The global fastener machinery market is experiencing robust growth, driven by rising demand from automotive, construction, and electronics industries. According to Grand View Research, the global fasteners market size was valued at USD 107.2 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. This sustained demand is directly fueling the need for advanced fastener manufacturing equipment, particularly high-precision cold heading, thread rolling, and assembly machines. As automation and Industry 4.0 technologies gain traction, manufacturers are increasingly investing in efficient, high-speed production systems. In line with this trajectory, Mordor Intelligence projects the fastener machine market to grow steadily, with a CAGR of approximately 5.8% over the forecast period (2023–2028), underpinned by technological innovation and regional industrial expansion—especially in Asia-Pacific, where automotive and infrastructure development continue to surge. In this competitive landscape, a select group of manufacturers have emerged as leaders, setting benchmarks in reliability, output, and smart manufacturing integration.

Top 9 Fastener Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Industrial Fasteners Institute

Domain Est. 2001

Website: indfast.org

Key Highlights: The Industrial Fasteners Institute, known as the IFI, is a trade association representing manufacturers of mechanical fasteners and formed parts produced in ……

#2 Fastener Insertion Machines

Domain Est. 1996

Website: haeger.com

Key Highlights: The global leader in fastener insertion technology. Our machines are engineered for the highest output, shortest cycle times, and unmatched process reliability….

#3 Birmingham Fastener

Domain Est. 1997

Website: bhamfast.com

Key Highlights: Partner with a one-stop fastener manufacturer and distributor for American-made, high-quality products, with custom services to take on your toughest jobs….

#4 Custom Fasteners Manufacturer

Domain Est. 1999

Website: nationalbolt.com

Key Highlights: National Bolt and Nut Corporation is a ISO Certified Nationwide custom fasteners manufacturer of nuts, washers, bolts and fasteners. Contact us today!…

#5 Midwest Fastener

Domain Est. 2000

Website: fastenerconnection.com

Key Highlights: Midwest Fastener is a fastener supplier and fastener manufacturer offering construction fasteners, drywall screws, and much, much more….

#6 PEM – PennEngineering

Domain Est. 1996

Website: pemnet.com

Key Highlights: PEM offers innovative fastening solutions for a variety of applications across industries like Automotive Electronics, Consumer Electronics, Datacom and more….

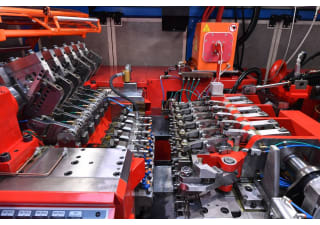

#7 Fastener Production

Domain Est. 1997

Website: hatebur.com

Key Highlights: Efficient & precise production of screws, nuts, bolts, rivets and other fasteners by hot/cold presses from Hatebur & Carlo Salvi….

#8 FASTENING PRODUCTS

Domain Est. 1997

Website: ykk.com

Key Highlights: We have produced and marketed fastening products such as zippers, hook-and-loop fasteners (Quicklon), fabric tapes and plastic products, snaps and buttons, and ……

#9 DAH

Domain Est. 2016

Website: fastenermachine.com

Key Highlights: We are professional in manufacturing the machine for fastener production and special designed machine for secondary process and automation purpose….

Expert Sourcing Insights for Fastener Machine

H2: 2026 Market Trends for Fastener Machines

The global fastener machine market is poised for significant transformation by 2026, driven by technological innovation, shifting industrial demands, and evolving manufacturing paradigms. Below are the key trends expected to shape the fastener machine industry in 2026:

1. Increased Automation and Smart Manufacturing Integration

By 2026, fastener machine manufacturers are anticipated to heavily adopt Industry 4.0 principles. Machines will increasingly feature IoT connectivity, real-time monitoring, predictive maintenance, and AI-driven process optimization. This shift enhances production efficiency, reduces downtime, and supports smart factory ecosystems, particularly in automotive and aerospace sectors.

2. Rising Demand from Electric Vehicles (EVs) and Lightweight Materials

The surge in electric vehicle production is reshaping fastener requirements. As automakers transition to aluminum, magnesium, and composite materials to reduce weight and improve energy efficiency, fastener machines are being adapted to handle non-ferrous and specialty alloys. Machines capable of precision forming and thread rolling for lightweight materials will see increased demand.

