The global metal roofing market is experiencing steady expansion, driven by rising demand for durable, energy-efficient building materials across residential, commercial, and industrial sectors. According to a 2023 report by Mordor Intelligence, the global metal roofing market was valued at USD 21.6 billion in 2022 and is projected to grow at a CAGR of 4.8% through 2028. This growth underscores the importance of high-performance ancillary components—like foam closures—that ensure weather-tight seals, thermal efficiency, and structural longevity in metal roofing systems. As manufacturers prioritize quality and compliance with evolving energy codes, selecting the right foam closure has become a critical factor in product differentiation and long-term performance. With increasing adoption of prefabricated and sustainable construction methods, demand for resilient, UV-resistant, and compressible foam closures continues to rise in tandem with the expanding metal roof sector.

Top 7 Foam Closures For Metal Roofing Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Metal Roofing Closure Systems

Domain Est. 2002

Website: foamparts.com

Key Highlights: Jacobs & Thompson manufacturers our own line up of custom foam closure systems, designed to seal gaps in metal roofing constructions….

#2

Website: metalsales.us.com

Key Highlights: Metal Sales is the nation’s largest manufacturer of metal roofing, wall, and building systems. We are the most awarded and highly recognized provider of metal ……

#3 Foam Closures & Sealants

Domain Est. 1999

Website: indacometals.com

Key Highlights: Foam closures and sealants are the small but critical components that make metal roofs weather-tight, sealing gaps and preventing leaks, pests, and moisture ……

#4 Closure

Domain Est. 2004

Website: marcoindustries.com

Key Highlights: Roofing foam that designed for UV resistance and longevity, available in a variety of thicknesses and profiles for every application….

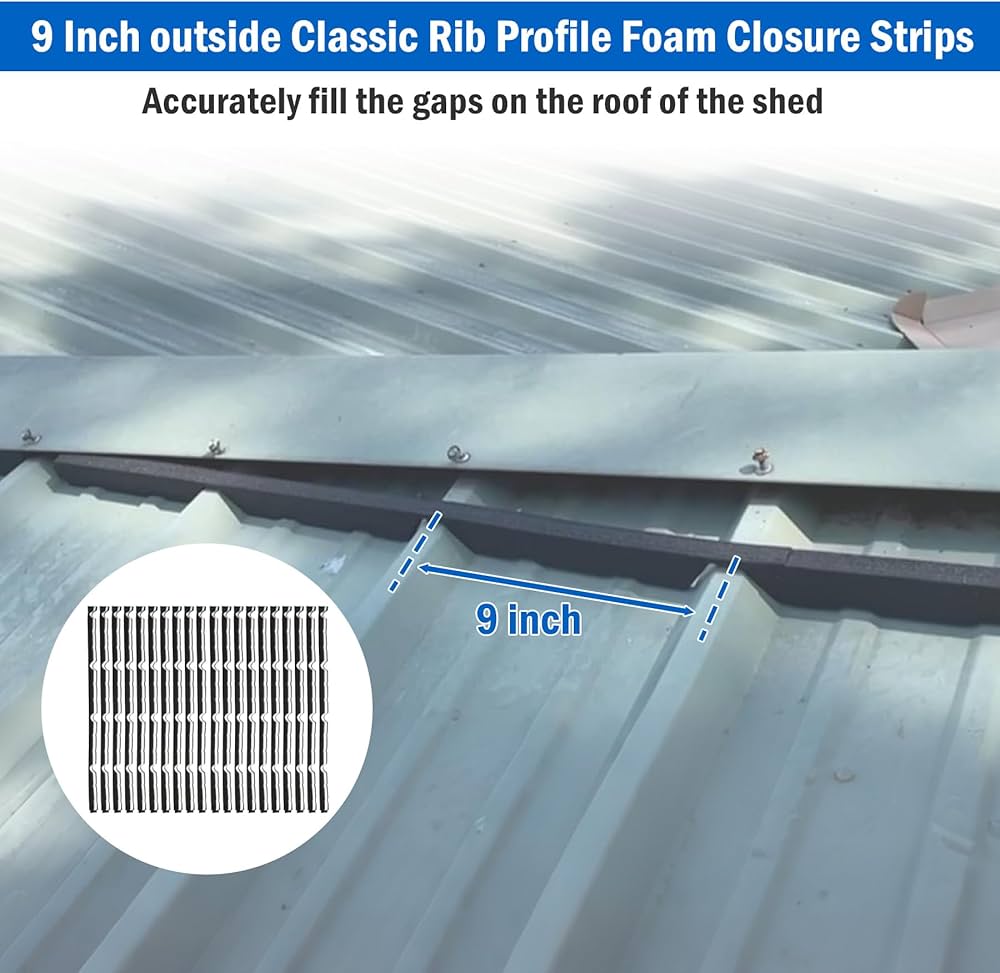

#5 Foam Closure Strips

Domain Est. 2013

Website: scmetals.com

Key Highlights: In stock $24.17 deliveryOne unit includes four 36″ foam closures with adhesive pre-applied. Foam closures are essential components used in metal roofing systems to create a tight ….

