The global explosion-proof motor market is experiencing robust growth, driven by increasing safety regulations and rising demand from hazardous industries such as oil & gas, chemical processing, and mining. According to Mordor Intelligence, the market was valued at USD 2.7 billion in 2023 and is projected to grow at a CAGR of over 5.8% from 2024 to 2029. This expansion is fueled by stricter industrial safety standards and the growing adoption of ATEX and IECEx-certified equipment worldwide. As operational safety becomes a non-negotiable priority, manufacturers are investing heavily in advanced materials, thermal management, and compliance certifications to meet evolving global requirements. In this competitive landscape, a select group of manufacturers have emerged as leaders, combining innovation, certification breadth, and global reach to dominate the space. Based on market presence, product reliability, and compliance credentials, here are the top 10 explosion-proof motor manufacturers shaping the industry.

Top 10 Explosion Proof Motor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Explosion Proof Motors

Domain Est. 1999

Website: worldwideelectric.com

Key Highlights: Worldwide Electric is a trusted manufacturer of Explosion Proof Motors, supplying high-quality, safety-certified solutions for distributors and OEMs….

#2 Explosion Proof

Domain Est. 1990

Website: abb.com

Key Highlights: ABB’s Explosion Proof motors are designed to provide exceptional performance and long life in harsh industrial processing applications….

#3 Explosion Proof Motors

Domain Est. 1995

Website: kollmorgen.com

Key Highlights: Explosion proof motors from Kollmorgen are best in class corrosion resistant motors fit for industrial environments. See our range of ATEX certified motors….

#4 Explosion Protected Drive Solutions by NORD

Domain Est. 1995 | Founded: 2003

Website: nord.com

Key Highlights: NORD DRIVESYSTEMS has supplied drive units for use in potentially explosive environments. Since 2003, this range has also included specially designed gear ……

#5 Hazardous Location Motors

Domain Est. 1997

Website: acim.nidec.com

Key Highlights: These motors are built to contain explosions inside the motor casing and prevent ignition outside the motor by containing sparks, flashing and explosions….

#6 NEMA Explosion proof AC motors

Domain Est. 1997

Website: marathonelectric.com

Key Highlights: Our line of explosion proof motors excels in reliability, safety, and versatility, making it the ideal choice for industries operating in hazardous environments ……

#7 Explosion

Domain Est. 1998

Website: vem-group.com

Key Highlights: The primary purpose of an explosion-proof motor is to minimize the risk of an explosion by preventing hot surfaces or electrical sparks from coming into contact ……

#8 AC Motors NEMA

Domain Est. 2021

Website: regalrexnord.com

Key Highlights: Free delivery over $3,500Regal Rexnord offers reliable explosion-proof AC motors. NEMA-compliant electric motors provide safety and performance….

#9 Explosion Proof Motors for Hazardous Environments

Domain Est. 2022

Website: esrcommerce.com

Key Highlights: Find high performing and reliable Explosion Proof AC electric motors that are UL listed and CSA certified for potentially hazardous locations….

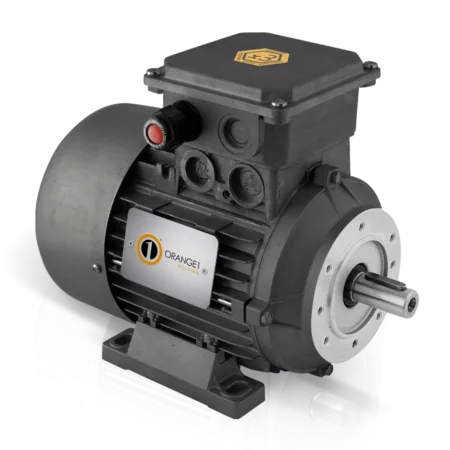

#10 Orange1 Atex certified Explosion Proof motors

Website: orange1.eu

Key Highlights: The Orange1 flameproof and explosion proof motors are asynchronous modular aluminum motors, with a squirrel cage rotor and a wound stator. They are protected ……

Expert Sourcing Insights for Explosion Proof Motor

H2: 2026 Market Trends for Explosion-Proof Motors

The global explosion-proof motor market is poised for significant evolution by 2026, driven by stringent safety regulations, expanding industrial automation, and growing investments in hazardous environments. These motors, designed to prevent ignition of flammable gases, vapors, or dust in volatile atmospheres, are critical components in industries such as oil & gas, chemical processing, mining, and pharmaceuticals. Below are key trends expected to shape the explosion-proof motor market in 2026:

