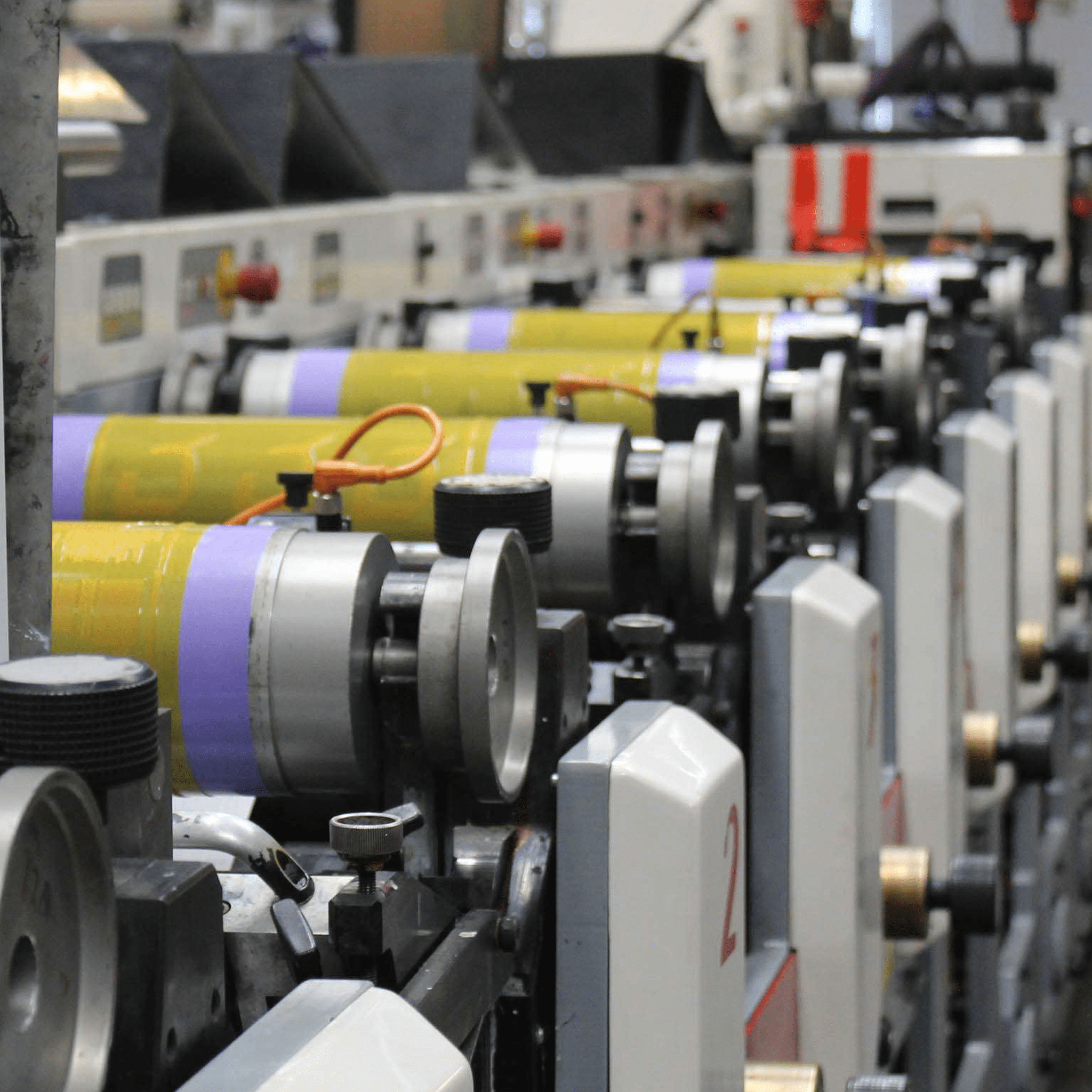

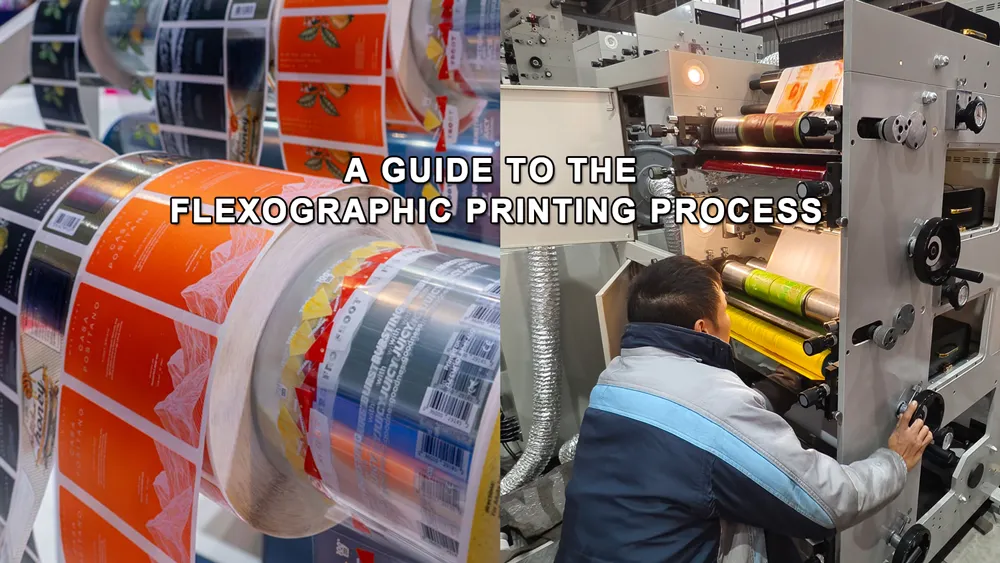

The global flexographic printing market continues to demonstrate robust growth, driven by rising demand for sustainable and high-speed packaging solutions across industries such as food & beverage, pharmaceuticals, and e-commerce. According to a 2023 report by Mordor Intelligence, the flexo printing market was valued at USD 14.8 billion in 2022 and is projected to grow at a CAGR of over 5.2% from 2023 to 2028. Similarly, Grand View Research estimates that the market size reached USD 15.1 billion in 2022 and anticipates a CAGR of 5.4% through 2030, citing advancements in digital integration, environmental regulations, and increased adoption of water-based inks as key growth catalysts. As sustainability and efficiency become central to packaging operations, leading flexo machine manufacturers are innovating with servo-driven technology, automated registration systems, and modular designs to meet evolving industry demands. This momentum has elevated the importance of selecting manufacturers that combine precision engineering with forward-thinking R&D. Below is a data-informed overview of the top 10 flexo machine manufacturers shaping the future of flexible and corrugated packaging today.

Top 10 Flexo Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Flexo presses that cope with challenges · SOMA

Domain Est. 2002

Website: soma-eng.com

Key Highlights: It took us 25 years to start from absolute ZERO to become top flexo press manufacturers worldwide, developing unique technology not found anywhere else….

#2 Nilpeter

Domain Est. 1996

Website: nilpeter.com

Key Highlights: Nilpeter is the world-leading manufacturer of flexo, offset, and digital printing solutions for narrow and mid web labels and flexible packaging….

