The global FRP (Fiberglass Reinforced Plastic) shower panels market is experiencing robust growth, driven by rising demand for durable, low-maintenance, and water-resistant bathroom solutions in both residential and commercial construction. According to Grand View Research, the global FRP panels market size was valued at USD 12.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. The increasing adoption of FRP in wet areas—attributed to its superior resistance to moisture, mold, and impact—has positioned it as a preferred alternative to traditional materials like ceramic tiles and natural stone. Additionally, the construction industry’s shift toward modular and prefabricated bathroom units is further accelerating the uptake of FRP shower panels. As urbanization and infrastructure development continue to surge, particularly in the Asia Pacific and North America regions, manufacturers are investing in innovation and scalable production to meet evolving consumer and regulatory standards. In this dynamic landscape, seven key players have emerged as leaders, combining advanced manufacturing capabilities, stringent quality control, and strong distribution networks to capture significant market share.

Top 7 Frp Shower Panels Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 FRP Panels

Domain Est. 2000

Website: mdcwall.com

Key Highlights: MDC’s Fiberglass Reinforced Plastic (FRP) panels are expertly engineered to not only withstand wet environments, but also those environments exposed to higher …Missing: shower m…

#2 Stabilit America

Domain Est. 2015

Website: stabilitamerica.com

Key Highlights: At Stabilit America, we specialize in the manufacturing and distribution of high-quality fiberglass reinforced panels for a wide variety of applications….

#3 Building Products

Website: valtoem.com

Key Highlights: VALTO, formerly Valto EM, is the first and largest global manufacturer of FRP wall paneling. We deliver quality products that perform in demanding environments….

#4 FM Approved FiberLite FRP Wall Panels

Domain Est. 1996

Website: nudo.com

Key Highlights: FiberLite FRP wall panels are fiberglass reinforced plastic panels that feature moisture and impact resistance, easy maintenance and competitive pricing….

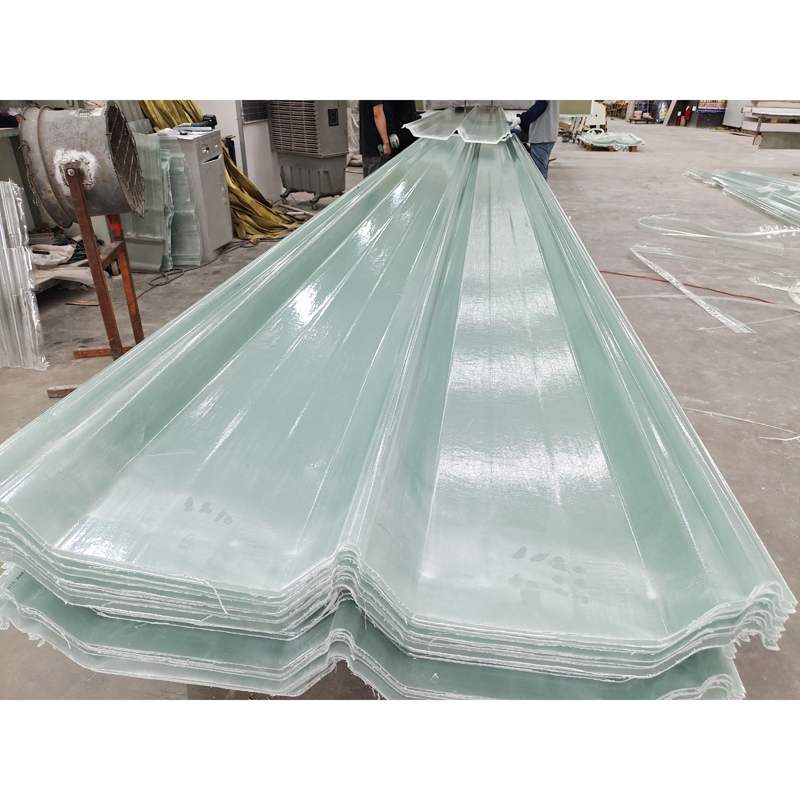

#5 Translucent Fiberglass Panels

Domain Est. 1996

Website: kalwall.com

Key Highlights: Discover the benefits of translucent fiberglass panels and translucent FRP for superior daylighting and energy efficiency in your next project….

