The global sintering furnace market is experiencing robust growth, driven by rising demand in industries such as aerospace, automotive, electronics, and advanced materials. According to Grand View Research, the global sintering furnace market size was valued at USD 1.3 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 6.8% from 2024 to 2030. Increasing adoption of powder metallurgy and stringent requirements for high-precision, high-temperature processing are key factors fueling this expansion. Additionally, Mordor Intelligence forecasts continued market momentum, citing advancements in vacuum and atmosphere-controlled sintering technologies and growing R&D investments in next-generation materials. As demand for reliable, energy-efficient, and scalable sintering solutions rises, a select group of manufacturers has emerged as leaders in innovation, performance, and global reach. Below are the top 10 sintering furnace manufacturers shaping the future of advanced material processing.

Top 10 Furnace For Sintering Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 ADDIN CO.,LTD

Domain Est. 2014

Website: addinco.com

Key Highlights: The leading manufacturer of Industrial / Dental Furnaces, “ADDIN Co., LTD“. COMPANY · PRODUCTS. ADDRESS. 290, Isanpo-gil, Ilsanseo-gu, Goyang-si, Gyeonggi-do ……

#2 The Nabertherm furnace world

Domain Est. 1999

Website: nabertherm.com

Key Highlights: As a manufacturer of industrial furnaces Nabertherm does not only offer the widest range of standard furnaces. Professional engineering in combination with ……

#3 Malhotra Engineers Sintering Furnace Manufacturer and Consultant …

Domain Est. 2008

Website: malhotraengineers.com

Key Highlights: Malhotra engineers is a proprietory company started in 1978. Last 35 years involved in manufacturing of Industrial furnaces with focus on Powder Metallurgy….

#4 Vacuum sintering furnace manufacturer

Domain Est. 2010

Website: ecm-furnaces.com

Key Highlights: The second part of the furnace is dedicated to the sintering process, which is conducted in between 1120°C and 1135°C. This process can take 10 to 30 minutes….

#5 PureSinter™ Furnace

Domain Est. 2015

Website: desktopmetal.com

Key Highlights: All-new vacuum furnace for combined debinding and sintering features breakthrough industrial performance at an affordable price….

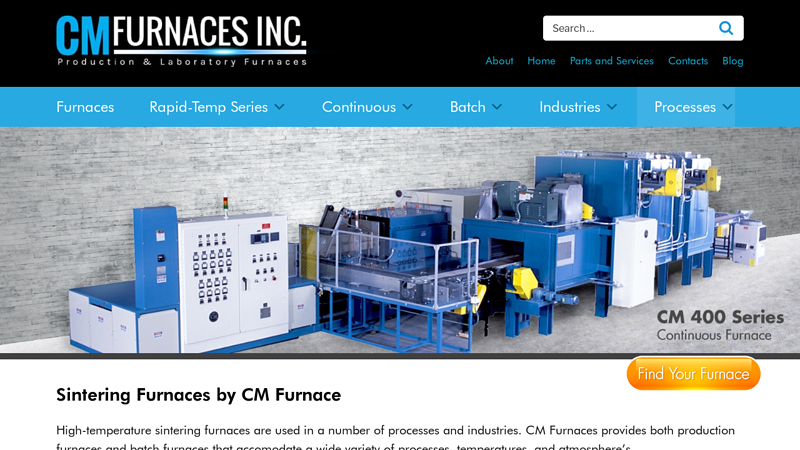

#6 Sintering Furnaces

Domain Est. 1998

Website: cmfurnaces.com

Key Highlights: CM Furnaces provides both production furnaces and batch furnaces that accomodate a wide variety of processes, temperatures, and atmosphere’s….

#7 Elnik Systems

Domain Est. 1998

Website: elnik.com

Key Highlights: For over 55 years, our family owned business has manufactured the most advanced MIM/AM Debind & Sinter furnaces and first stage debind ovens in the world….

