The global gear hobbing machine market is experiencing robust growth, driven by rising demand for precision gear components across the automotive, aerospace, and industrial machinery sectors. According to a 2023 report by Mordor Intelligence, the gear cutting tools market—including gear hobs—is projected to grow at a CAGR of 6.8% from 2023 to 2028, fueled by advancements in automation and the increasing production of electric vehicles that require high-precision transmission systems. Similarly, Grand View Research estimates that the global gear market size was valued at USD 97.6 billion in 2022 and is expected to expand at a CAGR of 6.3% through 2030, underpinned by growing industrialization and the need for energy-efficient mechanical power transmission solutions. As demand for accuracy, durability, and efficiency in gear manufacturing intensifies, leading gear hob producers are innovating with advanced coatings, optimized geometries, and smart tooling solutions. In this evolving landscape, selecting the right manufacturer becomes critical for OEMs and tier suppliers aiming to maintain competitive advantage. Below is a data-informed overview of the top 10 gear hobs manufacturers shaping the future of precision gearing.

Top 10 Gear Hobs Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Gleason

Domain Est. 1991

Website: gleason.com

Key Highlights: Within Gleason Corporation, Gleason-Pfauter is a development and technology center for gear manufacturing processes to produce high precision cylindrical gears, ……

#2 Gear Hobs

Domain Est. 2003

Website: supercuttingtools.com

Key Highlights: Super Hobs & Broaches is a Leading Manufacturer & Exporter of – Gear Hobs, Broaches, Master Gears, Shaving Cutters, Shaper Cutters, Power Skiving Cutters, ……

#3 gear hobs & form milling cutter

Domain Est. 2009

Website: fhusa-tsa.com

Key Highlights: Gear hobs and milling cutters with bore or axis, multi-starts and straight or helical flutes. We are producers of cutting tools worldwide….

#4 Gear Cutting Tools

Domain Est. 2017

Website: est-us.com

Key Highlights: EST is an industry-leading manufacturer of gear cutting tools including hobs, shaper cutters, skives, milling cutters and other specialty cutters….

#5 Gear Hobs Manufacturer

Domain Est. 2019

Website: stcgeartools.com

Key Highlights: Gear Hobs STC is a Manufacturer and Exporter of all types of Gear Cutting Tools in HSS and Carbide Materials made with maximum accuracy and proper finishing….

#6 Gear Hobbing Machines

Domain Est. 1997

Website: nidec.com

Key Highlights: GE15FR series are high-precision hobbing machines that meets high precision and high speed production needs for gears used in reducers. 1 · See all products ( ……

#7 Gear Hobbing Machine Tools Made in America by Bourn & Koch

Domain Est. 1997

Website: bourn-koch.com

Key Highlights: Bourn & Koch has provides gear hobbing machines for a wide variety of applications. Our gear hobbing machines are available up to 600mm….

#8 Gear Hobbing Tools

Domain Est. 2002

Website: star-su.com

Key Highlights: Star SU’s high performance solid carbide or high speed steel hobs with advanced coatings can be used in wet or dry cutting applications….

#9 Gear Hobs

Domain Est. 2023

Website: cti-usa.co

Key Highlights: In stockCTI-USA specializes in producing ultra-precision gear hobs tailored for cutting spur and helical gears, as well as various custom applications….

#10 KASHIFUJI WORKS, LTD.

Website: kashifuji.co.jp

Key Highlights: Manufacture and Sale of Machine Tools such as Hobbing Machines.Hobbing Machines for High Speed and Accurate Gear Hobbing. Gear Production Machines such as ……