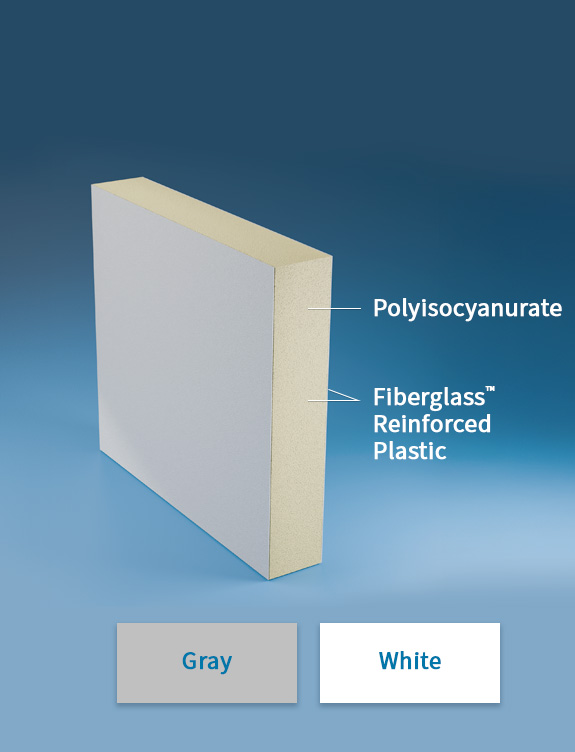

#6 FRP Thermal Wall Panels

Domain Est. 1997

Website: portafab.com

Key Highlights: Fireglass reinforced panels or FRP panels are ideal for areas with high moisture like restrooms, labs and kitchens….

#7 Fiberglass Reinforced Panels (FRP)

Domain Est. 1999

Website: lwsupply.com

Key Highlights: We offer standard FRP for high-wear spaces, designer FRP with various textures and finishes, and structural FRP for load-bearing applications….

Expert Sourcing Insights for Frp Shower Panels

H2: 2026 Market Trends for FRP Shower Panels

The global market for Fiberglass Reinforced Plastic (FRP) shower panels is poised for significant transformation by 2026, driven by technological advancements, evolving consumer preferences, and increasing demand for sustainable and low-maintenance building materials. As construction and renovation activities rebound in both residential and commercial sectors, FRP shower panels are gaining traction due to their durability, cost-efficiency, and aesthetic versatility.

One of the key drivers shaping the 2026 market landscape is the growing emphasis on water-resistant and mold-resistant materials in wet areas. With rising awareness of indoor air quality and hygiene—especially post-pandemic—consumers are favoring non-porous surfaces like FRP that inhibit microbial growth. FRP shower panels offer a seamless, easy-to-clean alternative to traditional ceramic tiles, making them ideal for healthcare facilities, senior living communities, hotels, and multifamily housing.

Another notable trend is the integration of advanced manufacturing techniques, such as digital printing and thermoforming, which allow FRP panels to mimic high-end materials like marble, stone, or wood grain. This aesthetic enhancement is broadening their appeal in premium residential markets, where design and functionality intersect. Additionally, manufacturers are investing in eco-friendly resins and recycled content to align with green building certifications like LEED and BREEAM, catering to environmentally conscious consumers and regulatory demands.

Regionally, the Asia-Pacific market is expected to witness the fastest growth due to rapid urbanization, expanding middle-class populations, and increased infrastructure development in countries like India and Vietnam. Meanwhile, North America and Europe will continue to adopt FRP panels in retrofit projects and accessible bathroom designs, particularly targeting aging populations requiring slip-resistant and easy-access solutions.

Supply chain optimization and localized production are also emerging as strategic priorities for manufacturers aiming to reduce lead times and transportation costs. This shift supports resilience amid global disruptions and enhances customization capabilities for regional markets.

