The global marine and recreational boating industry has witnessed steady expansion over the past decade, driven by rising recreational spending and growing interest in sustainable, high-quality craftsmanship—especially in the construction of traditional and hybrid fishing boats. According to a 2023 report by Mordor Intelligence, the global boat market was valued at USD 43.5 billion and is projected to grow at a CAGR of 4.8% through 2028, with wooden boat manufacturing retaining a niche yet resilient share due to its durability, aesthetic appeal, and cultural significance. As demand for eco-friendly and locally sourced materials continues to rise, so does the need for reliable wood suppliers specializing in marine-grade timber. From teak and mahogany to cedar and meranti, the choice of wood significantly impacts a vessel’s performance, longevity, and resistance to harsh aquatic environments. In this evolving landscape, a select group of manufacturers have emerged as leaders in supplying premium hardwoods tailored for fishing boat construction—balancing traditional artisanship with modern sustainability standards.

Top 10 Fishing Boat Wood Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Viking Yachts

Domain Est. 1997

Website: vikingyachts.com

Key Highlights: Viking Yachts, the premiere manufacturer of quality yachts ranging from 38 to 90 feet….

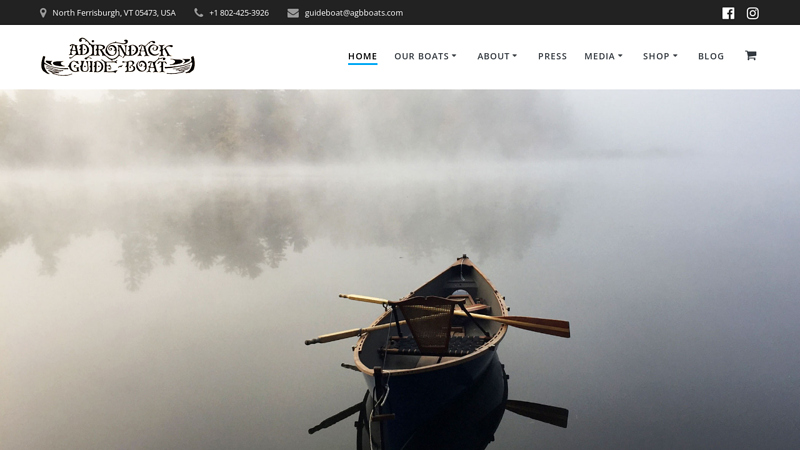

#2 Handmade Rowboat Company

Domain Est. 1997

Website: adirondack-guide-boat.com

Key Highlights: Premium handmade rowboat company, fishing boats, lake and river cruisers. A rowboat is always for sale, new or used. Composite and Cedar….

#3 Triton Fishing Boats

Domain Est. 1997

Website: tritonboats.com

Key Highlights: Triton built the first wood-free bass boat in 1996. See how we continue redefining our own industry setting standards with the best manufacturing processes….

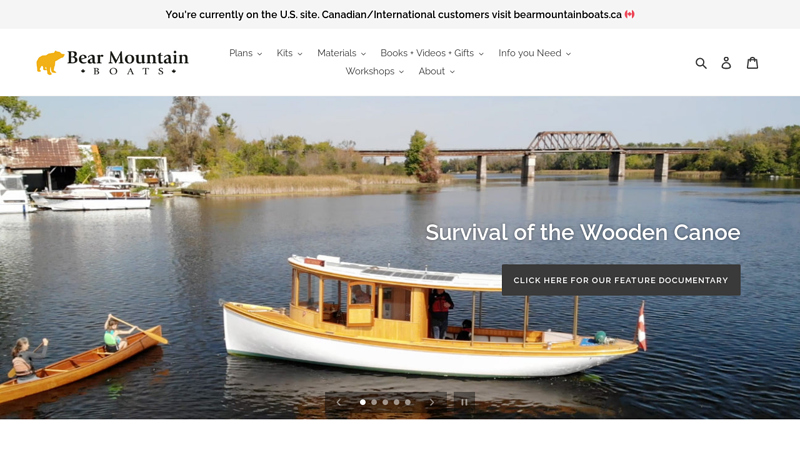

#4 Bear Mountain Boats

Domain Est. 1998

Website: bearmountainboats.com

Key Highlights: Bear Mountain Boats sells professional building plans for woodstrip canoes, kayaks, and small boats, and offers free advice and support to home boat ……

#5 Aristocraft Boats

Domain Est. 1999

Website: aristocraftboats.com

Key Highlights: A complete AristoCraft collection is housed in a museum-type setting, displaying one of every model boat produced, including some rare, one of a kind, boats….

