The global fastener market, driven by robust demand from automotive, construction, and industrial manufacturing sectors, is projected to grow at a CAGR of 4.8% from 2023 to 2028, according to Mordor Intelligence. Within this expansive market, Fillister head screws—a specialized type known for their cylindrical head with a slight dome and high torque transmission—are experiencing steady demand due to their mechanical advantages in precision applications. As industries prioritize reliability and performance, sourcing high-quality Fillister head screws has become critical. Backed by regional production hubs in Asia-Pacific, North America, and Europe, leading manufacturers are scaling output and investing in advanced threading and coating technologies. This list highlights the top 10 Fillister head screw manufacturers leveraging innovation, global distribution, and stringent quality standards to capture value in a competitive, growing marketplace.

Top 10 Fillister Head Screw Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 OEM Fein 43035034067 Fillister Head Screw

Domain Est. 2004

Website: ereplacementparts.com

Key Highlights: Shop for genuine 43035034067 Fein Fillister Head Screw today. Find factory authorized parts, great repair advice and same–day shipping on ……

#2 Fillister Head Screws

Domain Est. 2017

Website: boltingspecialist.com

Key Highlights: Fillister Head Screws are available in metric thread sizes ranging from M2.5 through to M10, and lengths of between 6 mm up to 100 mm as standard….

#3 Fillister Head

Domain Est. 1999

Website: associatedfasteners.com

Key Highlights: Fillister Head Machine Screw: Essential for versatile and secure fastening, ensuring stability and strength in various applications for lasting connections….

#4 A few common screw head types and what they are used for

Domain Est. 2001

Website: uccomponents.com

Key Highlights: FILLISTER SLOTTED Fillister head slotted screws have a large oversized head and are the preferred head type for counterbored holes. They are similar to a pan ……

#5 Fillister Head

Domain Est. 2002

Website: tsfasteners.com

Key Highlights: TS Fasteners, a renowned supplier of fillister head screws, offers a wide range of high-quality fastening solutions. Our commitment to excellence and solid ……

#6 Fillister Head Machine Screws

Domain Est. 2008

Website: aftfasteners.com

Key Highlights: Free delivery over $200Shop AFT for a large selection of fillister head machine screws in steel or stainless steel. Great prices. Most orders ship the same day….

#7 Machine Screws

Domain Est. 2010

#8 Fillister Head Screw

Domain Est. 2015

Website: southstatemfg.com

Key Highlights: Quick Overview. Slotted Fillister Head Machine Screw. Black Oxide Protective Finish. 8/32 Thread. Size. 1 Inch, 1/2 Inch, 3/8 Inch, 1/4 Inch….

#9 The Beginner’s Guide to Fillister Head Screws

Domain Est. 1999

Website: monroeengineering.com

Key Highlights: Fillister head screws are threaded fasteners are characterized by a tall, cylindrical-shaped head with a flat top….

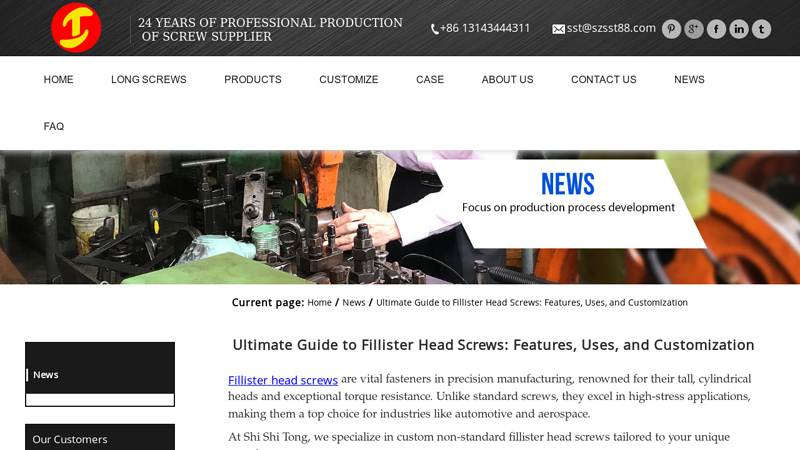

#10 Ultimate Guide to Fillister Head Screws

Domain Est. 2017

Website: sstls.com

Key Highlights: Fillister head screws are vital fasteners in precision manufacturing, renowned for their tall, cylindrical heads and exceptional torque resistance….

