The global glass kiln market is experiencing steady expansion, driven by rising demand in specialty glass production, craft manufacturing, and emerging applications in research and development. According to Mordor Intelligence, the global kiln market size was valued at USD 1.45 billion in 2023 and is projected to grow at a CAGR of 6.8% from 2024 to 2029, with increasing adoption of energy-efficient and compact kilns in small-scale and laboratory settings fueling innovation. A key trend within this growth is the rising popularity of microwave-compatible glass kilns, which offer faster heating cycles, improved temperature control, and reduced energy consumption compared to traditional models. As demand intensifies across art studios, educational institutions, and precision manufacturing, manufacturers are investing in advanced technologies to meet the need for reliability and consistency. This data-driven shift has given rise to a competitive landscape of innovators specializing in microwave glass kilns. Below, we examine the top 8 manufacturers leading this niche with proven performance, technical excellence, and strong market presence.

Top 8 Glass Kiln For Microwave Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Glass Kilns

Domain Est. 1997

Website: edhoy.com

Key Highlights: 4-day delivery 30-day returnsWe carry a variety of models, including glass fusing kilns, vitrigraph kilns and small kilns for jewelry making, from leading manufacturers such as Eve…

#2 Microwave Kiln

Domain Est. 2000

Website: dimosaico.com

Key Highlights: Fuse Glass Right in Your Microwave! Now you can create custom kiln-fired art without having to invest in a large kiln. Best of all, it works extremely fast….

#3 Glass Fusing

Domain Est. 2001

Website: paragonkilns.com

Key Highlights: Free delivery over $75 30-day returnsFusion 17 Bottle Slump Electric Kiln. Regular price From $2,475.00. Regular price $2,750.00 Sale price From $2,475.00. Save 10%. Unit price / p…

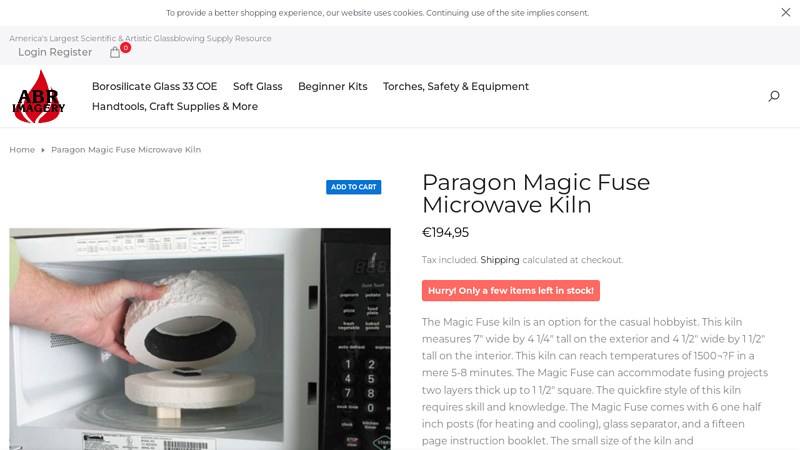

#4 Paragon Magic Fuse Microwave Kiln

Domain Est. 2002

Website: abrimagery.com

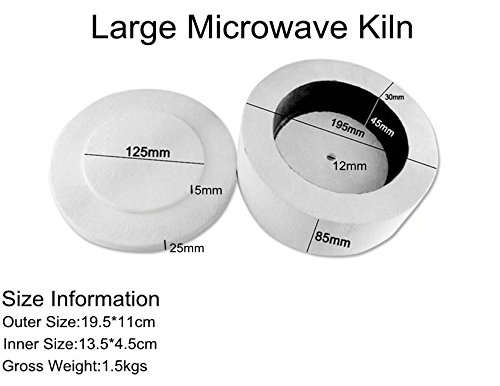

Key Highlights: The Magic Fuse kiln is an option for the casual hobbyist. This kiln measures 7″ wide by 4 1/4″ tall on the exterior and 4 1/2″ wide by 1 1/2″ tall on the ……

