The global foundation anchor bolt market is experiencing steady growth, driven by rising construction activities, infrastructure development, and increasing demand in industrial and commercial sectors. According to Grand View Research, the global construction anchors market was valued at USD 4.3 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. Similarly, Mordor Intelligence forecasts continued momentum in the anchor fasteners market, citing infrastructure modernization and urbanization—particularly in Asia-Pacific and Latin America—as key growth drivers. With safety, structural integrity, and compliance at the forefront of engineering standards, selecting high-performance anchor bolts from reliable manufacturers has become critical. As demand rises, a handful of manufacturers have distinguished themselves through innovation, quality certification, and global supply capabilities. Here’s a data-informed look at the top 10 foundation anchor bolt manufacturers shaping the industry.

Top 10 Foundation Anchor Bolt Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Foundation Systems and Anchors

Domain Est. 1998

Website: fsabolt.com

Key Highlights: Foundation Systems & Anchors, Inc. is a manufacturer and supplier of a variety of threaded rod products specifically to municipal, state and federal highway ……

#2 J.H. Botts, LLC

Domain Est. 1998

Website: jhbotts.com

Key Highlights: We stock a majority of the standard-size bolts used in the roadway lighting industry, along with bolts for the traffic signal and sign structure industries. We ……

#3 Foundation Bolts Manufacturer

Domain Est. 2005

Website: gsforgings.com

Key Highlights: Foundation Bolts Manufacturing. Our manufacturing abilities enable us to create custom anchor bolt solutions for any need, to the highest standards of quality….

#4 Anchoring Systems

Domain Est. 1990

Website: cmc.com

Key Highlights: Explore CMC’s advanced anchoring systems, including precision-engineered anchor bolt cages, designed for strength and stability in transmission, substation, ……

#5 Fasteners

Domain Est. 1995

Website: hilti.com

Key Highlights: Shop all products · Mechanical anchors · Chemical anchors · Anchor rods & elements · Cast-in anchors · Cast-in anchor channels · Screws · Nails · Threaded studs & ……

#6 Titen HD® Heavy

Domain Est. 1995

Website: strongtie.com

Key Highlights: A high-strength screw anchor for use in cracked and uncracked concrete, as well as uncracked masonry. The Titen HD offers low installation torque and ……

#7 Anchor Rods & Foundation Bolts

Domain Est. 1996

Website: dysoncorp.com

Key Highlights: Dyson Corp. is a leading provider of anchor rods and foundation bolts, including fasteners conforming to mil specs. We also fabricate custom anchor ……

#8 Bolt anchor

Domain Est. 1997

Website: fischer-international.com

Key Highlights: The anchors are made from normal steel, hot-dip galvanised steel, stainless steel, and highly corrosion-resistant steel. They safely introduce the loads into ……

#9 Machinery Foundation and Anchor Bolts

Domain Est. 1998

Website: rlrowan.com

Key Highlights: We carry a full line of anchor bolts from 5/8″ to 2+” in any length. From a standard one-piece bolt to a new high strength two-piece canister bolt….

#10 Royal Anchors

Domain Est. 2012

Website: royalanchors.com

Key Highlights: We are your single source for Anchor Foundation Bolts, Sag Rods, Brace Rods, and Connection Fasteners, delivering precision and reliability with every product….

Expert Sourcing Insights for Foundation Anchor Bolt

2026 Market Trends for Foundation Anchor Bolts: Strategic Growth and Innovation

The global foundation anchor bolt market is poised for significant transformation by 2026, shaped by evolving construction demands, technological advancements, and sustainability imperatives. This analysis examines key trends projected to influence market dynamics, product development, and competitive positioning in the lead-up to 2026.

1. Accelerated Demand from Infrastructure Modernization and Urbanization

Urban expansion, particularly in Asia-Pacific, the Middle East, and parts of Africa, will drive robust demand for new commercial, residential, and industrial buildings. Concurrently, aging infrastructure in North America and Europe is triggering large-scale renovation and seismic retrofitting projects. Anchor bolts are essential in both new construction and structural reinforcement, positioning the market for sustained growth. Governments investing in smart cities, transportation networks, and resilient public infrastructure will further amplify demand, especially for high-performance anchor solutions.

2. Dominance of Sustainable and Low-Carbon Construction Practices

Environmental regulations and green building certifications (e.g., LEED, BREEAM) are pushing the construction industry toward sustainable materials and practices. By 2026, anchor bolt manufacturers will increasingly adopt low-carbon steel production methods and explore recycled materials. Product transparency, including Environmental Product Declarations (EPDs), will become critical for market access. Demand for corrosion-resistant, long-life anchors will rise to reduce lifecycle emissions and maintenance costs, aligning with net-zero construction goals.

