The global expansion joint electrical conduit market is experiencing steady growth, driven by increasing demand for reliable electrical infrastructure across industrial, commercial, and infrastructure sectors. According to Grand View Research, the global electrical conduit market was valued at USD 17.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.4% from 2023 to 2030. This growth is fueled by rising construction activities, stringent safety regulations, and the need for durable cable protection systems in environments subject to thermal expansion, vibration, and mechanical stress. Expansion joint electrical conduits—specifically engineered to accommodate movement while maintaining electrical continuity and system integrity—are becoming critical components in modern building and industrial projects. As infrastructure development accelerates worldwide and industries prioritize long-term reliability, the demand for high-performance expansion joint conduits is growing in tandem. In this evolving landscape, a select group of manufacturers have emerged as leaders, combining innovation, compliance with international standards, and robust product performance. Based on market presence, product breadth, and engineering expertise, the following are seven of the top expansion joint electrical conduit manufacturers shaping the industry today.

Top 7 Expansion Joint Electrical Conduit Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 China Pvc Conduit Expansion Joint Manufacturer and Supplier …

Domain Est. 2022

Website: beisitelectric.com

Key Highlights: PVC Conduit Expansion Joint: China’s trusted manufacturer, supplier, and factory offering high-quality products. Buy from the leading company in the ……

#2 Metraflex, For Pipes in Motion

Domain Est. 1997 | Founded: 1958

Website: metraflex.com

Key Highlights: Metraflex is a Manufacturer of Expansion Joints, Strainers, Pump Connectors, Valves and other commercial piping specialties since 1958….

#3 Proco Products, Inc.

Domain Est. 1998

Website: procoproducts.com

Key Highlights: Proco Products is the leading expansion joint supplier supplying products globally for a variety of systems….

#4 Scepter Rigid PVC Conduit

Domain Est. 2009

Website: ipexna.com

Key Highlights: Scepter FT-4 rated rigid PVC electrical conduit for indoor and outdoor use. Whether exposed, concealed in walls, encased in concrete, or directly buried….

#5 XJG Conduit Expansion Couplings for EMT and Rigid/IMC

Domain Est. 1996

Website: eaton.com

Key Highlights: XJG conduit expansion couplings for EMT and rigid/IMC are used with EMT, rigid metal conduit and IMC to couple together two sections of conduit subject to ……

#6 PVC Conduit Clamps, Straps, Expansion Couplings

Domain Est. 1998 | Founded: 1923

Website: granitecityelectric.com

Key Highlights: PVC Conduit Clamps, Straps, Expansion Couplings from Granite City Electric, the Northeast’s premiere electrical supply company since 1923….

#7 PVC Coated Steel XJG Expansion Joints

Domain Est. 2010

Website: atkore.com

Key Highlights: PVC Coated Steel XJG Expansion Joints Cut Sheet (2) Used in highly corrosive environments to protect electrical circuits from damage from corrosion….

Expert Sourcing Insights for Expansion Joint Electrical Conduit

H2: Market Trends for Expansion Joint Electrical Conduit in 2026

The global market for expansion joint electrical conduit is poised for significant transformation by 2026, driven by evolving construction standards, infrastructure modernization, and increased demand for resilient electrical systems. Key trends shaping the sector include:

