The global stainless steel flux core wire market is experiencing steady expansion, driven by increasing demand across construction, automotive, and heavy industrial fabrication sectors. According to Grand View Research, the global flux-cored arc welding (FCAW) market size was valued at USD 1.37 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by the rising preference for high-efficiency welding solutions that offer superior deposition rates and performance in outdoor or challenging environments—qualities inherent to stainless steel flux core wires. Additionally, infrastructure development initiatives in emerging economies and stringent regulatory standards for structural integrity are pushing manufacturers to adopt advanced welding consumables. As competition intensifies, a select group of global producers is leading innovation in composition, usability, and performance. Based on market presence, technological capability, and product range, the following nine companies stand out as the top stainless steel flux core wire manufacturers shaping the industry’s future.

Top 9 Flux Core Wire Stainless Steel Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Stainless Flux

Domain Est. 2003

Website: twusa.com

Key Highlights: 180-day returnsStainless Flux-Core ; Manufacturer. Techniweld USA (50) ; Brand. Weldporn (2). Blue Demon (26). Techniweld USA Filler Metals (22) ; Origin. Made In USA (9)….

#2 Stainless Steel Flux

Domain Est. 1996

Website: esab.com

Key Highlights: Explore gas-shielded flux-cored wires for excellent stainless steel welding results, offering superior corrosion resistance and reduced ……

#3 UltraCore®

Domain Est. 1996

Website: promotions.lincolnelectric.com

Key Highlights: UltraCore Stainless Steel FCAW-G wires deliver deposition rates that rival other welding processes, along with a mindful design for easier out-of-position ……

#4 Kobelco Welding

Domain Est. 1998

Website: kobelcowelding.com

Key Highlights: Today, over 300 distributors across North America stock Kobelco welding wires, with KWAI holding a 40% market share in stainless steel flux-cored wires….

