The global metal brackets market is experiencing steady growth, driven by increasing demand in construction, furniture, and industrial manufacturing sectors. According to Mordor Intelligence, the global metal furniture market—which heavily relies on components like flat metal brackets—is projected to grow at a CAGR of over 5.2% from 2023 to 2028. This growth is particularly relevant for wood manufacturers integrating metal joinery solutions to enhance structural integrity and production efficiency. Flat metal brackets have become essential in modern woodworking operations, offering durability, ease of assembly, and design flexibility. As manufacturers seek reliable, cost-effective hardware to meet rising output demands, selecting the right bracket solutions is more critical than ever. Based on performance metrics, load capacity, material quality, and user feedback, the following list highlights the top 10 flat metal brackets trusted by wood manufacturers to support scalable, high-quality production.

Top 10 Flat Metal Brackets For Wood Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Custom Metal Brackets

Domain Est. 1999

Website: monarchmetal.com

Key Highlights: Custom Fabricated Metal Plates & Brackets. Turnaround times often just a few days; Custom manufactured to your specifications; Your order is cut, drilled, ……

#2 Steel Brackets, Tabs, & Miscellaneous

Domain Est. 1999

Website: industrialmetalsupply.com

Key Highlights: 30-day returnsSteel brackets and industrial metal power tabs are manufactured from premium materials and are used with other components to create various finished products….

#3 Leading Metal Bracket Manufacturers

Domain Est. 2001

Website: metalstamper.net

Key Highlights: World-class fabricators from the leading metal bracket companies can be found on this site. Easily connect with the top metal bracket manufacturer….

#4 Steel Brackets Sheet Metal Fabrication

Domain Est. 1999

Website: marlinwire.com

Key Highlights: Marlin’s in-stock metal brackets feature a range of bracket types, including T-plates, mending braces, corner braces, and flat corner braces….

#5 Concealed Flat Brackets – CFLAT & ECFLAT Brackets

Domain Est. 2003

Website: aandmhardware.com

Key Highlights: These flat shelf brackets can be discreetly concealed within your countertops, cabinets, shelves, or islands, leaving no visible traces….

#6 Metal Brackets

Domain Est. 2009

Website: ekenamillwork.com

Key Highlights: Rating 4.8 (233) View our entire collection of heavy-duty, sleek and modern metal brackets. Available in stainless and unfinished steel, iron, and designer painted options….

#7 Federal Brace

Domain Est. 2009

Website: federalbrace.com

Key Highlights: Shop our American-made support brackets, combining unwavering quality with style. Perfect for floating shelves, countertops, benches & mounting in your home ……

#8 Brackets & Braces

Domain Est. 2011

Website: wurthlac.com

Key Highlights: 3–7 day delivery 30-day returnsBrackets & Braces feature options like 1-1/4″ x 3/4″ steel desktop fasteners, ideal for securing furniture components. Choose from models rated for 1…

#9 VersaGard Brackets Metal Attachment Solutions

Domain Est. 2015

Website: westernstatesmetalroofing.com

Key Highlights: VersaGard is mounted in the flat of the panel, directly into the supporting structure of the roof, i.e., wood decking, wood or steel purlins, or trusses. No ……

