The global fire-resistant fabrics market is experiencing robust growth, driven by increasing safety regulations, rising demand from end-use industries such as oil & gas, firefighting, military, and electrical, and a growing emphasis on personal protective equipment (PPE). According to Grand View Research, the global flame-resistant clothing market was valued at USD 5.1 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. Similarly, Mordor Intelligence forecasts the fire-resistant fabrics market to grow at a CAGR of over 5.5% during the forecast period of 2023–2028, underpinned by heightened industrial safety standards and infrastructure development worldwide. With North America and Europe leading in market share due to stringent occupational safety norms, and Asia-Pacific emerging as a high-growth region fueled by industrialization and urbanization, the demand for reliable fireproof textiles has never been greater. As industry needs evolve, a select group of manufacturers has distinguished itself through innovation, quality, and global reach—setting the benchmark in performance and compliance. Here are the top nine fireproof fabric manufacturers shaping the future of safety textiles.

Top 9 Fire Proof Fabric Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Flame

Domain Est. 1994

Website: milliken.com

Key Highlights: As the first and only U.S.-based manufacturer to offer a non-PFAS fabric for every layer of firefighter turnout gear, Milliken is leading the way in protection ……

#2 PyroSafe® Flame Resistant Knitted Fabric

Domain Est. 1995

Website: antex.com

Key Highlights: PyroSafe by antex®, a new line of flame resistant cotton knits, offers protective clothing manufacturers dramatic new possibilities to expand their lines of ……

#3 Fire (Flame) Retardants

Domain Est. 1995

Website: rosebrand.com

Key Highlights: Rosco Flamex™ NF for Natural Fibers Works with most natural fiber fabrics to provide a safe and secure flame treatment….

#4 Leader in FR/AR Protective Fabric

Domain Est. 1996

Website: westex.com

Key Highlights: At Westex, we’re experts in protective textiles. For decades, we’ve made FR/AR fabrics that deliver durable, reliable protection and comfort in the field….

#5 Firetect

Domain Est. 1998

Website: firetect.com

Key Highlights: Firetect Manufacturing is certified for application in New York City and California of flame and fire retardants products for textile fabric, wood, hay, ……

#6 Flame Resistant Fabrics

Domain Est. 1998

Website: polartec.com

Key Highlights: Polartec® develops innovative flame resistant fabric technologies used to create protective layering systems that perform in the most demanding work……

#7 GlenGuard: Arc

Domain Est. 2004

Website: glenguard.com

Key Highlights: GlenGuard is the most comfortable, durable and versatile fabric used to make arc-rated and flame-resistant (AR/FR) protective apparel….

#8 Mount Vernon FR

Domain Est. 2011

Website: mvmfr.com

Key Highlights: Mount Vernon FR gives you the most choices in comfortable, cotton-rich FR fabrics made in the USA. Cotton-rich fabrics are soft, and are less likely to be ……

