The global fire-rated gypsum board market is experiencing robust growth, driven by increasing construction activities, stringent building codes, and a rising emphasis on fire safety in commercial and residential buildings. According to a 2023 report by Mordor Intelligence, the global gypsum boards market was valued at USD 37.5 billion in 2022 and is projected to grow at a CAGR of 5.8% from 2023 to 2028, with fire-resistant variants accounting for a significant share due to regulatory mandates and demand for passive fire protection systems. Similarly, Grand View Research highlights that the expanding infrastructure development in Asia Pacific and the adoption of green building standards are key growth accelerators, with fire-rated solutions gaining traction in high-rise buildings and public infrastructure. As demand intensifies, manufacturers are investing in innovation and product certification to meet fire safety benchmarks such as ASTM E119 and EN 13501-1. In this evolving landscape, six leading manufacturers have emerged as frontrunners in quality, performance, and global reach—shaping the future of fire-safe interior construction.

Top 6 Fire Rated Gypsum Board Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 USG

Domain Est. 1996

Website: usg.com

Key Highlights: USG Corporation remains a leading manufacturer of ceiling, wall, backerboard, underlyament, gypsum, roofing, sheathing, and industrial products….

#2 What is Fire Rated Gypsum Board?

Domain Est. 1995

Website: certainteed.com

Key Highlights: Fire-rated gypsum board is a form of drywall that helps prevent the spread of flames across a home or business. Gypsum is approximately 21% chemically ……

#3 National Gypsum® Company

Domain Est. 1998

Website: nationalgypsum.com

Key Highlights: National Gypsum® is a leading supplier of gypsum board and drywall products. Click here to discover more….

#4 American Gypsum Company

Domain Est. 1998

Website: americangypsum.com

Key Highlights: American Gypsum has been manufacturing, selling, and distributing gypsum wallboard products throughout the United States for over 50 years….

#5 USG ME Brand Fire Rated (FR) Gypsum Board

Domain Est. 2003

#6 Gold Bond® Fire

Domain Est. 2020

Website: goldbondbuilding.com

Key Highlights: Gold Bond Fire-Shield Gypsum Board consists of a fire-resistant gypsum core encased in heavy, natural-finish, 100% recycled paper on the face and back sides….

Expert Sourcing Insights for Fire Rated Gypsum Board

2026 Market Trends for Fire Rated Gypsum Board

The global fire-rated gypsum board market is poised for significant evolution by 2026, driven by a confluence of regulatory, technological, and economic factors. Here are the key trends expected to shape the landscape:

1. Stricter Building Codes and Regulatory Push Driving Demand:

Anticipated updates to international and regional building codes (such as the IBC, Eurocodes, and local standards) will continue to mandate enhanced fire safety measures in both commercial and residential constructions. Growing urbanization and high-rise developments, particularly in Asia-Pacific and the Middle East, will intensify the need for passive fire protection. Regulatory emphasis on occupant safety and structural integrity during fires will directly boost demand for certified fire-rated gypsum boards, making them a non-negotiable component in modern construction.

