The global pool equipment market is experiencing steady growth, driven by rising residential and commercial construction, urbanization, and increasing demand for automated and maintenance-efficient pool systems. According to Grand View Research, the global swimming pool market size was valued at USD 21.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.8% from 2023 to 2030. A critical yet often overlooked component within this ecosystem is the float valve for pool skimmers—essential for maintaining optimal water levels, preventing overflow, and ensuring efficient skimming performance. As automation and water conservation become key priorities for pool owners, demand for reliable, durable, and innovative float valves is on the rise. With North America and Europe leading in pool infrastructure and亚太 showing rapid adoption, manufacturers specializing in precision-engineered float valves are gaining strategic importance. Based on market presence, product innovation, distribution strength, and customer reviews, we’ve identified the top eight float valve manufacturers catering specifically to pool skimmer applications.

Top 8 Float Valve For Pool Skimmer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Waterway OEM Float Valve Assembly

Domain Est. 2007

Website: poolzoom.com

Key Highlights: In stock Rating 5.0 (2) Renegade Pool Skimmer Basket. $14.90. Specs & Details. Product Name, OEM Float Valve Assembly. Manufacturer Part Number, 542-6200. Sku ……

#2 Float Valve for IG Skimmer

Domain Est. 2010

Website: azpoolsupplies.com

Key Highlights: Float Valve for IG Skimmer – White ; Availability: in stock ; Skimmer Part Type, Float Valve ; Manufacturer, Custom Molded Products ; Model, Generic, Swimquip U3….

#3 Skimmer Float Valve, Waterway Renegade

Domain Est. 1998

Website: lesliespool.com

Key Highlights: In stock Rating 5.0 2 Waterway Skimmer Float Valve, Waterway Renegade is a replacement pool part to keep your swimming pool equipment working like new. Waterway Part Number: 542-…

#4 542

Domain Est. 1999

Website: poolweb.com

Key Highlights: In stock Rating 5.0 2 Waterway Plastics 542-6200 White Float Valve for Renegade Gunite and Vinyl Liner Inground Skimmers. Product Features. Genuine Waterway replacement part ……

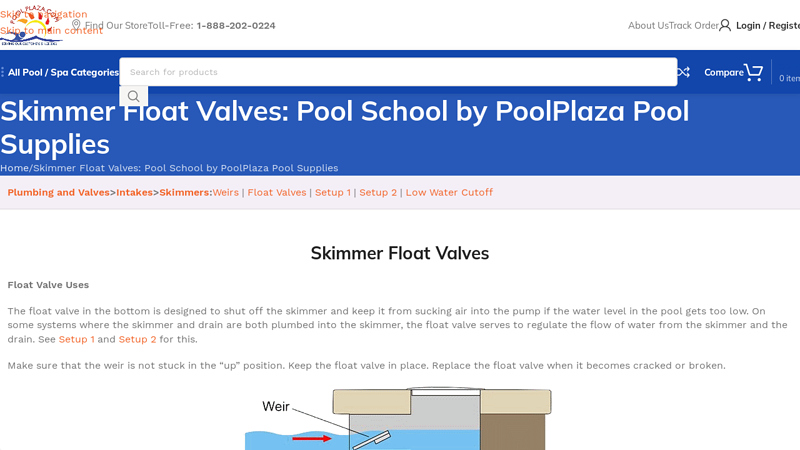

#5 Skimmer Float Valves

Domain Est. 2000

Website: poolplaza.com

Key Highlights: The float valve in the bottom is designed to shut off the skimmer and keep it from sucking air into the pump if the water level in the pool gets too low. On ……