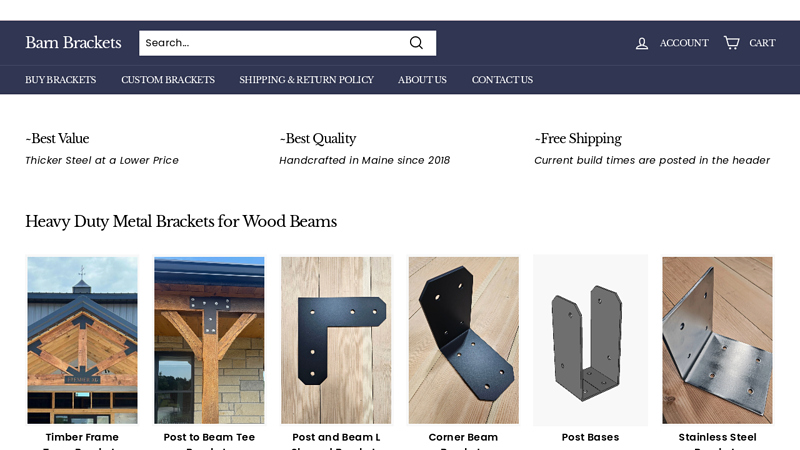

#10 Barn Brackets

Domain Est. 2021

Website: barnbrackets.com

Key Highlights: Post and Beam Brackets Best prices and thicker steel. Free Shipping. Made in Maine. We have a large collection of Post and beam brackets for sale online….

Expert Sourcing Insights for Flat Metal Brackets For Wood

H2: Market Trends for Flat Metal Brackets for Wood in 2026

The global market for flat metal brackets for wood is poised for steady growth by 2026, driven by advancements in construction technologies, rising demand in residential and commercial sectors, and increasing adoption of modular and prefabricated building systems. Several key trends are shaping the trajectory of this niche hardware segment.

-

Growth in Residential and Light Construction

The expansion of housing projects, particularly in emerging economies across Asia-Pacific, Latin America, and Africa, is fueling demand for reliable and cost-effective structural connectors. Flat metal brackets, known for their strength, ease of installation, and compatibility with wood framing, are being increasingly specified in low-rise residential builds, deck constructions, and renovation projects. Urbanization and government-backed affordable housing initiatives are expected to further boost market uptake. -

Rise of Prefabrication and Modular Construction

The construction industry is undergoing a shift toward off-site manufacturing and modular techniques to improve efficiency, reduce waste, and shorten project timelines. Flat metal brackets play a critical role in ensuring structural integrity in prefabricated wood-frame modules. Their standardized design allows for rapid assembly and disassembly, making them ideal for modern modular applications. This trend is particularly strong in North America and Western Europe, where labor costs and sustainability goals are driving innovation. -

Emphasis on Durability and Corrosion Resistance

With growing concerns over longevity and maintenance, manufacturers are focusing on enhanced material treatments such as galvanization, powder coating, and stainless steel variants. These improvements protect brackets from moisture, termites, and environmental degradation—especially critical in coastal or high-humidity regions. By 2026, corrosion-resistant flat metal brackets are expected to capture a larger market share, particularly in outdoor applications like decks, pergolas, and timber framing. -

Sustainability and Green Building Standards

Environmental regulations and green building certifications (e.g., LEED, BREEAM) are influencing material choices in construction. Wood, as a renewable resource, is seeing renewed interest, and its structural components—like metal brackets—must align with sustainable practices. Manufacturers are responding by using recycled steel and reducing carbon footprints in production. This alignment supports broader industry goals and increases demand for eco-conscious hardware solutions. -

Technological Integration and Smart Fastening Systems

While traditional brackets remain dominant, there is a growing interest in smart building components. Some companies are exploring integration with sensors or load-monitoring systems in structural brackets, though this remains in early stages. More immediately, CAD-integrated design tools allow architects and engineers to specify precise bracket types and placements, improving accuracy and reducing material waste. -

Competitive Landscape and Regional Shifts

Asia-Pacific is expected to be the fastest-growing market due to rapid urbanization and infrastructure development in countries like India, Vietnam, and Indonesia. Meanwhile, North America and Europe maintain strong demand driven by renovation activities and stringent building codes requiring structural reinforcement. Key players are investing in product innovation, regional distribution networks, and partnerships with lumber and building supply companies to expand market reach.

In conclusion, the flat metal bracket for wood market in 2026 will be shaped by construction modernization, sustainability imperatives, and regional economic dynamics. As demand for efficient, durable, and code-compliant building solutions grows, flat metal brackets will remain a foundational component in wood-based construction systems worldwide.