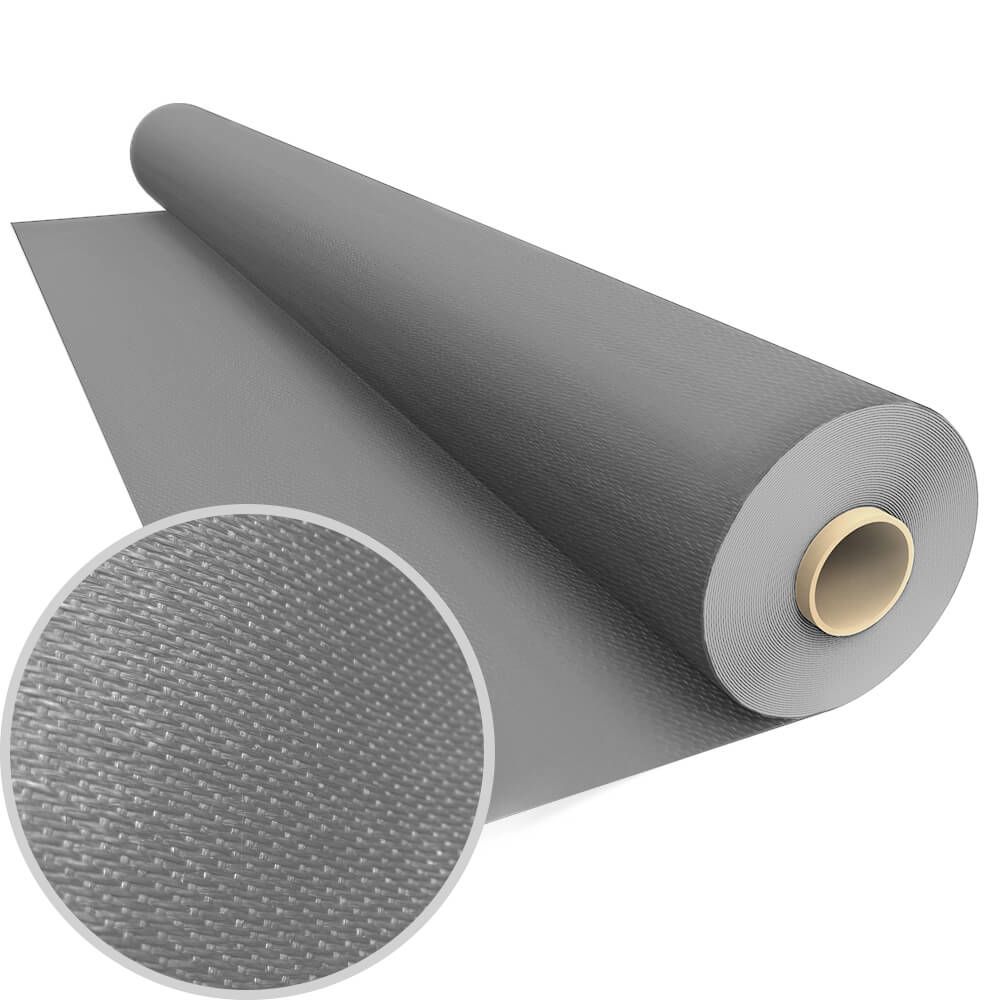

#9 Flame Resistant Fabrics Manufacturing

Domain Est. 2017

Website: frfabric.com

Key Highlights: LEVITEX Flame Retardant fabrics are used to make clothing that protects workers from serious injury when struck by arcs, flames, or molten metal….

Expert Sourcing Insights for Fire Proof Fabric

H2: Market Trends Shaping the Fire-Resistant Fabric Industry in 2026

By 2026, the global fire-resistant (FR) fabric market is poised for significant transformation, driven by evolving safety regulations, technological advancements, and shifting end-user demands. Building on the momentum of 2024-2025, H2 2026 will be a critical period reflecting the consolidation of key trends and the emergence of new market dynamics. Here’s an analysis of the dominant trends expected in the second half of 2026:

1. Regulatory Stringency as a Primary Growth Catalyst:

* Global Harmonization & Stricter Standards: H2 2026 will see intensified enforcement of fire safety codes worldwide, particularly in construction (facade materials, insulation wraps), public transport (seats, cables, interiors), and energy (oil & gas, renewables). Regulations like the EU’s Construction Products Regulation (CPR) and updates to NFPA standards in North America will mandate higher performance levels (e.g., improved flame spread, smoke density, toxicity limits).

* Focus on Real-World Performance: Regulations are moving beyond simple pass/fail flammability tests towards performance-based standards evaluating fabric behavior in simulated real-fire scenarios (e.g., heat release rate, char stability). This favors manufacturers investing in R&D for genuinely high-performance solutions.

2. Technological Innovation: Beyond Inherent vs. Treated:

* Next-Gen Inherent Fibers: Demand will surge for inherently FR fibers (e.g., meta-aramids, para-aramids, PBI, modacrylics, oxidized PAN) due to durability and consistent protection. Expect advancements in cost-effective production and enhanced comfort (softer hand, better moisture management) without sacrificing flame resistance. Blends optimizing cost, comfort, and protection will dominate.

* Smart FR Fabrics: H2 2026 will witness the commercialization of “smart” FR textiles integrated with sensors. These can monitor environmental conditions (heat, gas levels), worker vital signs, or fabric integrity (e.g., detecting degradation of FR properties), providing proactive safety alerts, especially in industrial and emergency response sectors.

* Sustainable FR Chemistries: For treated fabrics, there will be a strong push towards halogen-free and bio-based flame retardant treatments. Regulatory pressure (e.g., REACH SVHCs) and brand sustainability goals will accelerate the adoption of non-toxic, biodegradable, and recyclable FR finishes.