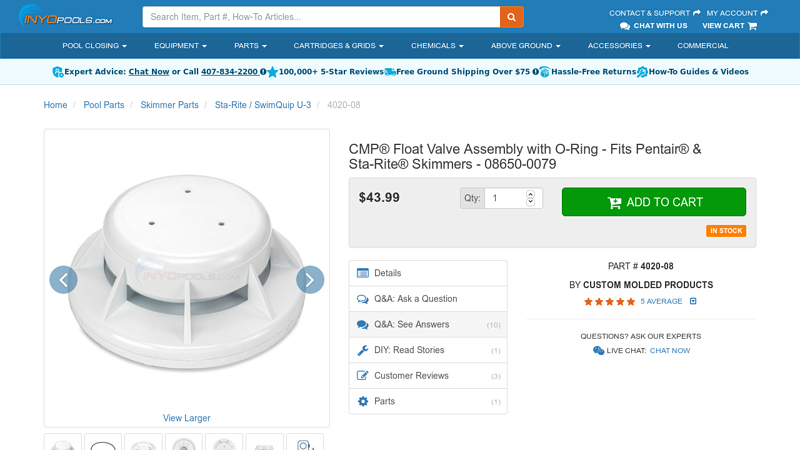

#6 CMP® Float Valve Assembly with O

Domain Est. 2001

Website: inyopools.com

Key Highlights: In stock Rating 5.0 (3) The Sta-Rite Float Valve Assembly (08650-0079) protects the pump from loss of prime if the skimmer clogs or flow through skimmer is restricted. The trimme…

#7 Pentair Bermuda Skimmers Float Valve Assembly, 506160Z

Domain Est. 2002

#8 Admiral Skimmer Float Valve Replacement Pentair 85015200

Domain Est. 2023

Website: shastapoolsupply.com

Key Highlights: In stock Rating 4.6 8 Genuine Pentair Replacement Part – Specifically engineered for Admiral skimmers, ensuring precise compatibility and easy installation. Reliable Water Flow ….

Expert Sourcing Insights for Float Valve For Pool Skimmer

H2: 2026 Market Trends for Float Valve for Pool Skimmer

The global market for float valves used in pool skimmers is poised for steady growth through 2026, driven by increasing residential and commercial pool construction, rising demand for automated pool maintenance systems, and advancements in water conservation technologies. As part of broader smart pool management trends, float valves—critical components that regulate water levels in skimmers to optimize filtration and prevent overflow—are evolving in design, material, and integration capabilities.

One major trend shaping the 2026 outlook is the growing emphasis on water efficiency, especially in drought-prone regions such as the southwestern United States, Australia, and parts of Southern Europe. Municipalities and homeowners alike are adopting automated water level control systems, including advanced float valves, to minimize water waste. This regulatory and environmental push is boosting demand for reliable, durable, and precise float valves that integrate seamlessly with existing pool infrastructure.

Additionally, the rise of smart home ecosystems is influencing product development. By 2026, manufacturers are expected to introduce float valves with sensor-based monitoring and IoT connectivity, allowing remote diagnostics and alerts via smartphone apps. While traditional mechanical float valves will remain dominant due to their reliability and cost-effectiveness, hybrid models combining mechanical operation with digital monitoring are gaining traction in premium residential and commercial segments.

Material innovation is another key trend. To enhance durability and resistance to chlorine, UV exposure, and mineral buildup, manufacturers are increasingly using engineering plastics such as acetal (POM) and reinforced polymers. These materials reduce maintenance frequency and extend product lifespan, appealing to both pool service professionals and end users.

Regionally, North America and Europe are expected to lead the market due to high pool ownership rates and stringent water regulations. Meanwhile, the Asia-Pacific region, particularly China and India, is emerging as a high-growth market, fueled by urbanization, rising disposable incomes, and expanding hospitality sectors.

In summary, the 2026 float valve for pool skimmer market will be shaped by sustainability demands, smart technology integration, material advancements, and regional expansion. Manufacturers who innovate in precision, durability, and compatibility with automated systems will be best positioned to capture market share in this evolving landscape.

Common Pitfalls When Sourcing a Float Valve for Pool Skimmer (Quality & IP)

Sourcing the right float valve for a pool skimmer involves more than just finding a compatible shape. Overlooking key quality and Ingress Protection (IP) factors can lead to premature failure, water waste, and costly maintenance. Here are the most common pitfalls to avoid:

Choosing Low-Quality Materials That Degrade Quickly

One of the most frequent mistakes is selecting float valves made from inferior plastics or metals. Low-grade materials are prone to cracking, warping, or corroding when exposed to constant sunlight (UV radiation), chlorine, and fluctuating water temperatures. This leads to leaks, improper sealing, and shortened lifespan—requiring frequent replacements and increasing long-term costs.

Ignoring Ingress Protection (IP) Rating for Outdoor Use

Float valves installed in pool skimmers are exposed to splashing, rain, and high humidity. A common oversight is not verifying an appropriate IP rating, particularly for any electronic or solenoid components (in automatic refill systems). An IP65 or higher rating ensures protection against water jets and dust—critical for reliable operation. Using a valve with insufficient IP protection risks internal damage, electrical shorts, and system failure.