Common Pitfalls Sourcing Flat Metal Brackets for Wood (Quality, IP)

When sourcing flat metal brackets for wood applications, overlooking critical quality and IP (Ingress Protection) considerations can lead to structural failures, safety hazards, and costly replacements. Below are common pitfalls to avoid:

Inadequate Material Quality and Corrosion Resistance

Selecting brackets made from low-grade steel or without proper surface treatment (e.g., zinc plating, galvanization) can result in rapid rusting, especially in humid or outdoor environments. This compromises structural integrity and shortens the bracket’s lifespan.

Ignoring Load Capacity and Structural Requirements

Many suppliers list generic strength ratings without specifying test conditions or safety margins. Using brackets with insufficient load-bearing capacity for the intended wood application can lead to joint failure, particularly under dynamic or heavy loads.

Poor Manufacturing Tolerances and Finish

Inconsistent hole placement, burrs, or warped brackets due to poor stamping or cutting processes make installation difficult and weaken the connection. Poor edge finishes can also damage surrounding wood or pose safety risks during handling.

Overlooking Environmental and IP Ratings

For outdoor or damp locations, brackets without appropriate IP ratings (e.g., IP54 or higher for dust and water resistance) may allow moisture ingress, accelerating corrosion. IP ratings are often ignored but crucial for long-term durability in harsh conditions.

Lack of Certification and Traceability

Sourcing from suppliers without material certifications (e.g., ISO, ASTM), mill test reports, or traceable batch numbers increases the risk of counterfeit or substandard products. This is especially critical in construction or safety-sensitive applications.

Incompatible Design for Wood Type and Fasteners

Bracket design must match the wood species and fastener type. For example, hardwoods may require pre-drilling, and using undersized screws can cause splitting or reduced holding power. Some brackets are optimized for softwoods only.

Insufficient Attention to Coating Thickness and Adhesion

Even if a bracket is galvanized or powder-coated, thin or poorly adhered coatings can chip or wear off during installation, exposing bare metal to corrosion. Verify coating thickness (e.g., microns for zinc) and adhesion standards.

Choosing Based Solely on Price

Opting for the cheapest option often leads to compromised quality, hidden defects, or non-compliance with safety standards. The long-term costs of maintenance, replacements, and liability far outweigh initial savings.

Avoiding these pitfalls requires due diligence in supplier vetting, clear specification of material, finish, load, and environmental requirements, and verification through testing or third-party certification when necessary.

Logistics & Compliance Guide for Flat Metal Brackets for Wood

This guide outlines the essential logistics and compliance considerations when sourcing, transporting, and selling flat metal brackets used for wood applications. Adherence to these guidelines ensures smooth operations, regulatory compliance, and customer satisfaction.

Product Classification and Tariff Codes

Accurate product classification is critical for international trade. Flat metal brackets for wood are typically classified under the Harmonized System (HS) Code based on material composition, function, and design:

- Primary HS Code Example: 7326.90 – Other articles of iron or steel (common for steel brackets)

- Alternative Codes:

- 8302.41 – Mounting brackets of base metal, unfastened

- 8302.49 – Other mounting fittings of base metal

- Verification Required: Always confirm the exact HS code with your customs broker or national customs authority, as sub-classifications may vary by country and specific product characteristics (e.g., zinc-coated, stainless steel, size).

Material and Safety Compliance

Ensure the brackets meet relevant material safety and quality standards:

- Material Specifications: Confirm composition (e.g., carbon steel, stainless steel, galvanized steel) and adherence to standards such as ASTM A36 or ISO 898-1 for mechanical properties.

- Coating and Corrosion Resistance: If coated (e.g., zinc plating, powder coating), verify compliance with environmental and durability standards like ASTM B633.

- Lead and Hazardous Substances: Comply with RoHS (Restriction of Hazardous Substances) directives in the EU and similar regulations elsewhere, especially if used in consumer or indoor applications.

