The global flooring interlock market has experienced steady expansion, driven by rising demand for easy-installation, durable, and cost-effective flooring solutions across residential, commercial, and industrial sectors. According to Mordor Intelligence, the global engineered wood and laminate flooring market—where interlocking systems dominate—is projected to grow at a CAGR of over 5.8% from 2023 to 2028. This growth is fueled by urbanization, renovations, and a shift toward modular construction techniques, particularly in North America and Europe. Additionally, Grand View Research reports that the global laminate flooring market size was valued at USD 37.2 billion in 2022 and is expected to expand at a CAGR of 6.1% through 2030, with interlocking mechanisms representing a significant share due to their tool-free assembly and reusability. As sustainability and installation efficiency become key purchasing drivers, manufacturers specializing in interlock technology are well-positioned to capitalize on this upward trend—making it essential to identify the top players innovating in product durability, design versatility, and environmental performance.

Top 10 Flooring Interlock Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 SnapLock Industries

Domain Est. 1998

Website: snaplock.com

Key Highlights: SnapLock Industries a leading manufacturer of interlocking modular flooring. We make RaceDeck, SnapSports, SnapLock Dance Floors, DuraGrid, ……

#2 Technical Tiles – Interlocking Flooring

Domain Est. 2001

Website: gerflorusa.com

Key Highlights: Explore Gerflor’s technical tiles for tough, modular flooring. Perfect for high-traffic, industrial, and commercial spaces….

#3 SelecTech Inc

Domain Est. 2001

Website: selectech.com

Key Highlights: Utilizing state-of-the-art technology and our innovative interlocking design, SelecTech’s StaticStop Flooring, FreeStyle Flooring, and Place N’ Go Flooring ……

#4 TechFloor: Interlocking Floor Tiles

Domain Est. 1996

Website: weathertech.com

Key Highlights: In stock 3–6 day deliveryCheck out our TechFloor tiles from WeatherTech. These interlocking squares can quickly upgrade any flooring in your home or garage….

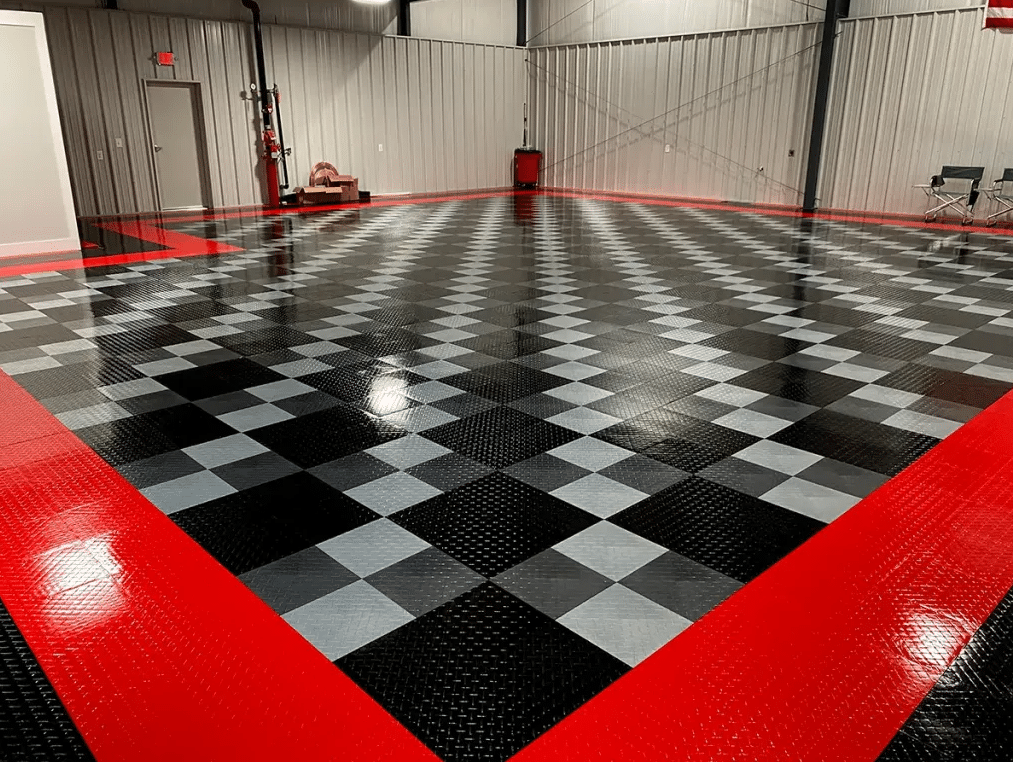

#5 RaceDeck Garage Floors

Domain Est. 2001

Website: racedeck.com

Key Highlights: Our patented interlocking system is the culmination of nearly 40 years of engineering and manufacturing premium modular flooring; Four PowerLocks per side on ……

