The global automotive gasket market size was valued at approximately USD 22.5 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% through 2030, according to Grand View Research. This growth is fueled by rising vehicle production, increased demand for fuel-efficient engines, and the expanding aftermarket for engine repair solutions. As engine reliability becomes a top priority for both OEMs and consumers, head gasket failures remain a common yet critical issue, driving demand for high-performance sealants. With the after-sales automotive chemicals segment gaining momentum, particularly in regions like Asia-Pacific and North America, manufacturers specializing in head gasket sealers are scaling innovation in formula durability and thermal resistance. In this competitive landscape, seven key players have emerged as leaders—combining advanced R&D, proven product efficacy, and strong market presence to dominate the space.

Top 7 Good Head Gasket Sealer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Cometic Gasket

Domain Est. 1996

Website: cometic.com

Key Highlights: Cometic manufactures gaskets and engine sealing solutions for Automotive, Powersport, V-Twin, Marine, and OEM, as well as Remanufactured Engine, Agricultural, ……

#2 Fel-Pro Gaskets

Domain Est. 1998

Website: felpro.com

Key Highlights: Trust Fel-Pro gaskets for innovative sealing solutions for your engine. From gasket sets to rear main seals, we have what you need for that next repair….

#3 Gaskets

Domain Est. 2000

Website: mahle-aftermarket.com

Key Highlights: MAHLE is the only gasket supplier that designed a package enabling a counterperson or technician to either see the actual gaskets inside….

#4 Performance

Domain Est. 2003

Website: gasgacinch.com

Key Highlights: Performance Gasgacinch Gasket Sealer remains flexible and makes it easier to assemble and disassemble the engine or transmission….

#5 Sealant For Coolant, Head Gasket & Radiator Leaks

Domain Est. 2008

Website: kseal.com

Key Highlights: K-Seal is the 1-step solution to permamently repair all engine coolant leaks. Save thousands in garage fees! Over 6 million bottles sold worldwide….

#6 Titan Head Gasket Sealers and Oil Stop Leaks

Domain Est. 2017

Website: titansealers.com

Key Highlights: Titan® Head Gasket Sealers are rated #1 by auto mechanics. We offer Hi-Tech automotive Oil Stop-Leaks, Transmission Sealers and Oil Additives for a wide ……

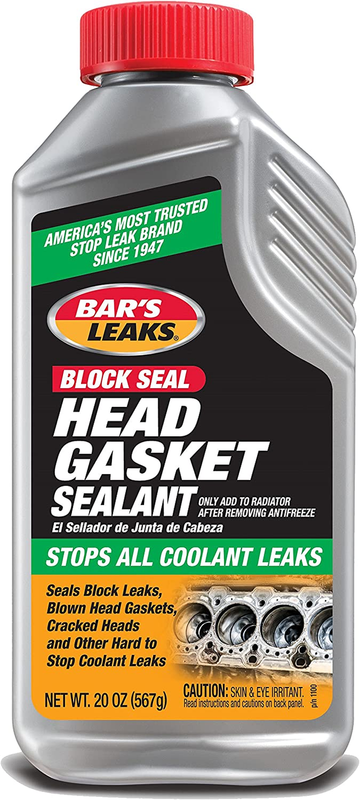

#7 Trust the Leader

Domain Est. 1997

Website: barsleaks.com

Key Highlights: Bar’s Leaks Professional Carbon Fiber Blown Head Gasket Repair is the strongest antifreeze-compatible solution on the market, period. It penetrates a leaking, ……

Expert Sourcing Insights for Good Head Gasket Sealer

H2: Market Trends for Good Head Gasket Sealer in 2026

As the automotive aftermarket continues to evolve, the market for head gasket sealers—particularly high-quality products branded as “Good Head Gasket Sealer”—is expected to experience notable shifts by 2026. Driven by changing vehicle demographics, advancements in engine technology, and consumer preferences, several key trends are shaping the landscape.

