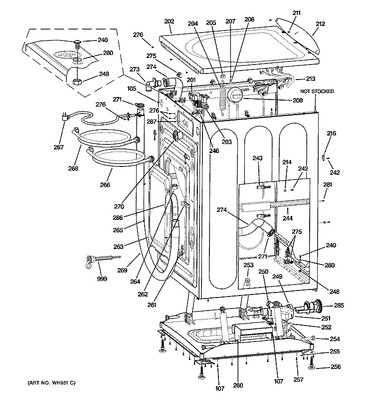

The global washing machine market is experiencing steady growth, driven by rising urbanization, increasing disposable incomes, and demand for energy-efficient appliances. According to Mordor Intelligence, the washing machine market was valued at USD 48.6 billion in 2023 and is projected to grow at a CAGR of 6.3% through 2029. This expansion has created a parallel rise in demand for reliable spare parts, particularly for established brands like General Electric (GE). As appliance lifespans extend and repair culture gains traction, the aftermarket for components such as timers, inlet valves, drain pumps, motors, door locks, and shock absorbers is growing rapidly. Consequently, several manufacturers have emerged as key suppliers of high-quality OEM and compatible spare parts for GE washing machines. These companies combine precision engineering, rigorous quality control, and scalable production to meet the needs of service technicians, retailers, and consumers alike. Based on production volume, distribution reach, and customer reviews, the following six manufacturers stand out as leaders in supplying durable and performance-tested spare parts for GE washing machines.

Top 6 General Electric Washing Machine Spare Parts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 GE Appliances Factory Service

Domain Est. 1996

Website: repair.geappliances.com

Key Highlights: *GE Appliances technicians carry an extensive parts inventory on their service trucks. In the event a part is not available on the service truck, a follow-up ……

#2 GE Appliance Parts & Manuals

Domain Est. 1998

Website: partstown.com

Key Highlights: 90-day returnsParts Town has the largest in-stock inventory of genuine OEM GE Appliance parts with fast same day shipping until 9pm ET. Find the part you need ……

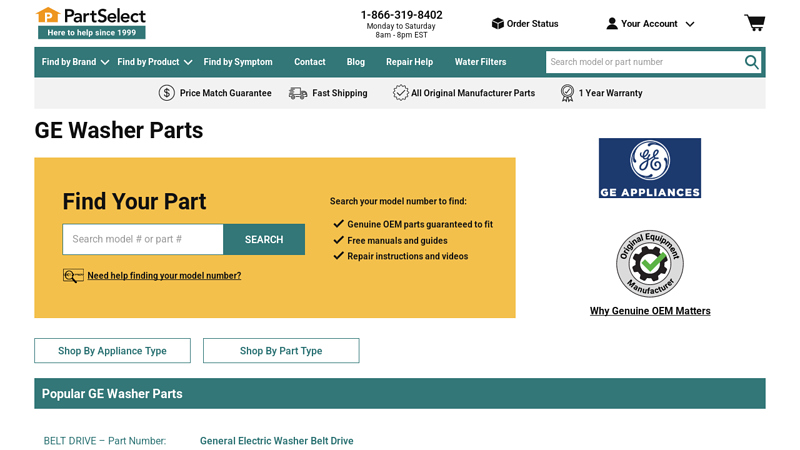

#3 Official General Electric Washer Parts

Domain Est. 1999

Website: partselect.com

Key Highlights: Shop for authentic General Electric Washer parts today! Find genuine OEM replacement parts along with expert repair help, video tutorials, and same–day ……