#6 Foam Closures For Metal Roofing Panels

Domain Est. 2015

Website: westernstatesmetalroofing.com

Key Highlights: Foam closure strips and plugs for metal roofing panels. WG-7 foam closures can be shipped inexpensively anywhere in the country….

#7 Foam Closure Strips for Metal Roofing

Domain Est. 2016

Website: odonnellmetaldeck.com

Key Highlights: Rating 5.0 (59) These flexible and lightweight closures are designed to handle closure shrinkage, moisture absorption, vapor transmission, and noise migration issues….

Expert Sourcing Insights for Foam Closures For Metal Roofing

H2: 2026 Market Trends for Foam Closures for Metal Roofing

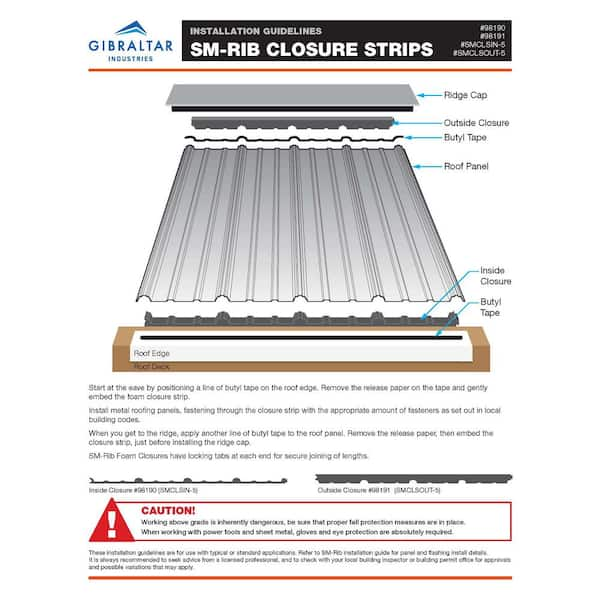

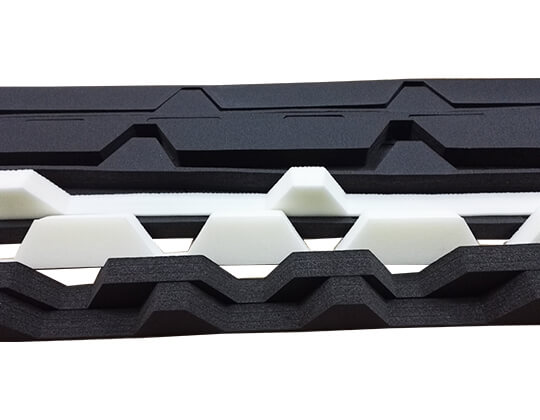

The global market for foam closures in metal roofing is poised for significant evolution by 2026, shaped by technological advancements, sustainability demands, and shifting construction dynamics. Foam closures—typically made from closed-cell or open-cell elastomeric foams—are essential components used to seal the gaps between metal roof panels and structural supports, preventing air and water infiltration, improving thermal efficiency, and reducing noise transmission.

-

Growing Demand Driven by Energy Efficiency Regulations

By 2026, stricter global energy efficiency standards in commercial and industrial construction are expected to boost demand for high-performance building envelope components. Foam closures contribute to improved building insulation and reduce thermal bridging, aligning with net-zero energy goals. Regulatory frameworks such as the U.S. Department of Energy’s Building Energy Codes and the EU’s Energy Performance of Buildings Directive (EPBD) will likely accelerate the adoption of advanced closure systems, including high-resilience foam solutions. -

Shift Toward Sustainable and Recyclable Materials

Environmental concerns are pushing manufacturers to develop eco-friendly foam closure alternatives. By 2026, there will be increased R&D focused on bio-based foams, recyclable polymers, and low-VOC (volatile organic compound) formulations. Companies are expected to emphasize circular economy principles, offering take-back programs or integrating post-consumer recycled content into foam closure production to meet green building certifications like LEED and BREEAM. -

