The global fiber optic connectors market is experiencing robust growth, driven by the escalating demand for high-speed data transmission across telecommunications, data centers, and enterprise networks. According to Mordor Intelligence, the fiber optic connectors market was valued at USD 1.95 billion in 2023 and is projected to grow at a CAGR of 7.8% from 2024 to 2029. This expansion is fueled by the ongoing deployment of 5G networks, the rise of cloud computing, and the increasing adoption of fiber-to-the-home (FTTH) infrastructure. FC connectors, known for their threaded coupling mechanism and superior stability in high-vibration environments, remain a critical component in many legacy and industrial applications despite the rise of newer connector types. As global bandwidth requirements continue to surge, manufacturers specializing in precision optical components are scaling production and innovating to meet evolving industry standards. In this competitive landscape, a select group of manufacturers have emerged as leaders in quality, reliability, and market reach—shaping the future of fiber optic connectivity.

Top 10 Fiber Optic Fc Connector Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 FC Connectors and Adapters

Domain Est. 1991

Website: corning.com

Key Highlights: Corning’s FC-PC connectors (722 series) offer superior performance with very high repeatability. These products are fully intermateable with standard NTT FC-PC ……

#2 SENKO Advanced Components, Inc. » Innovative Optical …

Domain Est. 1996

Website: senko.com

Key Highlights: SENKO specializes in Optical Interconnect solutions which are considered vital components to fiber optic network deployment, maintenance, and reliability….

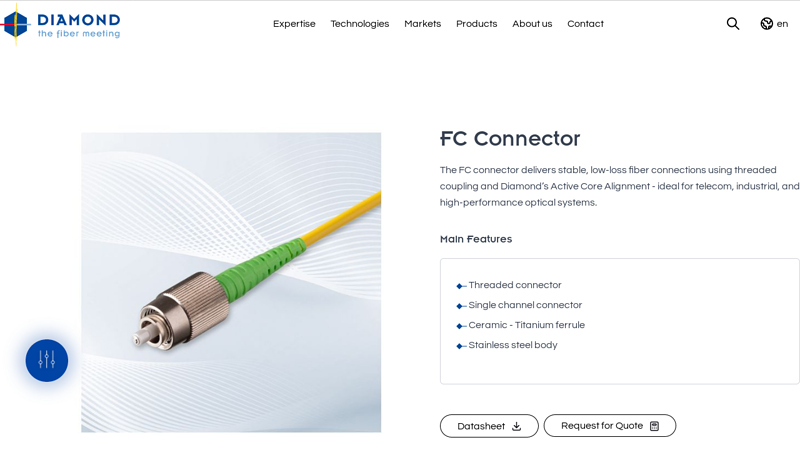

#3 FC Connector

Domain Est. 1997

Website: diamond-fo.com

Key Highlights: The FC connector by DIAMOND SA is a robust, high-precision fiber optic solution with threaded coupling and ACA technology for low-loss, vibration-resistant ……

#4 Fibertronics, Inc.

Domain Est. 2000

Website: fibertronics.com

Key Highlights: 2–12 day deliveryFibertronics, Inc. is an SBA certified woman-owned small business providing USA manufactured customized fiber optic and low voltage cable assemblies, ……

#5 Fiber Optics Products and Solutions

Domain Est. 1992

Website: te.com

Key Highlights: Deliver more bandwidth with TE fiber optics products and solutions, whether it’s for a component, system, or network application. Purchase fiber optics ……

#6 FO

Domain Est. 1996

Website: jae.com

Key Highlights: Sprung ferrule end offers stable connection, ensuring correct optical transmission. Plug connectors will be harnessed and supplied by our company. Catalog….

#7 US Conec

Domain Est. 1997

Website: usconec.com

Key Highlights: State-of-the-art connector with unmatched density, simple insertion/extraction, and field configurability….

#8 Fiber Optic Center

Domain Est. 1998

Website: focenter.com

Key Highlights: Shop Now. International distributor for fiber optic components, equipment and accessories while providing invaluable technical consultation and support….

#9 FCXtreme® connector for defense and aerospace applications

Domain Est. 2010

Website: sedi-ati.com

Key Highlights: The FCXtreme connector is a high-performance versatile, and compact FC-type connector, designed for defense and aerospace applications….

#10 FC Fiber Optics Connector

Domain Est. 2019

Website: abalone-tech.com

Key Highlights: The FC connector is a fiber-optic connector with a threaded body, which was designed for use in high-vibration environments….

Expert Sourcing Insights for Fiber Optic Fc Connector

2026 Market Trends for Fiber Optic FC Connectors: Analysis

As the global demand for high-speed data transmission continues to surge, the fiber optic connector market remains a critical component of modern communication infrastructure. Among the various connector types, the FC (Ferrule Connector) has long been a reliable staple, particularly in high-vibration and industrial environments due to its threaded coupling mechanism. Looking ahead to 2026, the market for FC connectors is expected to experience nuanced shifts shaped by technological evolution, industry-specific demands, and broader connectivity trends.