#6 Polar Kraft

Domain Est. 1999

Website: polarkraft.com

Key Highlights: These rugged, hand-crafted hulls are thoughtfully built and affordable, yet reliable in both fresh and salty water….

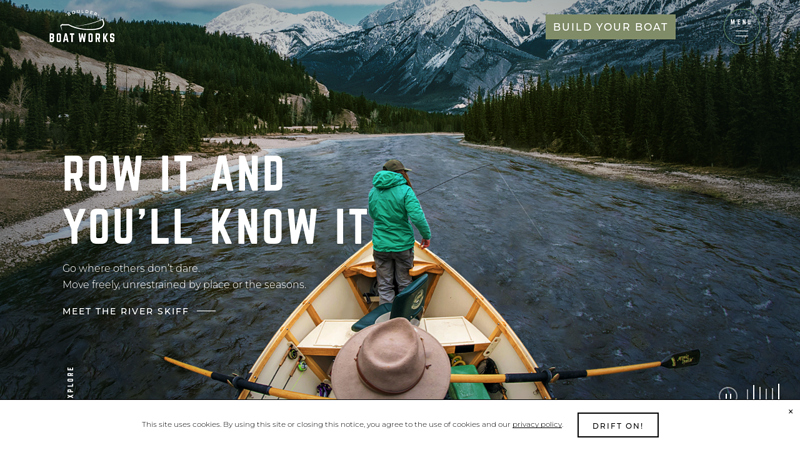

#7 Boulder Boat Works

Domain Est. 2001

Website: boulderboatworks.com

Key Highlights: At Boulder Boat Works, we manufacture polymer boats by hand in Carbondale, CO. Our river skiffs and drift boats are the lightest on the river, period….

#8 Stancraft Boats

Domain Est. 2002 | Founded: 1933

Website: stancraftboats.com

Key Highlights: Crafting Excellence Since 1933 · The Luxury Wooden Boat Company · Rivelle · Sleek · Exocet · Hammerhead · Hammerhead Widebody · Custom Models….

#9 Nordlund Boat Company

Domain Est. 2002

Website: nordlundboat.com

Key Highlights: For over 60 years we’ve been turning the dreams of adventures into reality with our custom yacht building service….

#10 Van Dam Custom Wooden Boats & Yachts

Domain Est. 2007

Website: vandamboats.com

Key Highlights: Building boats exclusively from wood, Van Dam ensures craftsmanship lives on as an art form for you and future generations to enjoy….

Expert Sourcing Insights for Fishing Boat Wood

H2: Market Trends for Fishing Boat Wood in 2026

As the global maritime and fishing industries evolve, the demand for traditional fishing boat construction materials like wood continues to reflect a blend of heritage, sustainability, and niche market appeal. By 2026, the market for fishing boat wood is expected to be shaped by environmental regulations, technological innovations, regional demand shifts, and a growing emphasis on sustainable sourcing. The following analysis outlines key trends influencing the fishing boat wood sector in 2026.

-

Sustainability and Eco-Certification Drive Demand

Environmental awareness is a dominant force in 2026, with increased scrutiny on timber sourcing. Buyers and builders are prioritizing FSC (Forest Stewardship Council) or PEFC-certified wood to ensure responsible forestry practices. Mangrove, cedar, teak, and African mahogany—commonly used in traditional wooden fishing boats—are under pressure due to overharvesting concerns. As a result, sustainably managed plantations and alternative hardwoods are gaining traction, particularly in Southeast Asia and West Africa. -

Regional Demand Variations

In developing coastal economies such as Indonesia, the Philippines, India, and parts of West Africa, wooden fishing boats remain prevalent due to affordability, local craftsmanship, and repairability. In these regions, the demand for fishing boat wood is stable or slightly increasing, supported by government subsidies and artisanal fishing communities. Conversely, in North America and Europe, wooden boats are largely confined to heritage restorations, tourism, or luxury craft, limiting bulk demand but sustaining a premium niche market. -

Competition from Composite and Fiberglass Materials

While wood maintains cultural and practical relevance in certain markets, composite materials and fiberglass continue to dominate new vessel construction due to lower maintenance, longer lifespan, and resistance to rot and pests. This trend has suppressed large-scale industrial demand for boat-building wood. However, hybrid designs—featuring wooden elements on otherwise modern hulls—are emerging, blending aesthetics with functionality. -

