The global glassware market is experiencing steady expansion, driven by rising demand in artisanal craftsmanship, architectural design, and specialty consumer products. According to Grand View Research, the global glass container market size was valued at USD 76.7 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 4.3% from 2024 to 2030. With the resurgence of handcrafted glass art and increasing interest in customized glass products, the demand for precision glass blowing molds has climbed proportionally. This growth is further amplified by advancements in mold materials and manufacturing techniques, enabling higher durability and intricate design capabilities. As the foundation of consistent, repeatable glass forming, high-quality molds are now more critical than ever. In this evolving landscape, identifying leading manufacturers with technical expertise, innovation, and global reach becomes essential for artisans, studios, and industrial producers alike. Here’s a data-informed look at the top nine glass blowing mold manufacturers shaping the industry.

Top 9 Glass Blowing Molds Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Farlows Scientific Glass Blowing

Domain Est. 1997

Website: farlowsci.com

Key Highlights: Farlow’s Scientific Glassware creates high-quality glass parts for industrial applications including medical, aquaculture, environmental testing and more….

#2 BF SIGNORETTI

Domain Est. 2020

Website: bfsignoretti.com

Key Highlights: BF SIGNORETTI Glass factory leader in the production and sale of artistic Murano glass. Chandeliers, Mirrors, Vases, Sculptures, custom-made creations….

#3 Molds & Mold Mix

Domain Est. 1997

Website: glasscolor.com

Key Highlights: American Pint Glass Mold – Graphite. BH-M-PINT-G American Pint Glass Mold – Graphite. From $1,584.00. Size… Hot Pop Mold, Punty Mold. – +….

#4 Make Your Own Glass

Domain Est. 1998

Website: glassmaking.cmog.org

Key Highlights: From hot glassworking to fusing, engraving and sandblasting, you and your family can do just about anything with glass—with the help of our experienced ……

#5 MOULD STUFF

Domain Est. 2000

Website: blenko.com

Key Highlights: 6–7 day delivery 30-day returnsApr 15, 2024 · We have always made our handmade, handcrafted and designed glass using moulds of one type or another – that’s the key to making simila…

#6 Mountain Glass Arts

Domain Est. 2002

Website: mountainglass.com

Key Highlights: Shop the largest selection of lampworking supplies, torches, tools & equipment. Borosilicate lampwork & Soft Glass beadmaking. Same Day Shipping Worldwide….

#7 Slumpy’s

Domain Est. 2005

Website: slumpys.com

Key Highlights: Welcome to Slumpy’s, the Glass Mold Company. More than just offering glass slump molds, we offer warm glass, glass tools, and warm glass supplies….

#8 Mold Blowing

Domain Est. 2016

Website: doughertyglassworks.com

Key Highlights: A detailed look at the art of glassblowing, where hands skillfully shape a glowing molten glass piece with tongs over a wooden mold….

#9 The Glass Foundry

Domain Est. 2019

Website: theglassfoundry.co.uk

Key Highlights: We offer bespoke collaboration in design, handmade manufacture & installation. Services include mould making, lost wax casting, glassblowing, fusing, slumping…

Expert Sourcing Insights for Glass Blowing Molds

H2: 2026 Market Trends for Glass Blowing Molds

The global market for glass blowing molds is poised for notable transformation by 2026, driven by technological advancements, increasing demand in artistic and industrial applications, and a growing emphasis on sustainable manufacturing. This analysis explores key trends shaping the glass blowing molds industry through 2026.

1. Rising Demand in Artisanal and Studio Glass Sectors

The resurgence of handmade and artisanal glassware continues to fuel demand for high-quality, customizable glass blowing molds. Artists and small studios are increasingly investing in precision-engineered molds to achieve complex designs and consistent results. By 2026, this segment is expected to account for a significant share of the mold market, particularly in North America and Europe, where craft-based economies are thriving.