3. Focus on Energy Efficiency and Sustainability

Environmental regulations and corporate sustainability goals are pushing manufacturers to adopt energy-efficient fastener machines. By 2026, expect wider use of servo-driven technology, regenerative braking systems, and low-emission production lines. Additionally, recyclability of tools and machines will become a competitive differentiator.

4. Regional Market Shifts and Localization of Production

Geopolitical factors and supply chain resilience are prompting a shift toward localized manufacturing. In North America and Europe, reshoring initiatives will boost demand for high-precision, flexible fastener machines. Meanwhile, Southeast Asia and India will emerge as key growth markets due to expanding industrial infrastructure and lower labor costs.

5. Advancements in Multi-Function and Customization Capabilities

Fastener machines are evolving to offer greater versatility. By 2026, multi-station machines capable of cold forming, threading, heat treatment, and inspection in a single line will be standard. Customization for niche applications—such as medical devices or renewable energy installations—will drive demand for modular and reconfigurable machine designs.

6. Growth in Aftermarket Services and Digital Support

As machines become more complex, aftermarket services—including remote diagnostics, software updates, training, and spare parts logistics—will become a significant revenue stream. OEMs are expected to offer digital service platforms, enhancing customer retention and machine uptime.

7. Consolidation and Strategic Partnerships

The competitive landscape will likely see increased consolidation among fastener machine manufacturers. Strategic partnerships with automation providers, material suppliers, and software developers will enable comprehensive turnkey solutions, improving time-to-market and technical capabilities.

In conclusion, the 2026 fastener machine market will be defined by intelligent automation, sustainability, and responsiveness to emerging industrial needs. Companies that invest in innovation, adapt to regional dynamics, and embrace digital transformation will be best positioned to capture growth in this evolving sector.

Common Pitfalls When Sourcing Fastener Machines (Quality and Intellectual Property)

Sourcing fastener machines, especially from international suppliers or lesser-known manufacturers, can present significant challenges related to both product quality and intellectual property (IP) risks. Being aware of these pitfalls is essential to ensure reliable production, avoid legal complications, and protect your business interests.

Quality-Related Pitfalls

Inadequate Machine Specifications and Performance Standards

Suppliers may provide machines that meet basic operational requirements but fall short of industry benchmarks for precision, durability, or throughput. This can result in inconsistent fastener quality, increased downtime, and higher maintenance costs. Always verify technical specifications against recognized standards (e.g., ISO, DIN) and request performance data or third-party certifications.

Use of Substandard Components and Materials

Some manufacturers cut costs by using inferior raw materials or non-genuine parts (e.g., low-grade steel, counterfeit bearings, or outdated control systems). This compromises machine longevity and reliability. Conduct factory audits or request material test reports (MTRs) to ensure component quality.

Lack of Proper Testing and Commissioning

Machines shipped without proper factory acceptance testing (FAT) may have undetected defects. Ensure the supplier performs comprehensive testing and provides video documentation or allows remote/onsite inspection before shipment.

Insufficient After-Sales Support and Spare Parts Availability

Poor technical support, limited spare parts inventory, or long lead times for replacements can cripple production. Confirm the supplier’s service network, response time, and availability of critical components before finalizing the purchase.

Hidden Defects or “Demo” Units Sold as New

Some suppliers may repackage used, refurbished, or demo machines as new. Conduct site visits or third-party inspections to verify machine condition and authenticity.

Intellectual Property (IP) Risks

Infringement of Patented Technologies

Fastener machines often incorporate patented mechanical designs, automation systems, or software. Sourcing from manufacturers that replicate protected technologies can expose your company to legal action, import bans, or seizure of equipment. Always verify the originality of technology used and request IP compliance documentation.

Counterfeit or Clone Machines

Low-cost suppliers may produce clones of well-known brands, violating trademarks and design patents. Using such machines not only poses legal risks but also often results in poor performance and lack of warranty support. Conduct due diligence on the manufacturer’s reputation and ownership of design rights.

Unauthorized Software and Licensing Issues

Machines with embedded control software may use unlicensed or pirated software, leading to compliance violations and potential cybersecurity vulnerabilities. Confirm software authenticity and licensing agreements with the supplier.

Lack of IP Ownership Clarity in Custom Machines

If you commission a custom-designed machine, unclear contracts may leave IP ownership ambiguous. Without proper agreements, the supplier could retain rights to the design or resell it to competitors. Ensure contracts explicitly assign IP rights to your company when applicable.