Rise of Engineered Wood and Treatments

Innovation in wood preservation and treatment technologies is extending the viability of wooden boats. By 2026, pressure-treated marine-grade plywood, acetylated wood, and epoxy-coated timber are being adopted to improve durability and reduce maintenance. These advancements help bridge the performance gap between wood and synthetic materials, revitalizing interest in wood among eco-conscious builders. -

Impact of Climate Change and Coastal Policies

Climate change is affecting timber availability and boat-building practices. Rising sea levels and increased storm intensity in tropical regions are disrupting traditional boat yards and increasing repair needs—temporarily boosting demand for replacement wood. Additionally, stricter coastal regulations in some countries are pushing small-scale fishers toward smaller, locally built wooden boats that comply with low-impact fishing guidelines. -

Artisanal Revival and Cultural Preservation

There is a growing movement to preserve traditional boat-building techniques as part of cultural heritage. UNESCO and regional initiatives in countries like Vietnam, Bangladesh, and Portugal are funding training programs and craft preservation projects, indirectly supporting the demand for specific boat-building woods and skilled labor. -

Supply Chain Constraints and Price Volatility

Geopolitical instability, export restrictions on tropical hardwoods, and transportation costs continue to affect wood availability. By 2026, supply chain diversification—such as sourcing from South American or Caribbean plantations—is helping mitigate risks, but price volatility remains a challenge, especially for high-demand species like teak.

Conclusion

The fishing boat wood market in 2026 is characterized by resilience in traditional economies, innovation in wood technology, and a strong undercurrent of sustainability. While not growing in volume like synthetic alternatives, wood remains irreplaceable in specific cultural, ecological, and economic contexts. Stakeholders who invest in sustainable sourcing, modern treatments, and community-based boat-building initiatives are best positioned to thrive in this specialized market segment.

Common Pitfalls When Sourcing Fishing Boat Wood (Quality and Intellectual Property)

Sourcing wood for fishing boats requires careful attention to both material quality and legal compliance. Overlooking key factors can lead to structural failures, safety hazards, and legal disputes. Below are common pitfalls to avoid.

Poor Wood Quality and Species Selection

Choosing the wrong wood species or substandard material compromises the boat’s durability and seaworthiness. Softwoods like standard pine lack the rot resistance and strength needed for marine environments. Even with hardwoods, inconsistent grading, improper drying, or hidden defects (knots, warping, insect damage) can lead to premature failure. Always verify the wood meets marine-grade standards and comes from reputable suppliers with proper moisture content testing.

Inadequate Moisture Content and Drying

Wood with high moisture content when installed can shrink, warp, or crack as it dries at sea. This creates gaps that allow water intrusion, leading to rot and delamination. Kiln-dried wood specifically treated for marine use is essential. Confirm that moisture levels are below 12–15% and that the drying process was properly documented.

Lack of Rot and Pest Resistance

Marine environments accelerate wood degradation. Using untreated or non-naturally resistant wood (e.g., non-teak hardwoods without preservatives) leads to fungal decay and insect infestation. Always opt for naturally durable species like teak, iroko, or white oak, or ensure treated wood complies with marine preservative standards (e.g., ACQ or borate treatments).

Ignoring Sustainable Sourcing and Certification

Unverified sourcing may involve illegal logging or environmentally destructive practices. Using uncertified wood risks supply chain disruptions, reputational damage, and fines. Ensure wood comes with FSC (Forest Stewardship Council) or PEFC certification to confirm legal and sustainable harvesting.

Intellectual Property (IP) Infringement in Design and Materials

Copying boat designs or using proprietary wood treatments without licensing exposes builders to legal liability. Some marine-grade wood finishes, laminates, or construction techniques are patented. Always verify that your designs and materials do not infringe on existing IP, and obtain necessary licenses when using third-party innovations.

Inconsistent Supply Chain and Traceability

Relying on unstable or opaque supply chains risks receiving inconsistent wood quality or counterfeit materials. Lack of traceability makes it difficult to address defects or prove compliance. Establish long-term relationships with suppliers who provide full documentation, including origin, treatment records, and quality certifications.

Failure to Account for Regional Environmental Conditions

Wood performance varies by climate—humidity, salinity, and UV exposure affect longevity. Sourcing wood without considering the boat’s operational region can lead to premature deterioration. Choose species and treatments suited to the specific marine environment, whether tropical, temperate, or arctic.

