The global epoxy resin market is experiencing robust growth, driven by rising demand across industries such as automotive, construction, and consumer goods. According to Mordor Intelligence, the global epoxy resin market was valued at USD 11.5 billion in 2023 and is projected to grow at a CAGR of over 6.2% from 2024 to 2029. A significant contributor to this expansion is the flourishing craft and jewelry sector, where epoxy resin’s versatility, transparency, and ability to capture intricate designs have made it a preferred material for artisans and commercial producers alike.

Parallel growth in e-commerce and handmade marketplaces has further amplified demand for high-quality epoxy resin jewelry, prompting increased production capacity among specialized manufacturers. Grand View Research notes that the global jewelry market size was valued at USD 330.4 billion in 2022 and is expected to grow at a CAGR of 5.5% through 2030, with handmade and customizable pieces gaining traction among consumers. As a result, manufacturers capable of combining scalable production with artistic precision are emerging as key players in this niche.

Within this expanding landscape, a select group of epoxy resin jewelry manufacturers have distinguished themselves through innovation, quality control, and supply chain efficiency. Based on production volume, market reach, customer reviews, and material sustainability practices, the following eight manufacturers represent the forefront of the industry in 2024.

Top 8 Epoxy Resin Jewelry Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

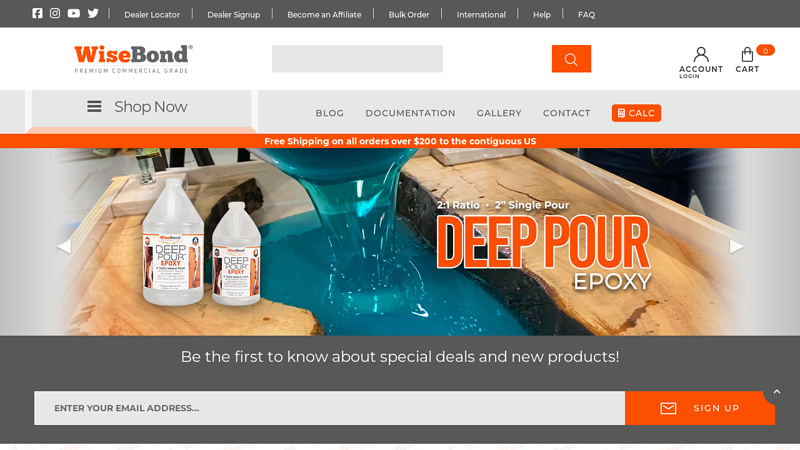

#1 WiseBond Deep Pour Epoxy Table Top Countertop Epoxy Art …

Domain Est. 2003

Website: wisebond.com

Key Highlights: Free delivery over $200 30-day returnsOur WiseBond® Deep Pour 2:1 Ratio, 2-Part Epoxy is a premium commercial grade live-edge wood slab river table and thick casting epoxy resin….

#2 UV high gloss finish on resin jewellery

Domain Est. 2009

Website: talkcomposites.com

Key Highlights: The uv resistance and gloss propertys should be at least as good as the epoxy coating resin, if not better. You could buy uv blocker additive ……

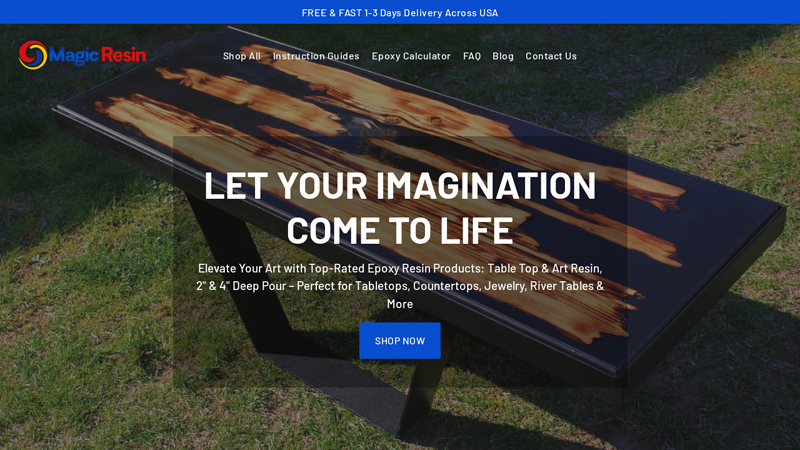

#3 Magic Resin USA: Clear Epoxy Resin Kits with FREE 1

Domain Est. 2010

Website: magicresin.com

Key Highlights: Discover top-quality clear epoxy resin at Magic Resin, perfect for coating and casting applications such as table tops, bar tops, counter tops, river tables….

