The global fine wire mesh market is experiencing robust growth, driven by increasing demand across industries such as pharmaceuticals, aerospace, filtration, and electronics. According to Grand View Research, the global wire mesh market size was valued at USD 39.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This expansion is fueled by advancements in precision manufacturing and rising need for high-efficiency filtration systems. Mordor Intelligence further projects steady growth in the fine wire mesh segment, supported by technological innovations and expanding applications in emerging economies. As demand for tighter tolerances and superior material performance intensifies, leading manufacturers are investing heavily in R&D and advanced weaving technologies. In this competitive landscape, nine key players have distinguished themselves through consistency, innovation, and global reach—setting the benchmark for quality and reliability in fine wire mesh production.

Top 9 Fine Wire Mesh Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Wire Mesh Manufacturers

Domain Est. 2001

Website: wire-cloth.net

Key Highlights: Instantly discover the leading wire mesh manufacturers and suppliers in the USA producing ISO certified products made from premium materials for unbeatable ……

#2 Wire Mesh & Wire Cloth Since 1854

Domain Est. 2007

Website: darbywiremesh.com

Key Highlights: Darby & Son, Inc. – a leading supplier of woven and welded wire mesh, wire cloth & wire screen since 1854. Darby has been a mainstay in the wire mesh industry ……

#3 Fine Wire Mesh

Domain Est. 2011

Website: iwimesh.net

Key Highlights: We, IWIMESH PVT. LTD. are specialised manufacturer, supplier and exporter top quality Fine Wire Mesh. The offered product is available in different sizes….

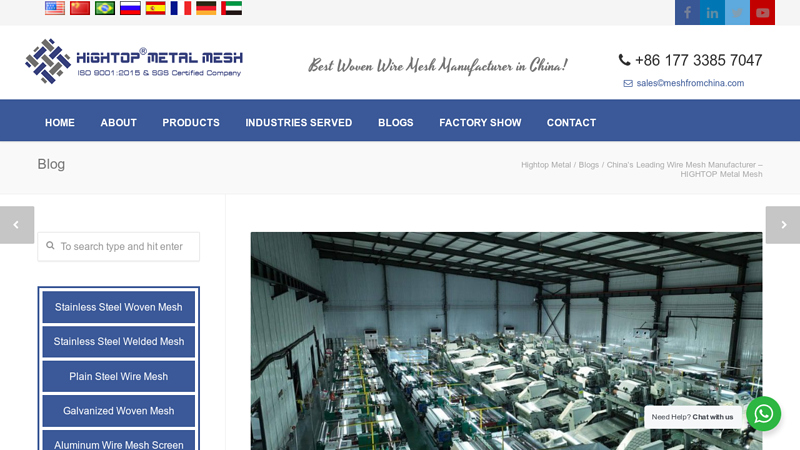

#4 China’s Leading Wire Mesh Manufacturer

Domain Est. 2014

Website: meshfromchina.com

Key Highlights: HIGHTOP’s woven wire mesh is manufactured using premium materials such as stainless steel, low-carbon steel, and aluminum alloys. Through ……

#5 Fine Wire Mesh manufacturer, supplier, exporter in Mumbai, India

Domain Est. 2017

Website: igwirescreen.com

Key Highlights: Fine wire mesh or wire cloth is thin woven wire meshes with mesh from 1×1 to 500 ×500, wire diameter and can be 0.025 mm to 2.03 mm (0.001 inch to 0.08 inch)….

#6 wire

Website: wire-mesh.eu

Key Highlights: We currently supply industrial products in the following range: Stainless Steel Wire Mesh Woven and Cloth with square openings: fine twill wire cloth with size ……

#7 Fine Stainless Steel Wire Mesh, Fine Epoxy Coated Mesh, Nickel …

Domain Est. 1998

Website: china-wiremesh.com

Key Highlights: YKM’s main products are stainless steel wire mesh,epoxy coated wire mesh,nickel wire mesh, copper wire mesh, low-carbon steel wire mesh and all kinds of ……

#8 IWM International Fine Wire and Woven Wire Mesh

Domain Est. 2015

Website: iwmesh.com

Key Highlights: IWM International manufactures metallic fine wire, woven wire mesh, and provides value-added contract manufacturing services….

#9 Trusted Top 10 Fine Wire Mesh Manufacturers and Suppliers

Domain Est. 2022

Website: ga.gt-meshfilter.com

Key Highlights: Dorstener Wire Tech is a leading provider of wire mesh and filtration products, catering to the needs of various industries worldwide. TWP Inc….