Weak Contractual Protections

Purchase agreements that lack clear IP indemnification clauses leave buyers exposed. Always include provisions requiring the supplier to defend against IP infringement claims and compensate for related losses.

By proactively addressing these quality and IP pitfalls—through due diligence, clear contracts, third-party verification, and supplier vetting—businesses can mitigate risk and ensure a reliable, legally sound investment in fastener machine procurement.

Logistics & Compliance Guide for Fastener Machine

Overview

This guide outlines the essential logistics and compliance considerations for the import, export, transport, installation, and operation of a Fastener Machine. Adhering to these procedures ensures smooth operations, regulatory compliance, and minimizes delays or penalties.

Shipping & Transportation

Ensure the fastener machine is securely packaged to prevent damage during transit. Use wooden crates or custom pallets with corner protectors and moisture barriers. Choose freight methods (air, sea, or land) based on urgency, cost, and destination. Coordinate with certified logistics providers experienced in industrial machinery handling. Provide accurate shipping documentation, including packing lists, commercial invoices, and bill of lading.

Import/Export Regulations

Verify the Harmonized System (HS) code for the fastener machine (typically under 8462 or 8479, depending on function) to determine applicable tariffs and duties. Comply with export control regulations such as EAR (Export Administration Regulations) if shipping from the U.S. Obtain necessary export licenses if the machine contains controlled technology. For imports, confirm compliance with local customs authority requirements, including import permits and conformity assessments.

Customs Clearance

Submit complete documentation package to customs, including:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin (if claiming preferential tariffs)

– Import/Export License (if applicable)

Ensure accurate machine valuation to avoid delays or penalties. Use a licensed customs broker to facilitate clearance, especially for high-value or regulated machinery.

Product Compliance & Certifications

Confirm the fastener machine meets safety and performance standards required in the destination country. Common certifications include:

– CE Marking (for EU markets – Machinery Directive 2006/42/EC)

– UKCA Marking (for UK post-Brexit)

– UL or CSA (for North America)

– CCC Mark (for China)

Maintain technical files, Declaration of Conformity (DoC), and user manuals in the local language.

Electrical & Safety Standards

Ensure voltage, frequency, and plug type are compatible with local power supplies. Machines designed for 480V/60Hz may require transformers for 400V/50Hz regions. Verify compliance with electrical safety standards (e.g., IEC 60204-1). Include emergency stop functions, guarding, and safety interlocks per regional regulations.

Installation & Site Preparation

Provide site requirements in advance: floor load capacity, ventilation, power supply, and space dimensions. Schedule qualified technicians for installation and commissioning. Conduct risk assessments and ensure all safety protocols are followed during setup.

Environmental & Waste Compliance

Dispose of packaging materials according to local environmental regulations (e.g., wood crates may require ISPM 15 treatment). Follow proper procedures for handling industrial waste during maintenance. Ensure machine lubricants and coolants comply with REACH (EU) or TSCA (U.S.) if applicable.

Documentation & Record Keeping

Maintain records of all compliance documentation for a minimum of 5–10 years, including:

– Certificates of Conformity

– Shipping and customs documents

– Maintenance logs

– Safety training records

These records may be required during audits or inspections.

Training & Operational Compliance

Provide operator and maintenance staff with documented training on safe machine operation, lockout/tagout (LOTO), and emergency procedures. Ensure all personnel are aware of compliance responsibilities under OSHA (U.S.), HSE (UK), or equivalent local occupational health and safety regulations.

Ongoing Regulatory Monitoring

Stay informed about changes in trade policies, safety standards, or environmental regulations that may affect the machine’s use or maintenance. Subscribe to regulatory updates from authoritative bodies such as EU Commission, OSHA, or ISO.

By following this guide, businesses can ensure the efficient, legal, and safe deployment of fastener machines across international markets.

Conclusion for Sourcing a Fastener Machine:

Sourcing the right fastener machine is a critical step in ensuring production efficiency, product quality, and long-term cost savings. A thorough evaluation of machine specifications, production capacity, automation level, and after-sales support is essential to make an informed decision. By aligning machine capabilities with specific manufacturing requirements—such as fastener type, material, volume, and precision—businesses can significantly enhance operational performance. Additionally, choosing a reliable supplier with a proven track record, technical expertise, and strong service support minimizes downtime and ensures smooth integration into existing workflows. Ultimately, a strategic approach to sourcing fastener machinery not only boosts productivity but also strengthens competitiveness in the fastener manufacturing industry.