The global fishing equipment market is experiencing steady growth, driven by rising recreational angling participation and increasing consumer demand for high-performance gear—especially in marine environments. According to Grand View Research, the global fishing gear market size was valued at USD 15.3 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030. A critical, though often overlooked, component of durable saltwater fishing poles is the eyelet—responsible for guiding the fishing line while withstanding corrosive marine conditions. As offshore and deep-sea fishing gain popularity, manufacturers are prioritizing corrosion-resistant materials like titanium, aluminum oxide, and silicon carbide in eyelet design. With the North American market leading in both production and consumption of high-end fishing equipment, innovation in eyelet technology has become a differentiator among premium rod brands. This list highlights the top eight manufacturers pioneering advancements in saltwater fishing pole eyelets, combining performance data, material science, and market presence to meet the demands of modern anglers.

Top 8 Eyelets For Saltwater Fishing Poles Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Pacific Bay International

Domain Est. 2000

Website: fishpacbay.com

Key Highlights: Pacific Bay International is a manufacturer and direct importer of a large selection of quality fishing rod components….

#2

Domain Est. 2001

Website: anglersresource.net

Key Highlights: Rod Components. Guides · Tops · Reel Seats · Reel Seat Parts and Accessories · Grips · Grip Accessories. Blanks and Supplies.Missing: saltwater manufacturer…

#3 Fishing Rod Parts & Components

Domain Est. 1997

Website: aftco.com

Key Highlights: Free delivery over $100 · 45-day returnsIt is the perfect finish for custom fishing rods used in fresh or saltwater applications. Available in case packs only!…

#4 Rodhouse

Domain Est. 2010

Website: rodhouse.com

Key Highlights: 4–12 day delivery 14-day returnsRodhouse is the essential online store for building and customizing your fishing rod. We offer all the highest-end materials for practicing your hob…

#5 Tip Top Rod Guides for Rod Building

Domain Est. 1995

#6 The American Tackle Company

Domain Est. 2002

Website: americantackle.us

Key Highlights: American Tackle Rod Guides. American Tackle Company (AT) is reinventing how fishing rod guides are designed, produced, and utilized….

#7 Fuji Guides

Domain Est. 2010

Website: getbitoutdoors.com

Key Highlights: Free delivery over $95 30-day returnsCategories ; Fuji LSV Double Foot Spin Cast Guides. $1.82 ; Fuji RV Reverse Double Foot Surf & Boat Rod Guides. $11.07 ; Fuji LRX Double Foot S…

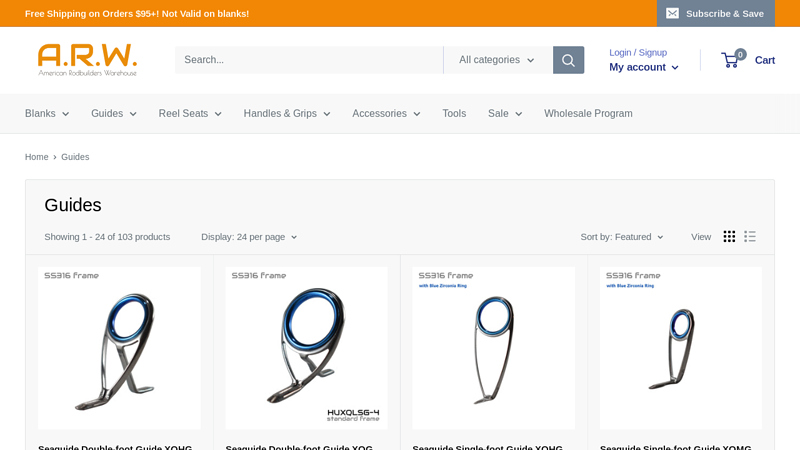

#8 Seaguide Fishing Rod Guides

Domain Est. 2019

Website: rodbuilderswarehouse.com

Key Highlights: Free delivery over $95 30-day returns…

Expert Sourcing Insights for Eyelets For Saltwater Fishing Poles

H2: 2026 Market Trends for Eyelets on Saltwater Fishing Poles

The market for eyelets used on saltwater fishing poles is poised for significant evolution by 2026, driven by advancements in materials science, increasing demand for high-performance fishing gear, and a growing recreational and commercial saltwater fishing industry. Eyelets—also known as guides—are critical components that affect casting performance, line durability, and overall rod sensitivity. As anglers seek more durable, lightweight, and corrosion-resistant equipment, manufacturers are adapting their product designs and material choices accordingly.

1. Material Innovation and Corrosion Resistance

By 2026, the dominant trend in eyelets will be the widespread adoption of advanced corrosion-resistant materials. Traditional stainless steel eyelets are being replaced or enhanced by titanium-coated, ceramic-insert, and zirconia-based guides that offer superior resistance to saltwater degradation. These materials not only prolong the lifespan of fishing rods but also maintain smooth line flow under harsh marine conditions. Manufacturers are increasingly partnering with material science firms to develop proprietary alloys and coatings specifically engineered for marine environments.