-

Regulatory Compliance and Safety Standards Driving Demand

Increasing enforcement of safety standards—such as ATEX in Europe, NEC/UL in North America, and IECEx internationally—is compelling industrial operators to upgrade legacy systems. By 2026, compliance with updated codes will be a primary growth driver, especially in emerging markets where industrial safety infrastructure is being modernized. -

Growth in Oil & Gas and Petrochemical Sectors

Despite the global push toward renewable energy, demand for explosion-proof motors will remain robust in the oil & gas sector, particularly in offshore drilling, LNG facilities, and refinery expansions. The Middle East, Asia-Pacific, and parts of Africa are expected to lead in capital expenditure, supporting motor demand. -

Adoption of Energy-Efficient and IE4+ Premium Motors

The shift toward energy efficiency standards (e.g., IE4 and upcoming IE5 classifications) will accelerate the replacement of older, less efficient motors. By 2026, manufacturers will increasingly focus on high-efficiency explosion-proof motors that reduce operational costs and align with ESG (Environmental, Social, and Governance) goals. -

Digitalization and Smart Motor Integration

The integration of IoT-enabled sensors and predictive maintenance technologies into explosion-proof motors is gaining momentum. Smart motors with remote monitoring, diagnostics, and condition-based maintenance capabilities will enhance safety and reduce downtime, particularly in hard-to-access hazardous zones. -

Expansion in Asia-Pacific and Latin America

Rapid industrialization in countries like India, China, Vietnam, and Brazil will fuel demand for explosion-proof motors. Government initiatives to develop chemical parks, LNG terminals, and mining operations will create new opportunities for motor manufacturers. -

Technological Advancements in Materials and Design

Innovations in motor enclosures—such as advanced composite materials and improved thermal management—will enhance durability and performance in extreme environments. Compact, lightweight designs will also gain favor to support modular plant layouts and retrofit applications. -

Supply Chain Localization and Resilience

Geopolitical uncertainties and post-pandemic supply chain disruptions have prompted manufacturers to localize production. By 2026, regional manufacturing hubs for explosion-proof motors are expected to rise, reducing lead times and improving after-sales service. -

Increased Competition and Strategic Mergers

The market will see intensified competition between established players (e.g., ABB, Siemens, WEG, Regal Rexnord) and regional manufacturers. Strategic partnerships, acquisitions, and R&D investments will be key to capturing market share, particularly in niche applications like hydrogen handling and battery manufacturing.

In conclusion, the 2026 explosion-proof motor market will be shaped by a confluence of regulatory rigor, technological innovation, and regional industrial growth. Companies that prioritize energy efficiency, digital integration, and compliance will be best positioned to capitalize on emerging opportunities in this specialized yet vital sector.

Common Pitfalls When Sourcing Explosion Proof Motors (Quality and IP)

Sourcing explosion proof motors requires careful attention to safety standards, environmental conditions, and regulatory compliance. Mistakes in selection or procurement can lead to equipment failure, safety hazards, or non-compliance with industry regulations. Below are common pitfalls related to quality and Ingress Protection (IP) ratings when sourcing explosion-proof motors.

1. Overlooking Certification and Compliance

One of the most critical pitfalls is assuming that a motor labeled “explosion proof” meets the necessary regional or international standards. Different markets require certifications such as ATEX (Europe), IECEx (International), or NEC/UL (North America).

- Pitfall: Selecting a motor without valid, up-to-date certification for the target region.

- Impact: Risk of non-compliance, legal liability, and operational shutdowns.

- Best Practice: Verify certification marks and ensure documentation is provided by the supplier.

2. Misunderstanding IP Ratings for Hazardous Environments

Ingress Protection (IP) ratings indicate a motor’s resistance to dust and water, but they do not define explosion protection.

- Pitfall: Confusing high IP ratings (e.g., IP65, IP66) with explosion-proof capability.

- Impact: A motor may be dust-tight and water-resistant but still not safe for use in explosive atmospheres.

- Best Practice: Confirm that the motor is designed and certified for hazardous locations (e.g., Class I, Zone 1), in addition to having an appropriate IP rating for environmental protection.

3. Assuming All “Explosion Proof” Motors Are Equal

Manufacturers may use the term “explosion proof” loosely, but design, materials, and build quality vary significantly.

- Pitfall: Choosing a lower-cost motor without assessing construction quality (e.g., housing thickness, sealing methods, rotor dynamics).

- Impact: Premature failure, overheating, or inability to contain an internal explosion.

- Best Practice: Evaluate motor design against recognized standards (e.g., API 541, NEMA, IEC 60079) and inspect for robust construction.

4. Ignoring Temperature Classification (T-Class)

Explosion proof motors must operate below the auto-ignition temperature of the surrounding gases.

