The global flatbed knitting machines market is experiencing steady growth, driven by rising demand for technical textiles, sustainable manufacturing solutions, and advancements in computerized knitting technology. According to a 2023 report by Mordor Intelligence, the industrial sewing and textile machinery market—including flatbed knitting systems—is projected to grow at a CAGR of approximately 5.8% over the forecast period 2023–2028. Increasing automation in apparel production and the expansion of on-demand manufacturing in the fashion industry are key drivers enhancing the adoption of high-precision flatbed knitting machines. Additionally, Grand View Research highlights the growing integration of digital design software and 3D knitting capabilities, which are redefining efficiency and customization in textile manufacturing. As demand for seamless, low-waste garment production rises, leading manufacturers are innovating to deliver faster, smarter, and more energy-efficient solutions. In this competitive landscape, nine key players have emerged as frontrunners in technology, market reach, and product innovation, shaping the future of flatbed knitting worldwide.

Top 9 Flatbed Knitting Machines Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Flat knitting machine,Steiger_Ningbo Cixing Co., Ltd.

Domain Est. 2005

Website: en.ci-xing.com

Key Highlights: Ningbo Cixing Co., Ltd(stock code: 300307) is one of the global suppliers of intelligent knitting machinery. It is a national high-tech enterprise dedicated ……

#2 Ramana Machines

Domain Est. 2013

Website: ramanainternational.com

Key Highlights: We specialise in a comprehensive range of knitting and textile machinery, including computerized flat knitting machines, circular knitting machines, warp ……

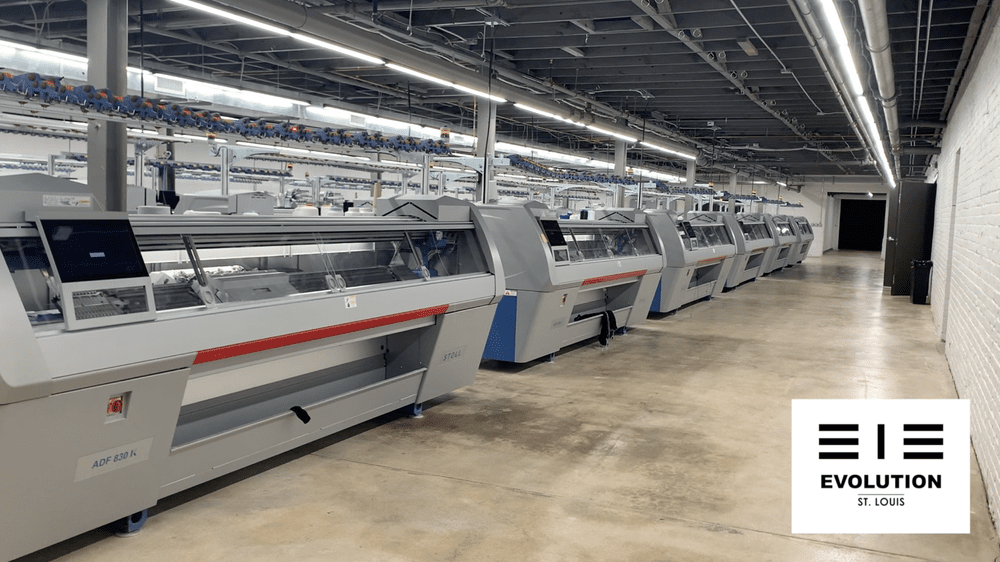

#3 Factory — Evolution St. Louis

Domain Est. 2019

Website: evolutionstl.com

Key Highlights: Evolution St. Louis uses STOLL’s high-tech flatbed knitting machines to manufacture a wide range of apparel in our 32,000 square foot facility….

#4 Stoll

Domain Est. 1995

Website: stoll.com

Key Highlights: The flat knitting machine business under the STOLL brand has been discontinued. The production site in Reutlingen has been closed since 31 October 2025….