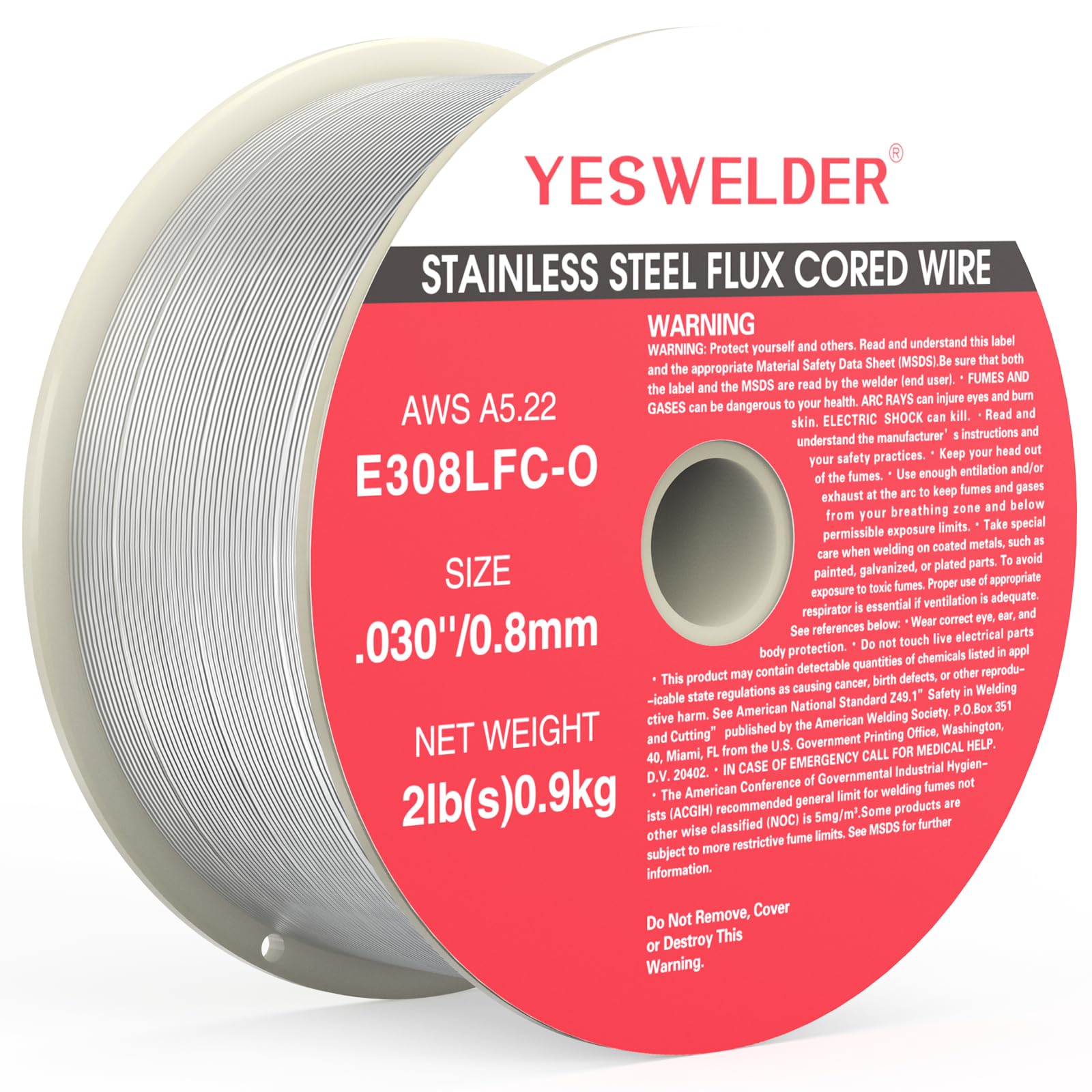

#5 Stainless Steel Flux Core Wire

Domain Est. 1999

Website: oxfordalloys.com

Key Highlights: Numerous grades of stainless steel flux core wire are available providing excellent arc performance, bead shape, and puddle control….

#6 FLUX CORED WELDING WIRE

Domain Est. 1999

Website: washingtonalloy.com

Key Highlights: PREMIUM FLUX CORED WIRE · CHOOSE FROM OUR COMPREHENSIVE LINE OF ALLOYS BELOW · MILD STEEL · LOW ALLOY/HIGH STRENGTH STEEL · STAINLESS STEEL · NICKEL ALLOY · HARDFACE….

#7 Flux Cored Wires For Stainless Steel

Domain Est. 2004

Website: en.sorex.com.tw

Key Highlights: Specification of stainless steel flux-cored wire arc welding according to AWS: It is based on welding wire types, composition, welding positions, and gas ……

#8 Stainless Steel Flux

Domain Est. 2006

Website: harrisproductsgroup.com

Key Highlights: Harris’ stainless steel flux-cored welding wires provide filler metal for welding stainless steel and other compatible metals….

#9 Brutus Flux Core Wire

Domain Est. 2019

Website: rockmountwelding.com

Key Highlights: In stockBrutus Flux Core is for wire feed welding of steels where the type of steel is unknown or for dissimilar steels. Welds are super strong and ductile….

Expert Sourcing Insights for Flux Core Wire Stainless Steel

H2: 2026 Market Trends for Flux Core Wire Stainless Steel

The global flux core wire stainless steel market is poised for steady growth through 2026, driven by increasing industrialization, infrastructure development, and advancements in welding technologies. This analysis examines key trends shaping the market landscape in the run-up to 2026 under the H2 (second half) outlook.

-

Rising Demand in Construction and Infrastructure

With governments across North America, Europe, and Asia-Pacific investing heavily in infrastructure renewal and green building projects, demand for durable and corrosion-resistant welding materials like flux core wire stainless steel is accelerating. The H2 2026 forecast indicates a surge in usage in structural applications, especially in bridges, high-rise buildings, and industrial facilities where weld integrity and resistance to environmental degradation are critical. -

Growth in Energy and Heavy Equipment Sectors

The energy sector—particularly renewable energy installations such as wind turbines and solar farms—and the heavy machinery industry are expected to drive significant demand in H2 2026. These industries require high-strength, low-maintenance welds, positioning flux core stainless steel wires as a preferred solution due to their superior arc stability, deposition rates, and performance in outdoor and challenging environments. -