#3 AV Flexologic

Domain Est. 1999

Website: flexologic.nl

Key Highlights: Discover AV Flexologic’s award-winning flexo plate mounting and prepress solutions. Over 50 years of innovation in flexographic printing technology….

#4 Miraclon

Domain Est. 2017

Website: miraclon.com

Key Highlights: Miraclon technology images flexographic printing plates for packaging including labels, flexible packaging, and corrugated cardboard….

#5 MPS provides flexo, offset and hybrid printing presses

Domain Est. 2021

Website: mps-printing.com

Key Highlights: MPS is a manufacturer of flexo, offset, and hybrid printing presses for the label converting and flexible packaging industry….

#6 Printing Presses by W&H

Website: wh.group

Key Highlights: As a market and technology leader, W&H offers machines for the market of flexible packaging made of paper, woven fabric and film: from extrusion to printing ……

#7 Mark Andy

Domain Est. 1995

Website: markandy.com

Key Highlights: Mark Andy Pro Series is a new platform for traditional flexo label production. Ideal for updating older, inline mechanical equipment and for emerging market ……

#8 Print and Packaging Solutions

Domain Est. 1995

Website: heidelberg.com

Key Highlights: Offset printing presses, digital printing technologies, post-press packaging machines, converting equipment and more – for the smart print shop….

#9

Domain Est. 1997

Website: retroflex.com

Key Highlights: From new flexo presses and web handling machinery to one-of-a-kind machinery designs, Retroflex opens a world of cost-effective solutions that work great!…

#10 High

Domain Est. 1998

Website: comexi.com

Key Highlights: Comexi flexographic printing machines deliver high-speed, precise and sustainable production for flexible packaging….