-

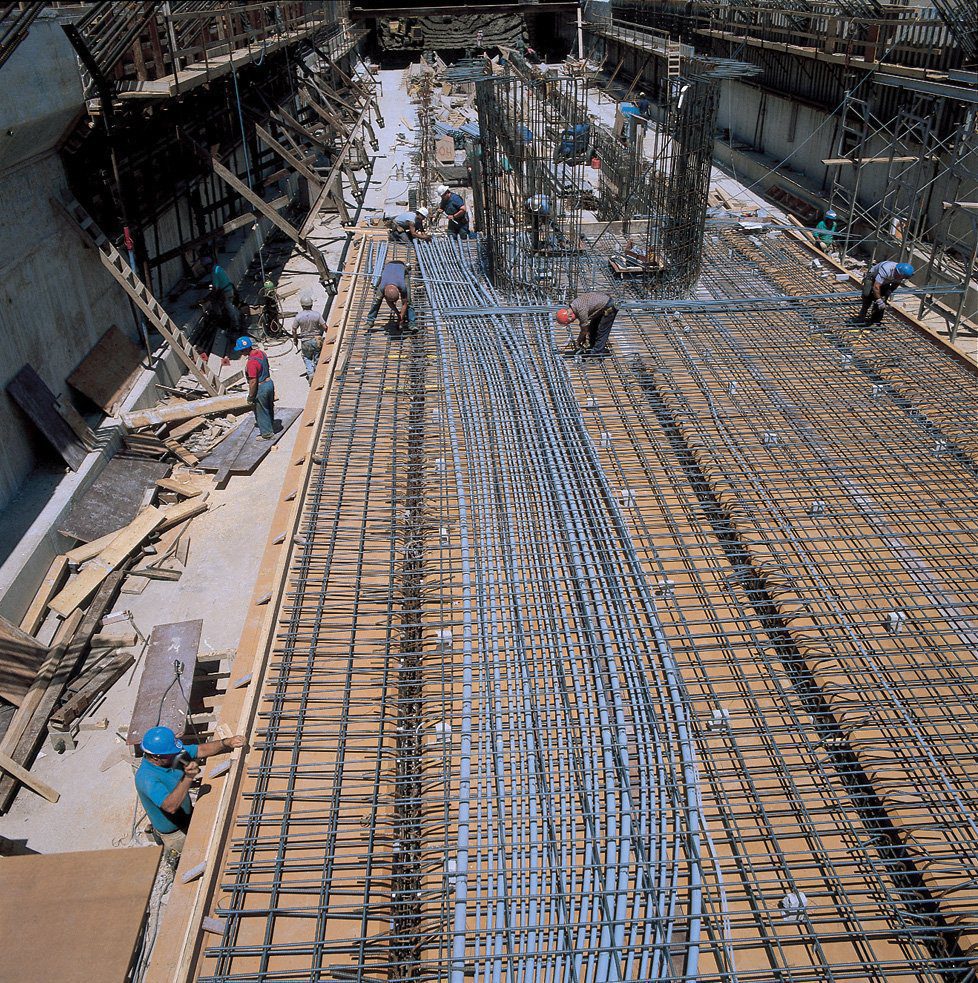

Growth in Infrastructure Investment

Governments and private entities worldwide are allocating substantial funds to upgrade aging infrastructure, especially in North America, Europe, and emerging economies in Asia-Pacific. Expansion joint electrical conduits—critical in accommodating structural movement in bridges, tunnels, and high-rise buildings—are seeing increased adoption in seismic-prone and high-temperature variation zones. This infrastructure push is a primary growth driver. -

Rise in Seismic Safety Regulations

Stricter building codes, particularly in earthquake-prone regions such as Japan, California, and Turkey, are mandating the use of flexible and movement-tolerant electrical systems. Expansion joint conduits meet these requirements by allowing controlled displacement without compromising electrical continuity, fueling demand across commercial, industrial, and public infrastructure projects. -

Adoption in Renewable Energy and Smart Buildings

Expansion joint conduits are increasingly being integrated into solar farms, wind turbine installations, and smart building systems where thermal expansion and vibration management are crucial. The growth of green energy infrastructure and automated facilities supports the need for durable, flexible conduit solutions. -

Material Innovation and Lightweight Design

Manufacturers are focusing on advanced materials such as corrosion-resistant stainless steel, flexible polymers, and hybrid composites to improve performance and longevity. Lightweight conduit systems are gaining traction for ease of installation and reduced structural load—especially in retrofit applications. -

Regional Market Dynamics

Asia-Pacific is expected to lead market growth due to rapid urbanization, industrial expansion, and government-led smart city initiatives. Meanwhile, North America and Europe will maintain steady demand, driven by infrastructure renewal programs and compliance with updated electrical safety standards. -

Sustainability and Compliance Focus

With increasing emphasis on sustainable construction, expansion joint conduits that support recyclability, reduced material waste, and longer service life are becoming preferred. Regulatory alignment with standards such as IEC, NEC, and ISO is critical for market access and competitiveness.

