The global EVA foam flooring market is experiencing robust growth, driven by rising demand for resilient, lightweight, and eco-friendly flooring solutions across residential, commercial, and recreational spaces. According to a report by Mordor Intelligence, the EVA foam market is projected to grow at a CAGR of over 5.8% from 2024 to 2029, fueled by increasing construction activities and the expanding fitness and wellness industry. Similarly, Grand View Research estimates that the global foam flooring market—which includes EVA-based products—is expected to exceed USD 80 billion by 2030, with a CAGR of 6.2%, underpinned by advancements in material technology and growing consumer preference for cushioned, noise-reducing flooring. As demand surges, a select group of manufacturers has emerged as leaders in innovation, scalability, and product quality. Here are the top 8 EVA flooring manufacturers shaping the industry through cutting-edge production, global distribution, and sustainable practices.

Top 8 Eva Flooring Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

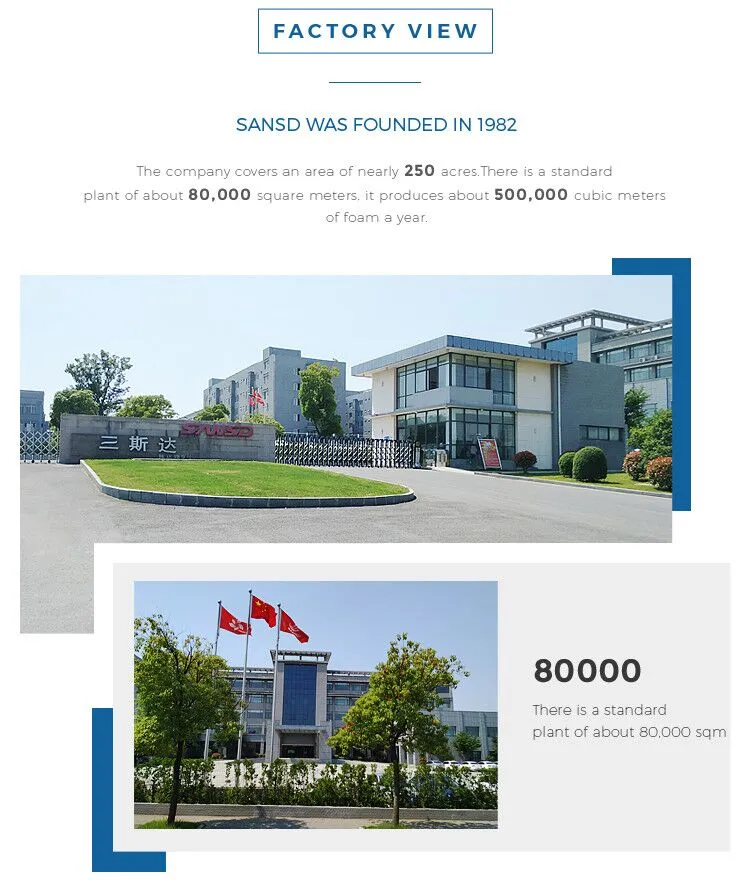

#1 EVA GLORY

Domain Est. 2012

Website: evaglory.com

Key Highlights: EVA Glory is a foam manufacturers for 50 years of experience. We provide many kinds of foam and integrated foam production solutions….

#2 SeaDek

Domain Est. 2002

Website: seadek.com

Key Highlights: SeaDek offers a wide range of PE/EVA foam products designed for boats, RVs, vehicles, pools, spas, and more. Durable, comfortable, and easy to apply….

#3 Marine Grade Adhesive Foam Sheets

Domain Est. 2002

Website: boatoutfitters.com

Key Highlights: Free delivery over $150Foam boat decking is an EVA-style foam used for many outdoor applications. It is a great addition or alternative to standard marine floorings like carpet or …

#4 Terms and Conditions

Domain Est. 2005

Website: avetcoinc.com

Key Highlights: Welcome to Avetco.com, the official website of Avetco Incorporated. Terms and Conditions apply to your use of the website and any purchases made from ……

#5 #1 Rated Boat Flooring

Domain Est. 2008

Website: marineflooring.net

Key Highlights: DECkadence out performs all others and is the best price point compared to alternatives such as high end boat carpet, EVA foam or other alternatives. DECKadence ……