Expert Sourcing Insights for Fine Wire Mesh

2026 Market Trends for Fine Wire Mesh

The fine wire mesh market is poised for dynamic evolution by 2026, driven by technological advancements, shifting industrial demands, and growing sustainability imperatives. Key trends shaping the landscape include:

1. Accelerated Demand in High-Tech and Medical Sectors

By 2026, the proliferation of advanced technologies will significantly boost demand for precision-engineered fine wire mesh. The electronics industry will rely heavily on ultra-fine meshes for EMI/RFI shielding in 5G devices, wearables, and IoT sensors. Concurrently, the medical sector will expand its use of biocompatible fine meshes in implants, filtration systems, and diagnostic equipment, fueled by aging populations and advancements in minimally invasive procedures.

2. Rising Emphasis on Customization and Advanced Materials

Manufacturers will increasingly focus on offering highly customized solutions, including complex weaves, variable aperture designs, and hybrid material compositions. The adoption of advanced alloys—such as high-purity stainless steel, nickel alloys, and specialty materials like tantalum and titanium—will grow to meet stringent performance requirements in aerospace, semiconductor manufacturing, and chemical processing applications.

3. Sustainability and Circular Economy Integration

Environmental regulations and corporate sustainability goals will drive innovation in recyclable and long-life mesh products. By 2026, producers will prioritize energy-efficient manufacturing processes, reduce material waste through precision cutting technologies, and develop reusable or easily recyclable mesh components, particularly in filtration and industrial processing.

4. Automation and Smart Manufacturing Adoption

The integration of Industry 4.0 technologies—such as AI-driven quality control, real-time monitoring, and automated weaving systems—will enhance production efficiency and consistency. This shift will enable faster turnaround times, tighter tolerances, and improved traceability, meeting the high standards required by end-users in critical applications.

5. Geographic Market Shifts and Supply Chain Resilience

Asia-Pacific, particularly China and India, will remain dominant in both production and consumption due to rapid industrialization and expanding electronics and healthcare sectors. However, nearshoring and supply chain diversification efforts in North America and Europe will create opportunities for regional manufacturing, driven by geopolitical considerations and the need for resilient, shorter supply chains.

6. Expansion in Renewable Energy and Environmental Applications

Fine wire mesh will play a crucial role in emerging clean technologies, including hydrogen fuel cells, battery electrode components, and advanced water purification systems. As global investments in renewable energy and environmental protection intensify, demand for high-performance filtration and catalytic support meshes will surge.

In summary, the 2026 fine wire mesh market will be characterized by innovation, specialization, and sustainability, with growth concentrated in high-value applications across technology, healthcare, and green industries. Companies that invest in R&D, digitalization, and sustainable practices will be best positioned to capitalize on these evolving opportunities.

Common Pitfalls When Sourcing Fine Wire Mesh (Quality, IP)

Sourcing fine wire mesh requires careful attention to detail, as even minor oversights can lead to significant quality issues, performance failures, or intellectual property (IP) risks. Below are key pitfalls to avoid:

Inadequate Specification of Mesh Parameters

Failing to clearly define critical specifications such as wire diameter, mesh count (openings per inch), aperture size, and tolerance ranges often results in receiving product that doesn’t meet functional requirements. Suppliers may interpret vague requests differently, leading to inconsistencies in filtration efficiency, flow rate, or structural integrity.

Overlooking Material Certification and Traceability

Not requiring material test reports (MTRs) or proof of material origin (e.g., 316L stainless steel) can expose buyers to substandard or counterfeit materials. This is especially critical in regulated industries (pharmaceuticals, food processing) where compliance and traceability are mandatory for safety and audit purposes.

Ignoring Weave Type and Surface Finish

Different weave types (plain, twill, Dutch) affect performance characteristics like strength, permeability, and clogging resistance. Similarly, surface finishes (e.g., electropolished vs. as-drawn) impact corrosion resistance and cleanliness. Failing to specify these can result in premature failure in harsh environments.

Underestimating Tension and Flatness Requirements

Fine wire mesh used in precision applications (e.g., printing screens, sensors) requires consistent tension and flatness. Poor quality control during manufacturing can lead to warping or uneven tension, compromising performance and yield in downstream processes.

Neglecting Intellectual Property Protection

When sourcing custom-designed mesh (e.g., proprietary weave patterns or composite structures), failing to establish clear IP agreements—such as non-disclosure agreements (NDAs) or ownership clauses—risks design theft or unauthorized replication by suppliers, especially in offshore manufacturing.

Relying Solely on Price as a Selection Criterion

Opting for the lowest-cost supplier often leads to compromised quality, inconsistent batch-to-batch performance, or hidden costs from rework and downtime. A total cost of ownership analysis, including reliability and supplier support, is more sustainable.