Expert Sourcing Insights for Fillister Head Screw

H2: 2026 Market Trends for Fillister Head Screws

The global market for fillister head screws is projected to experience steady growth and notable shifts by 2026, driven by evolving manufacturing demands, material innovations, and regional industrial expansion. Fillister head screws, characterized by their tall, cylindrical head with a flat top and external driving features, are commonly used in applications requiring high torque transmission and a flush or slightly protruding finish, such as automotive assemblies, electrical equipment, and machinery.

1. Rising Demand in Automotive and Electronics Sectors

The automotive industry remains a key driver for fillister head screws, particularly with the increased production of electric vehicles (EVs) and advanced driver-assistance systems (ADAS). These applications require durable, precision-engineered fasteners capable of withstanding vibration and thermal stress. Similarly, the electronics sector—especially in consumer devices and industrial control systems—relies on fillister head screws for secure component mounting. By 2026, the integration of smart manufacturing and miniaturized electronics is expected to boost demand for smaller, corrosion-resistant fillister screws made from stainless steel or alloy materials.

2. Shift Toward High-Performance Materials

Market trends indicate a growing preference for fillister head screws manufactured from high-strength, lightweight, and corrosion-resistant materials. Stainless steel, titanium, and specialty alloys are gaining traction, particularly in aerospace, medical devices, and marine applications. This shift is supported by advancements in coating technologies (e.g., zinc-nickel, PTFE) that enhance durability and reduce maintenance. Sustainability concerns are also pushing manufacturers to adopt recyclable materials and eco-friendly production processes.

3. Regional Market Dynamics

Asia-Pacific, led by China, India, and Japan, is anticipated to dominate the fillister head screw market by 2026 due to rapid industrialization, expanding infrastructure, and robust electronics manufacturing. North America and Europe will maintain strong demand, primarily fueled by automation, renewable energy projects, and aerospace innovation. However, supply chain localization and nearshoring trends may encourage regional production hubs to reduce dependency on imports.

4. Technological Advancements and Customization

Automation in assembly lines and the rise of Industry 4.0 are driving demand for standardized yet customizable fasteners. Fillister head screws with specialized drive types (e.g., Torx, hex socket) and anti-tamper features are increasingly sought after. Digital inventory systems and just-in-time (JIT) manufacturing are enabling faster turnaround and tailored solutions for OEMs.

5. Competitive Landscape and Consolidation

The market is moderately fragmented, with key players such as Stanley Engineered Fastening, Bossard Group, and Misumi expanding their product portfolios and investing in R&D. Strategic partnerships, mergers, and acquisitions are expected to increase as companies aim to enhance global reach and technological capabilities.

In summary, by 2026, the fillister head screw market will be shaped by technological innovation, material advancements, and sector-specific demand, positioning it as a critical component in high-performance industrial applications.

Common Pitfalls When Sourcing Fillister Head Screws (Quality, IP)

When sourcing fillister head screws, especially for precision applications requiring specific quality standards and IP (Ingress Protection) ratings, several common pitfalls can compromise performance, safety, and compliance. Being aware of these issues helps ensure reliable and durable fastening solutions.

Poor Material Quality and Inadequate Certification

One of the most frequent issues is receiving fillister head screws made from substandard materials. Suppliers may use low-grade stainless steel or unverified alloys that fail to meet required corrosion resistance or mechanical strength standards. This is especially critical when IP ratings are involved—such as in outdoor or wet environments—where material integrity directly impacts the screw’s ability to maintain an effective seal. Always request material test certificates (MTCs) and verify compliance with standards like ISO 3506 for stainless steel fasteners.