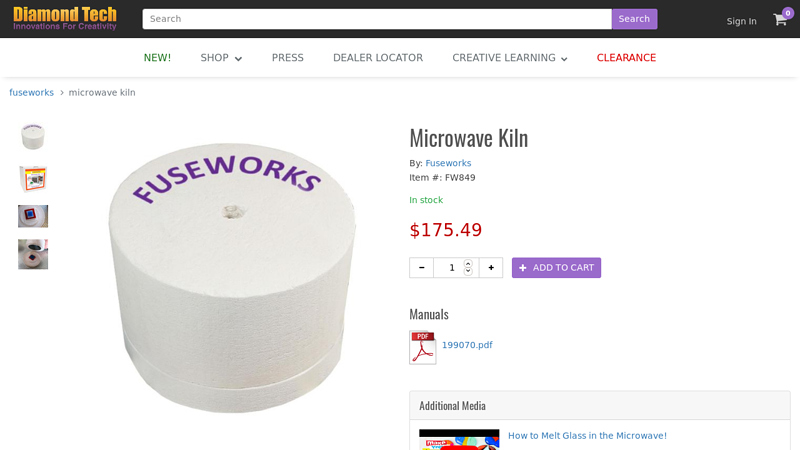

#5 Microwave Kiln

Domain Est. 2004

#6 MICROWAVE KILN 3 BRANDS 3 SIZES FUSEWORKS MAGICFUSE …

Domain Est. 2007

Website: microwave-kiln.com

Key Highlights: We carry microwave kilns in 3 sizes: small, medium and large. Microwave kilns are “containers kilns” which are placed in a microwave oven….

#7 Microwave Kiln Kit, 10pcs, DIY Glass Fusing Tools Accessories…

Domain Est. 2012

Website: sensorhaus.com

Key Highlights: Extra Large Microwave Kiln Kit 15 Piece Set For DIY Jewelry Making Tools Microwave Kiln Glass Kits Offer A Compact, Safe, And Energy-efficient Solution For ……

#8 FW849

Domain Est. 2016

Website: swartglass.com

Key Highlights: In stock Rating 2.0 2 Fuseworks Microwave kiln is lined with a high tech composite material especially formulated to fuse glass in a home microwave 800 watts – 1200 watts….

Expert Sourcing Insights for Glass Kiln For Microwave

H2: 2026 Market Trends for Glass Kilns for Microwave

The global market for glass kilns designed specifically for microwave applications is poised for notable transformation by 2026, driven by advancements in materials science, growing demand for energy-efficient manufacturing, and increasing applications in research, dentistry, and small-scale artisan production. These specialized kilns leverage microwave energy to heat glass materials more uniformly and rapidly than conventional electric or gas kilns, offering distinct advantages in precision and throughput.

One of the key trends shaping the 2026 landscape is the integration of smart technology and automation. Manufacturers are increasingly incorporating IoT-enabled sensors, real-time monitoring systems, and AI-driven temperature control algorithms into microwave glass kilns. This enables users to achieve highly consistent results, reduce thermal stress on glass, and minimize energy consumption—critical factors for both industrial and laboratory environments.

Another significant trend is the expansion of applications beyond traditional glass fusing and slumping. By 2026, microwave glass kilns are expected to see increased adoption in the dental and medical device sectors, where precise sintering of ceramic and glass-ceramic materials is essential. The ability of microwave kilns to deliver rapid, targeted heating supports the production of dental crowns, implants, and lab-on-a-chip devices with improved structural integrity and reduced processing time.

Sustainability is also a growing driver. As industries move toward low-carbon manufacturing, microwave kilns offer a compelling alternative due to their higher energy efficiency and shorter processing cycles. Compared to conventional kilns, microwave systems can reduce energy usage by up to 50%, aligning with global environmental regulations and corporate sustainability goals.

Geographically, the Asia-Pacific region is anticipated to lead market growth by 2026, fueled by rising investments in advanced manufacturing, increased R&D activities in materials engineering, and a burgeoning artisan glass industry in countries like China, Japan, and South Korea. North America and Europe will maintain strong demand, particularly in academic and high-tech industrial research labs.

