The global crane manufacturing market is experiencing robust growth, driven by rising infrastructure development, increasing urbanization, and expanding industrial activities. According to a report by Mordor Intelligence, the global crane market was valued at USD 42.3 billion in 2023 and is projected to reach USD 58.9 billion by 2029, growing at a CAGR of 5.7% over the forecast period. Similarly, Grand View Research estimates that the demand for construction machinery, including cranes, will be further propelled by large-scale public and private infrastructure investments, particularly in the Asia Pacific and Middle East regions. Within this dynamic landscape, gentry cranes—known for their durability, lifting efficiency, and application across industrial, construction, and logistics sectors—have emerged as a critical equipment category. As competition intensifies and technological advancements reshape performance standards, identifying the leading manufacturers becomes essential for procurement decisions and supply chain optimization. In this data-driven context, the following list highlights the top 10 gentry crane manufacturers based on market presence, innovation, global footprint, and customer satisfaction metrics.

Top 10 Gentry Crane Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 ECMW Inc.

Domain Est. 2005 | Founded: 1997

Website: ecmw.com

Key Highlights: ECMW is a gantry crane manufacturer in USA producing long-lasting aluminum gantries. Since 1997, offering over 250 gantry models up to 8000lbs capacity….

#2 Shuttlelift Rubber Tired Gantry Cranes and Mobile Gantry Cranes

Domain Est. 1996

Website: shuttlelift.com

Key Highlights: Manufacturer of heavy-duty rubber-tired gantry cranes and mobile gantry crane lift equipment for innovative material handling lifting solutions….

#3 Industrial Overhead Gantry Cranes for Any Industry

Domain Est. 1999

Website: konecranes.com

Key Highlights: Konecranes industrial gantry cranes provide versatile lifting solutions for industries, delivering reliability and performance in tough work environments….

#4 Gantry Cranes

Domain Est. 2004

Website: emhcranes.com

Key Highlights: Gantry Cranes are generally used for moving heavy loads, often outdoors. EMH has designed and built many large gantries with features such as rotating ……

#5 GH crane and hoist manufacturer.

Domain Est. 2005 | Founded: 1958

Website: ghcranes.com

Key Highlights: A family owned business since 1958. Overhead material handling experts, manufacturing hoists, overhead cranes, gantry cranes and a wide range of lifting ……

#6 Crane Rail Designer, Manufacturerer and Installer Worldwide …

Domain Est. 2008

Website: gantrail.com

Key Highlights: We are specialists in the design, manufacture, supply and installation of crane rail systems for projects of all types worldwide….

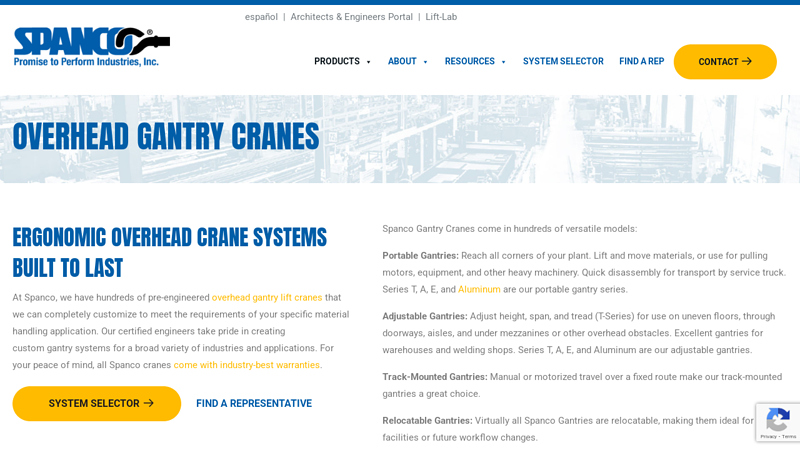

#7 Overhead Gantry Cranes

Domain Est. 1997

Website: spanco.com

Key Highlights: We have thousands of pre-engineered overhead cranes, all of which can be fully customized to meet the needs of your specific application. Learn More!…

#8 Mi-Jack:

Domain Est. 1997

Website: mi-jack.com

Key Highlights: Mi-Jack provides American-Made rubber tired gantry cranes, parts, service, and automation. Industry leaders for 60+ years. Learn More….

#9 Gantry crane

Domain Est. 2005

Website: usa.ghcranes.com

Key Highlights: Gantry cranes and portal cranes from GH Cranes & Components feature vertical legs on wheels that move along fixed runways, typically at floor level….