#6 Marine Flooring in North America

Domain Est. 2017

Website: ultradeck.ca

Key Highlights: Primarily serving clients across North America, UltraDeck provides durable, high-quality, marine flooring solutions for new or existing boats!…

#7 Eva Foam Boat Flooring 3M Self

Domain Est. 2023

Website: pellinogregorio.com

Key Highlights: 3M Self-Adhesive EVA Foam Boat Flooring, Brown With Black S – Official · Sold For $50 | Retail: $59.98 | Boat Flooring EVA Foam Marine Decking Sheet Faux Teak ……

#8 news

Domain Est. 2017

Website: evafoammaster.com

Key Highlights: ✓ Professional EVA Marine Pads by Melors As a trusted EVA foam flooring manufacturer, Melors specializes in producing high-performance EVA foam products….

Expert Sourcing Insights for Eva Flooring

H2: Market Trends for EVA Flooring in 2026

By 2026, the EVA (Ethylene-Vinyl Acetate) flooring market is poised for significant evolution, driven by shifting consumer preferences, technological advancements, and broader economic and environmental trends. Here’s a detailed analysis of key market trends expected to shape the EVA flooring landscape in 2026:

1. Sustainability and Eco-Consciousness Take Center Stage

- Demand for Recyclable and Biobased EVA: Consumers and commercial clients will increasingly favor EVA flooring made from recycled content or bio-sourced raw materials. Manufacturers will respond by investing in closed-loop production systems and transparent supply chains.

- Low-VOC and Non-Toxic Formulations: Health and indoor air quality concerns will push demand for EVA flooring certified by standards like FloorScore, GREENGUARD, and Cradle to Cradle. Low-emission, phthalate-free, and heavy-metal-free EVA options will dominate premium segments.

- Circular Economy Models: Rental, take-back, and refurbishment programs for EVA tiles—especially in commercial settings—will gain traction, reducing landfill waste and appealing to ESG-focused businesses.

2. Expansion into Commercial and Institutional Sectors

- Healthcare and Education Adoption: EVA’s shock absorption, slip resistance, and ease of cleaning will make it a top choice for hospitals, clinics, daycare centers, and schools. Antimicrobial additives will further enhance its appeal.

- Retail and Fitness Applications: High-traffic retail spaces and gyms will increasingly use EVA interlocking tiles for their durability, sound-dampening properties, and design flexibility.

- Modular and Temporary Installations: The rise of pop-up stores and flexible office spaces will boost demand for easy-to-install, reconfigurable EVA flooring systems.

3. Innovation in Design and Performance

- Realistic Aesthetics: Advances in printing and embossing technologies will allow EVA flooring to mimic natural materials like wood, stone, and concrete with greater authenticity, expanding its appeal beyond utility-focused applications.

- Enhanced Durability and Comfort: Next-gen EVA compounds with improved UV resistance, scratch protection, and compression recovery will extend product lifespan and reduce maintenance costs.

- Smart Flooring Integration: Early adoption of EVA flooring with embedded sensors for foot traffic monitoring, wellness tracking (in fitness centers), or anti-slip alerts may emerge in high-tech commercial environments.

4. E-Commerce and Direct-to-Consumer Growth

- Online Sales Surge: DIY homeowners and small businesses will increasingly purchase EVA flooring online due to competitive pricing, easy delivery, and detailed installation guides. Brands with strong digital presence and augmented reality (AR) visualization tools will gain market share.

- Customization Options: Online platforms will offer personalized color, pattern, and size configurations, leveraging digital manufacturing for on-demand production.

5. Regional Market Shifts and Supply Chain Resilience

- Asia-Pacific as a Growth Engine: Rapid urbanization, rising disposable incomes, and infrastructure development in countries like India, Vietnam, and Indonesia will drive regional demand.

- Localized Production: To mitigate supply chain disruptions and reduce carbon footprint, manufacturers will increasingly establish regional production hubs closer to key markets.

- Raw Material Volatility Management: Producers will diversify feedstock sources and adopt long-term contracts to hedge against fluctuations in ethylene and vinyl acetate prices.