3. Sustainability: A Non-Negotiable Requirement:

* Circular Economy Integration: End-of-life management will become crucial. Expect increased focus on recyclability of FR fabrics (especially mono-material constructions) and development of take-back programs. Regulations like extended producer responsibility (EPR) schemes will gain traction.

* Transparency & Traceability: Brands and industrial buyers will demand full supply chain transparency. Blockchain and digital product passports (DPPs) will track material origin, FR treatment chemicals, environmental impact (carbon footprint, water usage), and compliance, driven by ESG reporting requirements.

* Renewable Raw Materials: R&D into FR fabrics derived from bio-based polymers (e.g., modified cellulose, lignin-based compounds) will intensify, offering a more sustainable alternative to petroleum-based synthetics.

4. Diversification of End-Use Applications:

* Energy Transition: The rapid growth of electric vehicles (EVs) and energy storage systems (ESS) will be a major driver. Demand for FR fabrics used in battery enclosures, cable wraps, and insulation within EVs and grid-scale batteries will skyrocket due to lithium-ion battery fire risks.

* Aviation & Aerospace: Stringent fire safety for aircraft interiors (cabin walls, seats, insulation) and emerging applications in electric/hybrid aircraft will require lightweight, high-performance FR textiles.

* Consumer Goods Premiumization: Fire safety will increasingly influence premium consumer products: high-end home textiles (curtains, upholstery), outdoor gear (tents, awnings), and childcare products. Comfort and aesthetics alongside safety will be key differentiators.

* Infrastructure & Renewables: Offshore wind farms, solar panel installations, and hydrogen infrastructure projects will require specialized FR protective clothing and materials for maintenance and construction.

5. Supply Chain Resilience & Regionalization:

* Geopolitical & Trade Shifts: Companies will continue efforts to diversify supply chains away from over-reliance on specific regions (e.g., reducing dependence on single-source suppliers for key FR chemicals or fibers). Nearshoring and friend-shoring will gain importance for critical applications.

* Vertical Integration: Leading FR fabric producers may acquire or partner with fiber manufacturers or FR chemical specialists to secure supply and control quality/cost, particularly for high-demand inherent fibers.

6. Competitive Landscape: Consolidation and Specialization:

* Market Consolidation: Mid-sized players may struggle with R&D costs and regulatory compliance, potentially leading to M&A activity as larger players seek scale, technology, or market access.

* Rise of Niche Players: Simultaneously, specialized innovators focusing on ultra-high-performance fabrics, sustainable solutions, or smart textiles will attract investment and carve out profitable niches.

* Price Pressure vs. Value: While commodity-like treated fabrics face price pressure, manufacturers offering certified, sustainable, high-performance, or smart FR solutions will command premium pricing based on demonstrable value (safety, durability, compliance, ESG).

Conclusion for H2 2026:

The fire-resistant fabric market in H2 2026 will be characterized by regulatory-driven growth, technology-led innovation, and an inescapable focus on sustainability. Success will depend on a company’s ability to:

* Navigate complex and evolving global regulations.

* Invest in R&D for next-gen materials (inherent fibers, smart textiles, sustainable chemistries).

* Build transparent, resilient, and ethical supply chains.

* Offer solutions that integrate safety, performance, comfort, and environmental responsibility across diverse and growing applications, particularly energy transition and smart infrastructure.

Manufacturers who proactively address these trends will be well-positioned to capture significant market share in the increasingly sophisticated and demanding FR fabric landscape of 2026 and beyond.

Common Pitfalls When Sourcing Fire-Resistant Fabric (Quality and Intellectual Property)

Sourcing fire-resistant fabric requires careful attention to both quality assurance and intellectual property (IP) considerations. Buyers, especially in industries such as protective clothing, aerospace, construction, and defense, face several risks if due diligence is not conducted properly. Below are the most common pitfalls in these two key areas.

Quality-Related Pitfalls

1. Inadequate Certification and Compliance

One of the most frequent issues is sourcing fabric that lacks proper certification to recognized safety standards (e.g., NFPA 2112, ISO 11612, EN 11611, or ASTM F1506). Some suppliers may provide falsified or self-issued test reports. Always verify certifications through accredited third-party laboratories and request up-to-date documentation.