3. Technological Advancements in Smart and High-Performance Anchors

Innovation will focus on enhancing performance, safety, and ease of installation. Smart anchor bolts embedded with sensors for structural health monitoring (SHM)—measuring stress, vibration, and corrosion—are expected to gain traction in critical infrastructure such as bridges, power plants, and high-rises. Additionally, high-strength, lightweight materials like advanced alloys and composite anchors will emerge, offering superior load capacity and durability. Digital tools such as BIM (Building Information Modeling) integration will streamline anchor specification and placement, reducing errors and improving project efficiency.

4. Regional Shifts and Supply Chain Resilience

Geopolitical tensions and supply chain disruptions have highlighted the importance of regional manufacturing and localized sourcing. By 2026, manufacturers are likely to decentralize production to mitigate risks and reduce logistics costs. This trend will benefit regional suppliers and foster partnerships between anchor bolt producers and local construction firms. Meanwhile, regulatory harmonization in standards (e.g., ISO, ASTM, EN) will facilitate cross-border trade and ensure product reliability across global markets.

5. Increased Regulatory Scrutiny and Safety Standards

Safety failures related to structural anchoring—especially in seismic zones—will lead to stricter enforcement of installation protocols and quality control. Certification requirements for anchor systems, including post-installed anchors, will become more rigorous. Manufacturers will respond by offering comprehensive technical support, training programs, and traceable product documentation. Digital QR codes or blockchain tracking for anchor batches may become standard to ensure compliance and accountability.

Conclusion

By 2026, the foundation anchor bolt market will be defined by a convergence of sustainability, digitalization, and performance excellence. Companies that invest in eco-friendly materials, smart technologies, and resilient supply chains will gain a competitive edge. As infrastructure demands grow and regulatory landscapes evolve, anchor bolt manufacturers must adapt proactively to meet the needs of a safer, smarter, and more sustainable built environment.

Common Pitfalls When Sourcing Foundation Anchor Bolts (Quality & Intellectual Property)

Sourcing foundation anchor bolts—critical components in structural integrity—can be fraught with challenges, especially concerning quality assurance and intellectual property (IP) protection. Overlooking these aspects can lead to structural failures, legal disputes, and significant financial losses. Below are key pitfalls to avoid:

Poor Quality Control and Non-Compliance with Standards

One of the most frequent issues is receiving anchor bolts that fail to meet required mechanical or dimensional specifications. Suppliers, especially low-cost or unverified ones, may use substandard materials, improper heat treatment, or inaccurate threading, leading to reduced tensile strength and premature failure. Always verify compliance with recognized standards such as ASTM A307, A364, or ISO 898-1. Lack of proper certification (e.g., mill test reports, third-party inspection) increases the risk of defective products.

Inadequate Traceability and Documentation

Without full traceability—such as lot numbers, material certifications, and test results—it becomes difficult to verify the origin and quality of anchor bolts. This is particularly problematic in construction audits or post-failure investigations. Poor documentation also complicates compliance with building codes and regulatory requirements.

Counterfeit or Imitation Products

Some suppliers may offer anchor bolts that mimic reputable brands but lack the genuine performance characteristics. These counterfeit products often use inferior steel or incorrect manufacturing processes. Visual inspection alone is insufficient; mechanical testing and material verification are essential to detect fakes.

Intellectual Property Infringement

Using or sourcing anchor bolts that replicate patented designs (e.g., specialized embedment systems, anti-rotation features, or seismic-rated configurations) without authorization can lead to legal action. Many engineered anchor solutions are protected by patents, and procurement teams may unknowingly violate IP rights by selecting cost-effective clones. Always confirm IP compliance, especially when sourcing proprietary or high-performance systems.

Misrepresentation of Coatings and Corrosion Resistance

Anchor bolts are often exposed to harsh environments, making corrosion protection critical. Suppliers may falsely claim galvanization (e.g., hot-dip galvanized per ASTM A153) or use inadequate coatings that degrade prematurely. Inadequate coating thickness or improper application reduces service life and compromises structural safety.

Language and Specification Misunderstandings

Especially when sourcing internationally, differences in terminology, measurement units (imperial vs. metric), or interpretation of technical drawings can lead to incorrect products being delivered. Misaligned thread types, embedment lengths, or head styles may render bolts unusable or unsafe.

Lack of Supplier Qualification and Due Diligence

Procuring from unvetted suppliers increases the risk of inconsistent quality and unreliable delivery. Skipping audits, reference checks, or sample testing exposes projects to supply chain vulnerabilities. A qualified supplier should have a proven track record, quality management systems (e.g., ISO 9001), and technical support capability.

