The fence trailer manufacturing industry has experienced steady growth, driven by rising demand in agriculture, construction, and landscaping sectors. According to Grand View Research, the global utility trailer market—encompassing fence trailers—was valued at USD 13.7 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 4.6% from 2023 to 2030. This growth is fueled by increasing infrastructure development, the expansion of agribusiness, and a growing preference for durable, transportable equipment solutions. As demand for specialized hauling equipment rises, fence trailer manufacturers are innovating with stronger materials, enhanced load capacities, and customizable designs to meet diverse operational needs. In this competitive landscape, nine manufacturers have emerged as industry leaders, combining performance, reliability, and market reach to serve commercial and industrial users across North America and beyond.

Top 9 Fence Trailer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 China Semi Trailer Manufacturer – Benchi Heavy Industry

Domain Est. 2023

Website: bcheavyindustry.com

Key Highlights: Shandong Benchi Heavy Industry Co., Ltd. specializes in semi-trailer manufacturing, offering a variety of products such as car carrier trailers, lowbed trailers ……

#2 China fencing transportation trailer lease option Manufacturers Factory

Domain Est. 2023

Website: benhongtrailer.com

Key Highlights: BENHONG is one of the most professional fence semi trailer manufacturers in China, featured by quality products and competitive price….

#3 United Rentals

Domain Est. 1997

Website: unitedrentals.com

Key Highlights: United Rentals provides 3300+ equipment and tool classes for industrial & construction sites across the United States and Canada. Rent heavy equipment now….