2. Inconsistent Batch-to-Batch Performance

Fire-resistant properties can degrade or vary between production batches due to changes in raw materials, chemical treatments, or manufacturing processes. Suppliers without robust quality control systems may deliver inconsistent fabric performance, compromising end-user safety.

3. Misrepresentation of Fiber Composition

Some suppliers blend cheaper, non-flame-resistant fibers with FR fibers but market the fabric as fully compliant. For example, passing off modacrylic-blend fabrics as inherently FR without disclosing limitations. Always request a detailed fiber content breakdown and verify through independent lab testing.

4. Overlooking Durability and Wash Resistance

FR treatments (especially topical finishes) can wear off after repeated laundering or exposure to UV light and chemicals. Sourcing fabric without assessing its long-term performance in real-world conditions may lead to premature failure. Ensure the fabric maintains its fire resistance after a specified number of wash cycles.

5. Insufficient Testing for Real-World Conditions

Some fabrics perform well in lab tests but fail under actual use conditions—such as high humidity, mechanical stress, or exposure to oils and solvents. Relying solely on standard certifications without additional scenario-based testing can be risky.

Intellectual Property (IP) Pitfalls

1. Unlicensed Use of Proprietary Technologies

Many high-performance fire-resistant fabrics (e.g., Nomex®, Kevlar®, or Indura®) are protected by patents and trademarks. Sourcing generic versions that replicate these technologies without proper licensing can lead to legal action, shipment seizures, or reputational damage.

2. Counterfeit or Gray Market Materials

Suppliers may offer “equivalent” fabrics that are actually counterfeit or diverted from authorized channels. These may look identical but lack the performance and traceability of genuine branded materials. Always purchase from authorized distributors and verify authenticity through the IP holder.

3. Lack of Transparency in Technology Origin

Some manufacturers claim to use proprietary FR technologies but fail to disclose whether they are licensed or independently developed. This lack of transparency can expose buyers to infringement risks, particularly in export markets with strict IP enforcement.

4. Copying Design or Fabric Architecture

Even if a fabric uses different fibers, copying the weave structure, treatment process, or layered design of a patented product may still violate IP rights. Conduct freedom-to-operate (FTO) analyses when developing or sourcing custom FR fabrics.

5. Inadequate Contractual IP Protections

Purchase agreements often overlook clauses related to IP indemnification, liability for infringement, and rights to technical data. Without clear terms, buyers may bear legal and financial responsibility if the fabric violates third-party IP rights.

Conclusion

To avoid these pitfalls, conduct thorough supplier audits, demand verifiable test data and certifications, and consult legal experts when sourcing fabrics involving proprietary technologies. Partnering with reputable, transparent suppliers and investing in independent verification can mitigate both quality and IP risks effectively.

Logistics & Compliance Guide for Fire Proof Fabric

Fire proof fabric—more accurately referred to as fire-resistant or flame-retardant fabric—is subject to specific logistics handling and compliance requirements due to its safety-critical applications and chemical treatments. Proper management from manufacturing to end use ensures performance integrity, regulatory adherence, and worker safety. This guide outlines key logistics and compliance considerations.

Regulatory Compliance

Fire resistant fabrics must comply with a range of national and international standards depending on their intended use (e.g., protective clothing, furnishings, industrial applications). Key compliance areas include:

- Flammability Standards:

- USA: NFPA 701 (for textiles and films), NFPA 2112 (for flash fire protection), ASTM E84 (surface burning characteristics), and CAL TB 117 (for furniture and bedding).

- EU: EN 11612 (protective clothing against heat and flame), EN 14116 (limited flame spread), and compliance with REACH and EU Fire Safety Directive.

- Canada: CAN/ULC-S109 for flame spread of textiles.

-

Australia/NZ: AS/NZS 1530.3 (flammability tests).

-

Chemical Regulations:

Flame-retardant treatments may involve chemicals regulated under: - REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) – EU

- TSCA (Toxic Substances Control Act) – USA

-

Prop 65 – California (warning requirements for certain flame retardants)

-

Labeling Requirements:

Products must carry accurate labeling indicating compliance with relevant standards, care instructions, and safety warnings. In the EU, CE marking is mandatory for PPE applications.

Handling & Storage

Proper handling and storage are critical to maintain the fire-resistant properties of the fabric.