Avoiding these pitfalls ensures safer, longer-lasting fishing boats and protects against legal and financial risks.

Logistics & Compliance Guide for Fishing Boat Wood

Understanding Fishing Boat Wood Classification

Fishing boat wood refers to timber used in the construction, repair, or maintenance of fishing vessels. This includes structural components like keels, frames, planking, decking, and interior fittings. The type of wood—often durable hardwoods such as teak, iroko, or mahogany—affects regulatory requirements, especially concerning sustainability and international trade.

Regulatory Framework and International Standards

Fishing boat wood is subject to multiple international regulations. Key frameworks include the International Tropical Timber Agreement (ITTA), the Convention on International Trade in Endangered Species of Wild Fauna and Flora (CITES), and the EU Timber Regulation (EUTR). Compliance ensures that wood is legally harvested and traceable through the supply chain.

CITES Compliance for Protected Species

Certain woods used in boatbuilding, such as Brazilian rosewood or specific teak species, are listed under CITES Appendices. Exporters and importers must obtain CITES permits to legally transport these materials across borders. Failure to comply can result in confiscation, fines, or shipment delays.

Due Diligence under the EU Timber Regulation (EUTR)

Companies placing fishing boat wood on the EU market must perform due diligence to minimize the risk of illegal timber entering the supply chain. This includes assessing the risk of illegality, mitigating that risk through verification, and maintaining documentation such as supplier declarations, invoices, and felling permits.

Import and Export Documentation Requirements

Standard documentation for shipping fishing boat wood includes commercial invoices, packing lists, bills of lading, phytosanitary certificates (where applicable), and proof of origin. For regulated species, CITES permits or equivalent national documentation must accompany the shipment at all stages.

Phytosanitary and Quarantine Controls

Wood products may be subject to phytosanitary regulations to prevent the spread of pests and diseases. The International Standards for Phytosanitary Measures No. 15 (ISPM 15) often applies, requiring wood packaging materials to be heat-treated or fumigated and marked accordingly. While this primarily affects packaging, some raw timber shipments may also require treatment.

Country-Specific Import Restrictions

Different countries impose unique restrictions on imported wood. For example, the U.S. Lacey Act prohibits trade in illegally sourced wood products and requires detailed declarations of species and origin. Importers must research and comply with destination country requirements before shipping.

Sustainable Sourcing and Certification

Using certified wood—such as FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification)—demonstrates commitment to sustainable forestry and simplifies compliance. Certification can also enhance market access and reduce due diligence burdens under EUTR and similar regulations.

Transportation and Handling Best Practices

Fishing boat wood is often heavy and susceptible to moisture damage. Use weather-resistant packaging, secure loading, and moisture barriers during transport. Choose logistics partners experienced in handling timber to prevent warping, cracking, or contamination during transit.

Recordkeeping and Traceability

Maintain comprehensive records for at least five years, including supplier information, species identification, country of harvest, purchase contracts, and compliance documentation. Robust traceability systems help defend against audits and support responsible sourcing claims.

Risk Mitigation Strategies

To reduce compliance risks, conduct regular supplier audits, use third-party verification services, and invest in supply chain transparency tools such as blockchain or digital tracking platforms. Training procurement and logistics staff on timber regulations is also essential.

Penalties for Non-Compliance

Failure to meet legal requirements can result in severe consequences: shipment seizures, port delays, financial penalties, reputational damage, and legal action. Proactive compliance safeguards business continuity and supports ethical trade practices.

Conclusion and Best Practices Summary

Successfully managing the logistics and compliance of fishing boat wood requires understanding international regulations, maintaining accurate documentation, sourcing sustainably, and ensuring proper handling. Adopting a systematic, proactive approach to compliance minimizes risks and supports long-term operational success in the maritime and timber industries.

In conclusion, sourcing wood for fishing boats requires careful consideration of durability, resistance to moisture and rot, availability, and cost-effectiveness. Traditional hardwoods like teak, iroko, and cedar remain popular choices due to their natural resistance to water and decay, as well as their structural strength. However, sustainable sourcing practices are essential to minimize environmental impact and ensure long-term availability. Exploring locally available alternatives or certified sustainable timber can support both ecological responsibility and local economies. Additionally, proper treatment and maintenance of the wood can significantly extend the lifespan of the boat. Ultimately, selecting the right wood involves balancing performance, sustainability, and affordability to ensure a safe, durable, and environmentally conscious fishing vessel.