Expert Sourcing Insights for Flexo Machine

2026 Market Trends for Flexo Machines

The flexographic printing machine market is poised for significant evolution by 2026, driven by technological innovation, shifting consumer demands, and increasing environmental consciousness. Key trends shaping the industry include:

Advancements in Digital Integration and Automation

Flexo machine manufacturers are increasingly incorporating Industry 4.0 technologies, such as IoT-enabled monitoring, AI-driven predictive maintenance, and cloud-based control systems. These integrations enhance operational efficiency, reduce downtime, and improve print consistency. By 2026, smart flexo presses with real-time data analytics are expected to become standard in mid- to high-end segments, enabling greater automation and remote management across global supply chains.

Growth in Sustainable and Eco-Friendly Solutions

Environmental regulations and brand owner sustainability goals are accelerating demand for eco-conscious flexo solutions. This includes machines engineered for water-based and UV-LED inks, reduced energy consumption, and compatibility with recyclable and compostable substrates. Flexo machines with closed-loop ink systems and lower VOC emissions will gain traction, particularly in food packaging and consumer goods sectors aiming for carbon neutrality.

Rising Demand in Flexible Packaging

The global surge in e-commerce and demand for lightweight, durable packaging is fueling growth in the flexible packaging market—a key application for flexo printing. By 2026, flexo machines optimized for high-speed production of pouches, shrink films, and laminates will see increased adoption, especially in emerging economies across Asia-Pacific and Latin America where packaging modernization is underway.

Technological Improvements in Print Quality and Speed

Ongoing enhancements in plate technology, anilox roll precision, and servo-driven systems are narrowing the quality gap between flexo and gravure or offset printing. High-definition flexo (HD Flexo) and digital hybrid systems will allow finer detail and broader color gamut, making flexo a competitive choice for premium packaging. Faster job changeovers and reduced waste will further boost efficiency, appealing to converters seeking cost-effective short-run capabilities.

Regional Market Diversification

While North America and Western Europe remain strong markets due to regulatory compliance and technological adoption, the Asia-Pacific region is anticipated to lead in volume growth by 2026. Expanding middle-class populations, urbanization, and government support for local manufacturing in countries like India and Vietnam will drive investment in advanced flexo machinery.

In summary, the 2026 flexo machine landscape will be defined by smarter, greener, and more versatile printing solutions, positioning flexography as a dominant force in the evolving packaging industry.

Common Pitfalls When Sourcing Flexo Machines: Quality and Intellectual Property Risks

Sourcing flexographic printing machines from international suppliers—especially in cost-competitive markets—can present significant challenges related to quality control and intellectual property (IP) protection. Overlooking these aspects can lead to operational disruptions, legal liabilities, and damage to brand reputation. Below are key pitfalls to avoid.

Inadequate Quality Assurance Processes

Many buyers focus heavily on initial pricing but fail to assess the manufacturer’s quality control systems. Low-cost suppliers may use substandard materials, inconsistent assembly practices, or outdated technology, leading to frequent machine breakdowns, poor print quality, and increased maintenance costs. Without on-site inspections, third-party audits, or performance testing protocols, it’s difficult to verify the true reliability and durability of the equipment.

Lack of Transparent Manufacturing Standards

Some suppliers do not adhere to internationally recognized manufacturing standards (e.g., ISO 9001, CE marking, or GMP compliance). This absence can result in machines that do not meet safety, performance, or regulatory requirements in the buyer’s country. Hidden flaws in design or component selection may only become apparent after installation, causing costly downtime or rework.

Counterfeit or Clone Machinery

A significant risk in certain markets is the proliferation of machines that mimic branded, high-end models but are unauthorized copies. These clone machines often infringe on the original manufacturer’s patents, designs, or software. Purchasing such equipment may expose the buyer to intellectual property litigation, especially if the machines are imported into jurisdictions with strict IP enforcement.

Use of Unlicensed Software and Control Systems

Modern flexo machines rely on proprietary software for automation, registration control, and operational diagnostics. Some suppliers install pirated or reverse-engineered software to cut costs. This not only compromises machine performance and updates but also creates legal exposure for end-users who may unknowingly operate systems with unlicensed intellectual property.

Weak or Absent IP Clauses in Contracts

Sourcing agreements often lack clear provisions regarding ownership of technical designs, software rights, and liability for IP infringement. Without robust contractual safeguards, buyers may find themselves liable for third-party claims or unable to enforce warranties if the machine incorporates stolen technology.

Limited After-Sales Support and Spare Parts Availability

Low-quality or IP-infringing machines are frequently supported by under-resourced service networks. Spare parts may be generic, incompatible, or difficult to source, leading to extended downtime. In cases where parts replicate patented components, their use may also trigger IP disputes.