-

Rising Demand from Aging Vehicle Fleets

By 2026, the average age of vehicles on the road in North America and Europe is projected to exceed 12 years. Older engines are more prone to head gasket failures due to thermal stress and material fatigue. This aging fleet is a primary driver of demand for reliable, cost-effective repair solutions like head gasket sealers. Consumers increasingly favor temporary or permanent fixes that avoid expensive mechanic bills, boosting market growth for trusted brands. -

Growth in DIY Automotive Maintenance

The do-it-yourself (DIY) automotive repair segment is expanding, supported by accessible online tutorials, e-commerce platforms, and a cultural shift toward self-reliance. Good Head Gasket Sealer benefits from this trend, as it is marketed as an easy-to-use solution requiring no disassembly. By 2026, enhanced digital marketing and step-by-step video guides are expected to further empower consumers, increasing product adoption. -

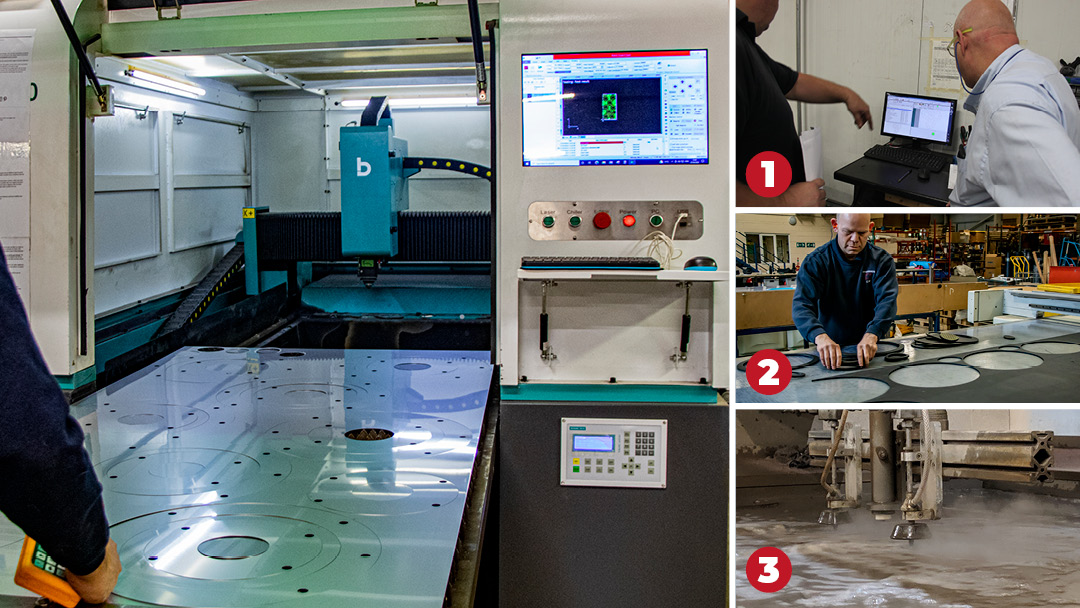

Technological Improvements in Sealer Formulations

Innovation in chemical engineering has led to next-generation sealants with ceramic fibers, sodium silicate compounds, and advanced polymers that withstand higher temperatures and pressures. By 2026, leading brands—including Good Head Gasket Sealer—are likely to offer condition-specific variants (e.g., for aluminum blocks, turbocharged engines) to improve efficacy and broaden market reach. These advanced formulations will differentiate premium products from generic alternatives. -

E-Commerce and Direct-to-Consumer Sales Expansion

Online retail platforms such as Amazon, AutoZone.com, and specialized automotive sites are becoming dominant channels for aftermarket products. By 2026, Good Head Gasket Sealer is expected to leverage targeted advertising, customer reviews, and subscription models to increase visibility and repeat purchases. Direct-to-consumer strategies will allow brands to gather user data and refine product offerings. -

Environmental and Regulatory Considerations

Environmental regulations are pushing automakers toward longer engine life and reduced emissions, indirectly supporting preventive maintenance products. While sealers are not directly regulated, eco-friendly formulations with biodegradable components may gain favor. By 2026, sustainability could become a differentiating factor, with consumers preferring brands that emphasize low environmental impact. -

Competitive Landscape and Brand Positioning

The head gasket sealer market remains crowded, with numerous brands competing on price and performance. Good Head Gasket Sealer is expected to focus on reputation, verified user results, and third-party testing to maintain trust. By 2026, brand authenticity and proven reliability will be critical in retaining market share amid rising competition.

In conclusion, the 2026 market for Good Head Gasket Sealer will be shaped by an aging vehicle base, DIY culture, product innovation, and digital commerce. Companies that invest in performance transparency, customer education, and sustainable practices are best positioned to succeed in this evolving segment.

