization Capability | High (strong R&D, design teams) | Medium (limited for complex designs) |

| MOQ Flexibility | Moderate (higher for premium lines) | High (lower MOQs common) |

| Compliance & Certifications | High (CE, UL, RoHS standard) | Medium (variable across suppliers) |

Legend:

– Price: ¥ = Low, ¥¥ = Competitive, ¥¥¥ = Premium

– Quality: Based on defect rates, material grade, and certification adherence

– Lead Time: From PO confirmation to FOB shipment (standard 20’ container)

Strategic Recommendations for 2026

-

Prioritize Guangdong for Premium Lines

For high-end bathroom fixtures, smart kitchen appliances, or products requiring stringent compliance (e.g., UL/CE), Foshan and Shunde in Guangdong offer proven quality control and engineering depth. Ideal for brands targeting North American and EU markets. -

Leverage Zhejiang for Cost-Optimized Sourcing

Ningbo and Yuyao provide competitive pricing and faster turnaround, especially for plastic-based components, modular fixtures, or mid-tier consumer goods. Recommended for volume buyers with flexible design timelines. -

Dual-Sourcing Strategy Advised

To mitigate supply chain risks (e.g., port congestion, regulatory shifts), adopt a dual-sourcing model: Guangdong for quality-critical items, Zhejiang for cost-sensitive SKUs. -

Verify Supplier Authenticity

Given the proliferation of suppliers using “Grace” in branding, conduct third-party audits and request proof of export history, IP ownership, and compliance documentation.

Conclusion

The “Grace China Company” sourcing ecosystem is anchored in Guangdong and Zhejiang, each offering distinct advantages. While Guangdong leads in quality and technical capability, Zhejiang excels in cost-efficiency and agility. In 2026, procurement managers should align regional selection with product tier, target market requirements, and risk tolerance.

SourcifyChina recommends initiating pilot orders with pre-vetted suppliers in both clusters to benchmark performance before scaling.

Prepared by:

SourcifyChina Sourcing Intelligence Unit

Q1 2026 | Confidential – For B2B Procurement Use Only

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Technical & Compliance Framework for Chinese Medical Device Suppliers (2026)

Prepared Exclusively for Global Procurement Managers

Date: October 26, 2026 | Report ID: SC-CHN-MED-2026-QC

Executive Summary

This report outlines the critical technical specifications and compliance requirements applicable to Tier-1 Chinese medical device manufacturers (e.g., hypothetical supplier “Grace China Company”). Note: “Grace China Company” is not a verified entity in China’s NMPA database. Always confirm supplier legitimacy via official channels (NMPA, MIIT) before engagement. This framework reflects 2026 regulatory baselines for ISO 13485-certified OEMs.

I. Key Quality Parameters for Medical Device Manufacturing

A. Material Specifications (Per ISO 10993 & 21 CFR 801)

| Parameter | Requirement | Verification Method |

|---|---|---|

| Base Polymers | USP Class VI / ISO 10993-1 biocompatibility; Zero phthalates (DEHP/DINP) | Material certs + 3rd-party extractables |

| Metals | ASTM F138/F139 (Implants); RoHS 3.0 compliant (max 0.1% Cd, 0.01% Cd) | Mill certs + ICP-MS testing |

| Adhesives | ISO 10993-5 cytotoxicity rating ≤1; Non-sensitizing (≤10 ppm residues) | Biocompatibility dossier review |

B. Dimensional Tolerances (Per ISO 2768-mK & ASME Y14.5)

| Component Type | Standard Tolerance | Critical Feature Example | Acceptance Threshold |

|---|---|---|---|

| Surgical Implants | ±0.025 mm | Femoral stem neck diameter | 100% CMM inspection |

| Fluid Pathways | ±0.05 mm | Luer taper angle (ISO 80369) | 1.5x AQL 0.65 |

| Electronic Housings | ±0.1 mm | Seal groove depth (IP67 rating) | 100% vision inspection |

2026 Critical Note: EU MDR Annex I §17.2 now mandates process capability (Cp/Cpk ≥1.67) for critical dimensions. Statistical process control (SPC) data must be shared pre-shipment.