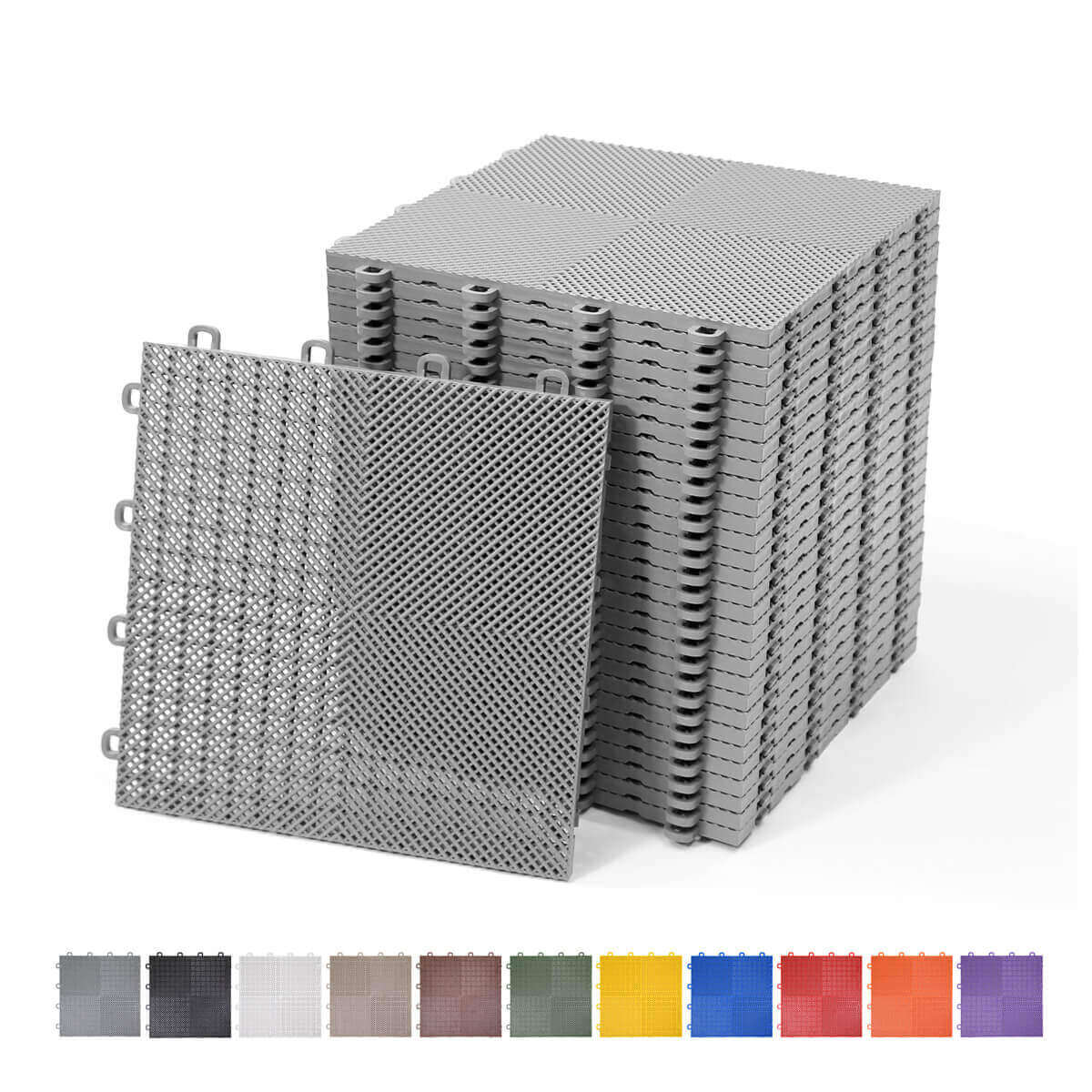

#6 Swisstrax Modular Flooring Tile, Kits & Accessories

Domain Est. 2004

Website: swisstrax.com

Key Highlights: Swisstrax manufactures a complete line of interlocking floor tile featuring innovative designs, unmatched quality and industry-leading warranties….