Assuming Universal Compatibility Without Verification

Not all float valves fit all skimmer models. Assuming interchangeability without checking dimensions, thread type, or mounting mechanism can result in improper installation. A poorly fitting valve may not seal correctly, leading to inaccurate water level control and inefficient skimming performance.

Overlooking Build Quality and Sealing Mechanism

Even similarly priced valves can vary significantly in internal construction. Pitfalls include weak hinges, poorly molded seals, or flimsy floats that don’t respond accurately to water level changes. A substandard sealing mechanism may allow water to bypass the valve, defeating its purpose and causing overfilling or underfilling of the pool.

Failing to Consider UV and Chemical Resistance

Pool environments are chemically aggressive and sun-intensive. Sourcing a valve without confirming UV-stabilized materials or chemical resistance (especially to chlorine and bromine) leads to embrittlement, discoloration, and failure. Always verify that the valve is specifically rated for outdoor swimming pool use.

Prioritizing Low Cost Over Long-Term Reliability

While budget is important, choosing the cheapest option often results in higher lifetime costs due to frequent replacements and water loss. Investing in a high-quality, IP-rated, and chemically resistant float valve reduces maintenance, conserves water, and ensures consistent pool operation.

Logistics & Compliance Guide for Float Valve For Pool Skimmer

Product Classification and HS Code

Identify the correct Harmonized System (HS) code for international shipping and customs clearance. Float valves for pool skimmers typically fall under HS Code 8481.80 (Other taps, cocks, and valves) or 9506.29 (Parts and accessories for aquatic sports equipment). Confirm the exact classification with local customs authorities or a licensed customs broker to avoid delays or penalties.

Import/Export Regulations

Compliance with import and export regulations varies by country. Ensure adherence to requirements from agencies such as the U.S. Customs and Border Protection (CBP), European Union Customs Union, or other regional authorities. Required documentation may include commercial invoices, packing lists, certificates of origin, and import permits. Verify any import restrictions or labeling requirements in the destination country.

Material Compliance and Safety Standards

Ensure the float valve complies with relevant material and safety standards. In the United States, components in contact with pool water should meet NSF/ANSI 50 standards for pool and spa equipment. In the European Union, compliance with REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) may be required. Confirm all materials used (e.g., brass, plastic, rubber) are certified accordingly.

Packaging and Labeling Requirements

Package float valves securely to prevent damage during transit. Use moisture-resistant and shock-absorbing materials, especially for bulk shipments. Label each package with essential information including product name, model number, manufacturer details, country of origin, and compliance marks (e.g., NSF, CE). Include multilingual labeling if shipping to non-English-speaking regions.

Shipping and Freight Considerations

Choose appropriate shipping methods—air, ocean, or ground—based on order volume, urgency, and destination. For international freight, work with a reputable logistics provider experienced in handling hardware and plumbing components. Declare accurate weight, dimensions, and value of goods to avoid customs assessments. Consider Incoterms (e.g., FOB, CIF) to clarify responsibilities between buyer and seller.

Environmental and Disposal Regulations

Be aware of environmental regulations regarding the disposal of packaging materials and end-of-life products. Some regions require recyclable packaging or impose extended producer responsibility (EPR) for plastic components. Provide disposal guidance to customers if applicable, especially for valves containing metallic or synthetic materials.

Warranty and After-Sales Compliance

Include warranty information and compliance documentation with each shipment. Maintain records of product certifications, test reports, and customer communications for audit or recall purposes. Ensure customer support is available to address compliance or performance concerns post-purchase.

Recordkeeping and Audits

Retain all logistics and compliance documentation for a minimum of five years. This includes shipping records, customs filings, certification renewals, and supplier compliance attestations. Regular internal audits help ensure ongoing adherence to regulatory requirements and improve supply chain transparency.

In conclusion, sourcing a float valve for a pool skimmer requires careful consideration of compatibility, material quality, durability, and proper water flow regulation. It is essential to select a valve that matches the specific design and dimensions of your skimmer system to ensure optimal performance and leak prevention. Prioritizing reputable suppliers and high-quality materials—such as corrosion-resistant plastics or brass—will contribute to long-term reliability and reduced maintenance. Additionally, verifying user reviews, warranty options, and local availability can streamline installation and future replacements. Ultimately, investing time in selecting the right float valve supports efficient water level management, enhances skimmer functionality, and contributes to overall pool system longevity.