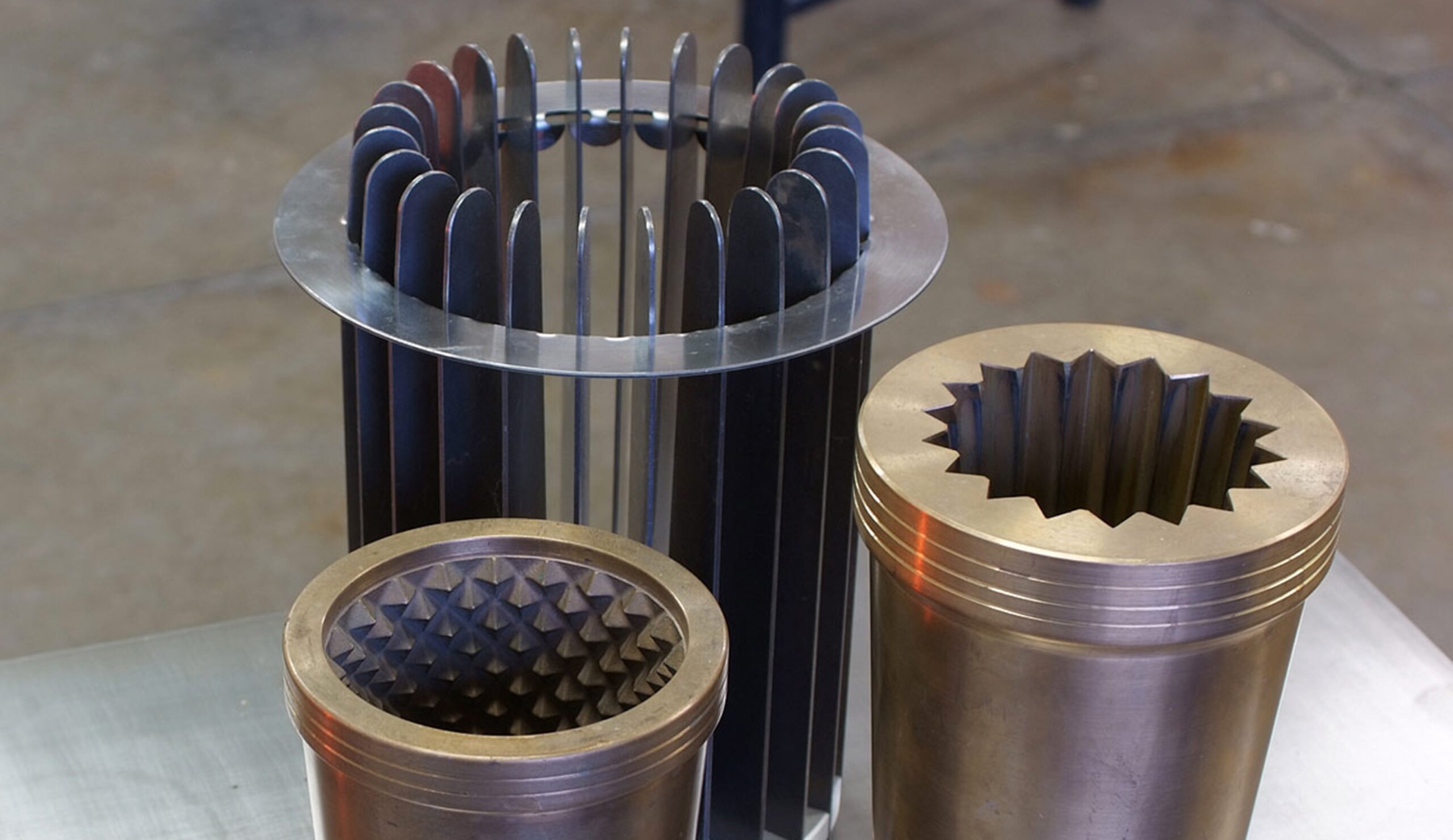

2. Adoption of Advanced Materials and Coatings

Manufacturers are transitioning from traditional steel molds to those made with advanced alloys and composite materials that offer improved heat resistance, durability, and surface finish. Innovations such as ceramic-coated and graphite-embedded molds are gaining traction due to their ability to reduce thermal shock and extend mold life. These enhancements are expected to lower long-term production costs and support high-volume manufacturing applications.