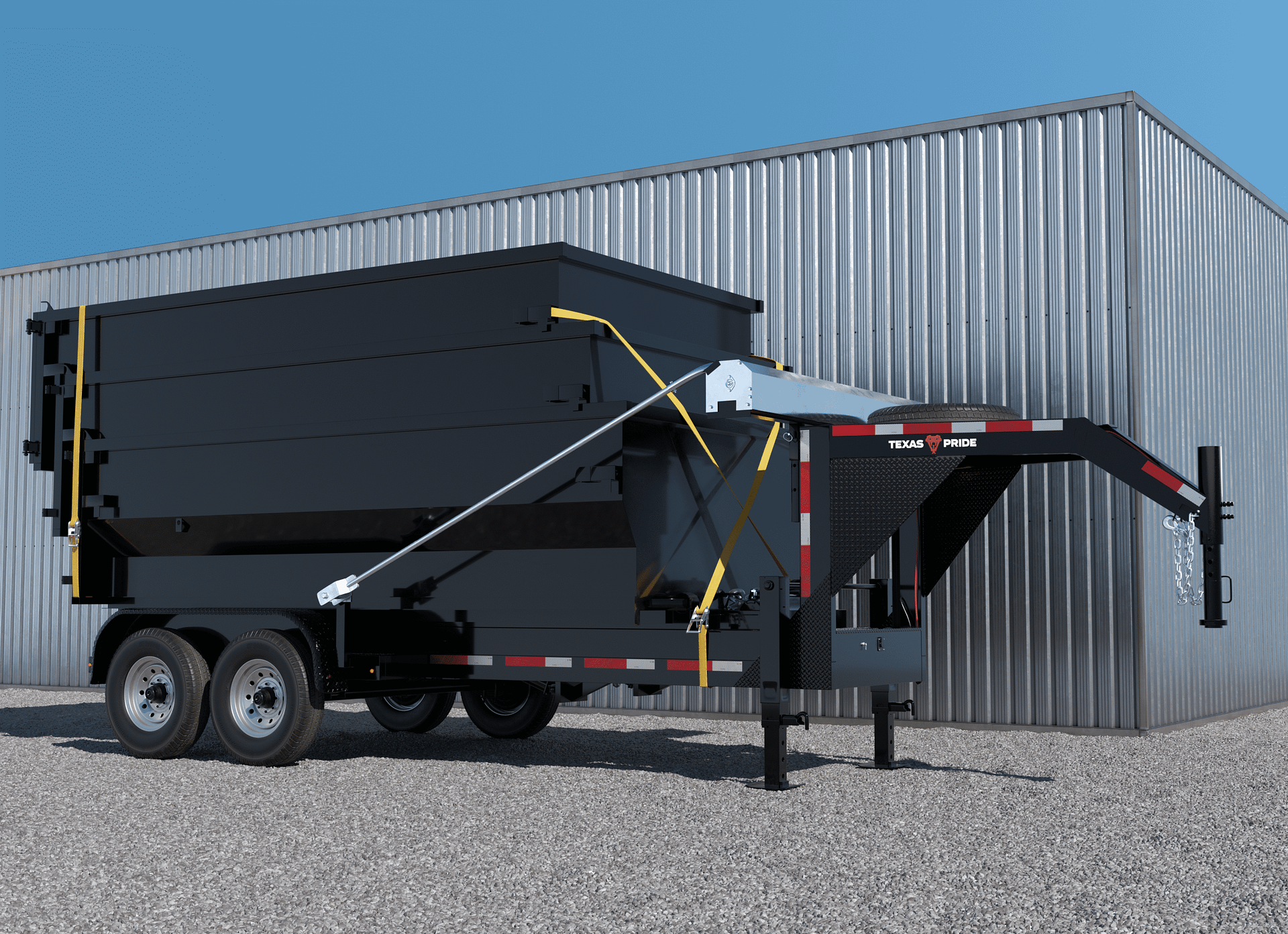

#4 Roll-Off Trailers for Sale – Built Strong

Domain Est. 2006

Website: texaspridetrailers.com

Key Highlights: Free deliveryBuilt-to-order roll-off trailers with heavy-duty dumpsters, smart lifts, and fast delivery—factory-direct from Texas Pride. Customize yours today….

#5 Rhinotrail

Website: rhinotrail.com

Key Highlights: At Rhinotrail, We offer customized semi-trailer products, including skeletal, flatbed, dump, fence, tanker, and low-bed trailers. From design to final assembly ……

#6 American Fence and Supply

Domain Est. 1997

Website: afence.com

Key Highlights: We specialize in a wide variety of fencing products, including chain-link, split rail, vinyl rail, electric, ornamental, wood, and farm and ranch fencing. Our ……

#7 Tarter USA

Domain Est. 2013 | Founded: 1945

Website: tarterusa.com

Key Highlights: Tarter has been offering American-made farm and ranch equipment since 1945. Whether you have cattle, horses, small animals, or just a garden, Tarter has the ……

#8 China Best SINOTRUK HOWO SHACMAN FAW Trucks Supplier …

Domain Est. 2024

Website: derunvehicle.com

Key Highlights: Shandong Derun Auto Co., Ltd is a leading manufacturer of trailers and trucks in China. Since its establishment in 2005, it has over 18 years of experience. We ……

#9 Big Tex Trailer Manufacturer Directory

Domain Est. 1997

Website: accio.com

Key Highlights: Need a reliable Big Tex trailer manufacturer? Discover verified suppliers offering durable utility, dump, and cargo trailers….

Expert Sourcing Insights for Fence Trailer

H2: 2026 Market Trends for Fence Trailers

The fence trailer market is poised for notable evolution by 2026, driven by increasing demand in agriculture, construction, and land development sectors. As infrastructure projects expand and rural property ownership rises globally, the need for efficient transportation of fencing materials has elevated the importance of specialized fence trailers. Here are the key trends shaping the fence trailer market in 2026:

1. Rising Demand in Agriculture and Ranching

Fence trailers are increasingly essential for large-scale farming and ranch operations, particularly in North America, Australia, and parts of Europe. With growing emphasis on land management, livestock containment, and perimeter security, farmers and ranchers are investing in durable, high-capacity fence trailers. The trend toward automation and efficient field operations further amplifies demand for rugged, easy-to-tow models.

2. Growth in Residential and Commercial Land Development

Urban sprawl and suburban expansion are fueling residential construction, which in turn drives the need for property fencing. Fence installation contractors are adopting specialized trailers to transport rails, posts, and panels more efficiently. In 2026, modular and adjustable fence trailers designed for compatibility with various fencing types (e.g., chain-link, vinyl, wood) are gaining popularity among contractors seeking versatility.