Expansion in Emerging Markets

Rapid urbanization and industrialization in regions such as Southeast Asia, India, and the Middle East are driving infrastructure development, leading to higher demand for durable and cost-effective roofing systems. Metal roofing, with its longevity and low maintenance, is gaining traction, thereby increasing the need for reliable foam closures. Local manufacturing and partnerships with regional construction firms are expected to grow by 2026 to meet this demand. -

Technological Innovation and Smart Integration

Advancements in material science are leading to the development of multifunctional foam closures with enhanced UV resistance, fire retardancy, and improved compression set performance. Some manufacturers are exploring smart foam technologies—incorporating sensors to monitor seal integrity or moisture levels—particularly for high-value industrial and data center applications. While still in early stages, these innovations may begin to emerge commercially by 2026. -

Supply Chain Resilience and Regionalization

Post-pandemic supply chain disruptions have prompted a shift toward regional sourcing and inventory localization. By 2026, foam closure manufacturers are likely to establish regional production hubs closer to key metal roofing markets to mitigate risks and reduce lead times. This trend supports faster project turnaround and aligns with just-in-time construction logistics. -

Competitive Landscape and Consolidation

The market is expected to witness increased competition and consolidation as larger building materials companies acquire niche foam closure specialists to expand their roofing system portfolios. This integration will drive innovation and offer bundled solutions (e.g., foam closures pre-attached to metal panels), enhancing ease of installation and performance reliability.

In conclusion, the 2026 market for foam closures in metal roofing will be characterized by innovation, sustainability, and regional growth. Stakeholders who invest in R&D, adopt green manufacturing practices, and align with regulatory trends will be best positioned to capitalize on these evolving opportunities.

Common Pitfalls Sourcing Foam Closures for Metal Roofing (Quality, IP)

When sourcing foam closures for metal roofing systems, overlooking key quality and intellectual property (IP) concerns can lead to compromised performance, legal risks, and long-term costs. Here are common pitfalls to avoid:

Poor Material Quality and Durability

Many suppliers offer foam closures made from low-grade materials that degrade quickly when exposed to UV radiation, extreme temperatures, and moisture. Inferior foams may compress permanently, crack, or lose sealing effectiveness, leading to water ingress, air leakage, and reduced energy efficiency. Always verify material specifications such as UV resistance, compression set, and temperature range to ensure long-term performance.

Inadequate Weather Resistance

Not all foam closures provide sufficient protection against wind-driven rain, snow, and condensation. Some products lack proper sealing geometry or water-shedding features, resulting in leaks and corrosion at vulnerable roof panel ends. Choose closures specifically engineered for metal roofing with proven weather barrier performance in real-world conditions.

Misalignment with Roof Profile Design

Foam closures must precisely match the profile of the metal roof panels (e.g., standing seam, corrugated, ribbed). Sourcing generic or improperly sized closures leads to gaps, poor fit, and compromised weather-tightness. Avoid one-size-fits-all solutions; instead, select profile-specific closures from reputable manufacturers.

Lack of Intellectual Property Compliance

Using foam closure designs that replicate patented profiles or geometries can expose contractors and building owners to IP infringement claims. Some closure designs are protected by patents related to their unique interlocking features, compression zones, or installation methods. Sourcing from suppliers who license or own the IP mitigates legal risk and ensures design integrity.

Insufficient Testing and Certification

Reputable foam closures should come with third-party test data for air, water, and structural performance (e.g., ASTM E331, AAMA 501.1). Suppliers who cannot provide verified testing results may be selling unproven products that fail under building code requirements or performance expectations.

Short-Term Cost Focus Over Lifecycle Value

Opting for the cheapest foam closure can lead to higher lifecycle costs due to premature failure, maintenance, and potential water damage. High-quality, IP-compliant closures may have a higher upfront cost but deliver superior durability, energy savings, and reduced liability over time.

By addressing these pitfalls—prioritizing material quality, fit, weather resistance, IP compliance, and verified performance—specifiers and contractors can ensure reliable, code-compliant metal roofing systems.

Logistics & Compliance Guide for Foam Closures For Metal Roofing

Product Overview

Foam closures are essential components used in metal roofing systems to seal the gaps between metal panels and structural elements (e.g., fascia, sidewalls, eaves). They are typically made from closed-cell or open-cell foam materials such as polyethylene or polyurethane, designed to provide weather resistance, prevent pest intrusion, and improve energy efficiency by reducing air infiltration.

