The global automotive engine market, particularly the segment for performance and replacement powertrains, has seen steady growth driven by increasing demand from the automotive restoration, aftermarket modification, and industrial equipment sectors. According to Grand View Research, the global automotive engine market was valued at USD 106.7 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. A key contributor to this trend is the rising popularity of crate engines—pre-built, drop-in powertrain solutions—among DIY enthusiasts and performance vehicle builders. Within this niche, the Ford 300 inline-6 cylinder crate engine remains a sought-after option due to its reliability, ease of maintenance, and compatibility with both vintage trucks and modern swaps. As demand grows, a select group of manufacturers has emerged as leaders in producing high-quality, performance-optimized versions of the Ford 300 6-cylinder crate engine, combining engineering precision with data-backed performance enhancements.

Top 6 Ford 300 6 Cylinder Crate Engines Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Ford 300 Inline 6 Long 4.9 Block Crate Engine Sale, Remanufactured

Domain Est. 2015

Website: spprecision.com

Key Highlights: Our Ford 300 Inline 6 Long Block Engine is on Sale. Better than a rebuilt 4.9 Crate Engine, this OEM motor is completely remanufactured with upgraded parts….

#2 Crate Engines

Domain Est. 1988

#3 Ford® Reman Gas Engines

Domain Est. 1988

Website: ford.com

Key Highlights: Shop Reman Gas Engines from the official Ford® Accessories store. View your favorite products. Filter by category, brand, price & color.Missing: 300 6…

#4 Performance Crate Engine & Motors

Domain Est. 1996

Website: jasperengines.com

Key Highlights: JASPER offers four levels of crate engines, or crate motors, aimed at improving the performance of your project vehicle….

#5 RAMPTECH® Ford 300 4.9L Engines

Domain Est. 1998

Website: sageparts.com

Key Highlights: Not all remanufactured engines are created equal. And some are recreated better than the original. Such is the case with the RAMPTECH® Ford 300 4.9L Engine….

#6 Ford 4.9 300 Premium Long Block 1968

Domain Est. 2011

Website: mabbcomotors.com

Key Highlights: This MABBCO® Remanufactured Premium Long Block is for a Ford 4.9 300 motor, model years 1968-1986. This block is identifiable by its mechanical fuel pump hole….

Expert Sourcing Insights for Ford 300 6 Cylinder Crate Engines

H2: 2026 Market Trends for Ford 300 6-Cylinder Crate Engines

As the automotive industry continues to evolve with a strong emphasis on electrification and emissions reduction, niche markets for classic and performance internal combustion engines—such as the Ford 300 inline-six crate engine—remain resilient due to enduring demand from restoration, off-road, and custom vehicle builders. Looking ahead to 2026, several key trends are shaping the market for Ford 300 6-cylinder crate engines:

-

Growing Enthusiasm for Classic Truck and SUV Restorations

The Ford 300 inline-six, originally used in trucks and vans from the 1960s through the 1990s, is experiencing renewed interest among classic Ford F-100, F-150, and Bronco restorers. As vintage truck culture gains popularity, particularly in North America, demand for reliable, period-correct powerplants like the 300 inline-six is rising. Crate engines offer plug-and-play convenience, making them a preferred choice for restomod projects seeking authenticity with modern reliability. -

Increased Demand for Fuel-Efficient, Torque-Forward Engines in Off-Road and Utility Builds

Despite its age, the Ford 300 is prized for its durability, low-end torque, and simplicity. Enthusiasts building off-road rigs or utility vehicles value its long stroke and robust bottom end. In 2026, custom builders are increasingly opting for upgraded 300 inline-six crate engines equipped with modern fuel injection, overdrive transmissions, and emissions-compliant components—bridging the gap between old-school character and improved drivability. -

Limited OEM Support, Rising Aftermarket Innovation

Ford no longer produces the 300 inline-six, but specialized aftermarket companies such as Jasper Engines, Summit Racing, and Blueprint Engines continue to offer crate versions with performance enhancements. By 2026, expect to see more drop-in crate solutions featuring electronic fuel injection (EFI), improved cooling, and compatibility with modern ECUs—catering to buyers who want vintage charm with contemporary performance. -

Sustainability and Longevity Driving Engine Reuse

Environmental concerns are prompting more builders to rebuild or remanufacture existing engines rather than rely on new production. The iron-block Ford 300 is highly rebuildable, contributing to its appeal in a market increasingly focused on sustainability. Crate engines made from remanufactured cores align with eco-conscious trends while offering cost-effective performance. -

Competition from V8 Swaps and Electrification

While demand remains steady, the Ford 300 faces competition from easier V8 conversions and the growing trend of EV powertrain swaps in classic trucks. However, purists and economy-focused builders continue to champion the 300 for its fuel efficiency, smooth idle, and OEM authenticity—helping maintain a stable niche market through 2026. -

Price Trends and Availability

By 2026, basic Ford 300 crate engines are expected to range from $2,500 to $4,500, with high-performance or fuel-injected versions commanding $6,000+. Availability may tighten slightly due to core shortages, but remanufacturers are adapting through improved recycling and machining techniques.