2. Lightweight and High-Strength Composite Guides

The demand for ultra-lightweight rods is pushing innovation in composite eyelet construction. Hybrid guides combining carbon fiber frames with ceramic rings are gaining traction, offering a high strength-to-weight ratio. These composites reduce overall rod weight without sacrificing durability, enhancing angler comfort during extended fishing sessions—a key selling point in the premium segment of the market.

3. Customization and Performance Optimization

By 2026, customization will be a major differentiator. High-end rod builders and OEMs are offering tailored eyelet configurations based on fishing technique (e.g., trolling, jigging, fly fishing) and target species (e.g., tuna, marlin, tarpon). Computer-aided design (CAD) and simulation tools enable precise placement and sizing of eyelets to optimize line trajectory and reduce friction, improving casting distance and accuracy.

4. Sustainability and Eco-Friendly Manufacturing

Environmental concerns are influencing production methods. Eyelet manufacturers are increasingly adopting sustainable practices, such as using recycled metals and minimizing hazardous waste in plating processes. Additionally, longer-lasting eyelets contribute to reduced gear turnover, aligning with broader industry sustainability goals.

5. Growth in Emerging Markets and E-Commerce

The expansion of recreational fishing in regions like Southeast Asia, Latin America, and coastal Africa is fueling demand for affordable yet reliable saltwater rods. This, in turn, drives the need for cost-effective, high-quality eyelets. Online retail platforms are facilitating direct access to specialized components, allowing DIY rod builders and small manufacturers to source advanced eyelets globally.

In conclusion, the 2026 market for eyelets on saltwater fishing poles will be characterized by innovation in materials, a focus on performance and durability, and a shift toward sustainable and customized solutions. As saltwater anglers become more technically sophisticated, eyelet manufacturers must continue to evolve to meet the demands of a competitive and environmentally conscious market.

Common Pitfalls When Sourcing Eyelets for Saltwater Fishing Poles (Quality and Intellectual Property)

Sourcing eyelets for saltwater fishing poles requires careful consideration of both quality and intellectual property (IP) concerns. These small yet critical components endure extreme conditions, making material durability and proper design essential. However, many importers and manufacturers fall into common traps that compromise product performance and expose them to legal risks.

Poor Material Quality and Corrosion Resistance

One of the most frequent pitfalls is selecting eyelets made from substandard materials. Saltwater environments are highly corrosive, necessitating components crafted from high-grade stainless steel (e.g., 316 stainless) or titanium. Sourcing from suppliers who use inferior alloys or inadequate plating—such as cheap nickel or low-grade stainless steel—leads to rapid pitting, rust, and failure. Always verify material certifications and conduct salt spray testing to ensure longevity.

Inconsistent Manufacturing Tolerances

Eyelets must fit precisely on fishing rod blanks and guide wraps. Inconsistent inner diameter, outer diameter, or height can lead to misalignment, poor casting performance, or even rod damage. Suppliers from regions with lax quality control may deliver mixed batches. Implement strict incoming inspection protocols and request sample testing before large-scale production.

Lack of IP Due Diligence

Many high-performance eyelet designs are patented or trademarked by established brands (e.g., Fuji, American Tackle, or Sic models). Sourcing generic copies that mimic protected designs—even if labeled as “compatible”—can lead to intellectual property infringement. Customs seizures, legal action, or forced product recalls are serious risks. Always conduct IP clearance searches and consider licensing or developing proprietary designs.

Misleading Marketing Claims

Suppliers may advertise eyelets as “corrosion-resistant” or “marine-grade” without providing test data or material specifications. These vague claims can mask poor-quality products. Require third-party lab reports, material test certificates (MTCs), and detailed technical documentation to validate performance claims.

Overlooking Supply Chain Transparency

Hidden costs and delays often arise when the supply chain lacks transparency. Some suppliers outsource production to unverified subcontractors, resulting in quality inconsistencies. Demand full visibility into the manufacturing process and conduct on-site audits when possible to ensure traceability and accountability.

Avoiding these pitfalls ensures durable, compliant, and high-performing eyelets that enhance the reliability of saltwater fishing poles—and protect your brand’s reputation.

Logistics & Compliance Guide for Eyelets For Saltwater Fishing Poles

Overview

Eyelets (also known as guides) for saltwater fishing poles are small but critical components used in fishing rod construction. They guide the fishing line along the rod blank and affect casting performance, durability, and sensitivity. Due to their use in outdoor and marine environments, eyelets must meet specific material, safety, and compliance standards. This guide outlines the logistics and regulatory considerations for manufacturing, importing, exporting, and distributing eyelets designed for saltwater fishing poles.

Material & Environmental Compliance

Corrosion Resistance Requirements

Saltwater fishing eyelets must be made from corrosion-resistant materials such as:

- Stainless steel (e.g., 304 or 316 grade)

- Titanium

- Ceramic-lined aluminum oxide

- Nickel-titanium alloys (NiTi)

These materials must comply with ASTM B693 (Standard Specification for Stainless and Alloy Steel Flanges, Forged Fittings, and Valves) or equivalent standards for marine applications.