Technological Advancements and Product Innovation

Manufacturers are focusing on developing low-smoke, ultra-low hydrogen, and self-shielded flux core wires to meet stringent environmental and safety regulations. In H2 2026, expect increased adoption of advanced formulations designed for automated and robotic welding systems, enhancing productivity in high-volume production environments such as shipbuilding and automotive manufacturing. -

Supply Chain Resilience and Regional Shifts

Post-pandemic supply chain restructuring continues to influence the market. In H2 2026, regional production hubs in India, Southeast Asia, and Mexico are expected to gain prominence due to cost advantages and favorable trade policies. This shift supports nearshoring strategies and reduces dependency on traditional suppliers, particularly from China. -

Sustainability and Regulatory Pressures

Environmental regulations are pushing the industry toward greener welding solutions. Flux core wires with reduced fume emissions and recyclable packaging are gaining traction. In H2 2026, compliance with standards such as ISO 14001 and OSHA guidelines will be a key competitive differentiator, prompting manufacturers to invest in eco-friendly R&D. -

Price Volatility and Raw Material Challenges

Fluctuations in the prices of key raw materials like nickel, chromium, and molybdenum may impact profit margins in H2 2026. However, long-term contracts and strategic sourcing partnerships are helping major producers stabilize input costs and maintain consistent supply.

Conclusion

The H2 2026 outlook for flux core wire stainless steel is optimistic, with growth anchored in infrastructure expansion, technological innovation, and sustainability initiatives. Companies that invest in product differentiation, regional diversification, and environmental compliance are likely to capture increased market share in this evolving landscape.

Common Pitfalls When Sourcing Flux Core Wire for Stainless Steel (Focus on Quality & IP)

Sourcing high-quality flux core wire for stainless steel welding is critical for achieving durable, corrosion-resistant, and structurally sound welds. However, several pitfalls can compromise weld integrity, increase costs, and even lead to intellectual property (IP) issues. Here are the key challenges to avoid:

Poor Quality Control and Inconsistent Chemistry

- Inaccurate Alloy Composition: Substandard wires may not meet the specified chemical requirements (e.g., Cr, Ni, Mo, C) of the designated stainless grade (e.g., 308L, 309L, 316L). This leads to weld metal with inadequate corrosion resistance, mechanical strength, or high-temperature performance.

- Flux Inconsistency: Variations in flux core composition affect arc stability, slag formation, spatter levels, and shielding gas requirements. Inconsistent flux can cause porosity, poor bead appearance, and difficulty in slag removal.

- Moisture Contamination: Flux core wires are hygroscopic. Poor packaging or storage allows moisture absorption, leading to hydrogen pickup in the weld metal and a high risk of hydrogen-induced cracking (HIC), especially critical in thick sections or high-constraint joints.

- Inadequate Manufacturing Standards: Lack of adherence to international standards (e.g., AWS A5.22) or inconsistent manufacturing processes result in variable wire diameter, poor feedability, and unreliable performance.

Lack of Traceability and Certification

- Missing or Fake Certificates of Conformity (CoC): Reputable suppliers provide CoCs (e.g., 3.1 or 3.2 per EN 10204) verifying compliance with specifications. Sourcing without proper, verifiable documentation makes it impossible to confirm material authenticity or quality.

- No Lot Traceability: Without unique lot numbers and traceability records, isolating and addressing quality issues (e.g., a batch causing cracking) becomes extremely difficult or impossible. This is crucial for quality audits and failure analysis.

- Counterfeit or Grey Market Goods: Illegitimate suppliers may repackage lower-grade wire or sell counterfeit products labeled as premium brands, offering no real quality assurance.

Intellectual Property (IP) and Brand Infringement

- Counterfeit Products: Direct copying of branded flux core wires (e.g., mimicking packaging, logos, and part numbers of major manufacturers like Lincoln Electric, ESAB, or Hobart) is a significant IP violation. These counterfeit products often use inferior materials and processes.