In summary, while the Ford 300 6-cylinder crate engine occupies a specialized segment, its market is sustained by passionate enthusiasts, restomod culture, and practical advantages in specific build applications. The 2026 landscape favors enhanced versions of this classic engine, integrating modern technology to meet evolving performance and regulatory expectations.

Common Pitfalls When Sourcing Ford 300 6-Cylinder Crate Engines: Quality and Intellectual Property Concerns

Sourcing a Ford 300 inline-six crate engine—often sought after for truck restorations, off-road builds, or fuel-efficient swaps—can present several challenges, particularly in the areas of component quality and intellectual property (IP) compliance. Buyers and builders must be vigilant to avoid costly mistakes.

Quality-Related Pitfalls

One of the most prevalent issues when sourcing Ford 300 6-cylinder crate engines is inconsistent or substandard build quality. Many crate engines are assembled by third-party rebuilders or aftermarket companies rather than Ford Motor Company itself, leading to variability in materials, machining precision, and assembly practices.

-

Use of Non-OEM or Low-Grade Parts: Some suppliers cut costs by using aftermarket pistons, bearings, or gaskets that don’t meet OEM specifications. This can result in premature wear, oil consumption, or engine failure under load.

-

Inadequate Machining and Tolerances: Improperly resurfaced blocks, poorly aligned crankshafts, or improperly honed cylinders can compromise longevity and performance. Engines that haven’t undergone proper blueprinting may not deliver the reliability expected from a “crate” unit.

-

Insufficient Testing: Reputable crate engines should undergo dynamometer testing or at least pre-lube and rotation checks. Many budget suppliers skip this step, increasing the risk of receiving a defective or improperly assembled engine.

-

Misrepresentation of “New” vs. “Rebuilt”: Some sellers label remanufactured engines as “new crate engines,” creating confusion. Buyers may pay a premium expecting a fully new block and internals, only to receive a core engine with mixed components.

Intellectual Property and Branding Concerns

The Ford 300 inline-six engine, while out of production, is still protected under certain intellectual property rights, especially when it comes to branding, logos, and OEM design elements.

-

Unauthorized Use of Ford Trademarks: Some crate engine suppliers market their products using Ford logos, part numbers, or branding without licensing. This can mislead buyers into believing the engine is factory-original or officially sanctioned by Ford, which it is not. Such practices may violate trademark laws and expose both seller and buyer to legal risk.

-

Counterfeit or Replica Components: Certain parts, such as valve covers, intake manifolds, or timing covers, may be cast to resemble OEM Ford pieces but are produced without authorization. These replicas can infringe on Ford’s design patents or trademarks, especially if they bear authentic branding.

-

Lack of Documentation and Traceability: Engines lacking proper build sheets, compliance labels, or sourcing documentation may be involved in IP violations. Without clear records, it becomes difficult to verify the authenticity of components or the legality of their reproduction.

Conclusion

To avoid these pitfalls, buyers should source Ford 300 6-cylinder crate engines from reputable, transparent suppliers who provide detailed build specifications, use high-quality or OEM-spec components, and refrain from unauthorized use of Ford trademarks. Verifying certifications, requesting dyno sheets, and confirming the legal status of branded parts can protect both the investment and the builder’s compliance with intellectual property standards.