#7 Protect

Domain Est. 2007

Website: protect-allflooring.com

Key Highlights: From new installs to remodels, our portfolio of fully adhered vinyl sheets, loose-lay floor covers and interlocking tiles support the most demanding ……

#8 Indoor & Outdoor Athletic Performance Surfaces

Domain Est. 2013

Website: ecoreathletic.com

Key Highlights: Ecore Flooring has an extensive portfolio of indoor and outdoor, high-performance rubber flooring, designed for athletes and fitness enthusiasts….

#9 Interlocking floor tiles wood VINYLTRAX

Domain Est. 2016

Website: swisstrax-europe.com

Key Highlights: Interlocking floor tiles wood or stone grain, use the VINYLTRAX tiles from SWISSTRAX, the great and best solution for your wood grain flooring….

#10 Interlocking Products

Domain Est. 2024

Expert Sourcing Insights for Flooring Interlock

H2: 2026 Market Trends for Interlocking Flooring

The interlocking flooring market is poised for significant transformation by 2026, driven by evolving consumer preferences, technological advancements, and sustainability imperatives. Several key trends are expected to shape the industry landscape:

-

Growth in DIY and Residential Demand

By 2026, the do-it-yourself (DIY) home improvement sector is anticipated to remain a major driver for interlocking flooring. As homeowners continue to invest in cost-effective, easy-to-install flooring solutions, interlock products—such as luxury vinyl tiles (LVT), engineered wood planks, and modular rubber tiles—will benefit from their user-friendly design and minimal need for adhesives or professional installation. Online retail platforms and video tutorials will further fuel this trend, broadening accessibility and adoption. -

Sustainability and Eco-Friendly Materials

Environmental concerns will increasingly influence purchasing decisions. Manufacturers are expected to pivot toward bio-based materials, recycled content, and low-VOC (volatile organic compound) emissions. Interlocking flooring systems that are recyclable or made from rapidly renewable resources (e.g., bamboo, cork, or recycled rubber) will gain competitive advantage. Certifications like FloorScore, Cradle to Cradle, and EPDs (Environmental Product Declarations) will become key differentiators in the 2026 marketplace. -

Technological Integration and Smart Flooring

Emerging technologies such as smart sensors and embedded heating systems are beginning to integrate with interlocking flooring formats. By 2026, the convergence of flooring and IoT (Internet of Things) could lead to the rise of “smart interlock floors” capable of monitoring foot traffic, detecting falls (especially in senior living facilities), or regulating underfloor temperature. While still niche, this segment is expected to grow, particularly in commercial and healthcare applications. -

Commercial and Modular Applications Expansion

Beyond residential use, interlocking flooring will see increased adoption in commercial spaces such as retail stores, gyms, educational institutions, and modular offices. The durability, ease of replacement, and acoustic benefits of interlock systems make them ideal for high-traffic and temporary installations. The rise of flexible workspaces and pop-up retail concepts will further boost demand for modular and reconfigurable flooring solutions. -

Regional Market Growth and Urbanization

Emerging markets in Asia-Pacific, Latin America, and Africa will contribute to global growth, driven by rapid urbanization and expanding middle-class populations. In developed regions like North America and Europe, renovation activities and aging infrastructure will sustain replacement demand. Localized manufacturing and distribution networks will become critical to meeting regional needs and reducing carbon footprints. -

Innovation in Design and Aesthetics

By 2026, consumers will expect interlocking flooring to offer high-end aesthetics that mimic natural materials such as hardwood, stone, and concrete—without the associated cost or maintenance. Advances in digital printing and embossing technologies will enable hyper-realistic textures and patterns, blurring the line between synthetic and natural flooring. -

Supply Chain Resilience and Localized Production

Post-pandemic supply chain challenges have prompted a shift toward regional production. In 2026, companies investing in localized manufacturing and just-in-time inventory systems will be better positioned to respond to market fluctuations, reduce shipping costs, and meet sustainability goals.