3. Integration of 3D Printing and Digital Design

Digital fabrication technologies, especially 3D printing, are revolutionizing mold production. By 2026, more glass artisans and industrial producers will leverage CAD-designed and 3D-printed sacrificial or prototype molds for rapid prototyping and custom shapes. This trend enables faster design iterations and lower entry barriers for small-scale producers.

4. Growth in Industrial and Architectural Applications

Beyond decorative art, the demand for glass blowing molds is expanding in industrial sectors such as lighting, optics, and architectural glass. Custom molds are increasingly used to produce complex glass components for LED fixtures, laboratory equipment, and building facades. The push for energy-efficient and aesthetically distinctive buildings is accelerating this trend, particularly in Asia-Pacific and the Middle East.

5. Sustainability and Circular Manufacturing Practices

Environmental regulations and consumer preferences are pushing manufacturers to adopt eco-friendly practices. By 2026, recyclable mold materials and energy-efficient mold heating systems will become standard. Additionally, closed-loop systems that reuse mold components and reduce waste are expected to gain prominence, especially in Europe where circular economy principles are strongly enforced.

6. Regional Market Shifts and Supply Chain Resilience

While North America and Europe remain dominant in the high-end mold market, Asia-Pacific—particularly China and India—is emerging as a hub for both mold production and consumption. Local manufacturing capabilities are improving, reducing reliance on imports. Companies are also diversifying supply chains to mitigate geopolitical and logistical risks, a trend accelerated by recent global disruptions.

7. Increased Focus on Automation and Smart Molds

The integration of IoT-enabled sensors and automation in mold systems is on the rise. Smart molds with real-time temperature and pressure monitoring will enhance production consistency and reduce defect rates. By 2026, automated mold handling systems are expected to become more common in large-scale glass manufacturing facilities, boosting productivity and reducing labor costs.

In conclusion, the glass blowing molds market in 2026 will be characterized by innovation, customization, and sustainability. As both artistic and industrial sectors evolve, mold manufacturers that embrace digital tools, advanced materials, and eco-conscious practices will be best positioned for growth.

Common Pitfalls When Sourcing Glass Blowing Molds: Quality and Intellectual Property Risks

Sourcing glass blowing molds, whether for artistic, industrial, or commercial production, involves navigating several potential pitfalls. Two of the most critical areas are ensuring consistent quality and protecting intellectual property (IP). Overlooking these aspects can lead to production delays, financial loss, legal disputes, and reputational damage.

Quality-Related Pitfalls

Inconsistent Material Composition and Durability

Not all molds are created equal. A common issue is sourcing molds made from substandard materials—such as low-grade steel, improperly treated cast iron, or inferior graphite—that degrade quickly under high temperatures and repeated thermal cycling. Poor material quality leads to warping, cracking, or surface pitting, which directly impacts the finish and dimensional accuracy of the blown glass. Buyers may unknowingly receive molds that fail after only a few uses, increasing long-term costs and downtime.