-

Environmental Conditions:

Store in a cool, dry, well-ventilated area away from direct sunlight and heat sources. Exposure to UV light and high humidity can degrade flame-retardant treatments. -

Packaging:

Use moisture-resistant packaging to prevent dampness. Avoid plastic wraps that trap moisture unless desiccants are used. -

Segregation:

Keep fire resistant fabrics separate from flammable materials or chemicals that could compromise their flame-resistant properties (e.g., oils, solvents, chlorine-based cleaners). -

Handling Precautions:

Use gloves if handling chemically treated fabrics to avoid skin contact. Follow SDS (Safety Data Sheet) guidelines for any treated materials.

Transportation

-

Classification:

Most fire resistant fabrics are not classified as hazardous materials, but treated fabrics with certain flame retardant chemicals (e.g., halogenated compounds) may require hazardous material classification under IATA, IMDG, or ADR regulations. Always verify with the fabric supplier and SDS. -

Documentation:

Ensure shipping documents include: - Product name and compliance certifications (e.g., NFPA, EN)

- SDS (if applicable)

-

Any special handling instructions

-

Packaging for Transit:

Use sturdy packaging to prevent tearing or contamination. Water-resistant outer wrapping is recommended for ocean or ground freight. -

Temperature Control:

Avoid extreme temperatures during transport, especially for chemically treated fabrics. Use climate-controlled containers if necessary.

Import/Export Considerations

- Customs Documentation:

Provide accurate HS (Harmonized System) codes. Fire resistant fabrics typically fall under: - 5903 (Textiles impregnated, coated, or laminated)

-

6211 (Protective garments, if applicable)

Confirm with local customs authorities. -

Country-Specific Regulations:

Some countries restrict or require certification for flame retardant chemicals. For example: - China: Requires CCC certification for certain protective textiles.

- India: BIS certification may apply.

-

Middle East: SASO or GCC certification may be required.

-

Duty & Tariff Implications:

Fire safety fabrics may qualify for reduced tariffs under certain trade agreements if used for safety or protective purposes.

Quality Assurance & Traceability

-

Batch Testing:

Maintain records of flammability and performance testing for each batch. Retain test reports (e.g., vertical flame, thermal shrinkage) for audit purposes. -

Traceability:

Implement a system to track fabric from raw material to finished product, including treatment processes and compliance documentation. -

Supplier Compliance:

Ensure all suppliers (especially chemical treatment providers) are certified and provide up-to-date SDS and compliance statements.

End-of-Life & Sustainability

-

Disposal:

Treated fabrics may require special disposal procedures due to flame retardant chemicals. Follow local environmental regulations. Incineration should be conducted in facilities equipped to handle hazardous emissions. -

Recycling Limitations:

Flame-retardant additives can complicate recycling. Check with recycling facilities and consider take-back programs offered by manufacturers. -

Sustainability Trends:

Increasing demand for eco-friendly flame retardants (e.g., phosphorus-based, bio-based). Ensure compliance with green certifications (e.g., OEKO-TEX®, Bluesign®) if marketing environmentally friendly products.

Conclusion

Effective logistics and compliance management for fire proof fabric requires attention to technical standards, chemical safety, transportation details, and regional regulations. Maintaining documentation, ensuring proper handling, and verifying supplier compliance are essential for legal operation and product performance. Regular audits and staying updated on regulatory changes will help mitigate risks and support market access globally.

Conclusion for Sourcing Fire-Resistant Fabric:

Sourcing fire-resistant fabric requires a strategic approach that balances safety, quality, compliance, and cost-effectiveness. It is essential to identify fabrics that meet specific industry standards—such as NFPA, ASTM, or EN norms—depending on the intended application, whether for industrial workwear, firefighting gear, military use, or interior furnishings. Evaluating material composition (e.g., inherent vs. treated flame resistance), performance under extreme conditions, durability, and comfort is crucial in making the right selection.

Working with reputable suppliers who provide certified materials, transparent documentation, and consistent quality control ensures long-term reliability and regulatory compliance. Additionally, considering sustainability and environmental impact is becoming increasingly important in responsible sourcing.

Ultimately, investing time in thorough research, requesting samples, verifying certifications, and building strong supplier relationships will lead to the procurement of fire-resistant fabrics that enhance safety, meet regulatory demands, and deliver value across the product lifecycle.