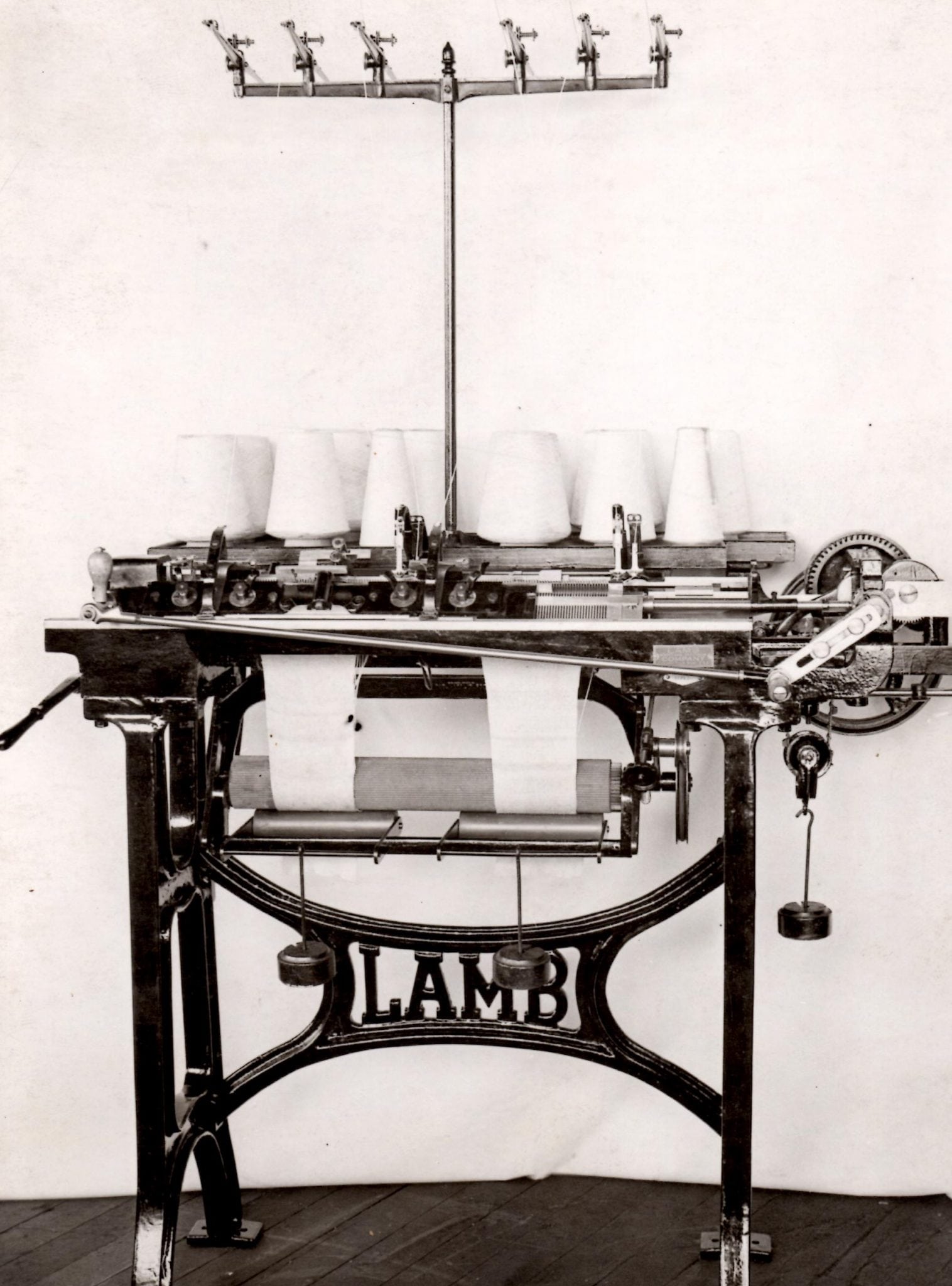

#5 Lamb Knitting Machine

Domain Est. 1998

Website: lambkmc.com

Key Highlights: Our knitting machines produce circular or flat knitted materials used in various industries. With our 60+ years of combined experience, LAMB also designs and ……