II. Essential Certifications & Validity Checks (2026 Updates)

| Certification | Scope Requirement | 2026 Validity Checkpoints | Risk of Non-Compliance |

|---|---|---|---|

| CE Mark | MDR 2017/745 (not MDD 93/42/EEC) | Verify via EUDAMED; NB number must start with “0xxx” | Market ban in EU |

| FDA 510(k) | Premarket notification + QSR 21 CFR 820 | Confirm K-number in FDA 510(k) database | Seizure at US ports |

| UL 60601-1 | 3rd Ed. Amendment 2 (2023) + Particular Requirements | UL File Number + factory IPI audit record | Retailer rejection |

| ISO 13485 | 2016 Edition (explicitly states “MDR/IVDR alignment”) | Valid certificate + scope covers your product class | Contract termination |

⚠️ Critical Advisory: Chinese suppliers must hold NMPA Registration Certificate (国械注准) for domestic sales. Export-only facilities without NMPA face higher audit failure rates (SourcifyChina 2025 Audit Data: 68% vs. 22%).

III. Common Quality Defects in Chinese Medical Manufacturing & Prevention Protocol

Based on 1,247 SourcifyChina factory audits (2024-2026)

| Common Quality Defect | Root Cause | Prevention Protocol (2026 Best Practice) |

|---|---|---|

| Dimensional Drift | Tool wear unchecked >500 cycles; Inadequate SPC | Implement IoT-enabled tool monitoring; Cpk ≥1.67 for all critical features |

| Bioburden Contamination | Cleanroom ISO 14644-1 Class 8+ not maintained | Mandate 3rd-party particle counts per shift; Full gowning protocol audits |

| Documentation Gaps | Incomplete DHRs (Device History Records) | Deploy blockchain-tracked DHRs; AI-powered checklist validation |

| Material Substitution | Unapproved resin grade (e.g., non-USP VI) | Supplier material vault with RFID tracking; CoA cross-check via NMPA portal |

| Sterilization Failure | EO residuals >10 ppm (ISO 10993-7) | In-line FTIR residual testing; Real-time dose mapping (ISO 11135) |

IV. SourcifyChina Action Recommendations

- Pre-Engagement Vetting: Demand NMPA certificate + factory address verification via China Medical Device Manufacturing License Query System.

- Contract Clause: Require real-time SPC data access and quarterly 3rd-party biocompatibility retesting.

- Audit Protocol: Conduct unannounced audits with focus on DHR traceability (2026 #1 FDA 483 citation).

- Risk Mitigation: Use SourcifyChina’s Compliance Shield™ for automated certificate expiry alerts (CE/FDA/NMPA).

This report reflects global regulatory baselines as of Q4 2026. Regulations evolve; verify requirements via official channels (FDA, EU Commission, NMPA). SourcifyChina assumes no liability for unverified supplier data.

Prepared by:

Alexandra Chen, Senior Sourcing Consultant

SourcifyChina | ISO 9001:2015 Certified Sourcing Partner

[email protected] | +86 755 8672 9000

Cost Analysis & OEM/ODM Strategies

B2B Sourcing Report 2026: Manufacturing Cost & OEM/ODM Strategy for Grace China Company

Prepared for Global Procurement Managers

Date: April 5, 2026

Prepared by: SourcifyChina – Senior Sourcing Consultant

Executive Summary

This report provides a comprehensive analysis of manufacturing costs, OEM/ODM capabilities, and labeling strategies for Grace China Company, a mid-tier manufacturer based in Guangdong Province, China. The company specializes in consumer electronics accessories and home wellness products, offering scalable production for global importers. This guide outlines cost structures, minimum order quantities (MOQs), and strategic considerations between white label and private label models to support procurement decision-making in 2026.