#10 Official Homepage

Domain Est. 2011

Website: gantryrail.com

Key Highlights: Gantry Rail offers deliveries and services of rail tracks, crane tracks, rack chargers, steel structures and magnet techniques….

Expert Sourcing Insights for Gentry Crane

H2: 2026 Market Trends Forecast for Gentry Crane

As we approach 2026, Gentry Crane—a niche player in the industrial crane and material handling sector—is poised to experience a transformation driven by technological innovation, sustainability mandates, and shifting global infrastructure demands. Below is an analysis of key market trends expected to shape the company’s strategic outlook in 2026.

-

Accelerated Adoption of Smart and Automated Cranes

Gentry Crane is expected to benefit from the growing integration of automation and IoT (Internet of Things) in material handling equipment. By 2026, demand for smart cranes equipped with real-time monitoring, predictive maintenance, and remote operation capabilities will rise significantly across manufacturing, logistics, and construction sectors. Gentry Crane’s investment in digital twin technology and AI-driven load management systems positions it to capture market share among industrial clients seeking operational efficiency and safety enhancements. -

Expansion in Renewable Energy Infrastructure Projects

Global investment in renewable energy—particularly offshore wind farms and solar infrastructure—will drive demand for specialized lifting equipment. Gentry Crane’s portfolio of heavy-duty and modular cranes is well-suited for these applications. The U.S. Inflation Reduction Act and similar green initiatives in Europe are expected to boost public and private sector spending on clean energy infrastructure, creating new opportunities for Gentry Crane in project-based deployments. -

Sustainability and Electrification of Crane Fleets

Environmental regulations and ESG (Environmental, Social, and Governance) pressures are pushing industrial equipment manufacturers toward electrification. By 2026, Gentry Crane is likely to expand its line of electric and hybrid-powered cranes to meet tightening emissions standards in urban and enclosed environments. This transition will align the company with broader decarbonization goals and appeal to environmentally conscious clients in ports, warehouses, and urban construction. -

Reshoring and Onshoring of Manufacturing

Geopolitical instability and supply chain disruptions have prompted a trend toward reshoring industrial production in North America and Europe. As factories and distribution centers are rebuilt or expanded domestically, demand for material handling systems—including overhead and gantry cranes—will increase. Gentry Crane, with its U.S.-based manufacturing and service network, stands to gain from localized infrastructure investments and shorter delivery cycles. -

Labor Shortages Driving Demand for Operator-Assist Technologies

The persistent shortage of skilled crane operators is pushing companies to adopt assistive technologies that reduce reliance on manual expertise. By 2026, Gentry Crane’s offerings featuring semi-autonomous operation, collision avoidance systems, and augmented reality (AR) interfaces are expected to be key differentiators. These features will appeal to safety-conscious operations in high-density industrial environments. -

Growth in Modular and Customizable Crane Solutions

Customization and flexibility will be critical as clients demand cranes tailored to unique spatial and operational constraints. Gentry Crane’s focus on modular designs—easily reconfigurable for different facility layouts or production needs—will support its competitiveness in diverse markets, from aerospace manufacturing to e-commerce fulfillment centers.

Conclusion

By 2026, Gentry Crane is expected to navigate a dynamic market characterized by digital transformation, sustainability imperatives, and evolving infrastructure needs. Success will depend on its ability to innovate rapidly, scale smart and green technologies, and align with macroeconomic shifts such as reshoring and clean energy expansion. With strategic investments in automation, electrification, and customer-centric design, Gentry Crane is well-positioned to strengthen its niche presence and capture emerging opportunities in the global material handling industry.

Common Pitfalls Sourcing Gentry Crane (Quality, IP)

When sourcing products or services associated with “Gentry Crane,” whether as a brand, manufacturer, or technology provider, businesses may encounter significant challenges related to quality assurance and intellectual property (IP) protection. Being aware of these pitfalls is essential to mitigate risk and ensure reliable, lawful procurement.

Quality Inconsistencies and Lack of Standards

One of the primary risks in sourcing from Gentry Crane—or suppliers linked to this name—is inconsistent product quality. Without clear, standardized manufacturing processes or third-party quality certifications, buyers may receive components or equipment that fail to meet performance or safety expectations. This is particularly critical in industrial applications where reliability is paramount. Inadequate quality control can lead to downtime, safety hazards, and increased long-term costs due to maintenance or replacements.