RoHS and REACH Compliance

Eyelets sold in the European Union must comply with:

- RoHS (Restriction of Hazardous Substances Directive 2011/65/EU): Limits the use of lead, cadmium, mercury, and other hazardous substances.

- REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals): Requires disclosure of Substances of Very High Concern (SVHCs).

Manufacturers must provide a Declaration of Conformity and maintain technical documentation.

Product Labeling & Packaging

Labeling Requirements

All eyelets and packaging must include:

- Manufacturer or distributor name and address

- Product identification (model/part number)

- Material composition (e.g., “316 Stainless Steel with Ceramic Insert”)

- Country of origin

- Compliance markings (e.g., CE mark for EU)

Packaging Standards

- Use anti-corrosion packaging (e.g., VCI paper or vacuum sealing) for bulk shipments in humid environments.

- Include desiccant packs in sealed containers to prevent moisture damage during transit.

- Label packages with handling instructions: “Fragile – Corrosion Sensitive.”

Import & Export Regulations

Harmonized System (HS) Code Classification

Eyelets for fishing poles typically fall under:

- HS Code 7326.90: Other articles of iron or steel (for metal eyelets)

- HS Code 8302.50: Base metal mountings, fittings, and similar articles (for assembled guides)

- Local customs authorities may require further classification; consult a customs broker.

Import Duties & Tariffs

- Duty rates vary by country. For example:

- U.S.: Typically 2.7% under HTS 8302.50.90

- EU: 2.7% under CN code 8302 50 00

- Australia: Often zero-rated if classified as fishing accessories

- Free Trade Agreements (e.g., USMCA, CPTPP) may reduce or eliminate duties—verify eligibility.

Import Documentation

Required documents include:

- Commercial invoice

- Packing list

- Bill of lading or air waybill

- Certificate of Origin (preferably Form A or Certificate of Origin for preferential tariffs)

- RoHS/REACH compliance certificate (for EU)

- FDA or EPA registration not required unless coated with regulated substances

Shipping & Transportation

Mode of Transport Considerations

- Air Freight: Fastest for urgent orders; subject to IATA Dangerous Goods Regulations if packaged with corrosive inhibitors.

- Sea Freight: Cost-effective for bulk; use moisture-resistant containers and silica gel packs.

- Land Transport (Truck/Rail): Ensure climate-controlled options if crossing extreme environments.

Incoterms Selection

Recommended Incoterms for international shipments:

- FOB (Free on Board): Clear responsibility transfer at port of origin.

- DDP (Delivered Duty Paid): Use when seller manages full logistics and customs clearance.

Quality Assurance & Testing

Corrosion Testing

Conduct salt spray testing per ASTM B117:

- Minimum 48–72 hours exposure at 5% NaCl, 35°C

- No visible pitting or rust on critical surfaces

Dimensional & Functional Testing

- Verify inner diameter, outer diameter, and height within ±0.1 mm tolerance

- Test line glide smoothness using standard monofilament under tension

Third-Party Certification

Consider certification from:

- SAE International (for material specs)

- ISO 9001:2015 (quality management systems)

- UL or TÜV for compliance validation in target markets

Environmental & Disposal Regulations

Waste Electrical and Electronic Equipment (WEEE)

While eyelets are not electronic, if sold as part of a kit with electronic components (e.g., sensor-equipped rods), WEEE compliance may apply in the EU.

End-of-Life Disposal

- Metal components are recyclable; provide recycling guidance on packaging.

- Avoid coatings containing chromium VI, which is restricted under ELV (End-of-Life Vehicles) and RoHS.

Conclusion

Successfully distributing eyelets for saltwater fishing poles requires adherence to material standards, environmental regulations, and global trade compliance. By focusing on corrosion resistance, proper documentation, and certified manufacturing processes, businesses can ensure product reliability and legal compliance across international markets.

In conclusion, sourcing high-quality eyelets for saltwater fishing poles is a critical step in ensuring the durability, performance, and longevity of the fishing rod. Given the harsh conditions of saltwater environments—such as constant exposure to corrosive salt, UV radiation, and high stress during casting and fighting fish—it is essential to select eyelets made from corrosion-resistant materials like stainless steel, titanium, or ceramic-coated aluminum. Features such as frame strength, ring smoothness, and proper alignment significantly impact line management and casting efficiency, reducing the risk of line wear and breakage.

When sourcing, prioritize reputable manufacturers and suppliers known for marine-grade components, and consider the specific fishing application (e.g., light inshore vs. heavy offshore) to match the appropriate eyelet size and strength. Additionally, proper installation techniques are just as important as the quality of the components themselves to maintain structural integrity.

Ultimately, investing in premium eyelets from reliable sources enhances rod performance, minimizes maintenance, and provides anglers with greater confidence and reliability in demanding saltwater conditions. A well-outfitted rod leads to a more successful and enjoyable fishing experience.