#8 Sintering Furnaces

Domain Est. 1999

Website: abbottfurnace.com

Key Highlights: Abbott Furnace Company designs and builds custom sintering furnaces around our clients’ manufacturing needs – the time, temperature, and atmosphere ……

#9 Zircom Sintering Furnace (for Zirconia Materials)

Domain Est. 2004

Website: kdfus.com

Key Highlights: Zircom Sintering Furnace delivers delicacy and beauty to your zirconia. It features molybdenum disilicide heater that provides clean, reliable, and consistent ……

#10 ACME

Domain Est. 2021

Website: acme-furnace.com

Key Highlights: As a high level heating equipment comprehensive service provider and Aviation & Aerospace partner, ACME is specialized in manufacturing of vacuum heat ……

Expert Sourcing Insights for Furnace For Sintering

H2: Projected 2026 Market Trends for Furnaces Used in Sintering

The global market for sintering furnaces is poised for significant transformation by 2026, driven by advancements in materials science, growing demand from high-tech industries, and a strong push toward energy efficiency and automation. As industries such as electric vehicles (EVs), aerospace, medical devices, and advanced ceramics expand, sintering furnaces—critical in densifying powdered materials through controlled high-temperature processes—are undergoing rapid innovation to meet evolving performance and sustainability standards.

1. Rising Demand from the Electric Vehicle and Battery Sectors

A primary driver shaping the 2026 sintering furnace market is the surge in EV production. Sintering plays a crucial role in manufacturing battery components (e.g., cathodes, anodes) and powdered metal parts for electric motors and transmissions. By 2026, manufacturers are expected to invest heavily in continuous and vacuum sintering furnaces capable of processing advanced materials like silicon anodes and nickel-rich cathodes. This trend is accelerating demand for high-precision, scalable sintering systems with tight atmosphere control.

2. Growth in Advanced Materials and Additive Manufacturing

The expansion of metal additive manufacturing (AM), particularly in aerospace and medical implant industries, is increasing the need for post-processing sintering equipment. By 2026, sintering furnaces tailored for debinding and sintering metal injection molded (MIM) and binder jetting components will experience robust growth. Furnaces with uniform temperature profiles, programmable ramp rates, and integrated cooling systems are becoming standard to ensure dimensional accuracy and material integrity.

3. Technological Advancements: Smart and Energy-Efficient Furnaces

In response to environmental regulations and operational cost concerns, furnace manufacturers are integrating Industry 4.0 technologies. By 2026, smart sintering furnaces equipped with IoT-enabled sensors, AI-driven process optimization, and real-time monitoring are expected to dominate the market. These systems improve yield, reduce energy consumption, and enable predictive maintenance. Additionally, innovations in insulation materials and hybrid heating (e.g., electric- and gas-assisted) are enhancing thermal efficiency.

4. Regional Market Shifts and Manufacturing Localization

Asia-Pacific, particularly China, Japan, and South Korea, will remain the largest regional market due to strong electronics and automotive manufacturing bases. However, North America and Europe are expected to see accelerated growth, driven by reshoring initiatives and investments in clean energy and defense technologies. Localized production of critical components will increase demand for modular and flexible sintering furnace solutions.

5. Focus on Sustainability and Green Manufacturing

Environmental regulations such as the EU Green Deal and U.S. clean energy incentives are compelling manufacturers to adopt low-carbon sintering technologies. By 2026, furnaces utilizing renewable electricity, hydrogen-based atmospheres, and heat recovery systems will gain market share. Suppliers are also offering carbon footprint tracking and lifecycle analysis for their equipment, aligning with corporate ESG goals.

6. Consolidation and Strategic Partnerships

The competitive landscape is expected to witness consolidation, with major industrial heating equipment providers acquiring niche sintering technology firms to broaden their portfolios. Strategic partnerships between furnace manufacturers and material scientists or AM companies will accelerate R&D in specialized applications, such as sintering high-entropy alloys or ceramic matrix composites.

Conclusion

By 2026, the sintering furnace market will be characterized by technological sophistication, sustainability integration, and application-specific customization. Key success factors will include adaptability to new materials, energy efficiency, digital integration, and global supply chain responsiveness. Companies that align their product development with these macro trends—particularly in EVs, AM, and green manufacturing—are likely to gain a competitive edge in the evolving industrial landscape.

When sourcing a furnace for sintering using hydrogen (H₂), especially in high-performance applications such as powder metallurgy, ceramics, or advanced materials manufacturing, several common pitfalls can compromise product quality, intellectual property (IP) protection, and operational safety. Below is a detailed breakdown of these pitfalls, focusing on quality assurance and IP risks, with specific attention to hydrogen-based sintering environments.

🔹 1. Inadequate Atmosphere Control & Purity Management

Pitfall: Poor control of H₂ flow, dew point, or oxygen levels leads to oxidation, carbon pickup, or inconsistent sintering.