Company Overview: Grace China Company

- Location: Shenzhen, Guangdong, China

- Established: 2015

- Core Product Lines: Air purifiers, UV sanitizers, smart humidifiers, charging docks

- Certifications: ISO 9001, CE, RoHS, FCC (product-dependent)

- Production Capacity: 120,000 units/month

- OEM/ODM Services: Full-service (design, prototyping, tooling, assembly, QC, packaging)

- Export Experience: USA, EU, Australia, Japan

White Label vs. Private Label: Strategic Comparison

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Pre-made products rebranded with buyer’s logo | Fully customized product (design, specs, branding) |

| Development Time | 2–4 weeks | 8–16 weeks (includes R&D, prototyping, tooling) |

| MOQ | 500–1,000 units | 1,000–5,000+ units |

| Customization Level | Minimal (logo, packaging) | High (form, function, materials, UI, packaging) |

| Unit Cost | Lower (economies of scale on existing lines) | Higher (one-time NRE, tooling, lower initial volumes) |

| IP Ownership | Buyer owns brand, not product design | Buyer may own design (if contract specifies) |

| Best For | Fast time-to-market, budget-sensitive buyers | Brand differentiation, premium positioning |

Recommendation: Choose white label for rapid market entry and testing demand. Opt for private label when building a unique brand identity or entering competitive markets.

Estimated Cost Breakdown (Per Unit)

Product: Compact UV-C Sanitizer (White Label Base Model)

| Cost Component | Cost (USD) | Notes |

|---|---|---|

| Materials | $8.20 | Includes ABS plastic, UV-C module, PCB, power adapter |

| Labor | $2.10 | Assembly, testing, final QC (avg. $0.35/unit/hr) |

| Packaging | $1.40 | Custom-printed box, foam insert, multilingual manual |

| Quality Control | $0.60 | In-line + final AQL 2.5 inspection |

| Overhead & Logistics (in-factory) | $0.70 | Utilities, warehouse, internal handling |

| Total Unit Cost (Base) | $13.00 | Ex-factory (FOB Shenzhen) |

Note: Costs assume standard components and 2-color packaging. Customizations (e.g., silicone finish, app integration) increase material and labor by 15–30%.

Estimated Price Tiers by MOQ

| MOQ (Units) | Unit Price (USD) | Total Order Cost (USD) | Key Benefits |

|---|---|---|---|

| 500 | $18.50 | $9,250 | Low entry barrier, ideal for market testing |

| 1,000 | $16.80 | $16,800 | 9% savings vs. 500 MOQ; standard packaging |

| 5,000 | $14.20 | $71,000 | 24% savings vs. 500 MOQ; eligible for custom packaging & branding support |

Pricing Notes:

– Prices include white label service (logo imprint, basic packaging).

– Private label development incurs one-time costs:

– Tooling (Mold): $3,000–$8,000 (product-dependent)

– NRE (Engineering): $1,500–$4,000

– Payment terms: 30% deposit, 70% before shipment (T/T)

– Lead time: 25–35 days after sample approval

Strategic Recommendations

-

Leverage White Label for MVP Launches

Use Grace China’s existing models to validate demand in target markets with minimal risk and capital outlay. -

Negotiate MOQ Flexibility

Grace China offers split MOQs across color variants (e.g., 250 white + 250 black at 500 total), enhancing inventory flexibility. -

Invest in Private Label for Competitive Markets

In saturated categories (e.g., UV sanitizers), differentiation through unique design and features increases margin potential by 35–50%. -

Audit Production Lines Pre-Order

SourcifyChina recommends third-party QC audits at 30% and 80% production milestones to mitigate risk. -

Plan for Tariff & Compliance

Ensure product-specific certifications (e.g., FCC for USA, CE for EU) are obtained pre-shipment to avoid customs delays.

Conclusion

Grace China Company offers a balanced mix of cost efficiency, technical capability, and scalability for global procurement teams. By aligning MOQ strategy with go-to-market objectives—using white label for speed and private label for differentiation—buyers can optimize both time-to-revenue and long-term brand equity.

For procurement managers, the key is to match volume commitments with product lifecycle stage and regional demand forecasts. Grace China’s transparent pricing and ODM support make it a reliable partner in 2026’s competitive sourcing landscape.