Finally, market consolidation and innovation are expected as major industrial heating equipment manufacturers partner with microwave technology specialists to develop hybrid systems. These next-generation kilns will likely offer dual-mode capabilities (microwave and conventional heating), enhancing versatility and broadening the range of compatible glass types and thicknesses.

In summary, by 2026, the glass kiln for microwave market will be characterized by technological sophistication, diversified applications, and a strong emphasis on efficiency and sustainability, positioning it as a niche yet rapidly evolving segment within the broader thermal processing industry.

Common Pitfalls When Sourcing a Glass Kiln for Microwave (Quality and Intellectual Property)

Sourcing a glass kiln designed for microwave use—often a DIY or small-scale innovation—presents unique challenges, especially concerning quality consistency and intellectual property (IP) risks. Being aware of these pitfalls can help avoid costly mistakes and potential legal issues.

Poor Material Quality and Inconsistent Performance

One of the most frequent issues is encountering substandard materials that compromise both safety and functionality. Many suppliers, particularly on online marketplaces, offer kiln kits or components made from low-grade refractory ceramics or insulating materials that cannot withstand repeated thermal cycling. This leads to cracking, reduced efficiency, or even hazardous failures during microwave operation. Inconsistent thickness or poor craftsmanship in the construction of the kiln chamber can also result in uneven heating, hotspots, and failed glass fusing projects.

Lack of Safety Certification and Testing

Microwave glass kilns operate under intense thermal and electromagnetic conditions, making safety paramount. A significant pitfall is sourcing products without proper testing or certification. Many available kilns—especially those from informal manufacturers—are not tested for microwave compatibility, which can lead to arcing, fire hazards, or damage to the microwave oven. Reputable suppliers should provide evidence of thermal stability tests, non-toxic material composition, and compatibility with standard microwave frequencies (typically 2.45 GHz).

Inadequate Thermal Insulation and Energy Efficiency

Low-quality kilns often feature insufficient insulation, leading to excessive heat loss, prolonged heating times, and higher energy consumption. Poor insulation not only reduces efficiency but can also pose burn risks due to high external surface temperatures. Buyers may assume all kilns perform similarly, but the difference in insulation quality—such as the use of ceramic fiber versus cheaper alternatives—greatly affects performance and safety.

Intellectual Property Infringement Risks

Many DIY microwave kiln designs circulate online under open-source or creative commons licenses, but some commercial vendors repackage and sell these designs without proper attribution or licensing. Sourcing from such vendors may inadvertently support IP violations. For example, a popular layered ceramic design originally shared by a hobbyist or educator might be mass-produced and sold without permission. Buyers should verify whether the product design respects original creators’ rights, especially if used commercially.

Misleading Marketing and Exaggerated Claims

Suppliers may overstate the capabilities of their kilns—such as maximum achievable temperatures, compatibility with all microwave models, or durability—without providing verifiable data. Claims like “fuses glass in 5 minutes” may only apply under ideal conditions with high-wattage microwaves, leading to customer dissatisfaction. Transparent specifications, user reviews, and third-party testing are crucial to validate such claims.

Limited After-Sales Support and Warranty

Many microwave kiln suppliers—particularly small or overseas vendors—offer little to no customer support or warranty. If a kiln arrives damaged or fails prematurely, recourse may be limited. Lack of technical guidance on proper usage or troubleshooting can also hinder effective operation, especially for beginners.

Conclusion

To avoid these pitfalls, buyers should prioritize suppliers with transparent manufacturing practices, verifiable safety testing, and respect for intellectual property. Researching the origin of the design, reading independent reviews, and seeking products with documented performance data can significantly reduce risks associated with quality and IP when sourcing a microwave glass kiln.