#4 Resinate

Domain Est. 2016

Website: resinate.ca

Key Highlights: Resinate is a company founded with the vision of providing a premium artistic resin that is locally manufactured and affordable in price….

#5 Craft Resin

Domain Est. 2019

Website: craft-resin.com

Key Highlights: Craft Resin is a crystal clear epoxy resin and premium mica powder for artists. We supply epoxy resin pro kits online for moulding, arts, and crafts….

#6 Epoxy Resin for Jewelry Making

Domain Est. 2021

#7 Jewellery resin

Domain Est. 2024

Website: smvthailand.com

Key Highlights: Rating 5.0 · Review by [email protected] use resin to create unique and innovative jewellery. This versatile material can be used to design pieces with bright colours an…

#8 Resin Jewelry Supplies Wholesale

Website: justresin.shop

Key Highlights: Searching for Resin Jewelry Supplies Wholesale? Find the perfect Resin Art Supplies for your next project with us. Shipping across USA and Worldwide….

Expert Sourcing Insights for Epoxy Resin Jewelry

2026 Market Trends for Epoxy Resin Jewelry

Rising Demand for Sustainable and Eco-Conscious Materials

By 2026, the epoxy resin jewelry market will see a significant shift toward sustainability. Consumers are increasingly demanding transparency in sourcing and environmentally responsible production. Artisans and brands are responding by adopting bio-based resins derived from renewable sources like plant oils, reducing reliance on petroleum-based epoxies. Additionally, the use of recycled materials—such as reclaimed metals, upcycled glass, and ethically sourced natural inclusions (dried flowers, seeds, or ocean-safe glitter)—will become standard practice. Certifications like “non-toxic,” “low VOC,” and “biodegradable” will play a crucial role in influencing consumer trust and purchasing decisions.

Personalization and Customization as Key Differentiators

The appetite for unique, personalized accessories will continue to grow, positioning customized epoxy resin jewelry as a dominant trend in 2026. Advances in digital design tools and social media platforms enable small creators to offer bespoke services, such as embedding photos, names, or meaningful symbols into resin pieces. Online marketplaces like Etsy and Shopify will further empower artisans to reach global audiences seeking one-of-a-kind gifts or self-expressive fashion items. Limited-edition collaborations between resin artists and influencers or niche brands will also become more common, enhancing exclusivity and market visibility.

Integration of Smart and Functional Elements

Innovation will push epoxy resin jewelry beyond aesthetics, with early adoption of smart features. While still emerging, hybrid designs incorporating lightweight, waterproof tech components—such as NFC chips for digital business cards or QR codes linking to personal stories—will begin to surface. Additionally, resin pieces designed with functional purposes, like UV-reactive elements for safety awareness or mood-sensitive pigments, will appeal to tech-savvy and experience-driven consumers. Though not mainstream, these integrations will signal a shift toward multifunctional wearable art.

Expansion of Artistic Techniques and Design Complexity

Artists will leverage advanced techniques such as deep pour casting, geode-style designs, and metallic pigment manipulation to create jewelry with gallery-quality appeal. By 2026, the boundary between craft and fine art will blur, with resin jewelry being showcased in art fairs and boutique galleries. Social media, especially platforms like Instagram and TikTok, will continue to drive viral trends, with tutorials and time-lapse videos fueling both consumer interest and DIY engagement. This democratization of design will foster a global community of creators experimenting with textures, layers, and embedded elements.

E-Commerce and Direct-to-Consumer Dominance

The epoxy resin jewelry market will remain heavily reliant on e-commerce, with direct-to-consumer (DTC) models outpacing traditional retail. Brands that invest in immersive online experiences—such as 360-degree product views, augmented reality (AR) try-ons, and detailed storytelling around craftsmanship—will gain competitive advantage. Subscription boxes offering resin kits and curated jewelry pieces will also grow, appealing to hobbyists and gift markets. Logistics improvements and sustainable packaging will further enhance customer satisfaction and brand loyalty.

Conclusion

By 2026, the epoxy resin jewelry market will be shaped by sustainability, personalization, technological integration, and digital innovation. Artisans and businesses that embrace eco-friendly practices, leverage online platforms, and push creative boundaries will thrive in this dynamic, community-driven industry.