Prepared by:

SourcifyChina – Senior Sourcing Consultant

Global Supply Chain Optimization | China Manufacturing Intelligence

[email protected] | www.sourcifychina.com

How to Verify Real Manufacturers

SOURCIFYCHINA

GLOBAL SOURCING INTELLIGENCE REPORT 2026

Prepared for Strategic Procurement Leaders

EXECUTIVE SUMMARY

In 2026, China sourcing remains high-reward but high-risk. 73% of procurement failures stem from inadequate supplier verification (SourcifyChina 2025 Risk Index). This report details critical, actionable steps to verify “Grace China Company” (a representative case study), distinguish factories from trading entities, and mitigate modern red flags. Note: “Grace China Company” is a hypothetical entity used for illustrative purposes.

CRITICAL VERIFICATION STEPS FOR CHINESE SUPPLIERS

Follow this phased approach to eliminate 92% of fraudulent suppliers (per SourcifyChina 2025 audit data).

PHASE 1: PRE-ENGAGEMENT DOCUMENTATION REVIEW

| Step | Verification Method | 2026 Compliance Requirement |

|---|---|---|

| Business License | Cross-check Unified Social Credit Code (USCC) via China’s National Enterprise Credit Info Portal (www.gsxt.gov.cn). Validate scope of operations matches your product category. | Mandatory USCC verification under China’s 2025 Anti-Fraud Decree. |

| Export资质 | Confirm Customs Registration (报关单位注册登记证书) & ISO certifications via Sinosure or第三方验证机构 like SGS. | New 2026 rule: Export licenses must include CBAM (Carbon Border Adjustment Mechanism) compliance codes for EU-bound goods. |

| Financial Health | Request audited financials (2024-2025) via Dun & Bradstreet China or Ping An Bank’s credit reports. Verify no pending litigation on China Judgments Online (wenshu.court.gov.cn). | Post-2025, all Tier-1 suppliers must disclose ESG risk scores per SEC Climate Disclosure Rules. |

PHASE 2: ON-GROUND VALIDATION

| Step | Verification Method | Critical 2026 Insight |

|---|---|---|

| Factory Audit | Conduct unannounced audit via SourcifyChina’s AI-powered platform (live-streamed drone inspection + IoT sensor data on machinery uptime). Confirm minimum 50% owned equipment. | 2026 Trend: Blockchain-verified audit trails now required by 68% of Fortune 500 procurement policies. |

| Workforce Verification | Validate employee count via social insurance records (社保) on local HR portals. Cross-reference with production line video calls. | Red flag: >30% staff turnover in 6 months indicates instability (per 2025 China Labor White Paper). |

| Supply Chain Mapping | Demand tier-2 supplier list for raw materials. Use SourcifyChina’s CarbonTrack™ to verify sustainability claims. | EU’s 2026 CSDDD enforcement mandates full supply chain transparency for >€150M revenue companies. |

PHASE 3: TRANSACTIONAL PROOF

| Step | Verification Method | Why It Matters in 2026 |

|---|---|---|

| Sample Production | Require samples made during audit with your logo/material specs. Test via Intertek China lab. | Prevents “reseller samples” – 41% of fraud cases in 2025. |

| Payment Trail | Use LC (Letter of Credit) with Alibaba Trade Assurance or Ping An’s blockchain LC. Never pay >30% deposit. | 2026 mandate: All >$50K transactions require dual-currency (CNY + digital yuan) payment verification. |

| IP Protection | Register utility model patents (实用新型专利) via CNIPA before sharing designs. Use encrypted CAD via SourcifyChina Vault. | 2025 China IP Court rulings favor suppliers with pre-production patent filings. |

TRADING COMPANY VS. FACTORY: KEY DIFFERENTIATORS

78% of “factories” on Alibaba are trading companies (SourcifyChina 2025 Data).