Logistics & Compliance Guide for Glass Kiln For Microwave

Product Classification and HS Code

Identify the correct Harmonized System (HS) code for international shipping. For a microwave-sized glass kiln, the most applicable HS code is typically 8514.40 (Electro-thermic appliances for industrial or laboratory use, including induction or dielectric heating equipment). However, verify with local customs authorities, as classification may vary by country depending on power rating, intended use (industrial vs. hobby), and design. Accurate classification ensures proper tariff application and regulatory compliance.

Import Regulations and Permits

Review destination country regulations for electrical heating devices. Some countries require import permits, pre-shipment inspections, or conformity assessments. For example, the European Union mandates CE marking under the Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive. In the U.S., compliance with FCC regulations for electromagnetic interference and adherence to UL/ETL safety standards may be required. Confirm whether the glass kiln is subject to energy efficiency standards or restricted substance regulations (e.g., RoHS).

Packaging and Shipping Requirements

Use robust, shock-resistant packaging with internal cushioning to protect fragile components (e.g., heating elements, thermocouples). Clearly label packages with “Fragile,” “This Side Up,” and “Do Not Stack” indicators. Ensure packaging meets International Safe Transit Association (ISTA) standards for vibration, drop, and compression testing. Include user manuals and safety documentation in the local language of the destination country. Avoid hazardous materials in packaging to comply with international shipping standards.

Voltage and Plug Compatibility

Verify electrical specifications (voltage, frequency, plug type) match the destination market. Most microwave-sized glass kilns operate on 120V or 230V. Include appropriate power cords or recommend compatible adapters. Devices shipped to regions with differing voltage standards must either support dual voltage or be clearly labeled for use with transformers. Non-compliant voltage configurations may lead to product rejection or safety hazards.

Safety and Environmental Compliance

Ensure the kiln complies with safety standards such as IEC 60335 (household and similar electrical appliances) or IEC 61010 (laboratory equipment). Confirm absence of hazardous materials per RoHS (Restriction of Hazardous Substances) in the EU or similar regulations in other regions. Provide a Declaration of Conformity (DoC) with each unit. For lithium battery components (if any, e.g., in digital controllers), follow IATA Dangerous Goods Regulations for air transport.

Documentation for Customs Clearance

Prepare complete shipping documentation, including commercial invoice, packing list, bill of lading/air waybill, and certificates of compliance (e.g., CE, FCC, RoHS). The commercial invoice must detail product description, HS code, value, country of origin, and buyer/seller information. Inaccurate or incomplete documentation can cause delays, fines, or shipment rejection.

Insurance and Liability

Obtain cargo insurance covering loss, damage, or delay during transit. Clarify liability terms with freight forwarders, especially for high-value or fragile items. Include warnings in product literature about proper installation, ventilation, and operational safety to mitigate post-sale liability risks.

End-of-Life and Recycling Compliance

Provide information on proper disposal and recycling in accordance with WEEE (Waste Electrical and Electronic Equipment) directives where applicable. Include take-back instructions or local recycling options in user manuals to support environmental compliance and corporate responsibility.

Conclusion: Sourcing a Glass Kiln for Microwave Applications

Sourcing a glass kiln suitable for microwave applications requires careful consideration of technical compatibility, material safety, and operational efficiency. While traditional glass kilns are not designed for use with microwave technology, specialized microwave-assisted hybrid heating systems do exist and offer promising advantages such as faster heating, energy efficiency, and improved temperature uniformity in specific glassworking processes.

When sourcing equipment, it is critical to verify whether the intended application involves a conventional kiln used alongside microwave tools or a true microwave-responsive kiln system. Suppliers should be evaluated based on expertise in microwave-compatible materials (e.g., susceptors, insulating ceramics), temperature control precision, and safety certifications.

In conclusion, while microwave-specific glass kilns are not standard in most studios or industrial settings, innovative hybrid solutions are emerging. Successful sourcing depends on clearly defining the application, consulting with technical specialists, and selecting suppliers with proven experience in microwave thermal processing. For most users, a conventional kiln remains the practical choice, but for advanced R&D or specialized manufacturing, investing in microwave-compatible systems may offer long-term benefits in efficiency and process control.