- “Look-Alike” Products: While not direct counterfeits, some suppliers produce wires designed to closely resemble established brands in packaging and naming, potentially causing consumer confusion and diluting brand value – a grey area potentially infringing on trade dress.

- Stolen Formulations: Sourcing from suppliers with dubious origins raises the risk of using wires based on proprietary flux or alloy formulations developed by legitimate manufacturers, constituting theft of trade secrets.

- Liability and Warranty Voiding: Using counterfeit or IP-infringing wire can void equipment warranties, invalidate project certifications, and expose the end-user to legal liability if weld failures occur due to substandard material.

Supplier Reliability and Support

- Unreliable Supply Chain: Choosing suppliers with poor logistics or financial instability risks project delays due to stockouts or inability to fulfill orders consistently.

- Lack of Technical Support: Reputable suppliers offer application expertise, troubleshooting, and validation support. Sourcing from suppliers without this support increases the risk of incorrect wire selection or improper welding parameters.

- Inadequate Packaging and Handling: Poor packaging (e.g., damaged spools, inadequate moisture barriers) during shipping and storage compromises wire quality before it even reaches the welder.

Neglecting Application-Specific Requirements

- Wrong Wire Grade Selection: Using a general-purpose stainless wire (e.g., 308L) for applications requiring higher corrosion resistance (e.g., 316L for chloride environments) or higher strength/ferrite control leads to premature failure.

- Ignoring Shielding Gas Compatibility: Not all flux core stainless wires are designed for the same shielding gases (e.g., CO2 vs. Ar/CO2 mixes). Using the wrong gas affects arc characteristics, penetration, and mechanical properties.

- Overlooking Positional Capability: Some wires are optimized for flat/horizontal welding only, while others are designed for all-position use. Selecting the wrong type for the required welding position compromises weld quality.

Mitigation Strategies:

* Source from authorized distributors of reputable manufacturers.

* Demand and verify valid, traceable Certificates of Conformity (CoC) for every batch.

* Inspect packaging carefully for signs of tampering or counterfeiting.

* Store wire properly in dry, climate-controlled environments using sealed containers or ovens as required.

* Prioritize suppliers with strong technical support and a proven track record.

* Conduct incoming inspection (e.g., visual, diameter check) and consider periodic third-party chemical analysis for critical applications.

* Be vigilant for pricing that seems too good to be true – it often indicates compromised quality or IP infringement.

Logistics & Compliance Guide for Flux Core Wire Stainless Steel

Overview

Flux Core Wire (FCW) for stainless steel is a type of welding consumable used in semi-automatic and automatic arc welding processes. Due to its composition and application, it is subject to specific logistics handling, storage, transportation, and compliance requirements. This guide outlines best practices and regulatory considerations for managing stainless steel flux core wire throughout the supply chain.

Classification & Identification

- Product Type: Flux Core Arc Welding (FCAW) Wire – Stainless Steel

- Common Alloys: 308L, 309L, 316L, 409, 410

- Form: Coiled wire on spools (typically 15–50 lb / 7–23 kg)

- UN Number: Not typically classified as hazardous under UN transport regulations (verify per product SDS)

- HS Code Example: 8311.10 (Welding Wire, not elsewhere specified) – confirm with local customs

Transportation & Shipping

- Packaging:

- Sealed moisture-resistant packaging (plastic wrap, vacuum sealed, or desiccant-inclusive bags)

- Spools placed in sturdy cardboard or wooden crates to prevent damage

- Shipping Modes:

- Suitable for road, rail, air, and sea freight

- Avoid exposure to extreme temperatures and moisture during transit

- Labeling Requirements:

- Product name, alloy type, diameter, net weight

- Handling labels: “Fragile,” “Keep Dry,” “This Side Up”

- Manufacturer and batch/lot number traceability

- Air Transport: Not classified as dangerous goods under IATA regulations when packaged appropriately (verify via Safety Data Sheet)

Storage Conditions

- Environment:

- Dry, indoor storage with controlled humidity (<50% RH recommended)

- Temperature range: 50°F–80°F (10°C–27°C)