Expert Sourcing Insights for Gear Hobs

H2: 2026 Market Trends for Gear Hobs

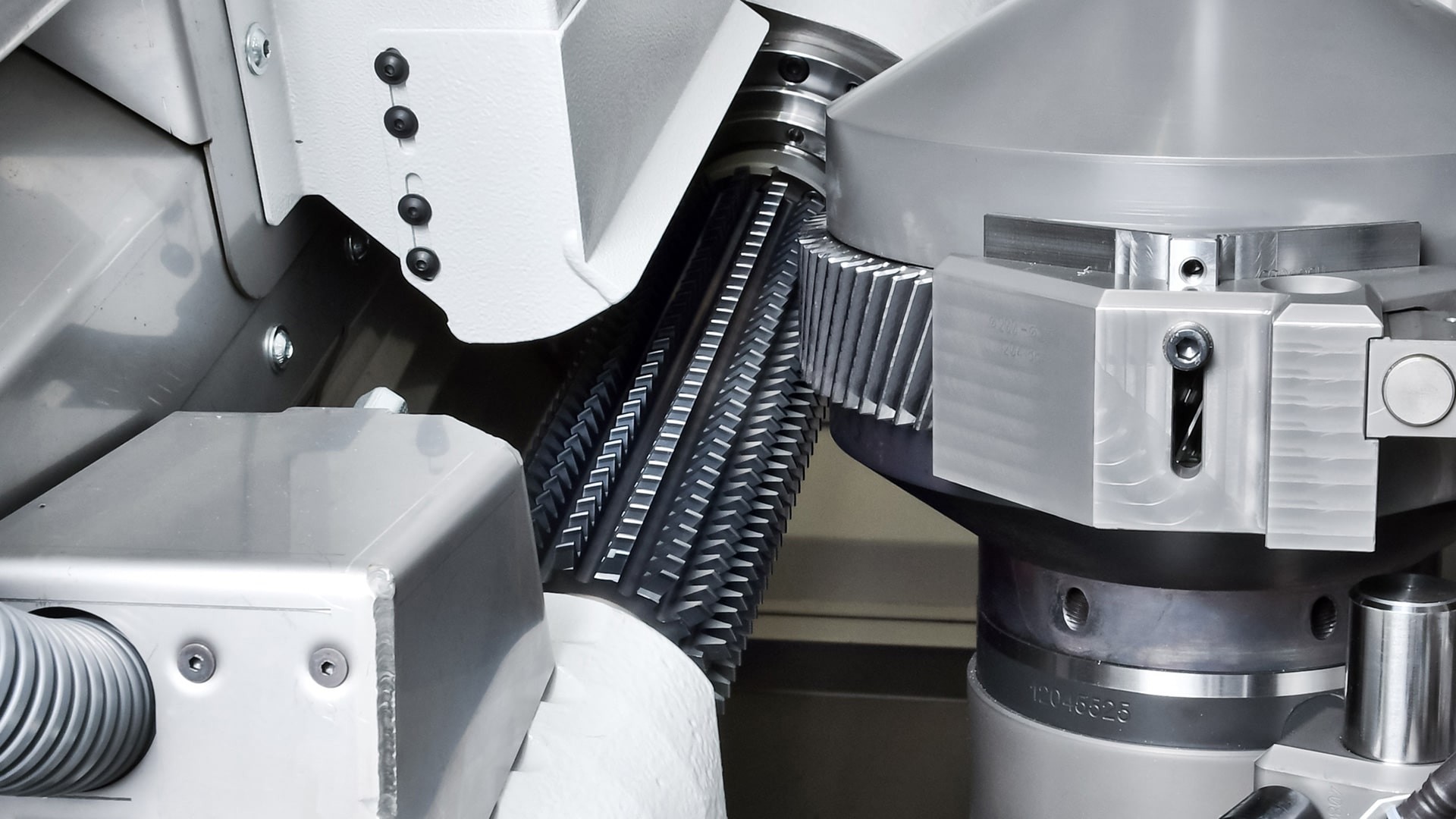

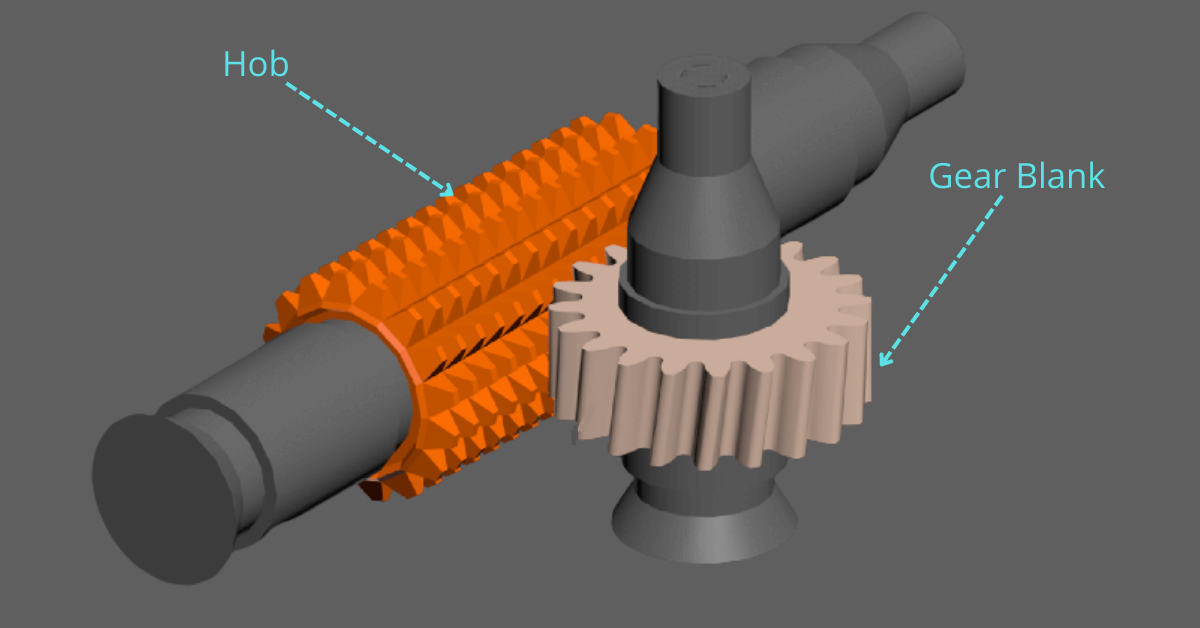

The global gear hobs market is poised for significant evolution by 2026, driven by advancements in manufacturing technologies, increasing demand for precision gears across automotive, aerospace, and industrial machinery sectors, and the growing adoption of automation. Gear hobs—specialized cutting tools used in the production of spur and helical gears—are becoming more sophisticated to meet tighter tolerances and higher efficiency requirements.

One of the dominant trends shaping the 2026 landscape is the integration of Industry 4.0 principles into gear hobbing processes. Smart manufacturing systems equipped with IoT-enabled monitoring, predictive maintenance, and real-time data analytics are enhancing the performance and lifespan of gear hobs. This digital transformation allows manufacturers to optimize cutting parameters, reduce tool wear, and minimize downtime—key factors improving overall productivity.

Another significant trend is the rising demand for high-performance, coated gear hobs. Advanced coatings such as TiAlN (Titanium Aluminum Nitride) and AlCrN (Aluminum Chromium Nitride) are being increasingly adopted to enhance thermal resistance, hardness, and wear resistance. These improvements are particularly crucial in high-speed hobbing operations, where tool longevity and precision are paramount.

Furthermore, the electric vehicle (EV) revolution is exerting a strong influence on gear hob demand. EVs require highly efficient, quiet, and durable transmission systems, leading to a surge in demand for precision-ground and fine-pitch gear hobs. This shift is prompting tool manufacturers to innovate in materials and geometries tailored specifically for EV gearbox applications.

Regionally, Asia-Pacific is expected to maintain its leadership in the gear hobs market by 2026, fueled by rapid industrialization in China, India, and Southeast Asia. Meanwhile, North America and Europe are focusing on high-precision, custom-designed gear hobs for aerospace and high-end automotive applications, supported by robust R&D investments.

Sustainability is also emerging as a key consideration. Manufacturers are exploring recyclable tool substrates and eco-friendly coating processes to align with environmental regulations and corporate sustainability goals.

In summary, the 2026 gear hobs market will be characterized by technological innovation, digital integration, sector-specific customization—especially for EVs—and a strong regional focus on Asia-Pacific growth, positioning gear hobs as critical enablers of next-generation manufacturing.