Misrepresentation of IP Ratings

Fillister head screws themselves do not carry IP ratings; rather, the rating applies to the assembled product or enclosure. However, suppliers may misleadingly claim that a screw “meets IP67” or similar, creating confusion. The actual IP performance depends on the joint design, gasketing, and torque application. Relying solely on the screw’s presence to achieve an IP rating is a critical error. Ensure that engineering teams validate full assembly performance rather than assuming the fastener alone ensures protection.

Inconsistent Thread and Head Dimensions

Low-quality manufacturing often results in dimensional inaccuracies, such as out-of-tolerance threads or head heights. Fillister head screws have a taller head than standard round head screws, designed for increased bearing surface and torque application. If the head height or thread pitch varies, it can lead to poor fit, stripping, or inconsistent torque, undermining joint integrity—particularly in high-vibration or load-bearing applications.

Insufficient Surface Finish and Coating

Improper or uneven plating (e.g., zinc, nickel, or PTFE coatings) can compromise both appearance and functionality. In environments requiring IP protection, pinholes or thin spots in coatings can allow moisture ingress, leading to corrosion and failure. Additionally, some coatings may not withstand assembly tools, resulting in galling or damage during installation. Specify appropriate finishes and conduct batch testing for coating thickness and adhesion.

Lack of Traceability and Documentation

Reputable sourcing requires full traceability, especially in regulated industries like medical, automotive, or aerospace. Many suppliers—especially from unverified sources—fail to provide lot traceability, inspection reports, or compliance documentation. This absence makes it difficult to address quality issues or conduct root cause analysis during failures.

Overlooking Driving Feature Quality

The driving recess (e.g., slotted, Phillips, or hex) must be precisely formed to prevent cam-out or tool slippage. Poorly cut drives increase the risk of installation damage, especially when automated assembly is used. This not only affects efficiency but can compromise the final seal and structural integrity, indirectly impacting the system’s IP performance.

Conclusion

To avoid these pitfalls, source fillister head screws from certified, reputable suppliers with clear quality management systems (e.g., ISO 9001). Clearly define material specifications, dimensional tolerances, surface treatments, and required documentation. Remember that while the screw contributes to environmental sealing, IP ratings are system-level attributes—never assume component-level claims equate to full protection.

Logistics & Compliance Guide for Fillister Head Screws

This guide outlines the essential logistics considerations and compliance requirements for handling, transporting, storing, and using fillister head screws in industrial and commercial applications. Adherence to these guidelines ensures product integrity, regulatory compliance, and operational safety.

Product Overview and Identification

Fillister head screws are characterized by their tall, cylindrical head with a flat top surface and a recessed drive (commonly slotted or socket). They are designed for applications requiring a high degree of torque and a flush or slightly protruding finish. Correct identification ensures compatibility and compliance during logistics and usage.

- Common Materials: Stainless steel (A2/A4), alloy steel, carbon steel, brass

- Finishes: Zinc plating, passivation, black oxide, electropolished

- Standards: ASME B18.3, DIN 7984, ISO 14583

- Typical Applications: Machinery assembly, electronics, automotive components

Packaging and Labeling Requirements

Proper packaging and labeling are critical for traceability, protection, and regulatory compliance during storage and transit.

- Inner Packaging: Screws should be sealed in moisture-resistant bags or anti-corrosion VCI (Vapor Corrosion Inhibitor) packaging, especially for corrosion-prone materials.

- Outer Packaging: Use sturdy corrugated cartons or reusable containers. Ensure packaging is labeled with:

- Product description (e.g., “Fillister Head Screw, M6 x 25mm, Stainless Steel A2”)

- Quantity and net weight

- Batch/lot number and date of manufacture

- Manufacturer or supplier name and contact

- Compliance markings (e.g., RoHS, REACH, CE if applicable)

Storage Conditions

Storage environments must prevent degradation, corrosion, and contamination.