- Quality Risk: Even trace O₂ or H₂O in the H₂ stream can oxidize sensitive materials (e.g., tungsten, titanium, stainless steel powders).

- Best Practices:

- Require furnaces with dual-purge systems (N₂ + H₂) and oxygen dew point monitoring (< -40°C).

- Ensure leak-tight construction (welded seals, metal gaskets) to prevent air ingress.

- Validate H₂ purity (>99.999%) and include gas purification units if needed.

🔹 2. Insufficient Temperature Uniformity & Calibration

Pitfall: Hot/cold spots in the furnace lead to non-uniform sintering, dimensional inconsistency, and part failure.

- Quality Risk: Materials sinter at different rates, causing warping or weak grain structures.

- Best Practices:

- Require temperature uniformity certification (e.g., ±5°C across the workload).

- Perform as-installed temperature mapping (SAT) per AMS 2750 or equivalent.

- Ensure multi-zone heating control with independent thermocouples.

🔹 3. Incompatible Materials of Construction

Pitfall: Furnace components degrade in H₂ environments (e.g., hydrogen embrittlement, reduced metal strength).

- Quality & Safety Risk: Catastrophic failure of heating elements, insulation, or retorts.

- Best Practices:

- Use H₂-compatible materials (e.g.,钼 (molybdenum), tungsten, or alumina for hot zones).

- Avoid steels prone to hydrogen embrittlement; use stainless steel 316L or Inconel where necessary.

- Confirm vacuum-rated seals and feedthroughs.

🔹 4. Inadequate Safety Systems for Hydrogen Use

Pitfall: H₂ is highly flammable (4–75% in air); leaks or improper venting can cause explosions.

- Quality & Safety Risk: Process interruption, damage, or injury.

- Best Practices:

- Require H₂ leak detection sensors, automatic shutoffs, and explosion-proof ventilation.

- Ensure compliance with NFPA 55, CGA G-5, or local H₂ safety codes.

- Include burn-off torches or flare stacks for safe H₂ exhaust.

🔹 5. Lack of Process Documentation & Traceability (IP Risk)

Pitfall: Vendors may not support secure logging or may expose proprietary sintering profiles.

- IP Risk: Sintering parameters (ramp rates, dwell times, gas mixtures) are trade secrets.

- Best Practices:

- Use furnaces with encrypted, user-locked control software (Siemens, Eurotherm, or proprietary).

- Ensure data export restrictions and role-based access control.

- Sign NDAs and IP ownership clauses before sharing process recipes.

🔹 6. Vendor Lock-in or Lack of Open Architecture

Pitfall: Proprietary control systems prevent data extraction or integration with internal MES/QMS.

- IP & Flexibility Risk: You cannot audit, reproduce, or transfer process data.

- Best Practices:

- Require open communication protocols (Modbus, OPC UA).

- Verify ability to export raw temperature, gas, and pressure logs.

- Avoid vendors that retain cloud access to your process data.

🔹 7. Underestimating Maintenance & Downtime

Pitfall: Frequent hot zone degradation or sensor drift in H₂ environments increases downtime.

- Quality Risk: Inconsistent batches due to uncalibrated systems.

- Best Practices:

- Choose furnaces with modular hot zones for quick replacement.

- Negotiate preventive maintenance (PM) schedules and spare parts availability.

- Ensure thermocouples are H₂-resistant (e.g., Type C: W/Re).

🔹 8. Inadequate Validation & Compliance Support

Pitfall: Furnace doesn’t support IQ/OQ/PQ (Installation/Operational/Performance Qualification).

- Quality & Regulatory Risk: Non-compliance in regulated industries (medical, aerospace).

- Best Practices:

- Require vendor to support IQ/OQ documentation.

- Confirm compliance with ASTM, ISO 2768, or AS9100 standards.

- Verify traceable calibration certificates for all sensors.

🔹 9. Overlooking Post-Sintering Cooling Control

Pitfall: Rapid or uncontrolled cooling in H₂ can cause thermal shock or undesirable phase transformations.

- Quality Risk: Cracking, residual stresses, or poor microstructure.

- Best Practices:

- Use programmable cooling rates with H₂ quench control.

- Consider pressure-controlled cooling to manage grain growth.

🔹 10. IP Exposure During Installation & Training

Pitfall: Vendor engineers gain access to proprietary materials or process flows during setup.

- IP Risk: Reverse engineering or unintentional disclosure.

- Best Practices:

- Limit access to non-critical areas during installation.