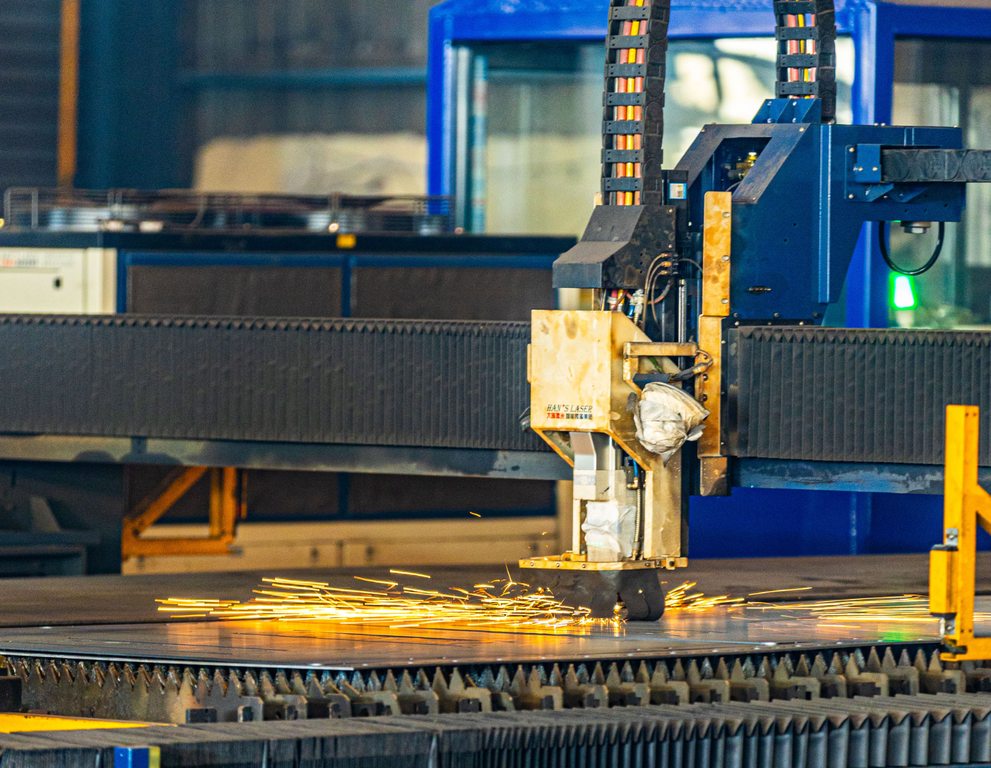

3. Technological Advancements and Material Innovation

Manufacturers are integrating lightweight yet durable materials such as high-strength steel alloys and corrosion-resistant coatings to enhance trailer longevity. In 2026, smart features like integrated load sensors, GPS tracking, and anti-theft systems are emerging in premium models, especially for commercial fleets aiming to improve logistics and asset management.

4. Emphasis on Safety and Regulatory Compliance

Safety standards for towing equipment are tightening in regions like the U.S. and EU. By 2026, manufacturers are focusing on compliance with updated DOT and CE regulations, including improved braking systems, LED lighting, and reflectivity standards. These changes are encouraging fleet upgrades and fostering a replacement cycle in the market.

5. Sustainability and Eco-Friendly Manufacturing

Environmental concerns are influencing production methods. Trailers made with recycled materials and energy-efficient manufacturing processes are becoming a selling point. Additionally, electric and hybrid utility vehicles used in conjunction with fence trailers on job sites are pushing demand for trailers compatible with alternative towing platforms.

6. E-Commerce and Direct-to-Consumer Sales Growth

Online marketplaces and manufacturer-direct sales are reshaping distribution. By 2026, more buyers—especially small contractors and DIY landowners—are purchasing fence trailers through e-commerce platforms offering customization, financing, and home delivery. This shift is pressuring traditional dealerships to enhance digital presence and customer experience.