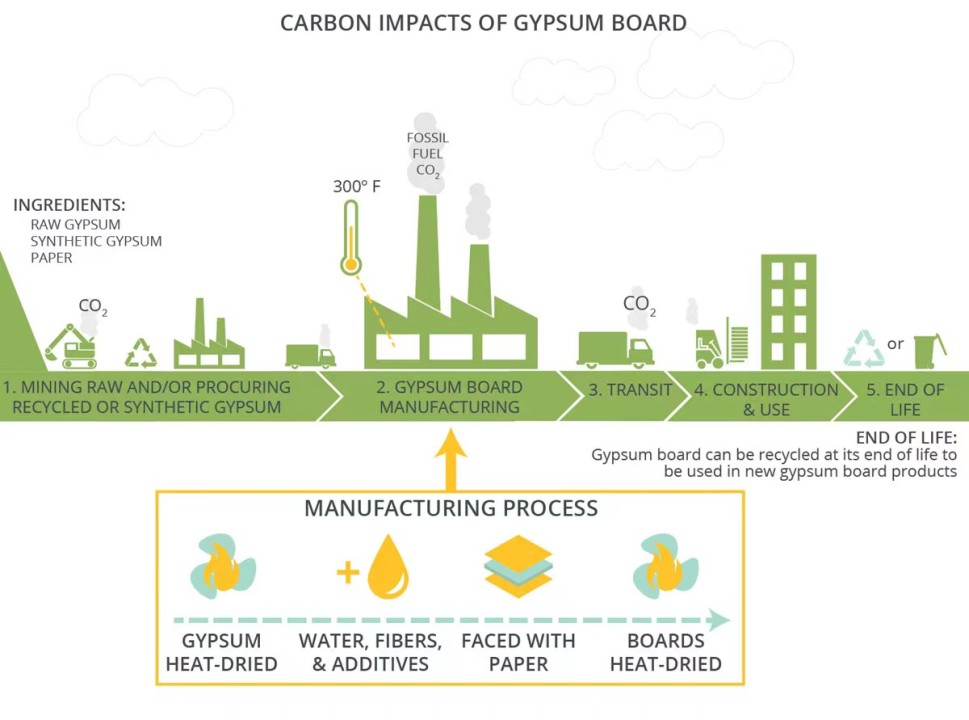

2. Technological Advancements Enhancing Performance and Sustainability:

Manufacturers are investing heavily in R&D to improve the fire resistance duration, thermal stability, and overall performance of fire-rated boards. Innovations include next-generation core additives (e.g., vermiculite, specialized glass fibers) and advanced paper facings that offer superior fire endurance beyond traditional 60–120 minute ratings. Concurrently, sustainability is a growing priority, with increased demand for boards made with recycled content and low-VOC (volatile organic compound) emissions. Bio-based binders and energy-efficient production processes are expected to gain traction, aligning with green building certifications like LEED and BREEAM.

3. Growth in Key End-Use Sectors and Regional Expansion:

The commercial construction sector—especially offices, hotels, healthcare facilities, and educational institutions—will remain the largest consumer of fire-rated gypsum board due to stringent safety requirements. Additionally, the residential segment is witnessing rising adoption, particularly in multi-family housing and luxury homes. Regionally, Asia-Pacific is expected to lead market growth, fueled by rapid infrastructure development in India, China, and Southeast Asia. North America and Europe will maintain strong demand driven by renovation activities and code compliance.

4. Supply Chain Resilience and Raw Material Volatility Concerns:

Ongoing fluctuations in the prices of raw materials such as gypsum, paper, and additives may impact production costs. Geopolitical tensions and logistics challenges could affect supply chain reliability. As a result, market players are likely to focus on vertical integration, local sourcing, and strategic inventory management to ensure consistent supply and maintain margins through 2026.

5. Increasing Competition and Market Consolidation:

The market will see intensified competition among key players like Saint-Gobain, USG Boral, Knauf, and National Gypsum, leading to product differentiation and value-added services. Mergers, acquisitions, and partnerships are expected as companies aim to expand geographic reach and technological capabilities. This consolidation could streamline innovation but may also reduce pricing flexibility in mature markets.

In summary, the 2026 fire-rated gypsum board market will be characterized by robust growth underpinned by regulatory mandates, technological innovation, and expanding construction activities—especially in emerging economies—while navigating challenges related to sustainability and supply chain stability.

Common Pitfalls When Sourcing Fire Rated Gypsum Board (Quality, IP)

Sourcing fire-rated gypsum board requires careful attention to both material quality and intellectual property (IP) considerations. Overlooking these aspects can lead to compromised safety, regulatory non-compliance, or legal exposure. Below are key pitfalls to avoid:

Inadequate Verification of Fire-Rating Certifications

A common mistake is assuming all gypsum boards with “fire-resistant” labeling meet required standards. Buyers may fail to verify third-party certifications such as UL (Underwriters Laboratories), ASTM E119, or EN 13501-1. Without valid certification documentation, the product may not perform as expected during a fire event, posing significant safety risks and liability issues.