Common Pitfalls When Sourcing a Good Head Gasket Sealer (Quality and Intellectual Property)

When searching for an effective head gasket sealer, avoiding quality compromises and intellectual property (IP) issues is crucial. Here are the most common pitfalls to watch out for:

Choosing Low-Quality or Ineffective Formulations

Many budget sealers on the market use outdated or subpar ingredients that fail under real-world engine conditions. These often contain simple sodium silicate or particles that clog cooling passages without forming a durable, heat-resistant bond. Poor-quality sealers may provide a temporary fix but typically fail within weeks, leading to repeated damage and more expensive repairs.

Ignoring Temperature and Pressure Resistance Ratings

Engines operate under extreme heat and pressure. A common mistake is selecting a sealer not rated for sustained high temperatures (typically above 250°F / 120°C) or combustion pressures. Using an under-specified product can result in rapid breakdown of the seal, causing coolant leaks, overheating, or even catastrophic engine failure.

Overlooking Compatibility with Coolant Types

Not all sealers are compatible with every coolant chemistry (e.g., OAT, HOAT, traditional green). Using an incompatible product can lead to gel formation, sludge, reduced cooling efficiency, or accelerated corrosion. Always verify compatibility with the existing cooling system to avoid damaging other components.

Falling for Counterfeit or Knockoff Products

The automotive aftermarket is rife with counterfeit sealers that mimic reputable brands. These often lack proper quality control, use inferior raw materials, and may not meet safety or performance standards. Purchasing from unauthorized distributors increases the risk of receiving fake products that compromise engine integrity.

Violating Intellectual Property (IP) Rights

Some manufacturers reverse-engineer proprietary sealant formulas and sell them under generic labels, potentially infringing on patents or trade secrets. Sourcing such products—especially for commercial or resale use—can expose buyers or resellers to legal liability. It’s important to ensure suppliers respect IP rights and offer legitimate, licensed products.

Relying on Misleading Marketing Claims

Aggressive advertising may exaggerate a sealer’s capabilities (e.g., “permanent fix for cracked heads” or “no need to remove head”). These claims can be misleading and set unrealistic expectations. Always verify claims with independent reviews, technical data sheets, and manufacturer certifications.

Skipping Proper Application and Pre-Cleaning Procedures

Even high-quality sealers fail if the system isn’t properly flushed and prepared. Residual oil, debris, or old sealer can prevent proper adhesion. Assuming the product will work “as-is” without following the manufacturer’s prep and usage instructions is a frequent cause of failure.

Purchasing from Unverified or Non-Specialist Suppliers

Buying from general marketplaces or non-specialist vendors increases the risk of receiving expired, stored improperly, or tampered-with products. Stick to reputable automotive suppliers or authorized dealers who maintain proper storage conditions and offer traceable product batches.

Avoiding these pitfalls ensures you invest in a reliable, legally compliant head gasket sealer that delivers both performance and peace of mind.

Logistics & Compliance Guide for Good Head Gasket Sealer

Product Overview

Good Head Gasket Sealer is a specialized automotive chemical product designed to repair and seal leaks in engine head gaskets. It is formulated to withstand high temperatures and pressures within internal combustion engines. As a chemical-based automotive additive, proper handling, storage, transportation, and regulatory compliance are essential.

Regulatory Classification

Good Head Gasket Sealer is typically classified as a hazardous material due to its chemical composition, which may include sealants, solvents, and proprietary additives. It may fall under the following regulatory categories:

– UN Number: UN 1993 (Flammable liquid, n.o.s.) – if flammable components exceed thresholds.

– Hazard Class: Class 3 – Flammable Liquids (if applicable).

– Packing Group: II or III, depending on flash point and volatility.

Always refer to the Safety Data Sheet (SDS) for the specific product batch to confirm classification.

Safety Data Sheet (SDS) Compliance

- Maintain up-to-date SDS for Good Head Gasket Sealer in accordance with OSHA (U.S.) or equivalent regulations (e.g., CLP/GHS in EU, WHMIS in Canada).

- Ensure SDS is accessible to all handlers, transporters, and emergency responders.