In conclusion, the 2026 interlocking flooring market will be defined by innovation, sustainability, and adaptability. Companies that prioritize eco-conscious materials, embrace digital transformation, and cater to both residential and commercial versatility will lead the next wave of growth in this dynamic sector.

Common Pitfalls Sourcing Flooring Interlock (Quality, IP)

Sourcing flooring interlock products—especially modular systems like interlocking tiles or panels—can be fraught with challenges related to both quality assurance and intellectual property (IP) risks. Avoiding these pitfalls is critical to ensuring product performance, legal compliance, and long-term business success.

Poor Material Quality and Durability

One of the most frequent issues when sourcing interlock flooring is receiving substandard materials. Suppliers may use inferior polymers, recycled content, or inadequate UV stabilizers, leading to premature cracking, fading, or warping. Without rigorous material testing and factory audits, buyers risk acquiring products that fail under normal use or environmental exposure.

Inconsistent Manufacturing Tolerances

Interlocking systems rely on precise engineering. Even minor deviations in dimensions or tolerances can prevent proper alignment, resulting in gaps, uneven surfaces, or dislodged panels. Sourcing from manufacturers without strict quality control processes often leads to inconsistent batch quality, making large-scale installations problematic.

Lack of Performance Testing and Certification

Many suppliers claim their interlock flooring meets safety or performance standards (e.g., slip resistance, load capacity, fire rating) without providing third-party test reports. Relying on unverified claims exposes buyers to liability and potential product failure. Always demand certified test data relevant to your region and application.

Intellectual Property Infringement

Flooring interlock designs—especially patented click mechanisms, surface textures, or locking geometries—are often protected by IP rights. Sourcing from suppliers who replicate patented designs without licensing can expose your business to legal action, shipment seizures, or costly litigation, particularly in markets like the U.S. or EU.

Insufficient Due Diligence on Supplier IP Ownership

Some manufacturers claim to own the designs they produce but are actually copying proprietary systems. Failing to verify IP ownership through documentation or legal opinions can result in unintended infringement. Always request proof of design rights or licensing agreements before placing orders.

Overlooking Tooling and Mold Ownership

When custom molds are used for interlock patterns, unclear ownership can lead to disputes. If the supplier retains mold rights, they may sell identical products to competitors. Ensure contracts specify that tooling and molds are either purchased outright or licensed exclusively to your brand.

Inadequate Packaging and Logistics Planning

Interlock flooring is sensitive to deformation during shipping. Poor packaging—such as insufficient edge protection or improper stacking—can damage interlocking edges, rendering panels unusable. Additionally, bulk shipments without climate control can cause warping in plastic-based tiles.

Failure to Audit Production Processes

Without on-site audits, it’s difficult to assess whether a supplier follows consistent manufacturing practices. Hidden issues like uncalibrated machinery, untrained staff, or poor raw material traceability can undermine quality, even if initial samples appear acceptable.

Ignoring Long-Term Supplier Reliability

Choosing suppliers solely on low cost can backfire if they lack financial stability or scalability. Disruptions in supply, inconsistent lead times, or sudden closures can jeopardize projects and damage customer relationships. Evaluate supplier track records and capacity before committing.

By addressing these common pitfalls proactively—through rigorous vetting, contractual safeguards, and quality assurance protocols—businesses can mitigate risks and ensure successful sourcing of flooring interlock products.

Logistics & Compliance Guide for Flooring Interlock

Product Overview and Classification

Flooring Interlock products typically consist of modular flooring tiles or planks designed for easy installation using interlocking mechanisms. These products are commonly made from materials such as PVC, rubber, EVA foam, or composite polymers. Accurate classification is essential for compliance and logistics planning. Identify the product under the appropriate Harmonized System (HS) code based on material composition, intended use, and regional regulations—common codes include 3918.10 (plastic floor coverings) or 4016.00 (rubber flooring). Proper classification ensures correct tariff application and import/export documentation.

Packaging and Handling Requirements

Ensure Flooring Interlock products are packaged to prevent damage during transit. Use robust, moisture-resistant packaging such as corrugated cardboard boxes or shrink-wrapped pallets. Individual tiles should be stacked flat with edge protectors if necessary. Clearly label packages with handling instructions (e.g., “This Side Up,” “Do Not Stack,” “Protect from Moisture”). Include product identifiers, batch numbers, and safety data where applicable. Proper packaging reduces freight claims and enhances customer satisfaction.