Failure to Conduct Supplier Due Diligence

Many companies skip comprehensive due diligence on potential suppliers, including background checks on IP history, past litigation, and customer references. This oversight increases the risk of partnering with manufacturers known for producing infringing or subpar equipment.

Conclusion

To mitigate these risks, buyers should implement rigorous supplier vetting, demand transparency in manufacturing and software sourcing, conduct technical inspections, and include strong IP indemnification clauses in procurement contracts. Partnering with legal and technical experts during the sourcing process can prevent costly quality failures and intellectual property violations.

Logistics & Compliance Guide for Flexo Machine

Overview

This guide outlines the essential logistics and compliance considerations for the transportation, installation, and operation of a flexographic (flexo) printing machine. Adhering to these guidelines ensures safe handling, regulatory compliance, and optimal machine performance.

Packaging and Handling Requirements

Flexo machines are precision equipment that require secure and protective packaging for transport. Use custom crating with shock-absorbing materials to prevent damage. Clearly label crates with handling instructions such as “Fragile,” “This Side Up,” and “Do Not Stack.” Ensure lifting points are identified and only use equipment rated for the machine’s weight during loading/unloading.

Transportation Logistics

Coordinate with a freight carrier experienced in handling industrial printing machinery. Confirm route suitability for oversized loads if applicable. Secure the machine with straps and braces inside the container or truck to prevent shifting. Monitor environmental conditions (temperature, humidity) during transit, especially for electronic components and sensitive parts.

Import/Export Compliance

Verify all import/export documentation, including commercial invoices, packing lists, and certificates of origin. Ensure the flexo machine complies with destination country regulations (e.g., CE marking for EU, UL/CSA for North America). Obtain necessary permits and clear customs efficiently by providing accurate HS (Harmonized System) codes—typically under machinery for printing (e.g., 8443.59).

Safety and Regulatory Standards

Ensure the machine meets recognized safety standards such as ISO 12100 (safety of machinery) and local occupational health and safety regulations. Install required safety guards, emergency stops, and warning labels. Confirm compliance with electrical standards (e.g., IEC 60204-1) and noise emission limits where applicable.

Environmental and Emissions Compliance

Flexo machines may use solvent-based, water-based, or UV inks. Operators must comply with environmental regulations regarding VOC (volatile organic compound) emissions, waste ink disposal, and solvent handling. Install appropriate ventilation and filtration systems as needed. Maintain records for environmental audits and adhere to local EPA or equivalent agency guidelines.

Installation and Site Preparation

Prepare the installation site according to manufacturer specifications. Ensure the floor can support the machine’s weight and is level. Provide adequate space for operation, maintenance access, and ventilation. Confirm availability of required utilities: power supply (voltage, phase, frequency), compressed air, and water (if needed for cleaning). Conduct a pre-installation site inspection.

Operator Training and Documentation

Provide comprehensive training for operators and maintenance personnel on safe operation, routine maintenance, and emergency procedures. Supply and maintain up-to-date technical manuals, safety data sheets (SDS) for inks and cleaners, and compliance documentation. Keep logs for machine servicing and safety inspections.

Maintenance and Ongoing Compliance

Follow the manufacturer’s maintenance schedule to ensure machine reliability and safety. Regularly inspect safety features and document all maintenance activities. Update compliance records as regulations evolve. Schedule third-party inspections if required by local authorities or insurance providers.

Emergency Preparedness

Establish emergency procedures for power failures, fire, or mechanical failure. Equip the facility with fire suppression systems suitable for electrical and chemical risks. Train staff on spill response and machine lockout/tagout (LOTO) procedures to prevent accidents during maintenance.

Recordkeeping and Audits

Maintain detailed records of shipping, customs clearance, installation, training, maintenance, and compliance certifications. These documents are critical for internal audits and regulatory inspections. Implement a document management system to ensure easy retrieval and version control.

Conclusion for Sourcing a Flexographic Printing Machine:

In conclusion, sourcing a flexographic printing machine is a strategic decision that significantly impacts production efficiency, print quality, and long-term operational costs. A thorough evaluation of technical specifications, production requirements, vendor reputation, after-sales support, and total cost of ownership is essential to ensure the selected machine aligns with business objectives. Whether opting for new or reconditioned equipment, investing in a reliable and scalable flexo machine enhances competitiveness in the packaging and printing industry. By prioritizing quality, automation features, and sustainability, businesses can achieve improved performance, reduce downtime, and support future growth. Ultimately, a well-informed sourcing decision leads to a robust printing operation capable of meeting current demands and adapting to future market trends.