- Temperature: Store between 10°C and 30°C (50°F to 86°F)

- Humidity: Relative humidity below 60%; avoid condensation

- Ventilation: Well-ventilated, dry area free from chemical fumes

- Shelving: Use non-corrosive shelving; keep off concrete floors with pallets

- Segregation: Store by material, size, and finish to avoid mix-ups and galvanic corrosion

Transportation and Handling

Safe and compliant transportation preserves product quality and ensures workplace safety.

- Stacking Limits: Observe manufacturer-recommended stacking heights to prevent container damage

- Securement: Palletized loads must be strapped and shrink-wrapped; use dunnage when necessary

- Handling Equipment: Use appropriate forklifts, pallet jacks, or conveyors; avoid dragging or dropping containers

- Environmental Protection: Shield from rain, direct sunlight, and extreme temperatures during transit

- Hazard Classification: Non-hazardous under most regulations (e.g., UN 3480), but confirm based on material and coating

Regulatory and Environmental Compliance

Fillister head screws may be subject to regional and international regulations depending on material composition and end-use.

- RoHS (EU): Restricts hazardous substances (Pb, Cd, Hg, Cr6+, PBB, PBDE). Ensure screws comply if used in electrical/electronic equipment.

- REACH (EU): Requires declaration of Substances of Very High Concern (SVHC). Suppliers must provide SVHC documentation upon request.

- Conflict Minerals (U.S. Dodd-Frank Act): If screws contain tin, tantalum, tungsten, or gold, due diligence may be required regarding sourcing.

- California Proposition 65: Warn if screws contain listed chemicals (e.g., lead in certain platings).

- Export Controls: Verify no ITAR or EAR restrictions apply, especially for aerospace-grade fasteners.

Quality Assurance and Documentation

Maintain documentation to support traceability and compliance audits.

- Certificates of Compliance (CoC): Request from supplier; must include material standard, finish, and applicable specifications.

- Mill Test Reports (MTR): Required for critical applications, especially in aerospace and medical industries.

- Traceability: Retain batch/lot records for a minimum of 5 years or per industry requirements.

- Incoming Inspection: Verify dimensions, thread accuracy, head geometry (per ASME B18.3), and surface finish upon receipt.

Disposal and End-of-Life

Environmental regulations govern the disposal of metal components and packaging materials.

- Recycling: Metal screws are 100% recyclable. Separate by material type (e.g., stainless vs. carbon steel).

- Hazardous Waste: Plated screws with hexavalent chromium or cadmium may require special handling.

- Packaging Waste: Follow local regulations for disposal of plastic bags, cardboard, and VCI materials.

- Waste Codes: Refer to local EPA or ECHA guidelines (e.g., EU Waste Code 17 04 01* for ferrous metals).

Summary

Effective logistics and compliance management for fillister head screws involves proper identification, packaging, storage, transportation, and documentation. Adherence to international standards and environmental regulations ensures product reliability and legal operation across global supply chains. Always consult supplier data sheets and regulatory updates to maintain compliance.

Conclusion for Sourcing Fillister Head Screws:

After evaluating various suppliers, material options, quality standards, and cost considerations, it is evident that sourcing fillister head screws requires a balanced approach that prioritizes quality, reliability, and compliance with industry specifications. Fillister head screws, with their tall head and high torque capacity, are essential in applications requiring security and resistance to cam-out, particularly in automotive, electronics, and machinery sectors.

The most favorable sourcing strategy involves partnering with certified suppliers who adhere to international standards (such as ISO, ASME, or DIN) and offer traceable materials with consistent thread accuracy and head dimensions. While cost competitiveness is important, compromising on quality may lead to product failure and increased long-term expenses.

Additionally, considering factors such as lead times, minimum order quantities, and packaging requirements ensures supply chain efficiency. Exploring both domestic and global suppliers provides flexibility, but due diligence through sample testing and supplier audits is crucial.

In conclusion, the successful sourcing of fillister head screws lies in a strategic selection process that emphasizes quality assurance, supplier reliability, and total cost of ownership, ensuring optimal performance and durability in the intended application.