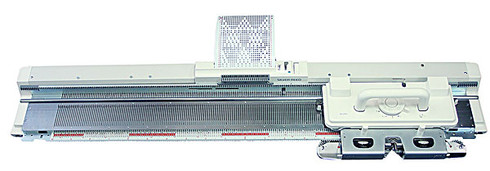

#6 Silver Reed Knitting Machines

Domain Est. 2001

Website: silverreed.com

Key Highlights: This innovative machine is the world’s first fully automated chunky metal bed knitting machine. Its advanced punch card mechanism enables automatic patterning, ……

#7 Flat bed knitting

Domain Est. 2011

Website: kern-liebers-textile.com

Key Highlights: KERN-LIEBERS Textile offers a wide range of products for all major flat knitting machines, including: Needles; Selectors; Couplings; Sinkers; Needle bed bars ……

#8 Kniterate

Domain Est. 2015

Website: kniterate.com

Key Highlights: Kniterate is a compact digital knitting machine that brings fashion fabrication into your workshop. Perfect for small fashion businesses and design studios….

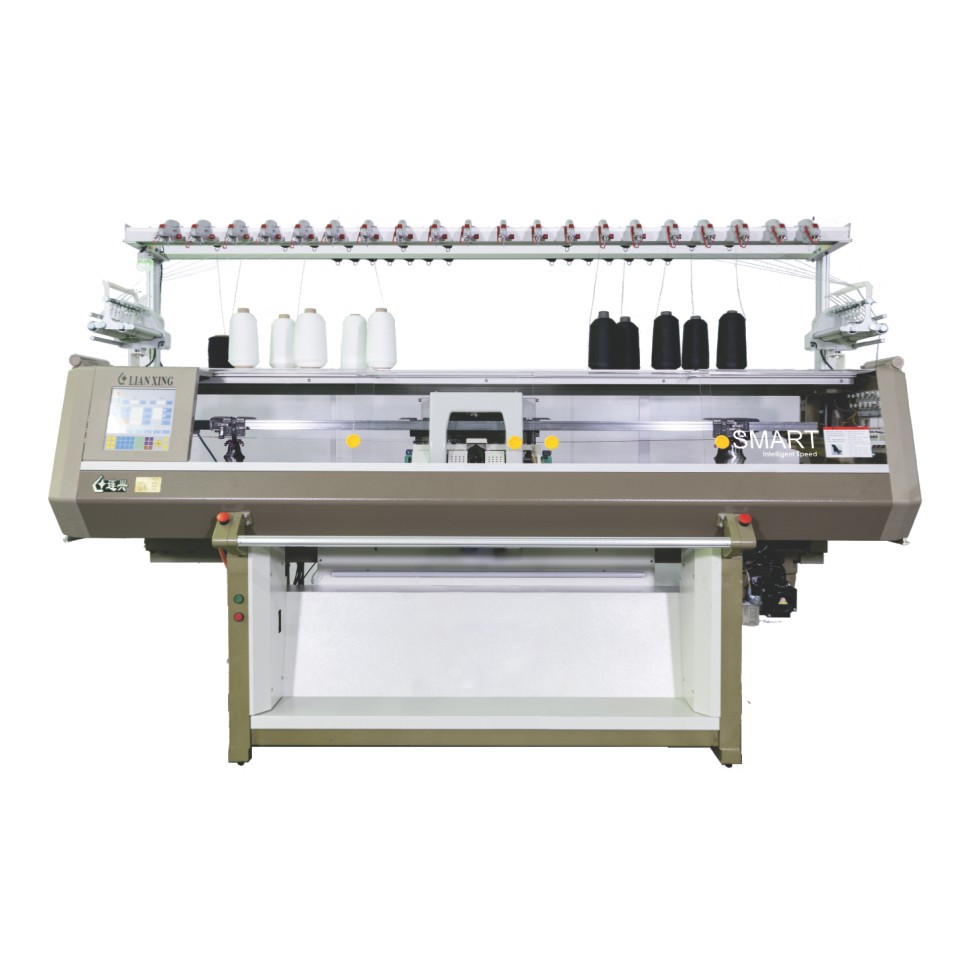

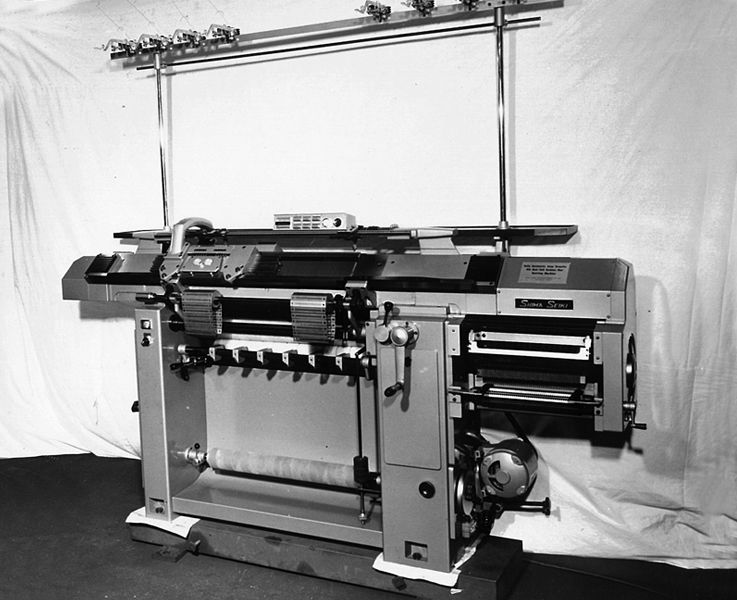

#9 2025 Flat Bed Knitting Machine

Domain Est. 2024

Website: changhua-knitting-machine.com

Key Highlights: This comprehensive guide, we’ll explore the essentials of flat bed knitting machines, their evolution, and why 2025 models are poised to ……

Expert Sourcing Insights for Flatbed Knitting Machines

H2: 2026 Market Trends for Flatbed Knitting Machines

The flatbed knitting machine market is poised for significant transformation by 2026, driven by technological innovation, shifting consumer demands, and evolving manufacturing strategies. Key trends indicate a strong move towards automation, sustainability, and customization, reshaping the industry landscape.

1. Accelerated Adoption of Automation and Smart Manufacturing:

By 2026, integration with Industry 4.0 principles will become standard. Flatbed knitting machines will increasingly feature embedded IoT sensors, real-time monitoring, and AI-driven optimization for predictive maintenance and production efficiency. Seamless connectivity with CAD/CAM systems and cloud platforms will enable end-to-end digital workflows, reducing waste and lead times. This shift supports mass customization and agile production, especially for on-demand and small-batch manufacturing.