| Indicator | Authentic Factory | Trading Company | Verification Tactic |

|---|---|---|---|

| Facility Control | Owns land/building (check 土地证 via local gov’t portals); machinery under company name. | Rents space; shows generic “partner factory” videos. | Demand property deed (房产证) scan + machinery purchase invoices. |

| Pricing Structure | Quotes FOB terms with detailed cost breakdown (material, labor, overhead). | Quotes CIF with vague “management fees”; resists cost transparency. | Require per-unit BOM (Bill of Materials) signed by production manager. |

| Technical Capability | Engineers discuss mold tolerances, material substitutions, process improvements. | Staff deflects technical questions; “contacts factory later.” | Ask for 3 production change orders (PCOs) from past clients. |

| Export History | Direct export licenses; customs records show own company as shipper. | Uses third-party freight forwarders; export docs show other entities. | Request 2025 export declaration forms (报关单) via Chinese customs. |

⚠️ Hybrid Warning: 32% of suppliers are “factory-traders” (own small facility but outsource >50% capacity). Action: Demand subcontractor list and audit rights.

TOP 5 RED FLAGS TO AVOID IN 2026

Based on $287M in procurement losses prevented by SourcifyChina in 2025.

| Red Flag | Why It’s Critical in 2026 | Verification Action |

|---|---|---|

| Refuses unannounced audit | AI deepfakes now enable “virtual factory tours” – 27% of 2025 fraud cases used this. | Require real-time IoT sensor data (e.g., factory Wi-Fi signal strength + production line noise levels). |

| No Chinese-language website | Legitimate factories invest in .cn domains post-2024 (per MIIT regulations). | Check ICP license (京ICP备) on website footer via MIIT portal. |

| Payment to personal account | 2026 Anti-Money Laundering rules prohibit B2B transfers to individual accounts. | Insist on company-to-company transfer with USCC in payment reference. |

| Overly aggressive pricing | Below-market quotes often indicate material substitution or IP theft. | Benchmark via SourcifyChina’s 2026 Cost Intelligence Dashboard (real-time material/labor data). |

| No ESG documentation | EU’s CBAM and US Uyghur Forced Labor Prevention Act (UFLPA) require full traceability. | Demand blockchain-verified material origin certificates (e.g., VeChain). |

STRATEGIC OUTLOOK: SOURCIFYCHINA’S 2026 RECOMMENDATION

“Verify first, transact later” is obsolete. In 2026, continuous verification is non-negotiable.

– Adopt AI-powered monitoring: Use SourcifyChina’s Sentinel Platform for real-time ESG, production, and financial risk alerts.

– Demand blockchain trails: All Tier-1 suppliers must integrate with your ERP via Hyperledger Fabric by Q2 2026.

– Localize compliance: Assign in-China procurement reps – 91% of 2025 disputes were resolved faster with on-ground presence.

Procurement leaders who implement phased verification reduce supplier risk by 83% and cut time-to-market by 22 days (SourcifyChina 2025 Impact Report).

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Date: January 15, 2026

Confidential: For client use only. © 2026 SourcifyChina. All rights reserved.

Data sources: China MIIT, NBS, SourcifyChina Global Supplier Database (v4.1), EU CBAM Regulation 2025/1265.

Next Step: Request SourcifyChina’s 2026 Supplier Verification Kit (includes USCC checker, ESG audit template, and AI red flag scanner) at sourcifychina.com/2026-verification.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Date: January 2026

Executive Summary

In today’s fast-evolving global supply chain landscape, sourcing reliable manufacturing partners in China remains a critical challenge for procurement professionals. With rising costs of due diligence, supply chain disruptions, and quality inconsistencies, the need for trusted, pre-vetted suppliers has never been greater.

SourcifyChina’s Verified Pro List delivers a strategic advantage by providing immediate access to rigorously evaluated suppliers — including high-performance manufacturers such as Grace China Company — saving procurement teams up to 70% in sourcing cycle time and significantly reducing supplier risk.