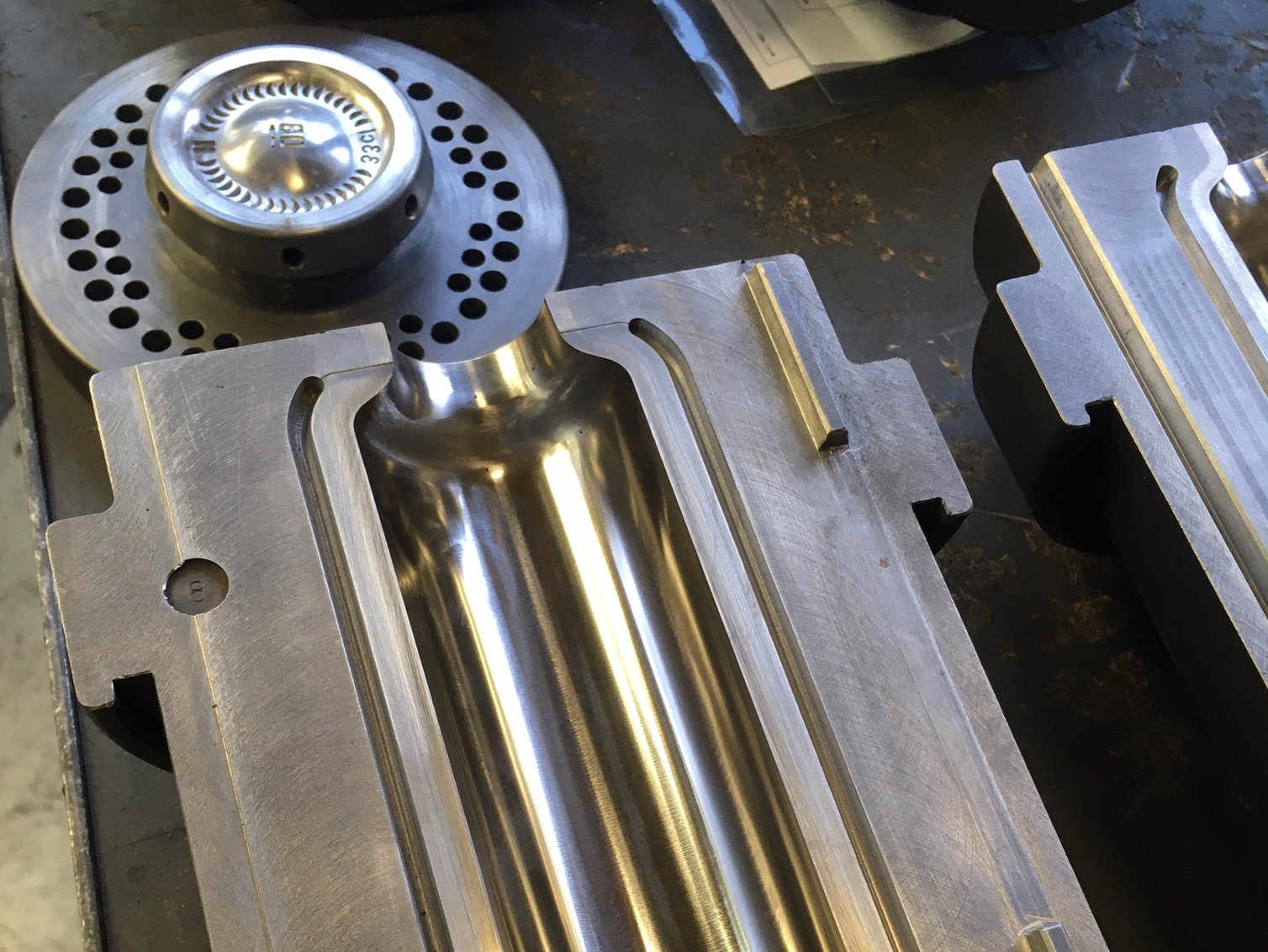

Poor Precision in Machining or Casting

Even with high-quality materials, imprecise manufacturing processes can ruin a mold’s functionality. Tolerances matter: uneven cavity walls, misaligned parts, or inaccurate dimensions result in glass pieces that are distorted, difficult to remove, or require excessive post-processing. This is especially problematic when replicating intricate designs or when molds must be interchangeable across production runs.

Inadequate Surface Finish

The interior surface of a glass blowing mold must be smooth and properly polished to allow easy release of molten glass and to ensure a clean aesthetic finish. Molds with rough, pitted, or poorly finished interiors can cause glass to stick, leading to breakage or surface defects. Some suppliers cut corners on finishing to reduce costs, compromising performance.