Transportation and Freight Considerations

Flooring Interlock products are generally shipped via ocean freight (LCL or FCL), air freight (for urgent or sample shipments), or ground transport (for regional distribution). Optimize shipment density by nesting tiles efficiently to reduce volume and lower freight costs. Confirm carrier compliance with International Maritime Organization (IMO) and International Air Transport Association (IATA) standards where relevant. Use temperature-controlled containers if shipping sensitive materials (e.g., foam or vinyl) in extreme climates.

Import/Export Documentation

Prepare complete documentation for international shipments, including commercial invoices, packing lists, bill of lading/air waybill, and certificates of origin. Include accurate product descriptions, HS codes, declared values, and country of manufacture. For exports to regions such as the EU, ensure compliance with CE marking requirements if applicable. In the U.S., verify adherence to Customs-Trade Partnership Against Terrorism (C-TPAT) guidelines. Maintain records for a minimum of five years for audit purposes.

Regulatory Compliance

Ensure Flooring Interlock products meet region-specific regulations:

– U.S.: Comply with CPSC (Consumer Product Safety Commission) standards and TSCA (Toxic Substances Control Act); verify phthalate and lead content limits.

– EU: Adhere to REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and RoHS directives; provide a Declaration of Conformity (DoC).

– Other Regions: Check local building codes, fire safety standards (e.g., ASTM E648, EN 13501-1), and environmental regulations.

Maintain up-to-date test reports from accredited laboratories for all compliance claims.

Sustainability and Environmental Regulations

Flooring Interlock materials may be subject to environmental regulations regarding recyclability, volatile organic compounds (VOCs), and end-of-life disposal. Comply with directives such as California’s Proposition 65 (warning labels for carcinogens or reproductive toxins) and the EU’s Construction Products Regulation (CPR). Encourage sustainable practices by using recyclable packaging and offering recycling programs for used tiles. Document environmental claims to avoid greenwashing penalties.

Warehousing and Inventory Management

Store Flooring Interlock products in dry, temperature-controlled environments away from direct sunlight to prevent warping or degradation. Stack pallets evenly and within weight limits to avoid collapse. Implement a first-in, first-out (FIFO) inventory system to manage shelf life, especially for polymer-based products. Use barcode or RFID tracking to improve order accuracy and reduce handling errors.

Returns and Reverse Logistics

Establish a clear returns policy for damaged, defective, or excess inventory. Inspect returned products for reuse, refurbishment, or recycling. Partner with logistics providers that offer reverse logistics services to manage return transportation efficiently. Track return reasons to identify quality or packaging issues and improve future shipments.

Risk Management and Insurance

Secure comprehensive cargo insurance covering loss, damage, theft, and delays during transit. Assess risks related to mode of transport, route, and geopolitical factors. Develop contingency plans for supply chain disruptions, including alternative shipping routes and backup suppliers. Conduct regular audits of logistics partners to ensure compliance with safety and security standards.

Continuous Improvement and Compliance Audits

Regularly review logistics performance metrics (on-time delivery, damage rates, customs clearance times) and compliance status. Conduct internal or third-party audits to verify adherence to legal, environmental, and safety standards. Stay informed about regulatory updates through industry associations and government portals to maintain ongoing compliance.

Conclusion for Sourcing Interlocking Flooring

Sourcing interlocking flooring requires a strategic approach that balances quality, cost, durability, and ease of installation. After evaluating various suppliers, materials, and product specifications, it is evident that choosing the right interlocking flooring solution depends on the specific needs of the project—whether for residential, commercial, or industrial use. Key considerations such as material type (e.g., rubber, PVC, foam, or engineered wood), certifications (e.g., slip resistance, fire safety, eco-compliance), and long-term maintenance should guide the decision-making process.

Establishing relationships with reputable suppliers who offer consistent product quality, timely delivery, and competitive pricing is essential to ensuring project success. Additionally, opting for modular interlocking systems provides flexibility for future reconfiguration or expansion, adding value over time.

In conclusion, thorough research, sample testing, and clear communication with suppliers will lead to a reliable and cost-effective sourcing strategy. Investing time upfront to select the right interlocking flooring solution not only enhances performance and safety but also contributes to long-term satisfaction and sustainability.