- Use dummy runs with inert materials during commissioning.

- Audit vendor subcontractors for IP compliance history.

✅ Summary: Key Due Diligence Checklist

| Area | Action |

|——|——–|

| Quality | Verify temp uniformity, H₂ purity, leak integrity, material compatibility |

| Safety | Confirm H₂ detection, ventilation, and explosion safeguards |

| IP Protection | Secure control software, enforce NDAs, limit data access |

| Compliance | Ensure IQ/OQ support, calibration traceability, regulatory alignment |

| Vendor Risk | Audit for open architecture, maintenance support, and IP ethics |

By proactively addressing these pitfalls, you ensure both high-quality sintered output and robust protection of your intellectual property when deploying hydrogen-based sintering furnaces. Always involve process engineers, EHS officers, and legal/IP counsel during sourcing.

Logistics & Compliance Guide for Furnace For Sintering

Overview

A sintering furnace is a high-temperature industrial furnace used to compact and form a solid mass of material by heat and pressure without melting it to the point of liquefaction. These furnaces are commonly used in powder metallurgy, ceramics, and advanced materials manufacturing. Due to their high operating temperatures, potential use of controlled atmospheres (such as hydrogen), and classification under industrial machinery regulations, sintering furnaces are subject to specific logistics and compliance requirements.

This guide outlines key considerations for the safe and compliant transportation, installation, operation, and maintenance of sintering furnaces, with a focus on models utilizing hydrogen (H₂) as a process or protective atmosphere.

1. Regulatory Compliance

1.1 International Standards

Sintering furnaces, particularly those using hydrogen, must comply with various international and regional standards, including:

- ISO 6974: Safety requirements for industrial furnaces.

- ISO 13705: Industrial furnaces and associated processing equipment – Safety requirements.

- EN 746-1 & EN 746-2: Safety of industrial thermoprocessing equipment (European standard).

- ASME BPVC: Boiler and Pressure Vessel Code (if applicable to furnace components).

- IEC 60204-1: Safety of machinery – Electrical equipment of machines.

1.2 Hydrogen-Specific Regulations

Due to the flammability and explosion risk of hydrogen (H₂), additional safety and compliance measures are required:

- NFPA 55 (Standard for the Storage, Use, and Handling of Compressed and Liquefied Gases) – Covers safe handling and storage of hydrogen.

- NFPA 2 (Hydrogen Technologies Code) – Applies to hydrogen generation, storage, and use in industrial systems.

- OSHA 29 CFR 1910.106 – Flammable liquids and gases regulations (U.S.).

- ATEX Directive (2014/34/EU) – For equipment used in potentially explosive atmospheres (EU).

- Pressure Equipment Directive (PED 2014/68/EU) – If hydrogen storage or piping systems are part of the furnace setup.

1.3 Environmental and Emissions Compliance

- Clean Air Act (U.S. EPA) – May apply if hydrogen combustion or off-gassing occurs.

- REACH & RoHS (EU) – Ensure materials used in furnace construction comply with hazardous substance restrictions.

- F-Gas Regulation (EU) – Not directly applicable to H₂, but relevant if cooling systems use fluorinated gases.

2. Logistics and Transportation

2.1 Packaging and Handling

- Furnaces must be secured on pallets or in crates with shock-absorbing materials to prevent damage during transit.

- All sensitive components (e.g., thermocouples, control panels, vacuum seals) should be protected or removed and shipped separately.

- Hydrogen supply systems (e.g., gas lines, valves, regulators) must be capped and sealed to prevent contamination.

2.2 Shipping Classification

- Sintering furnaces are typically classified as heavy industrial machinery.

- If shipped with hydrogen cylinders or integrated H₂ systems, additional hazardous materials (HAZMAT) regulations may apply.

- UN Number: UN1049 (Hydrogen, compressed) if hydrogen cylinders are included.

- Proper HAZMAT labeling, documentation, and carrier certification are required for hydrogen transport.

2.3 Import/Export Controls

- Check for export restrictions under EAR (Export Administration Regulations) or ITAR, especially for high-temperature or vacuum systems with dual-use potential.

- Customs Classification: Use correct HS Code (e.g., 8514.20 – Industrial electric furnaces).

- Provide technical specifications, certificates of conformity (CE, UL, etc.), and end-use statements if required.

3. Installation and Site Preparation

3.1 Facility Requirements

- Ventilation: Install in a well-ventilated area with hydrogen gas detection and exhaust systems.