6. Regulatory and Standardization Pressures

- Stricter Environmental Regulations: Governments in Europe and North America will enforce tighter rules on plastic use and end-of-life management, pushing manufacturers toward sustainable EVA alternatives.

- Harmonized Global Standards: Efforts to standardize EVA flooring performance and safety metrics (e.g., slip resistance, fire ratings) will facilitate cross-border trade and consumer trust.

Conclusion

By 2026, EVA flooring will transition from a niche, utility-focused product to a mainstream, high-performance flooring solution across residential, commercial, and institutional markets. Success will depend on innovation in sustainable materials, design versatility, and responsive supply chains. Companies that prioritize environmental responsibility, digital engagement, and sector-specific performance enhancements will lead the market.

Common Pitfalls When Sourcing EVA Flooring (Quality and Intellectual Property)

Sourcing EVA (Ethylene-Vinyl Acetate) flooring, often used in interlocking tiles for gyms, playrooms, and home workouts, can be cost-effective and efficient—but only if key quality and intellectual property (IP) risks are properly managed. Falling into common pitfalls can result in substandard products, legal disputes, or reputational damage. Below are the most frequent challenges to watch for.

Poor Material Quality and Durability

One of the most prevalent issues in sourcing EVA flooring is inconsistent material quality. Low-cost suppliers may use inferior EVA blends with higher filler content, leading to flooring that cracks, fades, or degrades quickly under UV exposure or heavy use. Buyers often overlook testing standards, resulting in products that fail under real-world conditions.

Lack of Certifications and Safety Standards

Many EVA flooring products—especially those marketed for children—must meet safety certifications such as CE, RoHS, REACH, or ASTM F963. Sourcing from suppliers who cannot provide verifiable documentation increases the risk of non-compliant products containing harmful chemicals like formamide or phthalates, which can lead to product recalls or legal liabilities.

Inaccurate Product Specifications

Suppliers may exaggerate thickness, density (measured in kg/m³), or shock absorption ratings. EVA tiles advertised as “10mm thick” might compress significantly under weight or vary in thickness between batches. Without third-party testing or sample verification, buyers may receive products that don’t meet performance expectations.

Inconsistent Color and Dimensional Accuracy

Color variation between production batches is a frequent problem, especially when scaling up orders. Additionally, interlocking tiles may not fit together seamlessly due to poor mold precision, resulting in gaps or uneven surfaces. These issues affect both aesthetics and functionality.

Intellectual Property Infringement

Sourcing EVA flooring from manufacturers who replicate patented designs—such as specific interlocking patterns, surface textures, or branding logos—can expose buyers to IP infringement claims. Some suppliers offer “copycat” versions of popular brands (e.g., mimicking designs from established fitness flooring companies), which may seem cost-effective but carry legal risks upon import or resale.

Hidden Tooling and Mold Ownership

When customizing EVA flooring, buyers often pay for mold development but fail to secure legal ownership of the tooling. This allows suppliers to reuse or resell the molds to competitors. Always ensure mold ownership is clearly defined in contracts to prevent unauthorized duplication.

Supply Chain Transparency Issues

Many EVA flooring products originate from regions with limited regulatory oversight. Without auditing suppliers or visiting factories, buyers risk sourcing from facilities with unethical labor practices or environmentally harmful production methods—potentially damaging brand reputation.

Insufficient Packaging and Logistics Planning

EVA tiles are lightweight but bulky. Poor packaging can lead to deformation or damage during shipping. Additionally, underestimating volume requirements can result in high freight costs or delivery delays, especially with air or sea freight from distant manufacturing hubs.

Failure to Verify Supplier Credentials

Not all suppliers are manufacturers; some are trading companies with limited control over production quality. Failing to conduct due diligence—such as requesting business licenses, factory audits, or references—increases the likelihood of working with unreliable partners.

No Sample Testing or Quality Control Protocols

Skipping pre-shipment inspections or independent lab testing leaves buyers vulnerable to receiving subpar products. Implementing a clear quality assurance process—including AQL (Acceptable Quality Level) standards and on-site QC checks—helps mitigate risks before bulk orders are finalized.