- Structural Safety: While not typically load-bearing structural components, brackets should meet minimum strength requirements appropriate for wood framing or furniture use per regional building codes.

Packaging and Labeling Requirements

Proper packaging and labeling ensure product integrity and regulatory compliance:

- Packaging: Use durable, moisture-resistant packaging suitable for bulk handling. Consider anti-corrosion measures such as VCI (Vapor Corrosion Inhibitor) paper for metal parts.

- Labeling:

- Product name and description (e.g., “Flat Metal Bracket for Wood Joinery”)

- Material type and finish (e.g., “Galvanized Steel”)

- Dimensions and quantity per package

- Manufacturer or supplier name and address

- Country of origin

- Barcodes or SKU for inventory tracking

- Compliance Marks: Include required certifications (e.g., CE marking for European markets, if applicable) and safety warnings if necessary.

Import/Export Documentation

Complete and accurate documentation is essential for customs clearance:

- Commercial Invoice: Includes product description, quantity, value, HS code, and Incoterms® (e.g., FOB, EXW).

- Packing List: Details weight, dimensions, and packaging per shipment.

- Bill of Lading or Air Waybill: Proof of shipment and contract of carriage.

- Certificate of Origin: Required for preferential tariffs under trade agreements (e.g., USMCA, EU agreements).

- Import Permits or Licenses: Rare for metal brackets, but verify with destination country authorities.

Transportation and Handling

Optimize logistics for cost-efficiency and product safety:

- Mode of Transport: Choose between sea freight (cost-effective for bulk), air freight (urgent/small batches), or ground transport (regional distribution).

- Weight and Dimensions: Calculate dimensional weight for shipping cost accuracy. Brackets are typically dense; optimize packaging to reduce dead space.

- Handling: Use pallets and stretch-wrapping to prevent shifting. Avoid exposure to moisture during transit to prevent rust.

- Storage: Store in dry, ventilated areas. Keep off concrete floors to minimize moisture absorption.

Regulatory and Environmental Compliance

Adhere to environmental and trade regulations:

- REACH (EU): Register substances of very high concern (SVHC) if applicable. Most standard metal brackets fall under exemption clauses but verify based on coating and treatment.

- Proposition 65 (California, USA): Disclose if products contain listed chemicals (e.g., lead, cadmium) above threshold levels.

- WEEE and Recycling: While not electronic, consider end-of-life recyclability. Steel brackets are highly recyclable; communicate this for sustainability reporting.

- Customs Valuation: Ensure transaction value reflects true cost; avoid undervaluation to prevent penalties.

Incoterms® and Liability

Clearly define responsibilities using Incoterms®:

- Recommended Terms:

- EXW (Ex Works): Buyer arranges transport; minimal seller responsibility.

- FOB (Free on Board): Seller delivers to port; risk transfers at loading.

- DDP (Delivered Duty Paid): Seller handles all logistics and customs; ideal for retail customers.

- Insurance: Recommend cargo insurance for international shipments to cover loss or damage.

Final Recommendations

- Partner with experienced freight forwarders familiar with metal goods.

- Conduct regular audits of supplier compliance and documentation.

- Stay updated on trade regulation changes (e.g., tariffs, sanctions).

- Provide technical specifications and compliance data sheets to customers upon request.

By following this guide, businesses can ensure reliable, compliant, and efficient handling of flat metal brackets for wood across global supply chains.

In conclusion, sourcing flat metal brackets for wood applications requires careful consideration of material quality, size and design compatibility, environmental resistance, and supplier reliability. Whether for construction, furniture assembly, or DIY projects, selecting the appropriate bracket—such as steel, stainless steel, or aluminum—ensures durability and structural integrity. It is essential to evaluate suppliers based on cost-effectiveness, product consistency, and delivery timelines to maintain project efficiency. By prioritizing these factors, one can secure high-quality flat metal brackets that enhance the strength and longevity of wooden structures while optimizing overall project outcomes.