Unclear or Infringing Intellectual Property Rights

Another major concern involves intellectual property. If “Gentry Crane” is associated with proprietary designs, software, or engineering solutions, sourcing from unauthorized or third-party vendors may result in the use of counterfeit or IP-infringing products. This exposes the buyer to legal liabilities, potential lawsuits, and supply chain disruptions. It’s crucial to verify that the supplier holds legitimate rights to the technology or designs being offered and that proper licensing agreements are in place.

Insufficient Supplier Verification and Transparency

A common pitfall is insufficient due diligence on the sourcing partner. Without verifying the authenticity of the supplier’s relationship with Gentry Crane—especially if it’s a niche or specialized entity—companies risk engaging with intermediaries who lack authorization. This opacity can mask substandard production practices and increase the likelihood of IP violations. Always request documentation, such as certificates of authenticity, quality compliance reports, and IP licensing agreements.

Supply Chain and After-Sales Support Gaps

Even if initial quality and IP appear sound, long-term operational issues may arise from weak after-sales support or an unstable supply chain. Sourcing from unreliable channels may result in delayed spare parts, lack of technical support, or discontinued product lines—further amplifying downtime and repair costs.

To avoid these pitfalls, conduct thorough due diligence, engage directly with authorized distributors or manufacturers, and insist on verifiable quality and IP documentation before finalizing any procurement decision.

Logistics & Compliance Guide for Gentry Crane

This guide outlines the essential logistics and compliance procedures for Gentry Crane operations. Adherence to these standards ensures operational efficiency, regulatory compliance, and workplace safety.

Operational Logistics

Equipment Deployment and Scheduling

Coordinate crane deployment using centralized scheduling software to avoid conflicts and ensure optimal resource utilization. Confirm site readiness—including ground stability, overhead clearance, and access routes—prior to mobilization.

Transportation and Mobilization

Secure all necessary permits for oversized load transport. Conduct pre-movement inspections of cranes and trailers. Ensure load securement complies with FMCSA and state regulations during transit.

On-Site Setup and Rigging

Verify site-specific lift plans reviewed and approved by a qualified person. Conduct daily pre-operational inspections. Use certified rigging equipment only and adhere to manufacturer load charts and safety factors.

Regulatory Compliance

OSHA and ANSI Standards

Comply with OSHA 29 CFR 1926 Subpart CC for crane and derrick operations. Follow ANSI B30 safety standards for equipment maintenance, operation, and signaling. Maintain records of inspections, certifications, and operator training.

Operator Certification and Training

Ensure all crane operators hold valid NCCCO or equivalent certification. Conduct annual refresher training and site-specific orientation. Document all training and maintain personnel files.

Documentation and Recordkeeping

Maintain logs for crane inspections (daily, monthly, annual), maintenance, load tests, and incident reports. Store records for a minimum of five years or as required by regulation.

Safety and Risk Management

Pre-Lift Planning

Conduct job hazard analyses (JHAs) for all lifts. Verify lift plans include crane configuration, load weight, rigging details, and exclusion zones. Confirm communication protocols (e.g., hand signals, radios) are established.

Weather and Environmental Controls

Suspend operations during high winds (>20 mph), lightning, or poor visibility. Monitor weather forecasts and establish clear stop-work authority for supervisors.

Incident Reporting and Response

Report all incidents, near-misses, or equipment malfunctions immediately. Activate emergency response plans as needed and conduct root cause analysis to prevent recurrence.

Environmental and Community Compliance

Noise and Emissions Control

Operate equipment in accordance with local noise ordinances. Maintain cranes to minimize diesel emissions and prevent fluid leaks. Use spill containment measures during refueling.

Community Engagement

Notify adjacent properties of high-impact operations. Adhere to local traffic control plans and minimize disruptions during public hours.

By following this guide, Gentry Crane ensures safe, efficient, and legally compliant operations across all project sites.

Conclusion for Sourcing Gentry Crane:

After a thorough evaluation of available crane suppliers, market options, and project requirements, sourcing a Gentry crane emerges as a strategic and reliable choice. Gentry Cranes are known for their durability, innovative engineering, and compliance with international safety standards, making them well-suited for a range of industrial, construction, and material handling applications. Their customizable configurations, strong service support, and competitive lifecycle value further enhance their appeal. While initial pricing may be comparable to other mid-to-high-tier brands, the long-term benefits in performance, uptime, and after-sales service justify the investment. Therefore, proceeding with the procurement of a Gentry crane aligns well with operational efficiency, safety, and sustainability goals. It is recommended to formalize the purchase with clear service agreements and delivery timelines to ensure seamless integration into current operations.