Avoiding these pitfalls requires thorough vetting, clear contracts, and proactive quality management. Investing time upfront in supplier evaluation and IP compliance safeguards both product integrity and long-term business success.

Logistics & Compliance Guide for Eva Flooring

Product Overview and Handling Instructions

Eva Flooring products are designed for durability, ease of installation, and environmental resilience. Proper handling during transportation and storage is essential to maintain product integrity. Always store rolls or tiles in a dry, well-ventilated area away from direct sunlight and extreme temperatures. Keep packaging intact until ready for installation to prevent moisture absorption and physical damage.

Transportation Requirements

Ensure that Eva Flooring materials are transported in enclosed, climate-controlled vehicles when possible, especially in regions with high humidity or extreme temperatures. Rolls and tiles must be secured upright or flat to avoid deformation. Avoid stacking heavy materials on top of flooring packages. Use pallets and shrink wrap to prevent shifting during transit. Notify carriers of product sensitivity to temperature and moisture to avoid claims disputes.

Storage Guidelines

Store Eva Flooring indoors at temperatures between 60°F and 75°F (15°C–24°C) with relative humidity levels of 30%–50%. Allow materials to acclimate for at least 48 hours in the installation environment prior to fitting. Do not store directly on concrete or damp surfaces—use pallets or elevated platforms. Limit stack height to manufacturer specifications to prevent compression damage.

Import and Export Compliance

Eva Flooring must comply with destination country regulations regarding chemical content, labeling, and packaging. Key certifications include ISO 9001 (Quality Management) and ISO 14001 (Environmental Management). For shipments to the EU, ensure compliance with REACH and CE marking requirements. For U.S. imports, adhere to CPSC and VOC emission standards under the EPA’s TSCA Title VI. Provide accurate Harmonized System (HS) codes (e.g., 3918.90 for plastic floor coverings) and commercial invoices.

Environmental and Safety Regulations

Eva Flooring is typically phthalate-free and low in volatile organic compounds (VOCs). Confirm material safety data sheets (MSDS/SDS) are available for all products. Comply with local waste disposal regulations; unused or off-cut materials may be recyclable through designated polymer recycling programs. Ensure production facilities meet RoHS and California Proposition 65 requirements if applicable.

Documentation and Traceability

Maintain complete shipment records including batch numbers, production dates, and test certifications for traceability. Provide customers with installation guides, warranty information, and compliance documentation upon delivery. Utilize barcode or QR code labeling for inventory and logistics tracking across the supply chain.

Quality Assurance and Inspection

Conduct pre-shipment inspections to verify product dimensions, color consistency, and packaging integrity. Address any non-conformances before dispatch. Partner with third-party inspection agencies for high-volume or international orders to ensure compliance with contractual and regulatory standards.

Customer Support and Compliance Assistance

Eva Flooring provides ongoing support for logistics planning and regulatory questions. Contact our compliance team for customs documentation, certification verification, or special handling needs. We are committed to sustainable, compliant, and efficient delivery of flooring solutions worldwide.

Conclusion for Sourcing EVA Flooring:

Sourcing EVA (Ethylene-Vinyl Acetate) flooring presents a compelling option for a wide range of applications, from residential and commercial spaces to gyms, playrooms, and even industrial environments. Its exceptional durability, shock absorption, water resistance, and ease of installation make it a practical and cost-effective flooring solution. As sustainability becomes increasingly important, responsible sourcing should prioritize suppliers who use eco-friendly manufacturing practices and offer recyclable or low-emission products.

When sourcing EVA flooring, it is essential to evaluate key factors such as material quality, certifications (e.g., non-toxic, phthalate-free, anti-slip), long-term performance, and supplier reliability. Bulk purchasing and direct engagement with manufacturers—especially from major producing regions like China, Southeast Asia, or Europe—can help reduce costs while ensuring consistent quality.

In conclusion, EVA flooring offers a versatile, safe, and resilient flooring option well-suited to diverse environments. With careful supplier selection, adherence to quality standards, and consideration of environmental impact, sourcing EVA flooring can deliver excellent value, performance, and customer satisfaction in both short- and long-term applications.