- The SDS must include information on:

- Hazard identification

- Composition and ingredients

- First-aid and firefighting measures

- Handling and storage

- Exposure controls and PPE

- Regulatory information

Packaging & Labeling Requirements

- Use UN-certified packaging designed for flammable or hazardous liquids.

- Ensure containers are leak-proof, tightly sealed, and compatible with chemical contents.

- Label all packages with:

- Proper shipping name (e.g., “Flammable Liquid, n.o.s.”)

- UN number

- Hazard class label (e.g., Class 3 flammable liquid)

- GHS pictograms (if applicable)

- Manufacturer/importer contact information

- Net quantity

Storage Guidelines

- Store in a cool, dry, well-ventilated area away from direct sunlight and heat sources.

- Keep away from open flames, sparks, and oxidizing agents.

- Use designated flammable storage cabinets if required by local fire codes.

- Maintain storage temperature between 40°F (4°C) and 100°F (38°C).

- Ensure secondary containment is in place to prevent environmental contamination in case of leaks.

Transportation & Shipping

- Domestic (U.S.): Comply with Department of Transportation (DOT) regulations under 49 CFR.

- International: Follow IATA (air), IMDG (sea), or ADR (road in Europe) as applicable.

- Required documentation:

- Shipper’s Declaration for Dangerous Goods (if shipping in regulated quantities)

- Properly completed Bill of Lading

- SDS accompanying the shipment

- Segregate from incompatible materials (e.g., strong oxidizers, acids).

- Use spill kits and fire extinguishers on transport vehicles when required.

Import & Export Compliance

- Verify customs classification (HTS code) for Good Head Gasket Sealer (typically under 3819.00 for prepared additives).

- Obtain necessary import/export licenses if required by destination country.

- Comply with REACH (EU), TSCA (U.S.), or other chemical control regulations.

- Ensure all foreign language labeling (e.g., in Canada, EU) meets local requirements.

Environmental & Disposal Compliance

- Do not dispose of down drains or in regular trash.

- Follow RCRA (U.S.) or local hazardous waste regulations for disposal.

- Used or spilled product must be collected using absorbent materials and disposed of via licensed hazardous waste handlers.

- Report significant spills to appropriate environmental authorities per local mandates (e.g., EPA, Environment Canada).

Worker Safety & Training

- Train employees in:

- Hazard communication (HazCom)

- Proper handling and PPE use (gloves, goggles, ventilation)

- Emergency response procedures

- Conduct routine safety drills and maintain training records.

- Provide appropriate personal protective equipment (PPE) such as nitrile gloves, safety goggles, and respirators if vapor exposure is possible.

Incident Response & Emergency Procedures

- In case of spill:

- Contain with absorbent materials

- Ventilate area

- Avoid ignition sources

- In case of fire: Use dry chemical, CO₂, or foam extinguishers. Water may be ineffective.

- In case of exposure:

- Skin contact: Wash with soap and water

- Eye contact: Flush with water for 15 minutes; seek medical attention

- Inhalation: Move to fresh air

- Post emergency contact numbers and maintain spill kits in storage/transport areas.

Recordkeeping & Audits

- Maintain records of:

- SDS versions and distribution

- Training logs

- Shipping documents

- Incident reports

- Waste disposal manifests

- Conduct periodic internal audits to ensure compliance with all applicable regulations.

Conclusion

Compliance with logistics and regulatory standards for Good Head Gasket Sealer is critical to ensuring safety, avoiding fines, and protecting the environment. Always refer to the latest product-specific SDS and consult with regulatory experts when shipping or storing hazardous materials. Regular training, proper documentation, and adherence to international and local regulations will support a compliant and safe operation.

In conclusion, sourcing a good head gasket sealer requires careful consideration of several key factors including the severity of the leak, compatibility with your engine type and coolant system, the sealer’s formulation (e.g., sodium silicate-based or pure cerametic), and whether a permanent or temporary fix is needed. Reading customer reviews, consulting mechanic recommendations, and choosing reputable brands such as Alumaseal, Bar’s Leaks, or K-Seal can significantly improve your chances of success. Additionally, proper engine preparation and adherence to application instructions are crucial for effective results. While a quality head gasket sealer can be a cost-effective and time-saving solution for minor leaks, it is not a substitute for professional repair in cases of severe engine damage. Ultimately, the right choice balances performance, reliability, and value—providing a dependable interim fix or long-term seal when used appropriately.