Logistics & Compliance Guide for Ford 300 6-Cylinder Crate Engines

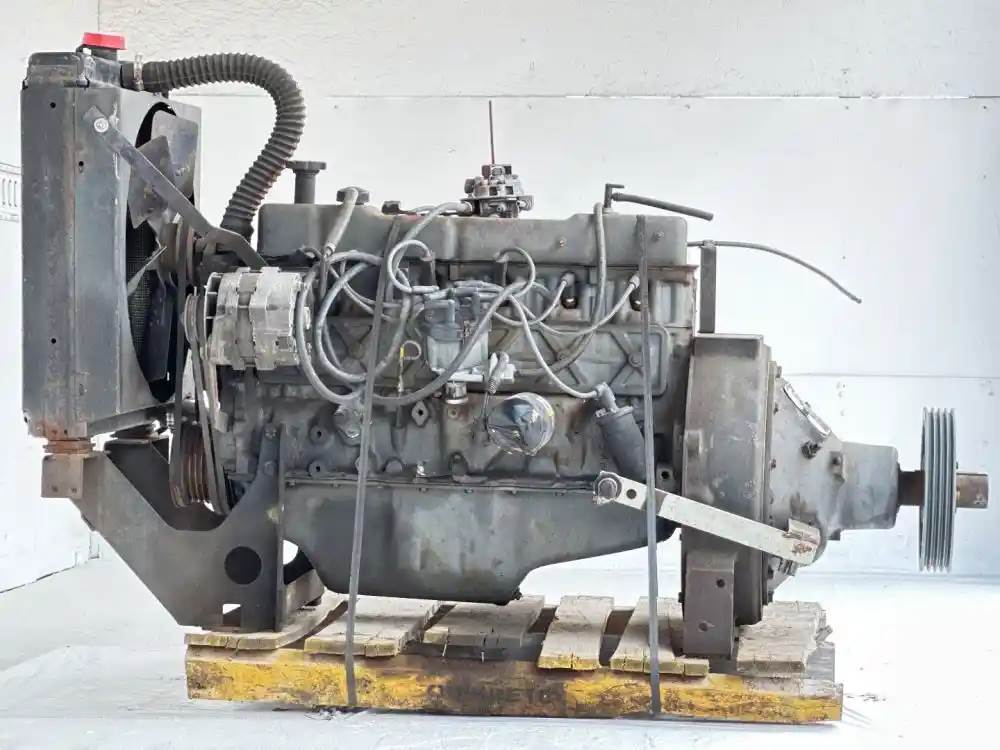

This guide outlines the essential logistics and compliance considerations when transporting and handling Ford 300 6-Cylinder Crate Engines. Adherence to these guidelines ensures safe, legal, and efficient operations.

Packaging and Preparation

Crate engines must be securely packaged to prevent damage during transit. The factory shipping crate should remain intact and undamaged. If repackaging is required, use heavy-duty wooden crates with internal bracing and vibration-dampening materials. All openings (intake, exhaust, oil pan, etc.) must be sealed with protective caps or plugs to prevent contamination. Drain all fluids unless otherwise specified by Ford or the distributor. Attach a durable shipping label with engine serial number, part number, and destination details.

Transportation and Handling

Use professional freight carriers experienced in automotive engine transport. The crate must be lifted using forklifts or pallet jacks via designated entry points—never lift by the engine mounts or external components. Load the engine onto a flat, stable surface in the transport vehicle and secure it with straps or braces to prevent shifting. Avoid extreme temperatures during storage or transit; prolonged exposure to freezing or excessive heat can compromise internal components or seals. Handle with care to avoid impact or tilting that could damage internal parts.

Import/Export Compliance (International Shipments)

For cross-border shipments, ensure compliance with destination country regulations. Provide accurate Harmonized System (HS) codes—typically 8409 91 90 for internal combustion engine parts. Complete all required customs documentation, including commercial invoice, bill of lading, and certificate of origin. Verify emissions and safety standards in the importing country; while crate engines are not installed, some regions may have restrictions on engine types or require conformity documentation. Check for any export controls under U.S. Department of Commerce regulations, especially for shipments to sanctioned regions.

Domestic Regulatory Compliance (U.S.)

In the United States, crate engines are regulated under EPA and state (e.g., CARB) emissions guidelines. While the engine itself is not subject to on-road emissions compliance until installed, sellers and installers must adhere to anti-tampering provisions under the Clean Air Act. Provide clear documentation stating the engine is intended for off-road, racing, or replacement use in exempt vehicles. For California sales, verify if the engine is CARB Executive Order (EO) certified; non-certified engines cannot be sold or installed in California for street use. Maintain records of engine specifications and compliance status.

Hazardous Materials Considerations

Though most crate engines are shipped dry, residual oils or cleaning agents may classify the shipment as containing hazardous materials. If any fluids are present, classify and label accordingly under DOT 49 CFR regulations. Use proper hazard labels and shipping papers if applicable. When in doubt, ship as non-hazardous with a written declaration confirming all fluids have been drained and sealed ports are contamination-free.

Documentation and Recordkeeping

Maintain a complete shipping dossier including packing list, purchase order, bill of lading, compliance statements, and proof of certification (if applicable). Retain records for a minimum of three years to support audit or regulatory inquiries. Provide end users with installation guidelines and emissions compliance information as required.

Final Inspection Upon Delivery

Upon receipt, inspect the crate for visible damage. Document and report any issues to the carrier and supplier immediately. Carefully open the crate and verify the engine matches the order specifications. Check all protective seals and mounts for integrity before proceeding with installation or storage.

In conclusion, sourcing a Ford 300 inline-six crate engine offers a reliable, durable, and cost-effective solution for engine replacements or performance upgrades, particularly in classic trucks, restorations, and off-road or work vehicles. Known for its rugged design and strong low-end torque, the 300 cubic inch inline-six has earned a loyal following among enthusiasts seeking simplicity and longevity. Crate engines provide the advantage of being pre-assembled, tested, and often warrantied, reducing labor costs and installation time.

When sourcing, it’s essential to evaluate reputable suppliers, compare new versus remanufactured options, and consider added features such as modern fuel injection conversions or performance upgrades. While the engine may not match the horsepower of modern V8s, its efficiency, serviceability, and potential for customization make it a compelling choice for the right application.

Ultimately, the Ford 300 6-cylinder crate engine remains a practical and timeless powerplant, and sourcing one thoughtfully ensures long-term satisfaction, performance, and reliability in a wide range of projects.