7. Regional Market Variations

North America remains the largest market due to extensive agricultural activity and private land ownership. However, fast-growing markets in Latin America, Southeast Asia, and Eastern Europe are showing increased adoption, driven by infrastructure investment and rising rural incomes.

In conclusion, the 2026 fence trailer market is defined by innovation, regulatory adaptation, and expanding applications across industries. Companies that prioritize durability, customization, and digital integration are best positioned to capture growth in this evolving landscape.

Common Pitfalls When Sourcing a Fence Trailer (Quality, IP)

Sourcing a fence trailer—especially one designed to meet specific quality standards or intellectual property (IP) requirements—can present several challenges. Being aware of these pitfalls helps ensure you receive a reliable, compliant, and legally sound product.

Poor Build Quality and Material Selection

One of the most frequent issues is receiving a fence trailer made with substandard materials or poor craftsmanship. Low-quality steel, inadequate welding, or flimsy components can compromise durability, safety, and longevity—especially under frequent transportation and outdoor exposure. Always verify material specifications (e.g., galvanized steel, tube thickness) and inspect sample units or manufacturing facilities.

Inadequate Weather and Load Resistance

Fence trailers are often used in harsh environments. A common oversight is failing to confirm that the trailer is designed to withstand heavy loads, extreme weather, and corrosion. Look for IP (Ingress Protection) ratings if electrical or electronic components (like lighting systems) are included. For example, an IP67 rating ensures dust-tight and water-resistant performance—critical for reliability in outdoor use.

Non-Compliance with Safety and Regulatory Standards

Many suppliers, especially overseas, may not adhere to regional safety regulations (e.g., DOT in the U.S., CE in Europe). Trailer brakes, lighting, reflectors, and coupling systems must meet local legal requirements. Sourcing without verifying compliance can lead to failed inspections, fines, or unsafe operation.

Intellectual Property (IP) Infringement Risks

When sourcing a custom-designed or branded fence trailer, there’s a risk of inadvertently purchasing a product that infringes on patents, trademarks, or design rights. Some manufacturers may copy protected designs without authorization. Conduct due diligence by reviewing design patents and requiring IP indemnification clauses in supplier contracts.

Lack of Design Documentation and Traceability

Without proper technical drawings, assembly manuals, or material certifications, it becomes difficult to ensure consistency across orders or troubleshoot issues. Suppliers may also lack traceability for components, which complicates warranty claims or recalls. Always request comprehensive documentation upfront.

Hidden Costs and Unclear Terms

Initial quotes may not include costs for shipping, import duties, taxes, or customization. Poorly defined terms around lead times, payment schedules, or warranty coverage can result in delays and disputes. Clarify all terms in writing before placing an order.

Inconsistent Quality Control

Even if a sample meets expectations, mass production can vary significantly without enforced quality control (QC) processes. Avoid suppliers who don’t allow third-party inspections or have weak QC protocols. Consider hiring an independent inspector to audit production batches.

Weak After-Sales Support and Warranty

Some suppliers offer little to no after-sales service, making it difficult to obtain spare parts, repairs, or technical help. A vague or limited warranty can leave you exposed to costly downtime. Ensure warranty terms are clear and support is accessible.

By proactively addressing these pitfalls—focusing on quality verification, regulatory compliance, and IP protection—you can reduce risks and ensure a successful fence trailer sourcing process.

Logistics & Compliance Guide for Fence Trailers

Understanding Fence Trailers

Fence trailers, also known as pipe or pole trailers, are specialized flatbed trailers designed to transport long, cylindrical materials such as fencing posts, pipes, conduit, or utility poles. These trailers feature vertical stakes or rails along the sides to contain and secure elongated loads. Due to the unique nature of the cargo and trailer design, specific logistics and regulatory compliance measures are essential for safe and legal transportation.

Regulatory Compliance Overview

All operations involving fence trailers must comply with federal, state, and local transportation regulations. The primary governing authority in the U.S. is the Department of Transportation (DOT), specifically the Federal Motor Carrier Safety Administration (FMCSA). Key compliance areas include:

- Size and Weight Limits: Adhere to federal and state restrictions on overall length, width, height, and gross vehicle weight (GVW). Fence trailers often carry extended loads, so over-length permits may be required.