In summary, by 2026, the FRP shower panel market will be shaped by innovation in design and materials, a strong focus on health and sustainability, and expanding applications across diverse sectors. Stakeholders who invest in product differentiation, eco-conscious manufacturing, and smart distribution channels are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls Sourcing FRP Shower Panels (Quality, IP)

Sourcing Fiberglass Reinforced Plastic (FRP) shower panels can be cost-effective and durable, but several common pitfalls related to quality and intellectual property (IP) can compromise performance and lead to legal or reputational risks. Being aware of these issues is critical for builders, contractors, and procurement professionals.

Poor Material Quality and Construction

One of the most frequent issues when sourcing FRP shower panels is receiving substandard materials. Low-quality panels may use inadequate resin content, weak or improperly layered fiberglass, or low-grade gel coats. These defects can result in premature cracking, delamination, warping, or surface degradation when exposed to moisture and heat. Panels may also have inconsistent thickness or poor finish, affecting both aesthetics and functionality.

Inadequate Water Resistance and Sealing

While FRP is inherently water-resistant, poor manufacturing processes can compromise this advantage. Inadequately sealed edges, porous surfaces, or weak joints increase the risk of water ingress, leading to mold, mildew, and structural damage over time. Buyers often assume all FRP panels offer full waterproofing, but low-quality or poorly assembled units may fail under real-world conditions.

Non-Compliance with Industry Standards

Many sourced FRP panels—especially from unverified suppliers—do not meet safety or performance standards such as ASTM C518 (thermal resistance), ASTM D790 (flexural properties), or local building codes. This non-compliance can lead to failed inspections, liability issues, or costly replacements. Always verify certifications and request test reports before procurement.

Misrepresentation of Intellectual Property (IP)

Some suppliers may falsely claim proprietary technology, patented designs, or exclusive formulations to justify premium pricing. In reality, they may be using generic or copied designs. This misrepresentation not only inflates costs but can expose buyers to IP infringement claims if the panels use protected patterns, textures, or manufacturing techniques without authorization.

Risk of IP Infringement from Copycat Designs

Sourcing from manufacturers in regions with lax IP enforcement increases the risk of inadvertently purchasing panels that replicate patented designs or registered trademarks. If these panels are installed in commercial projects, the end-user or contractor could face legal action from the original IP holder, even if unaware of the infringement.

Lack of Traceability and Documentation

Many low-cost suppliers fail to provide proper documentation, including material safety data sheets (MSDS), compliance certificates, or IP ownership records. Without this traceability, it becomes difficult to verify quality claims or defend against liability in case of failure or legal dispute.

Short-Term Cost vs. Long-Term Value

The temptation to select the lowest-priced FRP panels often leads to hidden long-term costs. Poor quality results in frequent maintenance, early replacement, and potential damage to surrounding structures. Investing in reputable suppliers with verifiable quality and IP compliance typically offers better lifecycle value.

Inadequate Warranty and Support

Low-quality or IP-infringing products often come with weak or unenforceable warranties. If panels fail or legal issues arise, buyers may find little recourse. Ensure suppliers offer comprehensive warranties and stand behind their product claims—both for durability and IP rights.

Avoiding these pitfalls requires thorough due diligence: vetting suppliers, requesting samples, verifying certifications, and consulting legal experts when necessary—especially for large-scale or commercial installations.

Logistics & Compliance Guide for FRP Shower Panels

Overview

Fiberglass Reinforced Plastic (FRP) shower panels are widely used in residential, commercial, and institutional construction due to their durability, moisture resistance, and ease of maintenance. Proper logistics and compliance management are essential to ensure these panels are handled, transported, stored, and installed in accordance with safety, quality, and regulatory standards.

Material Classification & Handling

FRP shower panels are typically classified as non-hazardous building materials. However, they are sensitive to impact, moisture, and temperature fluctuations during transport and storage.

– Packaging: Panels must be securely packaged in moisture-resistant wraps with edge protectors and placed on sturdy pallets.