Common Pitfalls Sourcing Gear Hobs (Quality, IP)

Sourcing gear hobs—critical cutting tools used to manufacture gears—can be fraught with challenges, especially concerning quality consistency and intellectual property (IP) protection. Organizations often encounter significant risks if these factors are not carefully managed during procurement.

Poor Quality Control and Inconsistent Tolerances

One of the most frequent issues when sourcing gear hobs, particularly from low-cost or unfamiliar suppliers, is inconsistent quality. Gear hobs require extremely tight tolerances and precise geometry to produce accurate, high-performance gears. Poorly manufactured hobs can lead to incorrect tooth profiles, premature tool wear, or even gear failure in end-use applications. Issues such as substandard material heat treatment, inadequate surface finishes, or deviations in helix angle and pitch can compromise performance. Without rigorous inspection protocols and adherence to international standards (e.g., DIN, ISO), buyers risk receiving tools that do not meet specifications, resulting in production downtime and increased costs.

Intellectual Property Infringement and Reverse Engineering Risks

Gear hob designs often incorporate proprietary geometries, coatings, or material treatments protected by patents or trade secrets. When sourcing from certain regions or third-party suppliers, there is a heightened risk of IP theft or unauthorized replication. Some suppliers may reverse-engineer branded hobs and offer counterfeit or imitation versions at lower prices. These knock-offs not only violate IP rights but also typically underperform due to inferior design and materials. Furthermore, using such tools can expose the buyer to legal liability, especially if the end-product gears are used in regulated industries like aerospace or automotive.

Lack of Traceability and Certification

Many suppliers—especially those in less-regulated markets—fail to provide comprehensive documentation, such as material certifications, heat treatment records, or inspection reports. Without traceability, it becomes difficult to verify tool quality or troubleshoot gear production issues. This lack of transparency can be particularly problematic in industries requiring strict compliance with quality management systems like ISO 9001 or AS9100.

Inadequate Post-Purchase Support and Re-sharpening Services

Gear hobs require periodic re-sharpening to maintain cutting accuracy and extend tool life. Some suppliers do not offer reliable reconditioning services or use improper grinding techniques that degrade hob performance over time. Sourcing from vendors without established support networks can lead to longer downtimes and higher total cost of ownership.