- Hours of Service (HOS): Drivers must follow FMCSA HOS rules to prevent fatigue-related incidents.

- Commercial Driver’s License (CDL): Operators transporting loads over 10,000 lbs. or combinations exceeding 26,001 lbs. GVWR typically require a valid CDL.

- Vehicle Maintenance: Conduct regular inspections and maintain detailed records in compliance with DOT regulations (e.g., pre-trip, post-trip, and periodic inspections).

Load Securement Requirements

Proper load securement is critical when using fence trailers. The FMCSA’s Securement Rules (49 CFR §393.112–§393.118) apply to logs, poles, and similar cylindrical objects. Key securement guidelines include:

- Front End Alignment: At least one longitudinal tiedown must secure the front end of the load to prevent forward movement.

- Tiedown Frequency: Use tiedowns every 10 feet or fraction thereof along the length of the load. Each tiedown must have a working load limit (WLL) appropriate for the cargo weight.

- Load Containment: Use side rails, stakes, or headers to prevent lateral shifting. Chains, straps, or wire ropes must be tensioned properly to eliminate slack.

- Overhang Restrictions: Loads may overhang the trailer, but must not exceed state-specific limits (typically up to 4 feet in front and 8 feet in rear). Overhanging loads require appropriate signage (e.g., “LONG LOAD” flag during daylight, illuminated标志 at night).

Permits and Special Considerations

Transporting oversized or over-length loads with a fence trailer often requires special permits:

- Over-Length Permits: Required if the total load exceeds standard length limits (usually 80–85 feet depending on state).

- Route Planning: Some states restrict travel on certain roads or bridges. Route surveys may be necessary for exceptionally long or heavy loads.

- Escort Vehicles: States may mandate pilot or escort vehicles for oversized loads, especially during nighttime or in high-traffic areas.

Safety and Operational Best Practices

To ensure safe and efficient operations:

- Pre-Trip Inspection: Check trailer lights, brakes, tires, securement hardware, and structural integrity before each use.

- Load Balancing: Distribute weight evenly to maintain trailer stability and prevent sway.

- Weather Awareness: High winds can affect long overhangs; avoid travel during severe weather.

- Driver Training: Ensure drivers are trained in handling long-load dynamics, securement procedures, and emergency protocols.

Documentation and Recordkeeping

Maintain accurate records to demonstrate compliance:

- Bill of Lading (BOL): Details cargo type, weight, origin, destination, and handling instructions.

- Permits: Keep copies of all applicable state or local permits in the vehicle.

- Inspection Reports: Retain logs of vehicle inspections and maintenance.

- Driver Logs: Use electronic logging devices (ELDs) or paper logs per HOS rules.

Conclusion

Operating a fence trailer requires adherence to strict logistics and compliance standards to ensure safety and regulatory conformity. By understanding load securement rules, obtaining necessary permits, and maintaining proper documentation, carriers can minimize risks and avoid penalties. Regular training and proactive planning are essential components of a successful fence trailer operation.

Conclusion for Sourcing a Fence Trailer:

After evaluating various suppliers, specifications, and cost considerations, sourcing a fence trailer requires a balanced approach that prioritizes durability, compliance with transportation regulations, and long-term value over initial price. Selecting a trailer built with high-quality materials—such as powder-coated steel or aluminum—and reliable components (e.g., robust axles, lighting systems, and couplers)—ensures operational efficiency and reduces maintenance costs over time. Additionally, partnering with reputable manufacturers or suppliers who offer warranties, strong customer support, and customization options tailored to your fencing operation’s specific needs will enhance productivity and safety.

In summary, a well-sourced fence trailer is a critical asset for any fencing business, contributing to streamlined transportation of materials, improved job site readiness, and overall operational professionalism. By conducting thorough due diligence and focusing on total cost of ownership, businesses can make a strategic investment that supports growth, efficiency, and reliability in the field.