Skipping Pre-Production Sampling and Validation

Bypassing prototype approval or first-article inspection increases the risk of receiving non-conforming bulk orders. Validating samples against technical specs before full production is essential for quality assurance.

Inadequate Supplier Vetting and Audits

Failing to audit a supplier’s quality management system (e.g., ISO 9001 certification), production capabilities, and testing infrastructure can result in undetected defects. This is especially important when sourcing from new or unfamiliar vendors.

By proactively addressing these pitfalls, buyers can ensure they receive high-quality, reliable fine wire mesh that meets both technical and legal requirements.

Logistics & Compliance Guide for Fine Wire Mesh

Fine wire mesh, used across industries such as filtration, aerospace, pharmaceuticals, and electronics, requires careful handling, packaging, and compliance with international regulations due to its delicate nature and potential end-use applications. This guide outlines key logistics and compliance considerations to ensure safe transportation and regulatory adherence.

Packaging and Handling

Proper packaging is essential to prevent damage during transit. Fine wire mesh is susceptible to tearing, deformation, and contamination.

- Protective Wrapping: Use anti-corrosive paper, plastic film, or foam liners to prevent scratches and oxidation.

- Rigid Containment: Ship mesh rolls or sheets in sturdy cardboard tubes, wooden crates, or custom-designed containers to avoid bending or crushing.

- Moisture Control: Include desiccants in packaging when shipping to humid environments to prevent rust (especially for stainless steel or carbon steel meshes).

- Labeling: Clearly mark packages with “Fragile,” “This Side Up,” and material specifications (e.g., mesh count, wire diameter, material grade).

Transportation and Storage

- Temperature and Humidity: Store and transport in controlled environments (ideally 10–25°C and <60% RH) to avoid condensation and material degradation.

- Stacking: Avoid stacking heavy items on top of fine wire mesh packages. Use pallets for stable transport.

- Vibration and Shock: Use cushioned transport vehicles and secure loads to minimize vibrations, especially for long-distance or international shipments.

Material Compliance and Certifications

Ensure all fine wire mesh products meet relevant industry and regional standards.

- Material Certifications: Provide Mill Test Certificates (MTCs) or Certificates of Conformity (CoC) for metals (e.g., ASTM, ISO, or EN standards for stainless steel, nickel alloys).

- Industry-Specific Standards:

- Pharmaceutical/Food Grade: Comply with FDA 21 CFR, USP Class VI, or EU 1935/2004 for food-contact materials.

- Filtration: Meet ASTM E2016 or ISO 29461 standards for air and liquid filtration media.

- Electromagnetic Shielding: Conform to IEEE-299 or MIL-STD-188 for EMI/RFI shielding applications.

- REACH and RoHS Compliance: Confirm that wire mesh materials do not contain restricted substances (e.g., lead, cadmium) if destined for the EU or electronics markets.

Import/Export Regulations

International shipments require adherence to customs and safety regulations.

- HS Code Classification: Use accurate Harmonized System codes (e.g., 7314.31 or 7314.49 for stainless steel wire mesh) to avoid customs delays.

- Export Controls: Check if material composition (e.g., high-nickel alloys) falls under export control regimes such as ITAR, EAR, or dual-use regulations.

- Documentation: Include commercial invoices, packing lists, certificates of origin, and material compliance documents with every shipment.

Environmental and Safety Considerations

- Waste Disposal: Follow local environmental regulations for disposal of packaging and scrap mesh materials.

- Worker Safety: Provide handling guidelines to prevent cuts from sharp wire edges; recommend use of gloves and protective gear.

- Sustainability: Opt for recyclable packaging and source materials from suppliers with responsible mining and production practices.

Quality Assurance and Traceability

- Batch Traceability: Maintain lot numbers and production records to track material origin and processing history.

- Pre-Shipment Inspection: Conduct visual and dimensional checks before dispatch to ensure product integrity.

- Customer Documentation: Provide detailed specification sheets, care instructions, and compliance documentation with each order.

Following these logistics and compliance guidelines ensures that fine wire mesh is delivered safely, meets regulatory requirements, and maintains its performance characteristics in critical applications.

In conclusion, sourcing fine wire mesh requires a careful evaluation of several key factors including mesh specifications (such as aperture size, wire diameter, and mesh count), material composition (e.g., stainless steel, brass, or copper), intended application (filtration, sieving, aerospace, medical, etc.), and compliance with industry standards. It is essential to partner with reputable suppliers who offer consistent quality, technical expertise, and reliable lead times. Additionally, considering cost-efficiency without compromising on precision and durability will ensure optimal performance in the end use. By conducting thorough research, requesting samples, and validating supplier credentials, organizations can secure a dependable supply of fine wire mesh that meets both technical requirements and operational goals.