– Handling: Use mechanical aids (e.g., forklifts, pallet jacks) to avoid bending or cracking. Workers should wear gloves to prevent scratches and contamination.

– Stacking: Store vertically when possible. If horizontal stacking is necessary, limit height to avoid deformation and ensure even support.

Transportation Requirements

- Vehicle Type: Use enclosed, dry trucks or containers to protect panels from weather and road debris.

- Securement: Panels must be strapped tightly to prevent shifting. Avoid over-compression that could damage edges or surfaces.

- Temperature Control: Avoid exposure to extreme temperatures (>60°C or <0°C) during transit to prevent warping or delamination.

- Documentation: Include packing lists, bills of lading, and material safety data sheets (MSDS) with shipments.

Storage Conditions

- Environment: Store in a dry, well-ventilated indoor area, away from direct sunlight and heat sources.

- Duration: Limit storage time; prolonged exposure to humidity or temperature swings may affect integrity.

- Orientation: Store vertically on racks with adequate spacing to prevent bowing or surface damage.

Regulatory & Compliance Standards

FRP shower panels must comply with regional and international building and safety regulations. Key standards include:

– Building Codes: Compliant with the International Building Code (IBC) and International Residential Code (IRC), particularly regarding moisture resistance and structural integrity.

– Fire Safety: Must meet flame spread and smoke development ratings per ASTM E84 or UL 723 (typically Class C or better).

– Indoor Air Quality: Compliant with VOC emission standards such as CA 01350 or LEED v4 for low-emitting materials.

– Sustainability: Products may need to meet environmental standards like GREENGUARD Certification or EPDs (Environmental Product Declarations).

Import & Export Considerations

- Customs Documentation: Include commercial invoices, packing lists, and certificates of origin.

- Tariff Classification: FRP panels typically fall under HS Code 3925.30 (Other articles of plastics, for building).

- Import Restrictions: Verify compliance with local construction material regulations in destination countries (e.g., CE marking in the EU, CCC in China).

- Phytosanitary Requirements: Wooden pallets must be ISPM-15 certified for international shipments.

Installation & On-Site Compliance

- Training: Installers should be trained in manufacturer-recommended methods to ensure watertight joints and proper fastening.

- Ventilation: Follow OSHA guidelines if adhesives or sealants with VOCs are used during installation.

- Inspection: Final installations must pass building inspector review for code compliance, especially in wet areas.

Quality Assurance & Traceability

- Batch Tracking: Maintain lot numbers and production dates for traceability in case of recalls or defects.

- Certifications: Retain test reports for fire resistance, structural performance, and durability.

- Warranty Compliance: Follow manufacturer storage and handling guidelines to preserve warranty validity.

Disposal & Recycling

- End-of-Life: FRP panels are not biodegradable but may be recyclable through specialized facilities.

- Landfill Disposal: Follow local waste management regulations; some regions classify FRP as non-hazardous construction waste.

- Recycling Options: Investigate regional programs for composite material reprocessing.

By adhering to this guide, distributors, contractors, and facility managers can ensure the safe, compliant, and efficient logistics management of FRP shower panels throughout their lifecycle. Always consult manufacturer specifications and local regulatory bodies for project-specific requirements.

In conclusion, sourcing FRP (Fiberglass Reinforced Plastic) shower panels offers a durable, cost-effective, and low-maintenance solution for both residential and commercial bathroom applications. Their resistance to moisture, mold, and impact makes them ideal for wet environments, while their lightweight nature simplifies installation and reduces structural load. When sourcing FRP panels, it is essential to evaluate key factors such as product quality, compliance with industry standards, supplier reliability, and long-term performance. Prioritizing reputable manufacturers and certified materials ensures enhanced durability and safety. Additionally, considering customization options, color finishes, and ease of installation can further improve project efficiency and aesthetic appeal. Overall, with the right sourcing strategy, FRP shower panels present a smart investment in terms of longevity, hygiene, and cost savings over time.