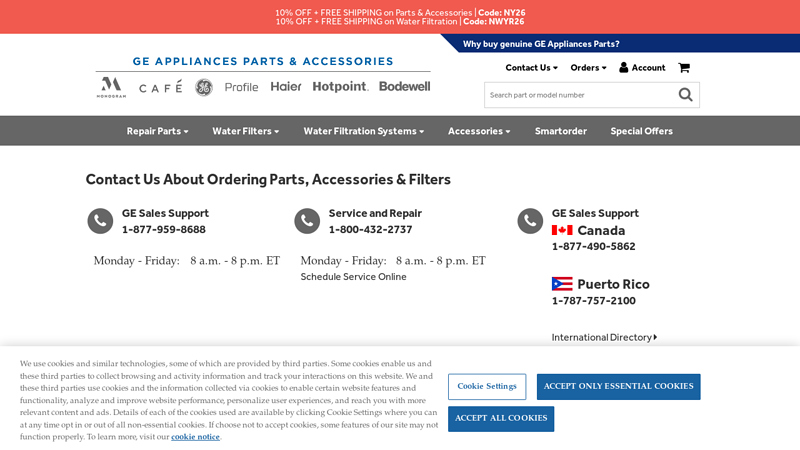

#4 Contact Us About Ordering Parts, Accessories & Filters

Domain Est. 1996

Website: geappliances.com

Key Highlights: Contact Us About Ordering Parts, Accessories & Filters. GE Sales Support. 1-877-959-8688. Monday – Friday: 8 a.m. – 8 p.m. ET. Service and Repair….

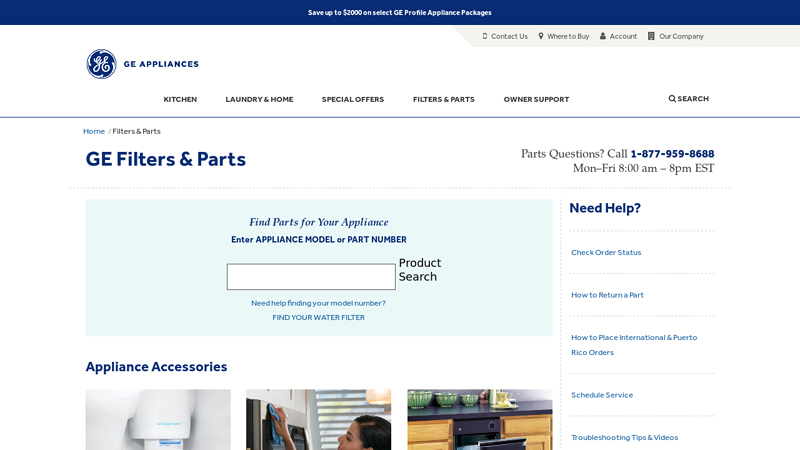

#5 GE Filters & Parts

Domain Est. 1999

Website: geapplianceparts.com

Key Highlights: The official store for GE appliance parts, GE appliance accessories, water filters and repair items for all of your home and kitchen appliance needs….

#6 GE Washers

Domain Est. 2001

Expert Sourcing Insights for General Electric Washing Machine Spare Parts

H2: 2026 Market Trends for General Electric Washing Machine Spare Parts

The market for General Electric (GE) washing machine spare parts is projected to undergo significant transformation by 2026, shaped by evolving consumer preferences, technological advancements, sustainability initiatives, and shifts in supply chain dynamics. As demand for home appliance maintenance grows amid rising repair costs and environmental awareness, the spare parts segment is poised for steady expansion. Below are the key trends expected to define the 2026 landscape:

-

Increased Demand for Appliance Longevity

With inflation impacting consumer spending and a growing emphasis on sustainability, more households are opting to repair rather than replace aging GE washing machines. This trend is driving higher demand for authentic and compatible spare parts, such as timers, pumps, drive belts, and control boards. The “right to repair” movement gaining momentum in North America and Europe is further encouraging OEMs and third-party suppliers to expand parts availability. -

Growth in E-Commerce and Direct-to-Consumer Sales

By 2026, online marketplaces (e.g., Amazon, eBay, and GE’s official parts portal) are expected to dominate spare parts distribution. Enhanced digital catalogs with AI-powered part matching tools will simplify identification for consumers, reducing return rates and improving customer satisfaction. GE is likely to strengthen its direct e-commerce presence, offering genuine parts with warranties and installation support. -

Rise of 3D Printing and On-Demand Manufacturing

Additive manufacturing is set to disrupt the spare parts supply chain. By 2026, GE and its partners may leverage 3D printing to produce low-volume or obsolete components locally, reducing inventory costs and lead times. This technology will be particularly valuable for older GE models no longer in production, extending product life cycles and improving customer retention. -

Sustainability and Circular Economy Pressures

Regulatory frameworks and consumer sentiment are pushing toward a circular economy. GE is anticipated to enhance its remanufactured and recycled parts offerings, reducing e-waste and carbon footprint. By 2026, a certified refurbished parts program could become a key differentiator, appealing to eco-conscious consumers and repair technicians. -