In summary, the 2026 outlook for expansion joint electrical conduit is characterized by robust demand fueled by infrastructure development, regulatory compliance, and technological innovation. Companies that invest in R&D, sustainability, and global certification will be best positioned to capitalize on emerging opportunities.

Common Pitfalls in Sourcing Expansion Joint Electrical Conduit (Quality, IP)

Sourcing expansion joint electrical conduit requires careful attention to both quality and Ingress Protection (IP) ratings to ensure safety, longevity, and compliance. Overlooking key factors can lead to system failures, safety hazards, and costly replacements. Below are common pitfalls to avoid:

Inadequate IP Rating for the Environment

One of the most frequent mistakes is selecting a conduit with an IP rating that doesn’t match the installation environment. For example, using an IP54-rated expansion joint in a washdown or outdoor setting exposed to heavy rain may allow water and dust ingress, leading to electrical faults. Always verify the required IP rating (e.g., IP66, IP68) based on exposure to moisture, dust, chemicals, and submersion conditions.

Poor Material Quality and Corrosion Resistance

Low-quality materials—such as substandard stainless steel, inferior elastomers, or non-compliant polymers—can degrade rapidly in harsh environments. This leads to premature failure, leaks, or compromised structural integrity. Ensure materials meet industry standards (e.g., 304 or 316 stainless steel for corrosion resistance) and are certified for the intended application.

Lack of Third-Party Certification and Testing

Sourcing conduits without certified test reports or third-party validation (e.g., UL, CE, ATEX) increases the risk of non-compliance and safety issues. Always request documentation proving the product has undergone IP testing, pressure cycling, and environmental exposure tests relevant to your application.

Incorrect Sizing and Movement Accommodation

Choosing an expansion joint that does not properly accommodate thermal movement, vibration, or misalignment can result in stress on the conduit system. This may cause cracking, disconnection, or failure under operational conditions. Confirm the joint’s axial, lateral, and angular movement capabilities align with the system’s mechanical demands.

Misalignment Between IP Rating and Sealing Mechanism

Even if a conduit claims a high IP rating, poor gland design or improper sealing components (e.g., loose clamping, low-quality O-rings) can compromise protection. Inspect the sealing mechanism and ensure it maintains integrity under dynamic movement and temperature fluctuations.

Neglecting Installation and Maintenance Requirements

Some expansion joints require precise installation torque, alignment, or periodic maintenance to maintain IP integrity. Sourcing products without clear installation guidelines or serviceability can lead to improper setup and early degradation. Choose suppliers who provide comprehensive technical support and installation documentation.

Cost-Driven Decisions Over Performance

Opting for the lowest-cost option often sacrifices durability, safety, and compliance. While budget is important, prioritize long-term performance, warranty, and lifecycle cost over initial price—especially in critical infrastructure or hazardous environments.

Logistics & Compliance Guide for Expansion Joint Electrical Conduit

Overview and Purpose

This guide outlines the logistics and compliance considerations for the procurement, transportation, installation, and maintenance of expansion joint electrical conduit systems. These specialized conduits are designed to accommodate structural movement in buildings and infrastructure while maintaining the integrity and safety of electrical wiring. Ensuring proper handling, regulatory compliance, and logistical coordination is essential for performance, safety, and code adherence.

Regulatory and Safety Compliance

Expansion joint electrical conduits must comply with national and international electrical and building codes. Key standards include:

– National Electrical Code (NEC) – NFPA 70: Articles 342 (RMC), 344 (IMC), and 358 (EMT) govern conduit types and applications. Expansion joints must maintain grounding continuity and mechanical protection.

– International Building Code (IBC): Requires provisions for building movement; expansion joints must be designed to handle expected structural displacements.

– UL 2196: Standard for fire resistance of electrical circuit protective systems, critical when conduits pass through fire-rated assemblies.