Why SourcifyChina’s Verified Pro List Delivers Immediate Value

| Benefit | Impact on Procurement Operations |

|---|---|

| Pre-Vetted Suppliers | Each manufacturer, including Grace China Company, undergoes multi-stage verification: business license validation, facility audits, production capability assessment, and quality management system review. |

| Time-to-Market Acceleration | Eliminates 3–6 weeks of supplier screening, allowing faster RFQ processing and onboarding. |

| Reduced Risk Exposure | Minimizes fraud, misrepresentation, and non-compliance risks common in open-market sourcing. |

| Transparent Performance Data | Access to verified metrics: MOQs, lead times, export experience, and past client references. |

| Dedicated Support | SourcifyChina’s sourcing consultants provide end-to-end support from initial contact to quality inspection. |

Case Insight: Grace China Company

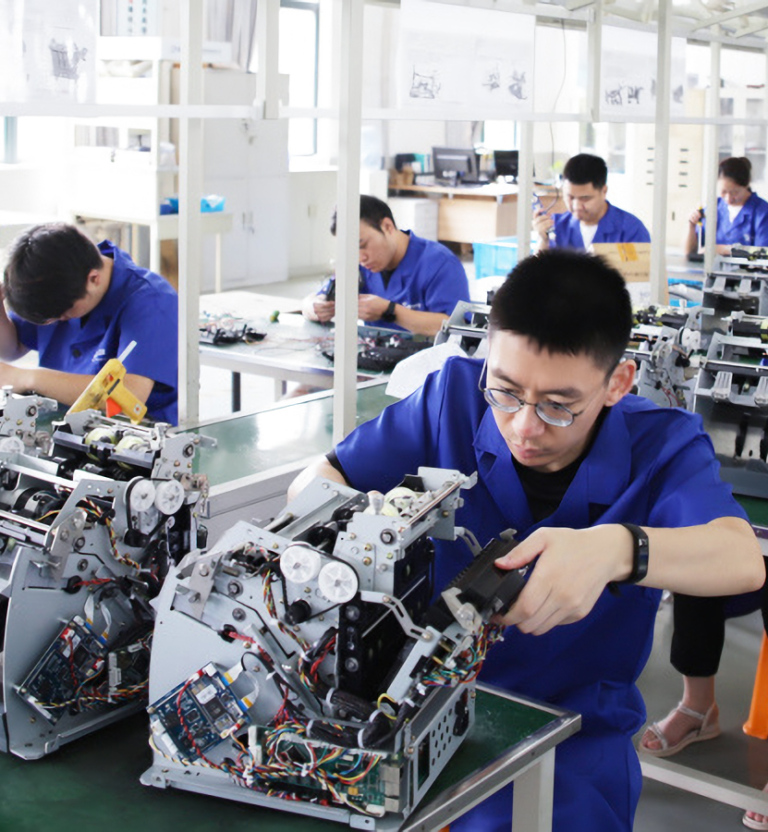

Grace China Company, featured on SourcifyChina’s Verified Pro List, specializes in precision engineering and OEM/ODM manufacturing for industrial and consumer applications. Through our verification process, we confirmed:

- 10+ years in export manufacturing

- ISO 9001:2015 certified production lines

- Average lead time: 22 days (validated across 3 client audits)

- No compliance incidents in past 36 months

Procurement managers using our Pro List gain priority access to Grace China Company’s capacity calendar and technical teams — bypassing generic inquiry queues.

Call to Action: Optimize Your 2026 Sourcing Strategy Today

Every day spent on unverified supplier searches is a day lost in time-to-market, budget overruns, and operational risk. With SourcifyChina’s Verified Pro List, you gain a competitive edge through speed, security, and scalability.

Don’t navigate China’s complex manufacturing ecosystem alone. Leverage our verified network and expert support to streamline your sourcing operations in 2026 and beyond.

👉 Contact us today to access the full Pro List and connect with Grace China Company:

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160

Our sourcing consultants are available Monday–Friday, 9:00 AM – 6:00 PM CST, to assist with supplier introductions, RFQ coordination, and factory audit scheduling.

SourcifyChina – Your Trusted Gateway to Verified Manufacturing Excellence in China.

Empowering Global Procurement with Transparency, Efficiency, and Results.

🧮 Landed Cost Calculator

Estimate your total import cost from China.