Shipping & Handling

- Packaging: Foam closures are commonly shipped in compressed rolls, bags, or boxed units to optimize space and reduce shipping costs. Packaging should be moisture-resistant and durable to prevent damage during transit.

- Storage Conditions: Store in a dry, cool environment away from direct sunlight, extreme temperatures, and sources of UV exposure to prevent material degradation.

- Handling Precautions: Avoid dragging or dropping packaged closures. Use appropriate lifting equipment for large bundles to prevent physical damage to the foam material.

Transportation Requirements

- Mode of Transport: Suitable for standard freight via truck, rail, or containerized ocean freight. Air freight is possible for urgent shipments but may increase costs.

- Load Stability: Secure loads with straps or shrink wrap to prevent shifting during transit. Use dunnage where necessary to protect from vibration and compression.

- Labeling: Clearly label packages with product name, part number, quantity, and handling instructions (e.g., “This Side Up,” “Protect from Moisture”).

Regulatory Compliance (U.S. Focus)

- Building Codes: Foam closures must comply with relevant sections of the International Building Code (IBC) and International Residential Code (IRC), particularly regarding fire performance and air barrier requirements.

- Fire Safety: Many jurisdictions require foam closures to meet ASTM E84 (Surface Burning Characteristics) with a maximum flame spread index of 25 and smoke-developed index of 450. Verify local code requirements.

- Environmental Regulations: Ensure compliance with EPA regulations regarding volatile organic compounds (VOCs). Some foam products may need to meet low-VOC standards.

- Flame Retardants: If flame-retardant additives are used, confirm compliance with federal and state chemical safety regulations (e.g., TSCA in the U.S.).

International Trade Considerations

- Harmonized System (HS) Code: Typically classified under HS 3901.90 (other plastic plates, sheets, film, foil, and strip) or similar subcategories depending on composition. Confirm exact code with customs broker.

- Import/Export Documentation: Required documents include commercial invoice, packing list, bill of lading/air waybill, and certificate of origin. Additional certifications may be needed based on destination country.

- REACH & RoHS (EU): If exporting to the European Union, ensure compliance with REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives, particularly for chemical content.

Quality Assurance & Certification

- Third-Party Testing: Provide test reports from accredited labs for fire performance, compression resistance, durability, and UV stability.

- Manufacturer Certifications: Ensure production facilities comply with ISO 9001 (Quality Management) and ISO 14001 (Environmental Management) standards where applicable.

- Product Documentation: Maintain Safety Data Sheets (SDS) and technical data sheets (TDS) for each product variant.

Installation & Field Compliance

- Compatibility: Verify compatibility with specific metal panel profiles and sealants used on-site.

- Air Barrier Compliance: When used as part of an air barrier system, ensure the foam closure integrates properly with other components to meet energy code requirements (e.g., IECC).

- Inspection Readiness: Contractors should be prepared to present product certifications and installation instructions during building inspections.

Disposal & Environmental Responsibility

- End-of-Life: Foam closures are generally non-biodegradable. Dispose of according to local solid waste regulations.

- Recycling: Check with local facilities—some polyethylene foams may be recyclable through specialized programs.

- Sustainability Claims: If marketing recycled content or recyclability, ensure claims are substantiated and compliant with FTC Green Guides.

Summary

Proper logistics and compliance management for foam closures in metal roofing ensures product integrity, regulatory adherence, and successful installation. Key focus areas include secure shipping, environmental and fire safety compliance, accurate documentation, and alignment with building codes across regions. Always consult local authorities and project specifications to confirm all requirements are met.

In conclusion, sourcing foam closures for metal roofing is a critical step in ensuring the long-term performance, energy efficiency, and weather resistance of a roofing system. These closures play an essential role in preventing moisture infiltration, minimizing air leakage, reducing noise transmission, and enhancing thermal insulation. When selecting foam closures, key factors such as material compatibility, UV resistance, compression recovery, durability, and proper fit with the specific metal roofing profile must be carefully evaluated.

It is advisable to work with reputable suppliers who provide high-quality, tested products and technical support to ensure correct installation and optimal performance. Additionally, considering environmental conditions and local building codes will further guide the selection process. By prioritizing quality and compatibility in sourcing foam closures, building professionals can significantly improve the integrity and lifespan of metal roofing systems, ultimately delivering greater value and protection to building owners.