2. Surge in Demand for Sustainable and Circular Production:

Environmental concerns will propel investment in machines capable of handling recycled yarns (e.g., rPET, regenerated cellulose) and supporting zero-waste knitting techniques. Digital patterning and precise yarn control will minimize material waste, aligning with circular economy goals. Brands aiming for ESG compliance will favor manufacturers using energy-efficient, low-impact flatbed systems, particularly in Europe and North America.

3. Growth in Technical and Wearable Textiles:

Beyond apparel, flatbed knitting machines will see increased use in technical textiles, including medical garments, sportswear with integrated sensors, and automotive interiors. The ability to produce 3D-shaped, seamless components with variable elasticity and functional zones makes flatbed tech ideal for high-performance applications. This diversification will open new revenue streams for machine manufacturers.

4. Expansion of Localized and On-Demand Manufacturing:

The trend toward nearshoring and reshoring, amplified by supply chain disruptions, will boost demand for compact, flexible flatbed machines suitable for micro-factories and urban production hubs. These machines support made-to-order models, reducing inventory costs and enabling rapid response to fashion trends—particularly appealing to fast-fashion and premium lifestyle brands alike.

5. Advancements in Machine Versatility and Ease of Use:

By 2026, user-friendly interfaces, automated setup, and modular designs will lower operational barriers, allowing smaller businesses and designers to leverage high-end knitting capabilities. Enhanced software will simplify complex designs and facilitate collaboration between designers and engineers, accelerating product development cycles.