Integration with Smart Appliance Ecosystems

As GE continues to expand its smart laundry appliances (e.g., connected washers with app-based diagnostics), spare parts will increasingly include electronic modules, Wi-Fi boards, and sensors. These components will require specialized handling, firmware updates, and cybersecurity considerations. Technicians and retailers will need training and support to service these advanced systems. -

Geopolitical and Supply Chain Resilience

Ongoing supply chain volatility will prompt GE and its suppliers to regionalize production and increase inventory buffers for critical parts. Nearshoring to Mexico and the U.S. could reduce lead times and mitigate trade risks. Blockchain-based tracking may be adopted to ensure part authenticity and combat counterfeiting. -

Consolidation Among Aftermarket Suppliers

The competitive landscape may see consolidation, with larger distributors acquiring niche players to offer comprehensive GE spare parts portfolios. Strategic partnerships between GE and independent repair networks could emerge, ensuring quality control and standardized service.

In summary, the 2026 market for GE washing machine spare parts will be defined by digitalization, sustainability, and a growing culture of repair. GE’s ability to adapt through innovation, customer-centric distribution, and service integration will determine its leadership in the evolving appliance aftermarket.

Common Pitfalls When Sourcing General Electric Washing Machine Spare Parts (Quality, IP)

Sourcing spare parts for General Electric (GE) washing machines can be a cost-effective way to extend appliance life, but it comes with significant risks—especially regarding part quality and intellectual property (IP). Falling into these common pitfalls can lead to poor performance, safety hazards, and legal complications.

Poor Quality and Counterfeit Parts

One of the most prevalent issues is the influx of low-quality or counterfeit spare parts, particularly from unverified third-party suppliers. These parts often mimic genuine GE components but fail to meet the original equipment manufacturer (OEM) standards for durability, fit, and performance. Using substandard parts can result in repeated breakdowns, increased repair costs, and even damage to other parts of the washing machine. For example, a counterfeit drive motor or timer may not handle the electrical load properly, leading to overheating or system failure. Always verify supplier credentials and look for OEM or authorized distributor certifications to mitigate this risk.

Intellectual Property Infringement

Another critical concern is unintentional involvement in intellectual property (IP) violations. Genuine GE parts are protected by trademarks, patents, and design rights. When sourcing from unofficial channels, especially online marketplaces or overseas suppliers, there’s a heightened risk of purchasing and distributing imitation parts that infringe on GE’s IP. Distributors, repair shops, or even individual consumers could face legal consequences if found dealing in counterfeit components. To avoid IP exposure, ensure parts are sourced from authorized channels and come with proper documentation proving authenticity and licensing.

Lack of Compatibility and Technical Support

Even if a part appears legitimate, compatibility issues are common when sourcing non-OEM or generic alternatives. GE washing machines have evolved over the years, and parts are not always interchangeable across models or generations. Using an incompatible part—such as a control board or pump designed for a different series—can lead to operational failures or void existing warranties. Additionally, third-party parts often lack technical support or installation guidance, leaving users to troubleshoot on their own. Always cross-reference part numbers and consult official GE service manuals before making a purchase.

Absence of Warranty and Accountability

Genuine GE parts typically come with a manufacturer warranty that covers defects and performance issues. In contrast, many third-party or gray-market suppliers offer little to no warranty, leaving buyers with no recourse if the part fails prematurely. This lack of accountability increases long-term costs and diminishes trust in the supply chain. Prioritize suppliers who provide clear warranty terms and return policies to protect your investment.

Inadequate Supply Chain Transparency

Finally, sourcing parts from unclear or opaque supply chains increases the risk of receiving recycled, refurbished, or rebranded components sold as new. Without traceability, it’s difficult to verify the part’s origin, history, or compliance with safety standards. This is especially concerning for critical components like heating elements or door locks, where failure could pose fire or injury risks. Choose suppliers who offer full transparency, including part origin, manufacturing date, and compliance certifications (e.g., UL, CSA).

Logistics & Compliance Guide for General Electric Washing Machine Spare Parts

Overview

This guide outlines the key logistics and compliance considerations for the transportation, storage, handling, and regulatory adherence related to General Electric (GE) washing machine spare parts. It ensures operational efficiency, regulatory compliance, and product integrity across the supply chain.