Sourcing from Unreliable or Non-Compliant Suppliers

Procuring fire-rated boards from suppliers without a proven track record can result in substandard materials. Some vendors may adulterate core compositions or reduce board density to cut costs, undermining fire performance. Always audit suppliers and request test reports, batch certifications, and factory inspection records.

Ignoring Regional Building Code Requirements

Fire-rated gypsum boards must comply with local building codes, which vary by country or region. Using boards certified to U.S. standards (e.g., UL) in a project governed by EU regulations (e.g., CE marking) may lead to non-compliance. Ensure the product meets the specific fire resistance duration (e.g., 1-hour, 2-hour rating) required by the project’s jurisdiction.

Overlooking Intellectual Property (IP) Infringement Risks

Some manufacturers may replicate patented technologies—such as proprietary core additives, joint systems, or panel designs—without licensing. Sourcing such products exposes the buyer to IP litigation, especially in international markets where enforcement is increasing. Always confirm that the supplier holds proper IP rights or licenses for fire-performance technologies used in the board.

Failure to Conduct On-Site or Third-Party Quality Testing

Even with documentation, physical and performance verification is essential. Relying solely on supplier-provided data without independent testing (e.g., fire endurance tests, core density checks) increases the risk of receiving counterfeit or degraded materials. Implement quality control protocols, including random sampling and lab testing.

Assuming All Fire-Rated Boards Are Interchangeable

Different fire-rated systems (e.g., single-layer vs. multi-layer assemblies) have specific installation requirements. Using a board outside its certified assembly—such as substituting in a tested wall or ceiling configuration—can void approvals and compromise fire integrity. Always match the product to its listed system in certification directories.

By addressing these pitfalls proactively, procurement teams can ensure the fire-rated gypsum board meets both performance standards and legal requirements, safeguarding building occupants and project stakeholders.

Logistics & Compliance Guide for Fire Rated Gypsum Board

Product Overview and Classification

Fire Rated Gypsum Board is a specialized construction material engineered to resist the spread of fire for a specified duration. It contains additives such as glass fibers, vermiculite, or other fire-resistant components that enhance thermal stability. These boards are classified according to fire resistance ratings (e.g., 30, 60, 90, 120 minutes) based on standardized fire tests such as ASTM E119 or UL 263. Proper classification ensures compatibility with building code requirements for specific applications, including walls, ceilings, and shaft enclosures.

Regulatory and Compliance Standards

Fire Rated Gypsum Board must comply with various national and international standards to ensure performance and safety. Key standards include:

– ASTM C1396/C1396M: Standard Specification for Gypsum Board

– ASTM E119: Standard Test Methods for Fire Tests of Building Construction and Materials

– UL Design Numbers: Underwriters Laboratories classifications (e.g., U300, G525) verifying fire resistance in specific assemblies

– International Building Code (IBC): Specifies required fire resistance ratings based on occupancy and building type

– NFPA 101 (Life Safety Code): Addresses fire protection requirements for occupant safety

Manufacturers must provide certification and test reports demonstrating compliance with these standards. Always verify that the product carries the appropriate listing for the intended assembly.

Packaging and Handling Requirements

Fire Rated Gypsum Board is typically shipped in shrink-wrapped bundles on wooden pallets to prevent moisture ingress and physical damage. Each bundle should be clearly labeled with:

– Product type and fire rating

– UL/ASTM designation

– Manufacturer name and batch number

– Handling instructions (e.g., “This Side Up,” “Protect from Moisture”)

Boards must be handled with mechanical equipment (e.g., forklifts or pallet jacks) to avoid breakage. Manual lifting should follow ergonomic guidelines to prevent worker injury. Never drag bundles across surfaces.