- Avoid condensation and direct sunlight

- Shelving:

- Elevate from floors to prevent moisture absorption

- Use pallets; avoid direct contact with concrete

- Shelf Life:

- Typically 12–24 months if sealed and stored properly

- Once opened, use within 2–4 weeks or reseal with desiccant

- Inventory Management:

- First-In, First-Out (FIFO) rotation

- Label with receipt and opening dates

Handling Procedures

- Personal Protective Equipment (PPE):

- Gloves to prevent oil/skin contamination

- Safety glasses and steel-toed boots

- Spool Handling:

- Use proper lifting techniques or material handling equipment

- Avoid dropping or impacting spools to prevent wire deformation

- Moisture Prevention:

- Do not open packaging until ready for use

- Store opened spools in sealed containers with desiccant packs

Regulatory Compliance

- Safety Data Sheets (SDS):

- Maintain up-to-date SDS for each product (required under OSHA HazCom/GHS)

- SDS typically classifies FCW as non-hazardous but may include nuisance dust warnings

- OSHA (U.S.):

- General Duty Clause applies to safe handling

- Exposure to welding fumes regulated under permissible exposure limits (PELs)

- REACH/CLP (EU):

- Verify SVHC (Substances of Very High Concern) status

- Proper labeling per CLP Regulation (EC) No 1272/2008

- RoHS (EU):

- Generally compliant; confirm absence of restricted substances (Pb, Cd, etc.)

- Customs & Import:

- Provide accurate documentation: commercial invoice, packing list, certificate of origin

- Check for anti-dumping or countervailing duties on steel products in destination country

Environmental & Disposal Considerations

- Waste Disposal:

- Empty spools (metal/plastic): Recycle per local regulations

- Contaminated wire or off-cuts: May be classified as industrial metal waste

- No special hazardous waste designation unless contaminated

- Spill Response:

- Not applicable for intact wire; minor metal fragments can be swept and recycled

- Avoid inhalation of fine metal dust during cutting or grinding

Quality Assurance & Traceability

- Lot Traceability:

- Maintain records linking wire to heat number, test reports (e.g., tensile, chemical analysis)

- Required for ASME, AWS, and ISO-certified applications

- Certifications:

- Ensure product meets AWS A5.22 (Specification for Stainless Steel FCAW Electrodes)

- Mill Test Reports (MTRs) available upon request

- Inspection Upon Receipt:

- Check for packaging integrity, moisture damage, physical deformation

- Reject damaged or compromised spools

Emergency Preparedness

- Fire Response:

- Not flammable; use standard Class A, B, C extinguishers if surrounding materials ignite

- First Aid:

- Skin contact: Wash with soap and water

- Inhalation of dust: Move to fresh air; seek medical attention if irritation persists

Summary

Proper logistics and compliance management of stainless steel flux core wire ensures product integrity, weld quality, and regulatory adherence. Key focus areas include moisture control, safe handling, documentation, and adherence to regional safety and environmental standards. Always consult the manufacturer’s guidelines and SDS for product-specific requirements.

Conclusion for Sourcing Flux Core Stainless Steel Wire:

Sourcing flux core stainless steel wire requires a strategic approach that balances quality, cost, and supply chain reliability. After evaluating suppliers, material certifications, welding performance, and total cost of ownership, it is clear that selecting the right provider involves more than just competitive pricing. Key factors such as consistent chemical composition, proper packaging to prevent moisture absorption, availability of technical support, and adherence to industry standards (e.g., AWS A5.22) are critical to ensuring weld integrity and process efficiency.

Prioritizing suppliers with proven quality control, responsive customer service, and logistical reliability helps minimize downtime and rework, ultimately supporting operational productivity. Additionally, building long-term relationships with reputable manufacturers or distributors can lead to better pricing, customized solutions, and supply stability—especially important given the volatility of raw material costs in the stainless steel market.

In conclusion, a successful sourcing strategy for flux core stainless steel wire should focus on total value rather than initial cost, emphasizing quality assurance, technical compatibility, and strong supplier partnerships to support consistent welding performance and project success.