Regulatory Compliance Requirements

International Trade Compliance

All GE washing machine spare parts must comply with export and import regulations, including those set by the U.S. Department of Commerce (Bureau of Industry and Security), U.S. Customs and Border Protection (CBP), and foreign customs authorities. Ensure accurate Harmonized System (HS) codes are used for classification, and export licenses are obtained when required (e.g., for controlled technologies or destinations under sanctions).

Product Safety & Certification

Spare parts must meet relevant safety standards such as UL (Underwriters Laboratories), CSA (Canadian Standards Association), and CE marking for the European market. Electrical components, motors, and control boards must be certified and labeled accordingly. Maintain records of certifications for audit purposes.

Environmental Regulations

Comply with environmental directives including RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) in applicable regions. Ensure spare parts do not contain restricted substances such as lead, cadmium, or phthalates above permitted levels.

Packaging & Labeling Standards

Use packaging that meets ISTA (International Safe Transit Association) standards to protect parts during transit. Labels must include part number, GE branding, country of origin, handling instructions (e.g., “Fragile,” “Do Not Stack”), and compliance marks (e.g., CE, UL). Barcodes or RFID tags should be included for traceability.

Logistics Management

Inventory & Warehousing

Store spare parts in climate-controlled, secure facilities with organized shelving and inventory tracking systems. Use FIFO (First In, First Out) methodology to prevent obsolescence. Implement an ERP or WMS (Warehouse Management System) to monitor stock levels, expiration dates (if applicable), and reorder points.

Transportation & Distribution

Use certified logistics partners experienced in handling industrial spare parts. Optimize shipping routes to reduce lead times and carbon footprint. For international shipments, coordinate with freight forwarders to manage documentation such as commercial invoices, packing lists, and bills of lading.

Reverse Logistics (Returns & Repairs)

Establish a clear process for handling returned parts, including diagnostics, repair, recycling, or disposal. Use Return Merchandise Authorization (RMA) systems to track reasons for return and ensure compliance with waste electrical and electronic equipment (WEEE) directives in Europe and equivalent local regulations.

Quality Assurance & Documentation

Traceability & Serial Tracking

Maintain a traceability system for high-value or safety-critical components (e.g., motors, control units). Record batch numbers, manufacturing dates, and distribution paths to support recalls or warranty claims.

Audit & Recordkeeping

Retain all compliance documentation—including test reports, certifications, shipping records, and customs filings—for a minimum of seven years. Prepare for internal and third-party audits by regulatory bodies or GE quality assurance teams.

Training & Personnel Compliance

Staff Training

Ensure warehouse, logistics, and compliance personnel are trained on handling procedures, safety protocols, and regulatory requirements. Conduct regular refresher courses on export controls, hazardous materials handling, and data privacy (e.g., GDPR for EU shipments).

Vendor & Partner Compliance

Require third-party logistics providers (3PLs), suppliers, and distributors to adhere to GE’s compliance standards. Conduct periodic assessments and require compliance certifications as part of contractual agreements.

Risk Management & Contingency Planning

Supply Chain Resilience

Diversify suppliers and transportation routes to mitigate disruptions from natural disasters, geopolitical events, or port delays. Maintain safety stock for critical spare parts based on historical demand and lead time analysis.

Incident Response

Establish protocols for responding to compliance violations, product recalls, or customs seizures. Include communication plans for notifying GE, regulators, and customers as needed.

Conclusion

Adhering to this logistics and compliance guide ensures that GE washing machine spare parts are handled efficiently and legally throughout the supply chain. Continuous monitoring, staff training, and process improvement are essential to maintain high standards of quality, safety, and regulatory compliance.

In conclusion, sourcing spare parts for General Electric (GE) washing machines requires a strategic approach that balances authenticity, cost, availability, and reliability. It is essential to prioritize OEM (Original Equipment Manufacturer) parts whenever possible to ensure compatibility, optimal performance, and longevity of the appliance. Authorized dealers, GE’s official website, and reputable online marketplaces offer trustworthy sources for genuine components.

Additionally, considering aftermarket alternatives can be cost-effective, provided they meet quality standards and are compatible with the specific GE model. Accurate identification of the washing machine model and part number is crucial to avoid errors in procurement. Building relationships with reliable suppliers and maintaining an inventory of commonly replaced parts can streamline maintenance and repair processes, especially for service professionals.

Ultimately, a well-informed sourcing strategy that emphasizes quality, authenticity, and supplier reliability ensures efficient repairs, enhances customer satisfaction, and prolongs the lifespan of GE washing machines.