Failure to Secure Proper Licensing for Proprietary Systems

Some high-performance anchor bolt systems require licensing for use, particularly in engineered structural applications. Using such systems without proper authorization not only violates IP rights but may also void performance warranties and liability insurance.

To mitigate these risks, implement a robust sourcing strategy that includes supplier vetting, independent quality inspections, clear technical specifications, and legal review of IP considerations. Ensuring compliance and authenticity protects both structural integrity and legal liability.

Logistics & Compliance Guide for Foundation Anchor Bolt

Overview of Foundation Anchor Bolts

Foundation anchor bolts are critical components used to secure structural elements, such as columns and base plates, to concrete foundations. Ensuring proper logistics and compliance throughout their lifecycle—from manufacturing to installation—is essential for structural integrity, safety, and regulatory adherence.

Regulatory and Industry Standards

Anchor bolts must comply with recognized industry standards to ensure quality and performance. Key standards include:

– ASTM F1554: Standard Specification for Anchor Bolts, Steel, Grade 36, 55, and 105

– AISC 360: Specification for Structural Steel Buildings (governs use in steel construction)

– ACI 318: Building Code Requirements for Structural Concrete (covers embedment and design)

– ISO 898-1: Mechanical properties of fasteners made of carbon steel and alloy steel

– Local building codes and seismic requirements (e.g., IBC, CBC)

Compliance with these standards ensures bolts are fit for purpose and meet load, corrosion, and durability requirements.

Material and Manufacturing Compliance

Manufacturers must provide certification documentation, including:

– Mill test reports (MTRs) verifying chemical composition and mechanical properties

– Certificates of Conformance (CoC) to ASTM or ISO standards

– Traceability through heat numbers and batch identification

– Third-party inspection reports (if required by project specifications)

Galvanization or other protective coatings (e.g., hot-dip galvanizing per ASTM A153) must be applied where corrosion resistance is required, especially in outdoor or marine environments.

Packaging and Marking Requirements

Proper packaging prevents damage during transit and storage:

– Bolts should be bundled and secured to prevent bending or deformation

– Threaded ends must be protected with caps or tape

– Each bundle must be clearly marked with:

– ASTM designation (e.g., F1554 Gr. 55)

– Size, length, and thread pitch

– Heat number and manufacturer identification

– Project-specific tagging (if applicable)

Transportation and Handling

- Anchor bolts should be transported on flatbed trucks or enclosed trailers with adequate bracing

- Use cranes or forklifts with soft slings to prevent thread damage during loading/unloading

- Avoid dragging or dropping bundles to prevent bending

- Segregate different grades, sizes, or coatings to prevent mix-ups

Storage and Inventory Management

- Store bolts indoors or under cover to prevent moisture exposure and corrosion

- Elevate bundles off the ground using wooden pallets

- Maintain a dry, ventilated storage area

- Implement a first-in, first-out (FIFO) inventory system

- Conduct periodic inspections for rust, thread damage, or coating degradation

Documentation and Traceability

Maintain a complete compliance trail:

– Purchase orders and supplier agreements

– Mill test reports and CoCs

– Inspection and test records (e.g., dimensional checks, tensile testing)

– Shipping and delivery logs

– Site acceptance reports

Digital record-keeping systems improve traceability and audit readiness.