- Pitfall: Selecting a motor with an unsuitable T-class for the specific hazardous environment.

- Impact: Risk of igniting flammable gases or vapors, even if the motor housing is explosion-proof.

- Best Practice: Match the motor’s temperature class (e.g., T4, T6) to the hazardous area’s gas group and ambient conditions.

5. Inadequate IP Rating for Operating Environment

While explosion proofing addresses internal ignition risks, IP ratings protect against external contaminants.

- Pitfall: Using a motor with insufficient IP rating in dusty, wet, or outdoor locations (e.g., IP54 instead of IP65/66).

- Impact: Moisture or dust ingress can degrade insulation, cause short circuits, or reduce motor lifespan.

- Best Practice: Select an IP rating appropriate for the installation environment—e.g., IP66 for high-pressure washdown areas or outdoor use.

6. Poor Sealing and Gland Selection

Even with a high IP rating, improper cable entry or conduit connections can compromise protection.

- Pitfall: Using non-certified or mismatched cable glands or conduit connectors.

- Impact: Creates entry points for dust, moisture, or explosive gases—undermining both IP and explosion-proof integrity.

- Best Practice: Use certified, properly rated cable glands designed for hazardous areas and ensure correct installation.

7. Lack of Traceability and Quality Documentation

Low-quality suppliers may provide counterfeit or substandard products lacking proper documentation.

- Pitfall: Accepting motors without material test reports (MTRs), certification copies, or traceable serial numbers.

- Impact: Inability to verify authenticity or perform audits; potential safety and compliance risks.

- Best Practice: Require full documentation, including test reports, certification, and country of origin.

8. Neglecting After-Sales Support and Spare Parts Availability

Explosion proof motors often require specialized maintenance and certified repairs.

- Pitfall: Sourcing from suppliers with limited service networks or no authorized repair facilities.

- Impact: Extended downtime, higher lifecycle costs, and potential voiding of certifications after third-party repairs.

- Best Practice: Choose reputable suppliers with local support, training, and access to genuine spare parts.

Conclusion

Sourcing explosion proof motors demands more than just matching basic specs. Ensuring quality and appropriate IP ratings—while verifying certifications, environmental suitability, and long-term support—is essential for safety, reliability, and compliance. Avoiding these common pitfalls helps protect personnel, equipment, and operations in hazardous environments.

Logistics & Compliance Guide for Explosion Proof Motors

Overview of Explosion Proof Motors

Explosion proof motors are specialized electric motors designed to operate safely in hazardous environments where flammable gases, vapors, dust, or combustible materials may be present. These motors are engineered to contain any internal explosion and prevent the ignition of surrounding hazardous atmospheres. Due to their critical safety function, their logistics and compliance requirements are strictly regulated.

Regulatory Standards and Certifications

Explosion proof motors must comply with international and regional standards to ensure safety and interoperability. Key certifications include:

- ATEX (EU Directive 2014/34/EU): Mandatory for equipment placed in hazardous areas within the European Union. Requires CE marking and an EU Declaration of Conformity.

- IECEx (International Electrotechnical Commission System): Global certification for equipment used in explosive atmospheres. Facilitates international trade.

- UL/CSA (North America): Governed by standards such as UL 1446 and CSA C22.2 No. 100. UL 1203 covers explosion-proof and dust-ignition-proof electrical enclosures.

- NEC (National Electrical Code) – Article 500 to 506: Defines hazardous locations in the U.S. and installation requirements.

- Other Regional Requirements: Include INMETRO (Brazil), PESO (India), and GOST-R (Russia), which may require additional local certifications.

Ensure motors are marked with appropriate certification labels (e.g., ATEX, IECEx, UL) and documentation is available for customs and safety inspections.

Hazardous Location Classification

Understanding the classification of hazardous areas is essential for compliance:

- Class I: Locations with flammable gases or vapors (e.g., petroleum refineries).

- Class II: Locations with combustible dust (e.g., grain elevators, coal handling).

- Class III: Locations with ignitable fibers or flyings (e.g., textile mills).

- Divisions and Zones:

- Division 1 (Zone 0/1): Hazardous conditions exist under normal operation.

- Division 2 (Zone 2): Hazardous conditions are unlikely and only under abnormal conditions.

Select motors rated for the specific class, division/zone, and gas group (e.g., IIA, IIB, IIC) and temperature class (e.g., T4, T6).