In summary, the 2026 flatbed knitting machine market will be defined by intelligence, sustainability, and flexibility. Companies investing in digital integration, eco-friendly production, and niche applications will lead the market, while traditional players risk obsolescence without strategic adaptation.

Common Pitfalls When Sourcing Flatbed Knitting Machines (Quality and Intellectual Property)

Sourcing flatbed knitting machines, particularly from global suppliers, can offer cost advantages but comes with significant risks related to quality and intellectual property (IP). Being aware of these pitfalls is crucial to avoid costly mistakes and long-term operational disruptions.

Poor Build Quality and Material Standards

Many low-cost suppliers use substandard materials and manufacturing processes to reduce prices. This can lead to machines with poor durability, frequent breakdowns, and inconsistent knitting performance. Components such as needle beds, drive systems, and electronic controls may wear out quickly, increasing maintenance costs and downtime.

Inadequate or Missing Quality Control Processes

Reputable manufacturers implement rigorous factory acceptance testing and quality assurance protocols. However, some suppliers skip or minimize these steps. Without proper calibration and testing, machines may fail to meet technical specifications upon delivery, requiring expensive on-site adjustments or even replacement.

Misrepresentation of Machine Capabilities

Suppliers may exaggerate technical capabilities—such as gauge, speed, or compatibility with complex stitch patterns—to close sales. This misrepresentation becomes evident only after installation, resulting in unmet production goals and potential loss of customer contracts.

Use of Counterfeit or Reverse-Engineered Components

Some machines incorporate cloned or counterfeit electronic controls, motors, or software that mimic well-known brands. These components often lack reliability and technical support. Worse, they may infringe on existing patents and trademarks, exposing the buyer to legal risk.

Intellectual Property Infringement Risks

Purchasing a machine that copies patented designs or proprietary software—intentionally or not—can lead to IP litigation. Buyers, especially in regulated markets like the EU or North America, may face customs seizures, import bans, or legal action from original equipment manufacturers (OEMs) enforcing their IP rights.

Lack of Software Authenticity and Support

Modern flatbed machines rely on proprietary knitting software. Sourcing machines with pirated, cracked, or unlicensed software not only violates copyright laws but also denies access to updates, technical support, and compatibility with design ecosystems. This limits long-term usability and scalability.

Voided Warranties Due to IP or Quality Issues

Even if a supplier offers a warranty, it may be unenforceable if the machine uses infringing technology or is built with poor craftsmanship. International enforcement of warranty claims can be difficult and costly, leaving the buyer with limited recourse.

Hidden Costs from Downtime and Repairs

Low initial purchase prices can be deceptive. Inferior machines often require frequent maintenance, spare parts replacements, and technical troubleshooting—costs that far exceed savings from the initial deal. Downtime in production further amplifies these losses.

Limited After-Sales Support and Spare Parts Availability

Reliable technical support and a steady supply of spare parts are essential. Many budget suppliers offer minimal after-sales service, especially outside their home country. This can lead to prolonged machine stoppages when components fail or software malfunctions.

Conclusion

To mitigate these risks, conduct thorough due diligence: verify supplier credentials, inspect machines in person or via third-party audits, review technical documentation, and consult legal experts on IP compliance. Investing in reputable brands or certified reconditioned machines often proves more cost-effective over the machine’s lifecycle.

Logistics & Compliance Guide for Flatbed Knitting Machines

Overview

Flatbed knitting machines are sophisticated textile manufacturing equipment used primarily in the production of seamless garments, technical textiles, and custom knitted fabrics. Due to their size, weight, and technical nature, shipping and importing these machines require careful planning and adherence to international regulations. This guide outlines key logistics and compliance considerations for transporting flatbed knitting machines across borders.

Packaging and Handling Requirements

Flatbed knitting machines must be securely packaged to prevent damage during transit. Best practices include:

– Use of custom wooden crates with internal bracing to immobilize components.