Stable Niche Demand Amidst Dominance of Smaller Connectors

By 2026, FC connectors will likely maintain a stable but niche position within the broader fiber optic connector landscape. While connectors like LC, SC, and newer variants such as MPO dominate data centers and telecom networks due to their smaller form factors and higher port density, FC connectors continue to hold strong in applications where mechanical stability and secure connections are paramount. Industries such as industrial automation, aerospace, defense, and certain segments of the oil and gas sector will continue to rely on FC connectors for their superior resistance to vibration and accidental disconnection. This sustained demand in specialized fields will prevent a steep decline but will also limit widespread market growth.

Impact of 5G and Fiber Deep Deployments

The ongoing rollout of 5G networks and fiber-to-the-home (FTTH) expansions will influence FC connector usage indirectly. While these deployments primarily favor smaller, high-density connectors, some backhaul and fronthaul infrastructure—especially in ruggedized outdoor cabinets or legacy system integrations—may still incorporate FC connectors. However, the trend toward miniaturization and cost efficiency in 5G infrastructure could further marginalize FC connectors in mainstream telecom applications, pushing their use into legacy maintenance and specific high-reliability nodes.

Competition from Advanced Connector Technologies

By 2026, the market will see increased competition from next-generation connectors offering improved performance, easier installation, and better scalability. Connectors supporting higher data rates (beyond 400G and toward 800G) with lower insertion loss and higher return loss will gain traction. While FC connectors can support high performance, their larger size and manual threading process make them less attractive for high-density environments. Innovations in APC (Angled Physical Contact) polishing and hybrid multimode/single-mode compatibility may extend the relevance of FC connectors in test and measurement equipment, where precision and repeatability are valued.

Regional Market Dynamics

Asia-Pacific, particularly China and India, will remain key markets for fiber optic components. However, demand for FC connectors in this region will be more concentrated in industrial and governmental projects rather than consumer-facing broadband. In contrast, North America and Europe may see gradual phase-outs of FC connectors in new installations, with demand driven primarily by replacement parts and legacy system support.

Conclusion

In summary, the 2026 market for fiber optic FC connectors is poised for stability in specialized, high-reliability sectors rather than broad expansion. While general market trends favor smaller, faster, and more scalable solutions, the FC connector’s robust design ensures its continued relevance in environments where connection integrity cannot be compromised. Manufacturers focusing on FC connectors will need to emphasize durability, customization for industrial applications, and compatibility with legacy systems to maintain market share in an increasingly competitive and evolving landscape.

Common Pitfalls When Sourcing Fiber Optic FC Connectors (Quality, IP)

Sourcing fiber optic FC connectors requires careful evaluation to ensure performance, reliability, and compatibility. Below are key pitfalls related to quality and IP (intellectual property or ingress protection) that buyers often encounter.

Poor Manufacturing Quality

Low-cost FC connectors may use substandard materials such as inferior ceramics for ferrules or low-grade metal housings. This can lead to misalignment, high insertion loss, and reduced durability. Always verify compliance with IEC 61754-13 standards and request test reports for return loss and insertion loss.

Inconsistent Ferrule Precision

The ferrule is critical for signal integrity. Poorly polished or out-of-tolerance ferrules cause signal degradation. Ensure suppliers provide connectors with precise ferrule concentricity (<0.5 µm) and surface quality (scratch-dig specifications).

Lack of Ingress Protection (IP) Certification

Many FC connectors are marketed as “dust-resistant” or “ruggedized” without formal IP ratings. For harsh environments, confirm the IP rating (e.g., IP67 for dust-tight and water immersion up to 1 meter). Unrated connectors may fail in outdoor or industrial applications.

Misrepresentation of IP67 or IP68 Ratings

Some suppliers claim IP67/68 compliance without third-party testing. Request test certificates from accredited labs to verify sealing performance under pressure and temperature cycling. Beware of self-declared ratings.

Counterfeit or Non-Original Components

Cloned or counterfeit FC connectors may mimic reputable brands but lack reliability. These often fail prematurely under stress. Source from authorized distributors and verify batch traceability and branding authenticity.

Inadequate Plating and Corrosion Resistance

Poor plating on the connector body (e.g., zinc or nickel) leads to corrosion in humid environments. Ensure connectors use durable plating such as stainless steel or gold-plated coupling nuts, especially for outdoor use.

Missing Documentation and Compliance

Suppliers may omit critical documentation such as RoHS, REACH, or ISO 9001 certifications. Without these, compliance and traceability are compromised. Always request full technical and compliance documentation.

Insufficient Testing and Quality Control

Some manufacturers skip 100% optical and mechanical testing. Confirm that each batch undergoes insertion loss, return loss, and mating cycle testing. Ask for QC process details and sample test data.