Mitigating these pitfalls requires due diligence in supplier qualification, clear contractual IP protections, and investment in long-term partnerships with reputable manufacturers who prioritize quality and compliance.

Logistics & Compliance Guide for Gear Hobs

Overview

Gear hobs are precision cutting tools used in the manufacturing of gears and splines. Due to their high value, specialized nature, and material composition, their logistics and compliance requirements demand careful planning and adherence to international standards. This guide outlines key considerations for the safe, efficient, and compliant transportation and handling of gear hobs.

Packaging Requirements

Proper packaging is essential to prevent damage during shipping and storage.

– Use rigid, moisture-resistant containers (e.g., wooden crates or reinforced cardboard with internal foam/foam inserts).

– Individually wrap each hob in anti-corrosion paper (VCI paper recommended) to prevent rust.

– Secure hobs within the container to avoid movement; use foam padding or custom-cut inserts.

– Clearly label packages with “Fragile,” “This Side Up,” and “Precision Tool” indicators.

– Include desiccants in sealed packaging when shipping to humid climates.

Transportation & Handling

Gear hobs are sensitive to shock, temperature, and humidity.

– Use temperature-controlled freight for international or long-distance shipments.

– Avoid air freight for very heavy hobs unless urgent; consider sea or ground freight for cost and stability.

– For air transport, comply with IATA Dangerous Goods Regulations if hobs are coated with or contain regulated substances (e.g., certain cutting fluids or coatings).

– Use trained personnel for handling; avoid dropping or stacking heavy packages on top of hob containers.

– Maintain a clean handling environment to prevent contamination of cutting edges.

Export & Import Compliance

Ensure all regulatory requirements are met for cross-border movement.

– Harmonized System (HS) Code: Typically 8207.50 (Interchangeable tools for hand tools or machine tools, for threading or tapping, of hobs, cutters, etc.). Confirm with local customs authorities.

– Export Controls: Check if hobs fall under export control regimes such as the U.S. Export Administration Regulations (EAR) or EU Dual-Use Regulation. High-precision hobs may be subject to licensing if intended for military or aerospace applications.

– Documentation: Prepare commercial invoice, packing list, bill of lading/air waybill, and certificate of origin. Include detailed product specifications (module, pressure angle, number of threads, material).

– Restricted Destinations: Verify sanctions lists (e.g., OFAC, EU sanctions) to ensure the destination country is permitted.

Material & Environmental Compliance

Many gear hobs contain high-speed steel (HSS) or carbide, which may have regulatory implications.

– Comply with REACH (EU) and RoHS directives if exporting to Europe; ensure no restricted substances (e.g., certain heavy metals) exceed allowable limits.

– Declare cobalt content if hobs are carbide-tipped, as cobalt may be subject to conflict minerals reporting (e.g., under U.S. Dodd-Frank Act Section 1502).

– Follow proper disposal guidelines for damaged or obsolete hobs; recycling through certified metal reclaimers is recommended.

Quality & Certification

Maintain traceability and meet customer requirements.

– Provide material test certificates (MTCs) or mill certifications for critical applications.

– Include tool identification (part number, serial number, ISO standards met) on packaging and documentation.

– Comply with ISO 9001 (quality management) and ISO 14001 (environmental management) if applicable to your operations.

Storage Guidelines

Proper storage extends tool life and performance.

– Store in a dry, temperature-stable environment (ideally 15–25°C, <60% RH).

– Use sealed cabinets with desiccants for long-term storage.

– Avoid direct contact with concrete floors; use shelving or pallets.

– Rotate stock using FIFO (First In, First Out) to prevent aging or coating degradation.

Incident Response & Insurance

- Insure high-value shipments against loss, theft, and damage.

- Document any damage upon receipt and file claims promptly with carriers.

- Maintain recall procedures in case of non-compliant or defective batches.

Summary

Effective logistics and compliance for gear hobs require attention to packaging, transportation conditions, international regulations, and material standards. By following this guide, manufacturers, distributors, and end-users can ensure the safe and legal movement of gear hobs while maintaining their precision and performance.

Conclusion for Sourcing Gear Hobs:

Sourcing high-quality gear hobs is a critical step in ensuring precision, durability, and efficiency in gear manufacturing processes. By carefully evaluating suppliers based on factors such as material quality, technical expertise, certifications, lead times, and cost-effectiveness, manufacturers can secure reliable tools that meet stringent performance standards. Engaging with reputable suppliers—either domestic or international—with proven track records in producing precision cutting tools helps minimize downtime, reduce rework, and extend tool life. Additionally, considering customization capabilities and ongoing technical support ensures that gear hobs are optimized for specific applications. Ultimately, a strategic sourcing approach to gear hobs contributes significantly to enhanced production capabilities, consistent product quality, and long-term operational success in the gear manufacturing industry.