Lack of Proper Heat Treatment

Molds must undergo appropriate heat treatment (such as annealing or tempering) to relieve internal stresses and enhance thermal shock resistance. Skipping or improperly applying this process can result in premature cracking or failure during use, particularly in molds subjected to rapid temperature changes.

Intellectual Property-Related Pitfalls

Unintentional Infringement of Protected Designs

Glass mold designs—especially complex or artistic shapes—may be protected by copyrights, design patents, or trade dress rights. Sourcing molds from suppliers who replicate proprietary designs without authorization exposes the buyer to legal liability. Even if the buyer is unaware, courts may hold them accountable for using infringing tools in commercial production.

Lack of IP Clarity in Custom Mold Development

When commissioning custom molds, many buyers assume they automatically own the resulting design or tooling. However, without a clear contract specifying IP ownership, the mold maker may retain rights to reproduce and sell the design to competitors. This undermines exclusivity and can erode market advantage, particularly for unique product lines.

Reverse Engineering Risks

Some overseas or low-cost suppliers may reverse-engineer popular molds and offer “compatible” versions at lower prices. While this might seem like a cost-saving measure, these molds often infringe on existing IP and may also suffer from quality compromises. Using them can lead to cease-and-desist letters, product recalls, or litigation.

Insufficient Documentation and Traceability

Reputable suppliers provide detailed documentation, including material certifications, design files, and IP disclaimers. Sourcing from vendors who offer little or no documentation increases the risk of unknowingly acquiring infringing or substandard molds. This lack of traceability also complicates quality control and regulatory compliance, especially in commercial manufacturing settings.

Mitigation Strategies

To avoid these pitfalls, buyers should:

– Vet suppliers thoroughly, requesting samples and references.

– Specify material grades, tolerances, and surface finishes in contracts.

– Conduct IP due diligence when using third-party designs.

– Use written agreements that clearly assign IP rights for custom molds.

– Work with reputable manufacturers who respect IP laws and provide full traceability.

By proactively addressing quality and IP concerns, glass artisans and manufacturers can ensure reliable production and protect their creative and commercial investments.

Logistics & Compliance Guide for Glass Blowing Molds

Glass blowing molds are specialized tools used in the creation of artistic and functional glassware. Due to their materials (typically steel, graphite, or wood), weight, and international trade implications, shipping and handling them requires careful attention to logistics and regulatory compliance. This guide outlines key considerations for safe, efficient, and compliant transportation.

Classification and Harmonized System (HS) Codes

Accurate classification is essential for customs clearance and duty determination. Glass blowing molds generally fall under the following HS categories:

- 8207: Tools for working in the hand, whether or not power-operated, with interchangeable working parts; interchangeable tools for tools of heading 8205.

- More specifically: 8207.40 – Molds for glass.

- 7326: Other articles of iron or steel (if made primarily of steel and not fitting under 8207).

- 4415: Packing cases, boxes, crates, and similar articles, when used for export (for packaging).

Always verify the exact HS code with a certified customs broker, as classification may depend on material composition, design, and country of destination.

Export Controls and Permits

Most glass blowing molds are not subject to strict export controls, but the following checks are recommended:

- Dual-Use Considerations: While uncommon, molds with advanced engineering or precision tolerances could theoretically fall under dual-use regulations (e.g., items that could be used in defense or strategic industries). Confirm with national export control authorities if in doubt.

- Country-Specific Restrictions: Some countries restrict imports of industrial tools or machinery. Verify import policies in the destination country.

- No Standard Export License Required: In most cases (e.g., U.S. Department of Commerce), simple molds do not require an export license unless destined for embargoed countries (e.g., Iran, North Korea).

Packaging and Handling Requirements

Due to weight and fragility (especially graphite or wooden components), proper packaging is critical:

- Material Protection: Wrap molds in anti-corrosive paper or VCI (Vapor Corrosion Inhibitor) film if made of steel to prevent rust.

- Secure Crating: Use sturdy wooden crates with internal bracing to prevent movement during transit. Label crates with “Fragile,” “This Side Up,” and “Heavy.”