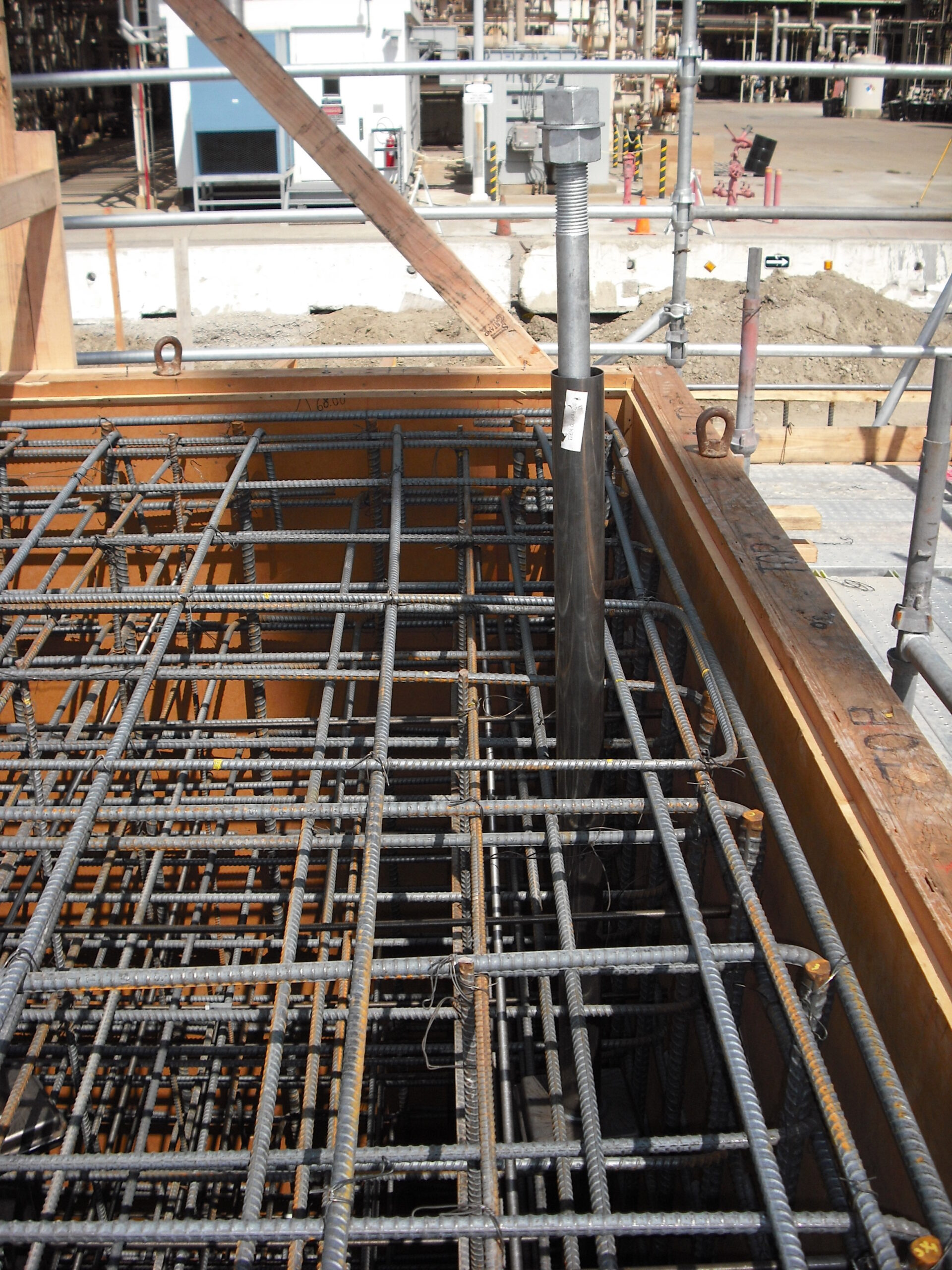

Installation and Quality Control

- Verify bolt dimensions, grade, and coating match project specifications before installation

- Use calibrated torque wrenches for tensioning if required

- Follow approved installation procedures (e.g., correct embedment depth, alignment)

- Conduct pull-out or tension tests as specified by the engineer

- Document installation with photos and inspection sign-offs

Non-Conformance and Corrective Actions

- Isolate non-compliant bolts immediately

- Report deviations to the project engineer and quality manager

- Conduct root cause analysis for rejected batches

- Implement corrective actions (e.g., rework, replacement, supplier audit)

- Update procedures to prevent recurrence

Environmental, Health, and Safety (EHS) Considerations

- Follow safe handling practices to prevent injuries from sharp threads or heavy loads

- Dispose of galvanizing waste (e.g., zinc residue) in accordance with environmental regulations

- Use personal protective equipment (PPE) during handling and installation

Conclusion

Adhering to logistics and compliance protocols for foundation anchor bolts ensures structural reliability, regulatory compliance, and project success. A systematic approach—from sourcing and documentation to handling and installation—minimizes risks and supports long-term performance.

Conclusion for Sourcing Foundation Anchor Bolts:

Sourcing foundation anchor bolts requires a strategic approach that balances quality, cost, compliance, and supply chain reliability. These critical structural components play a vital role in ensuring the stability and safety of buildings and infrastructure, making it essential to procure them from reputable suppliers who adhere to recognized industry standards such as ASTM A307, ASTM F1554, or ISO specifications.

Key considerations in the sourcing process include material grade, dimensional accuracy, corrosion resistance (e.g., hot-dip galvanization or stainless steel options), and the technical capabilities of the manufacturer. Engaging suppliers with proven quality control processes, certification, and traceability ensures long-term performance and compliance with engineering requirements.

Additionally, evaluating lead times, logistical support, and the supplier’s ability to accommodate project-specific modifications helps mitigate delays and maintain construction schedules. Establishing strong partnerships with reliable vendors, backed by thorough vetting and performance monitoring, contributes to successful project outcomes.

In conclusion, a well-structured sourcing strategy for foundation anchor bolts—grounded in technical specifications, quality assurance, and supply chain efficiency—ensures structural integrity, regulatory compliance, and overall project success.