– OSHA Regulations: Installation must follow workplace safety standards for electrical work and fall protection when installed at height.

– Local Jurisdictional Codes: Always verify requirements with local authorities having jurisdiction (AHJs), as amendments may apply.

Material and Product Specifications

Ensure all expansion joint conduit systems meet the following specifications:

– Conduit material (steel, aluminum, or non-metallic) compatible with environmental conditions (e.g., corrosion resistance for outdoor or high-humidity areas).

– Listed and labeled by a Nationally Recognized Testing Laboratory (NRTL) such as UL, ETL, or CSA.

– Expansion fittings must allow for specified movement (typically ±1 inch or more laterally and axially) without compromising electrical continuity or physical protection.

– Integral bonding jumpers or listed bonding conductors to maintain grounding across the expansion joint.

Logistics and Supply Chain Management

Efficient logistics planning is crucial for timely project execution:

– Procurement Planning: Order expansion joint kits well in advance due to potential lead times for custom configurations. Specify movement capacity, conduit size, and environmental ratings.

– Packaging and Handling: Conduits and fittings should be shipped in protective packaging to prevent deformation. Label fragile components clearly.

– Storage: Store materials in a dry, secure area off the ground. Avoid exposure to moisture, extreme temperatures, or mechanical damage.

– Just-in-Time Delivery: Coordinate deliveries with construction schedules to minimize on-site storage and risk of theft or damage.

Transportation and Receiving

- Use flatbed or enclosed trailers with appropriate tie-downs to prevent shifting during transit.

- Inspect shipments upon delivery for damage, missing parts, or incorrect items. Document discrepancies immediately with photos and notify the supplier.

- Verify product certifications (e.g., UL listing) are included with shipments for compliance audits.

Installation Best Practices

- Follow manufacturer instructions for assembly and installation.

- Install expansion joints at predetermined structural movement locations (e.g., building expansion joints, seismic gaps).

- Ensure proper alignment and support on both sides of the joint to prevent stress on the conduit system.

- Test electrical continuity across the joint post-installation using a low-resistance ohmmeter.

- Coordinate with other trades (structural, mechanical, architectural) to ensure clearances and access.

Inspection and Certification

- Conduct pre-energization inspections by a qualified electrical inspector or engineer.

- Include expansion joint installations in final electrical system testing and commissioning.

- Maintain documentation including product cut sheets, UL listings, inspection reports, and as-built drawings for compliance records.

Maintenance and Long-Term Compliance

- Include expansion joint conduits in routine building maintenance programs.

- Inspect annually for signs of damage, misalignment, corrosion, or compromised grounding.

- Update compliance records if modifications are made to the electrical system or building structure.

- Re-certify system integrity after any major building retrofit or seismic event.

Conclusion

Proper logistics and compliance management for expansion joint electrical conduit systems ensures long-term safety, regulatory adherence, and structural resilience. By integrating code requirements, supply chain coordination, and quality installation practices, project stakeholders can mitigate risks and support reliable electrical infrastructure in dynamic building environments.

Conclusion for Sourcing Expansion Joints for Electrical Conduit

Sourcing expansion joints for electrical conduit systems is a critical step in ensuring the long-term reliability, safety, and performance of electrical installations, particularly in environments subject to thermal fluctuations, vibration, or structural movement. After evaluating various suppliers, materials, standards, and installation requirements, it is clear that selecting the right expansion joint involves balancing durability, compliance, and cost-effectiveness.

Key considerations include material compatibility (such as stainless steel or flexible metallic conduit), adherence to electrical and building codes (e.g., NEC, IEC), environmental resistance (corrosion, moisture, and temperature extremes), and ease of installation. Partnering with reputable suppliers who provide certified, high-quality products ensures compliance and reduces maintenance risks.

In conclusion, a strategic sourcing approach—focusing on product quality, regulatory standards, technical support, and lifecycle value—will enhance system integrity and minimize downtime or hazards. Investing in properly specified expansion joints tailored to the application environment ultimately supports safer, more resilient electrical infrastructure.