- Explosion Relief: Provide explosion-proof construction or relief panels if H₂ is used indoors.

- Floor Load Capacity: Ensure the floor can support the furnace weight (typically 1,000–5,000 kg).

- Clearance: Maintain minimum clearance (per manufacturer) for heat dissipation and maintenance access.

3.2 Gas Supply Infrastructure

- Hydrogen Piping: Use stainless steel piping rated for H₂ service; avoid materials prone to hydrogen embrittlement.

- Leak Testing: Perform pressure and leak tests using inert gas (e.g., N₂) before introducing H₂.

- Gas Detection: Install fixed hydrogen sensors with alarms set at 1–25% LEL (Lower Explosive Limit).

- Emergency Shutoff: Include manual and automatic H₂ shutoff valves.

3.3 Electrical and Utility Connections

- Ensure proper voltage, phase, and amperage supply per furnace specifications.

- Ground all components to prevent static discharge (critical with H₂).

- Connect to backup power or UPS if process integrity is critical.

4. Operational Safety and Compliance

4.1 Hydrogen Handling Procedures

- Only trained personnel should operate H₂-fed furnaces.

- Follow lockout/tagout (LOTO) procedures during maintenance.

- Conduct pre-operational checks for leaks, pressure, and sensor function.

- Purge the furnace chamber with inert gas (e.g., N₂ or Ar) before introducing H₂ to prevent explosive mixtures.

4.2 Monitoring and Alarms

- Install continuous monitoring for:

- H₂ concentration

- Oxygen levels (to avoid explosive atmospheres)

- Temperature and pressure

- Integrate alarms with facility safety systems (e.g., fire suppression, ventilation).

4.3 Emergency Response

- Post emergency procedures near the furnace.

- Equip the area with:

- Fire extinguishers (Class C for electrical/gas fires)

- Emergency H₂ shutoff

- Eyewash and safety shower (if chemical cleaning agents are used)

- Train staff in hydrogen fire response (note: H₂ flames are nearly invisible; use thermal cameras if needed).

5. Maintenance and Documentation

5.1 Preventive Maintenance

- Schedule regular inspection of:

- Heating elements

- Seals and gaskets

- Gas lines and valves

- Safety interlocks and sensors

- Replace worn components using OEM or certified parts.

5.2 Recordkeeping

Maintain logs for:

– H₂ usage and cylinder changes

– Leak tests and safety inspections

– Maintenance and repairs

– Operator training and certifications

5.3 Compliance Audits

- Conduct periodic safety audits to ensure adherence to:

- OSHA, NFPA, or local fire codes

- Environmental regulations

- Insurance requirements

6. Disposal and Decommissioning

- Recycle metal components through certified scrap vendors.

- Properly decommission and purge H₂ lines before dismantling.

- Dispose of insulation materials (e.g., ceramic fiber) according to local hazardous waste regulations.

Conclusion

Sintering furnaces using hydrogen (H₂) require strict adherence to safety, environmental, and transportation regulations. Proper logistics planning, facility preparation, and ongoing compliance management are essential to ensure safe and efficient operation. Always consult the furnace manufacturer’s guidelines and local regulatory authorities when installing or operating H₂-based sintering systems.

Note: This guide is for informational purposes only and does not substitute for legal or engineering advice. Regulations vary by jurisdiction; verify all requirements with local authorities.

Conclusion for Sourcing a Furnace for Sintering:

After a thorough evaluation of technical requirements, production needs, and supplier capabilities, sourcing a sintering furnace requires a strategic balance between performance, reliability, energy efficiency, and total cost of ownership. The selection should align closely with the specific material composition, desired sintering atmosphere (e.g., vacuum, inert gas, hydrogen), temperature profile, and throughput requirements.

Key considerations such as maximum operating temperature, temperature uniformity, control system sophistication, and safety features must be prioritized to ensure consistent product quality and process repeatability. Additionally, vendor reputation, after-sales support, lead time, and compliance with industry standards (e.g., CE, UL) play a crucial role in long-term operational success.

Based on the analysis, it is recommended to proceed with a qualified supplier offering a furnace design that meets current production demands while allowing for scalability. Investing in advanced monitoring and automation features may enhance process control and reduce operational downtime. Ultimately, the chosen furnace should not only fulfill technical specifications but also contribute to improved yield, energy savings, and overall manufacturing efficiency.