Non-Standard Thread or Coupling Mechanism

FC connectors rely on a threaded coupling nut. Variations in thread pitch or tolerance can cause cross-threading or unreliable connections. Ensure compatibility with existing infrastructure by verifying thread specifications (typically 2.5mm pitch, M10×1).

Overlooking Temperature and Environmental Ratings

Connectors used in extreme temperatures may suffer from material expansion or seal failure. Verify operating temperature range (e.g., -40°C to +85°C) and ensure elastomer seals are rated for intended conditions.

By avoiding these common pitfalls, procurement teams can ensure reliable, high-performance fiber optic connectivity and reduce long-term maintenance costs.

Logistics & Compliance Guide for Fiber Optic FC Connectors

Overview

Fiber Optic FC (Ferrule Connector) connectors are widely used in telecommunications, data centers, and industrial applications for reliable, high-precision optical signal transmission. Due to their delicate nature and global deployment, proper logistics handling and compliance with international standards are essential to ensure product integrity, safety, and market access.

Packaging & Handling Requirements

FC connectors are sensitive to contamination, mechanical stress, and electrostatic discharge (ESD). To preserve optical performance:

– Use anti-static packaging materials (e.g., ESD-safe bags or trays).

– Seal connectors with protective dust caps before packaging.

– Employ rigid secondary packaging (e.g., corrugated boxes with cushioning) to prevent physical damage during transit.

– Clearly label packages with “Fragile,” “Do Not Stack,” and “Keep Dry” indicators.

– Avoid exposure to extreme temperatures, humidity, or direct sunlight during storage and transport.

Shipping & Transportation

- Ship via temperature-controlled and shock-monitored transport when possible, especially for long-distance or international routes.

- Use carriers experienced in handling electronic or precision optical components.

- For air freight, comply with IATA Dangerous Goods Regulations if batteries or laser components are included in associated equipment.

- Maintain a chain of custody documentation for high-value or mission-critical shipments.

Import/Export Compliance

- Verify Harmonized System (HS) Code: Typically 8536.69 (electrical connectors) or 9001.10 (optical fibers and connectors), depending on regional classification.

- Confirm export control regulations (e.g., U.S. EAR or EU Dual-Use Regulation) – most FC connectors are not controlled, but verify if integrated with encryption or military-grade optics.

- Provide accurate commercial invoices, packing lists, and certificates of origin.

- Comply with destination country’s technical regulations (e.g., CE marking in Europe, RoHS, REACH).

Regulatory & Safety Standards

Ensure FC connectors meet applicable international standards:

– IEC 61753 & IEC 61754-13: Performance and interface standards for optical connectors.

– RoHS (EU): Restriction of Hazardous Substances – ensure lead, cadmium, and other restricted materials are below thresholds.

– REACH (EU): Registration, Evaluation, Authorization, and Restriction of Chemicals – declare SVHCs if applicable.

– CE Marking: Required for sale in the European Economic Area; indicates conformity with health, safety, and environmental protection standards.

– FCC (USA): Not typically required for passive connectors unless part of a larger active system.

– UL/CSA: May be required if used in safety-rated systems or North American installations.

Environmental & Disposal Compliance

- Follow WEEE (Waste Electrical and Electronic Equipment) directives in applicable regions for end-of-life disposal.

- Partner with certified e-waste recyclers for responsible handling of connector components, especially metal ferrules and plastic housings.

- Avoid landfill disposal; encourage return or recycling programs for used or defective connectors.

Documentation & Traceability

- Maintain product traceability through batch/lot numbers and manufacturing dates.

- Provide compliance documentation (e.g., Declaration of Conformity, RoHS Certificate, REACH Statement) with shipments.

- Keep records of testing certifications (e.g., IL/RL performance, durability) for audit purposes.

Conclusion

Proper logistics management and adherence to global compliance standards are critical for the successful distribution of Fiber Optic FC connectors. By following these guidelines, manufacturers and distributors can ensure product reliability, regulatory compliance, and customer satisfaction across international markets.

Conclusion for Sourcing Fiber Optic FC Connectors

In conclusion, sourcing fiber optic FC connectors requires careful consideration of several key factors including quality, compatibility, supplier reliability, and cost-effectiveness. FC connectors, known for their threaded coupling mechanism and excellent stability, are ideal for high-vibration environments and applications requiring precise alignment, such as in telecommunications, data centers, and test equipment.

When selecting a supplier, it is essential to prioritize manufacturers or distributors that adhere to international standards (such as IEC and TIA), offer consistent product quality, and provide proper certification and testing data. Evaluating factors such as insertion loss, return loss, durability, and material quality ensures optimal performance and long-term reliability of the optical network.

Additionally, building relationships with reputable suppliers, considering total cost of ownership over initial price, and staying informed about technological advancements will support successful integration of FC connectors into your fiber optic infrastructure. Ultimately, a strategic sourcing approach will enhance network performance, reduce downtime, and ensure scalability for future demands.