Storage Conditions and Shelf Life

Store Fire Rated Gypsum Board in a clean, dry, well-ventilated area, ideally indoors or under a waterproof canopy. Boards must be elevated on pallets or skids at least 15 cm (6 inches) off the ground to prevent moisture absorption. Avoid direct contact with concrete floors. Maintain temperatures between 10°C and 32°C (50°F–90°F) and relative humidity below 70%. Exposure to moisture can compromise fire performance. While gypsum board has an indefinite shelf life under proper conditions, inspect for damage, warping, or mold before installation.

Transportation and Shipping

Transport Fire Rated Gypsum Board on enclosed trucks or trailers to protect from weather and contaminants. Secure pallets with straps or braces to prevent shifting during transit. Avoid stacking loads higher than recommended to prevent crushing. In international shipments, ensure compliance with customs documentation and material safety data sheet (MSDS/SDS) availability. Declare the product as non-hazardous, but note that damaged or wet gypsum may release nuisance dust.

Installation Compliance and Quality Assurance

Installation must strictly follow manufacturer-approved systems and listings (e.g., UL Design, GA-600). Deviations, such as improper joint treatment, incorrect fastener spacing, or substitution of components, void fire rating certification. Use only tested accessories like joint compounds, tapes, and sealants compatible with fire-rated assemblies. Inspect installed systems for gaps, missing fasteners, and penetration seals. Third-party inspections may be required for occupancy permits.

Documentation and Traceability

Maintain complete documentation throughout the supply chain, including:

– Mill test reports

– UL/Intertek certification documents

– Batch and lot numbers

– Delivery receipts

– Signed installation affidavits

This traceability ensures accountability and supports compliance audits or fire incident investigations. Provide documentation to general contractors and building officials as required by local codes.

Environmental and Disposal Considerations

Fire Rated Gypsum Board is recyclable, but contaminated or mixed waste may require landfill disposal. Do not incinerate, as sulfur compounds may release harmful gases. In demolition projects, separate gypsum from other debris to facilitate recycling. Follow local environmental regulations (e.g., EPA, EU Waste Framework Directive) for disposal. Some manufacturers offer take-back programs for unused materials.

Training and Certification for Handlers

Personnel involved in handling, installing, or inspecting Fire Rated Gypsum Board should receive proper training. This includes:

– Safe handling practices

– Fire-rated system installation per manufacturer guidelines

– Awareness of compliance requirements

– Recognition of product defects

Certification programs from industry associations (e.g., Gypsum Association, USG, CertainTeed) enhance workforce competency and ensure code-compliant installations.

Emergency Procedures and Incident Response

In case of water exposure or fire damage during storage or transit, isolate affected materials and assess integrity. Wet boards may lose fire resistance and should not be installed. Report significant incidents to the manufacturer and project stakeholders. Maintain spill kits and PPE (gloves, masks) for handling damaged boards to minimize dust exposure.

Conclusion for Sourcing Fire-Rated Gypsum Board

Sourcing fire-rated gypsum board is a critical step in ensuring building safety, regulatory compliance, and long-term performance in residential, commercial, and industrial constructions. The selection process must balance fire resistance performance, quality certifications, cost-efficiency, and availability. Key considerations include adherence to recognized standards such as ASTM E119 or EN 13501-1, verification of fire resistance ratings (e.g., 1-hour, 2-hour), and compatibility with other building systems such as framing and insulation.

Working with reputable suppliers and manufacturers who provide certified test reports, technical support, and consistent product quality is essential. Additionally, sourcing locally where possible can reduce lead times and transportation costs, while still meeting required fire safety codes. Sustainability and environmental impact are also becoming increasingly important factors in material selection.

In conclusion, a strategic and informed approach to sourcing fire-rated gypsum board—prioritizing safety, compliance, durability, and supplier reliability—ensures that construction projects meet both current regulatory requirements and long-term performance expectations, ultimately contributing to safer and more resilient built environments.