- Weight Distribution: Balance heavy molds to avoid tipping and ensure safe lifting.

- Moisture Control: Include desiccant packs in sealed crates, especially for ocean freight.

Shipping Methods and Freight Considerations

Choose the appropriate method based on urgency, cost, and destination:

- Air Freight: Recommended for small, high-value, or urgent shipments. Faster but more expensive. Comply with IATA regulations for packaging.

- Ocean Freight (FCL/LCL): Cost-effective for large or heavy shipments. Use full container load (FCL) for large orders or less than container load (LCL) for smaller volumes. Allow 4–8 weeks for transit.

- Ground Transport: Suitable for domestic or regional shipping within continents (e.g., U.S. or EU). Use palletized freight with lift gate service if needed.

Import Duties and Taxes

Understand financial obligations in the destination country:

- Duty Rates: Vary by country; typically range from 0% to 8% for molds under HS 8207.40.

- VAT/GST: Most countries apply value-added tax (e.g., 20% in the UK, 10% in Japan). The importer usually pays this upon arrival.

- Customs Brokerage: Engage a local customs broker to handle clearance, documentation, and duty payment.

Required Documentation

Ensure all paperwork is accurate and complete:

- Commercial Invoice: Details seller, buyer, description of goods, quantity, value, currency, and Incoterms® (e.g., FOB, DDP).

- Packing List: Itemizes contents, weights, dimensions, and packaging type per crate.

- Bill of Lading (B/L) or Air Waybill (AWB): Issued by carrier; serves as receipt and contract of carriage.

- Certificate of Origin: May be required to claim preferential tariffs under trade agreements (e.g., USMCA, EU agreements).

- Dangerous Goods Declaration (if applicable): Not typically required unless shipping graphite dust or flammable components.

Incoterms® Guidance

Select appropriate Incoterms® to define responsibilities:

- FOB (Free On Board): Seller delivers to port; buyer handles main carriage and import. Common for ocean freight.

- EXW (Ex Works): Buyer assumes all risk and cost from seller’s facility. Use when buyer has logistics control.

- DDP (Delivered Duty Paid): Seller manages all logistics and pays import duties. Best for customer convenience but higher risk/cost for seller.

Special Considerations for Materials

- Graphite Molds: Non-toxic but can generate fine dust. Package securely to contain debris. No hazardous material classification under UN/DOT unless powdered.

- Wooden Molds or Crates: May require ISPM 15 certification (heat-treated and stamped) for international shipping to prevent pest spread.

- Steel Molds: Susceptible to corrosion; use rust protection and sealed packaging.

Compliance with International Standards

- ISO Standards: While no specific ISO standard governs molds, general industrial safety and packaging standards (e.g., ISO 1610:2017 for packaging) may apply.

- REACH & RoHS (EU): Not typically applicable unless molds contain restricted substances (e.g., certain coatings or platings). Verify if applicable.

Best Practices Summary

- Always verify HS codes with a customs expert.

- Use robust, climate-appropriate packaging.

- Choose Incoterms® that align with your risk tolerance and customer expectations.

- Work with experienced freight forwarders familiar with industrial tool shipments.

- Retain records for at least 5 years for audit purposes.

By following this guide, manufacturers, artisans, and distributors can ensure the reliable and compliant global movement of glass blowing molds.

In conclusion, sourcing glass blowing molds requires careful consideration of material quality, mold design, compatibility with your glassworking techniques, and the reputation of suppliers. Whether opting for ceramic, steel, or graphite molds, it is essential to prioritize durability, precision, and heat resistance to ensure consistent and high-quality results. Exploring both local artisans and international manufacturers can provide access to custom solutions and cost-effective options. Building relationships with trusted suppliers, evaluating customer reviews, and testing molds on a small scale before large investments further supports informed decision-making. Ultimately, selecting the right molds contributes significantly to the efficiency, creativity, and success of glassblowing projects.