– Application of moisture-resistant wrapping and desiccants to prevent corrosion.

– Proper labeling with “Fragile,” “This Side Up,” and handling instructions.

– Removal or securement of delicate parts such as needles, electronic controls, and yarn guides.

– Documentation of pre-shipment condition with photographs and inspection reports.

Transportation Modes and Routes

Selecting the appropriate transportation method depends on machine size, urgency, and destination:

– Ocean Freight: Most cost-effective for heavy, non-urgent shipments. Machines are typically shipped as FCL (Full Container Load) due to size.

– Air Freight: Suitable for urgent or high-value units; significantly faster but more expensive. Requires advance coordination due to weight and size constraints.

– Overland Transport: Often used for regional distribution. Ensure trucks have sufficient load capacity and secure tie-down points.

– Route planning should account for infrastructure limitations (e.g., low bridges, road weight limits) when delivering to final destinations.

Import and Export Compliance

Compliance with international trade regulations is critical:

– Obtain necessary export licenses if required by the country of origin (e.g., for dual-use technology).

– Ensure Harmonized System (HS) code accuracy—typically classified under 8447.20 (knitting machines) for customs clearance.

– Prepare a commercial invoice, packing list, bill of lading/air waybill, and certificate of origin.

– Comply with destination country’s import duties, VAT, and product safety standards (e.g., CE marking in the EU, FCC in the U.S.).

Safety and Technical Regulations

Flatbed knitting machines must meet safety and electromagnetic compatibility (EMC) standards:

– Confirm compliance with regional safety directives such as:

– EU: Machinery Directive 2006/42/EC and EMC Directive 2014/30/EU

– USA: OSHA and FCC Part 15 regulations

– Provide technical documentation, user manuals, and declarations of conformity.

– Machines with laser alignment or servo motors may require additional certifications.

Customs Clearance and Duties

Efficient customs processing depends on accurate documentation:

– Declare the correct value, including freight and insurance (CIF or DDP terms).

– Be aware of preferential trade agreements (e.g., USMCA, RCEP) that may reduce or eliminate tariffs.

– Anticipate potential customs inspections—ensure machines are easily accessible for examination.

– Use a licensed customs broker in the destination country to facilitate clearance.

Installation and After-Sales Support

Post-delivery considerations include:

– Schedule technician-assisted uncrating and installation to avoid warranty issues.

– Verify electrical compatibility (voltage, frequency, plug type) with local infrastructure.

– Provide training and documentation in the local language, if required.

– Maintain records of compliance and shipping for warranty and audit purposes.

Environmental and Disposal Compliance

Address end-of-life and environmental obligations:

– Comply with WEEE (Waste Electrical and Electronic Equipment) directives in applicable regions.

– Ensure proper disposal or recycling of packaging materials (wood, plastics, metals).

– Provide information on environmentally safe decommissioning of electronic components.

Conclusion

Shipping flatbed knitting machines involves coordinated logistics and strict adherence to international trade and safety regulations. By following this guide, manufacturers, exporters, and importers can ensure safe, compliant, and efficient transportation of these high-value industrial assets. Engaging experienced freight forwarders and compliance experts is strongly recommended.

In conclusion, sourcing flatbed knitting machines requires a strategic approach that balances technical specifications, production needs, budget constraints, and long-term business goals. These machines are essential for producing high-quality, intricate knitted garments and fabrics, especially in fashion, prototyping, and small-to-medium-scale manufacturing. When sourcing, it is crucial to evaluate machine capabilities—such as gauge, number of feeders, automation level, and compatibility with design software—alongside the reputation and support services of suppliers.

Additionally, considering factors like after-sales service, training availability, spare parts accessibility, and warranty terms ensures smooth integration and operation. Sourcing from reputable manufacturers, whether domestic or international, often provides better reliability and technical support. Ultimately, investing in the right flatbed knitting machine enhances production efficiency, product quality, and design flexibility, giving businesses a competitive edge in the evolving textile and apparel industry. A well-informed sourcing decision today lays the foundation for innovation, scalability, and sustainable growth tomorrow.