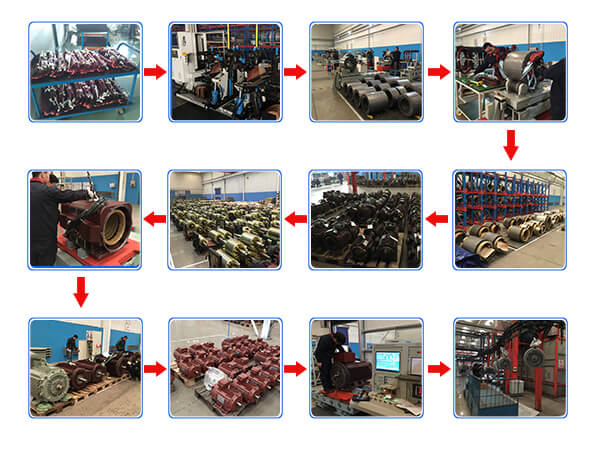

Packaging and Handling Requirements

Due to their sensitive construction and safety-critical nature, explosion proof motors require careful packaging and handling:

- Protective Packaging: Use wooden crates or heavy-duty pallets with corner protectors. Seal motors in moisture-resistant wrap to prevent corrosion.

- Impact Protection: Include shock-absorbing materials (e.g., foam inserts) to protect flanges, shafts, and terminal boxes.

- Orientation Labels: Clearly mark “THIS SIDE UP” and “FRAGILE” to prevent improper handling.

- Documentation: Include test certificates, installation manuals, and compliance declarations inside the packaging or in a sealed envelope attached externally.

Transportation and Shipping Considerations

Shipping explosion proof motors involves special precautions:

- Hazardous Materials Classification: While the motors themselves are not typically classified as dangerous goods, verify with the manufacturer and local regulations (e.g., IATA, IMDG, ADR).

- Carrier Coordination: Use carriers experienced in handling industrial equipment. Notify them of the motor’s weight, dimensions, and handling requirements.

- Environmental Protection: Ensure motors are not exposed to extreme temperatures, moisture, or direct sunlight during transit. Avoid high-vibration transport unless adequately secured.

- Customs Clearance: Provide complete documentation, including commercial invoice, certificate of origin, test reports, and compliance certificates (ATEX, IECEx, etc.) to avoid delays.

Installation and Site Compliance

Proper installation is critical to maintain the motor’s explosion proof integrity:

- Qualified Personnel: Installation must be performed by trained electricians familiar with hazardous area requirements.

- Sealing and Bonding: Conduit entries must be properly sealed to prevent gas migration. Bonding and grounding must comply with NEC or local electrical codes.

- Ventilation and Clearances: Ensure adequate airflow and clearance around the motor per manufacturer specifications.

- Inspection and Testing: Conduct pre-commissioning checks, including continuity, insulation resistance, and torque verification on flame paths.

Maintenance and Documentation

Ongoing compliance requires strict maintenance protocols:

- Regular Inspections: Follow manufacturer-recommended intervals for checking flame paths, gaskets, and housing integrity.

- Record Keeping: Maintain logs of inspections, repairs, and certifications. Retain all compliance documentation for audit purposes.

- Repairs and Modifications: Only authorized service centers should perform repairs. Unauthorized modifications invalidate certifications.

- Decommissioning: When retiring a motor, document removal and ensure proper disposal in accordance with environmental regulations.

Conclusion

Explosion proof motors are vital for safety in hazardous environments, and their logistics and compliance must be managed rigorously. Adherence to international standards, proper handling, accurate documentation, and certified installation are essential to ensure operational safety and regulatory compliance across global supply chains. Always consult the motor manufacturer and local regulatory authorities for specific project requirements.

Conclusion for Sourcing Explosion-Proof Motors

In conclusion, sourcing explosion-proof motors requires a comprehensive approach that balances safety, compliance, performance, and cost-efficiency. These specialized motors are critical in hazardous environments where flammable gases, vapors, or combustible dust are present, making reliability and adherence to international standards—such as ATEX, IECEx, or NEC (National Electrical Code)—non-negotiable.

Key considerations in the sourcing process include verifying certifications, ensuring compatibility with the specific hazardous area classification (e.g., Class I, Division 1 or Zone 0), evaluating the motor’s construction materials, temperature rating, efficiency, and duty cycle. Additionally, supplier reliability, technical support, lead times, and serviceability play a vital role in long-term operational success.

By conducting thorough due diligence, engaging with reputable manufacturers or certified distributors, and aligning procurement decisions with both technical requirements and safety regulations, organizations can ensure the acquisition of high-quality explosion-proof motors that enhance operational safety, minimize downtime, and support regulatory compliance across industrial applications such as oil & gas, chemical processing, mining, and wastewater treatment.

Ultimately, investing in the right explosion-proof motor is not merely a procurement decision—it is a commitment to workplace safety, regulatory adherence, and operational excellence.