Common Pitfalls When Sourcing Epoxy Resin Jewelry: Quality and Intellectual Property Issues

Sourcing epoxy resin jewelry can be lucrative, but it comes with significant risks related to both product quality and intellectual property (IP) infringement. Being aware of these common pitfalls helps protect your brand, customers, and business reputation.

Quality-Related Pitfalls

Inconsistent Resin Curing and Yellowing

One of the most frequent quality issues is inconsistent curing due to poor resin formulation or improper mixing ratios. Suppliers may use low-grade epoxy that doesn’t fully harden, leading to sticky or soft pieces. Additionally, UV-stable additives are often omitted in cheaper resins, resulting in rapid yellowing when exposed to sunlight—damaging the aesthetic appeal and perceived value of the jewelry.

Bubbles, Cracks, and Surface Defects

Low-quality production processes often result in visible bubbles, cracks, or uneven surfaces. Inadequate degassing, rushed curing, or poor mold maintenance contribute to these flaws. Jewelry with such defects not only looks unprofessional but can also break easily, leading to customer dissatisfaction and returns.

Poor Finish and Detail Reproduction

Inferior molds or unskilled craftsmanship can lead to dull finishes, loss of fine details, or rough edges. High-quality epoxy jewelry should have a glass-like finish and sharp design features. When sourcing, especially from low-cost manufacturers, expect reduced attention to detail unless quality control is explicitly enforced.

Use of Toxic or Non-Safe Materials

Some suppliers may use epoxy resins that contain harmful substances or fail to comply with safety standards (e.g., REACH, CPSIA). Resin jewelry worn close to the skin must be non-toxic and hypoallergenic. Sourcing without verifying material safety data sheets (MSDS) or certifications can expose your business to legal liability and health concerns.

Intellectual Property (IP) Pitfalls

Selling Copyrighted or Trademarked Designs

Many epoxy resin jewelry pieces replicate popular characters, logos, or artistic designs protected by copyright or trademark. Suppliers may offer “inspired by” versions, but these often cross the line into infringement. Sourcing such items—even unknowingly—can result in cease-and-desist letters, product seizures, or lawsuits, especially on platforms like Etsy, Amazon, or Shopify that enforce IP policies strictly.

Lack of Design Originality and Market Saturation

Relying on generic or overused designs from mass suppliers leads to a lack of differentiation. When multiple sellers offer identical or near-identical pieces, price competition increases and brand value diminishes. This also raises the risk of unintentionally mimicking original designs created by independent artists.

No Documentation or Proof of IP Ownership

Suppliers, particularly in unregulated markets, rarely provide proof of design ownership or licensing. Without written documentation confirming that designs are original or properly licensed, you assume full legal risk. Always request IP clearance documentation before placing bulk orders.

Counterfeit Packaging and Branding

Some suppliers include counterfeit logos, branded boxes, or misleading labels that mimic well-known jewelry brands. Sourcing products with such packaging—even if unintended—can implicate your business in trademark infringement and damage your credibility.

Mitigation Strategies

To avoid these pitfalls, conduct thorough due diligence:

– Request product samples to assess quality firsthand.

– Verify material safety and compliance certifications.

– Audit suppliers for quality control processes.

– Ensure all designs are original or properly licensed.

– Use contracts that include IP indemnification clauses.

By proactively addressing both quality and IP concerns, you can build a sustainable and reputable epoxy resin jewelry business.

Logistics & Compliance Guide for Epoxy Resin Jewelry

Product Classification & Regulatory Overview

Epoxy resin jewelry is generally categorized as a consumer craft product or accessory. While jewelry itself may not face stringent regulations, the materials used—specifically epoxy resin—can fall under chemical safety regulations. In many jurisdictions, epoxy resins are regulated due to the presence of potentially hazardous components such as epichlorohydrin or bisphenol A (BPA).

Ensure your product complies with applicable regulations:

– U.S. (Consumer Product Safety Commission – CPSC): While epoxy resin jewelry is not a children’s product by default, if marketed to children under 12, it must comply with the Consumer Product Safety Improvement Act (CPSIA), including lead and phthalate limits.

– European Union (REACH & RoHS): Comply with REACH regulations for chemical substances. Epoxy resins must not contain Substances of Very High Concern (SVHC) above threshold limits. RoHS may apply if the jewelry contains electronic components.

– California Proposition 65: Requires a warning label if the product contains chemicals known to cause cancer or reproductive harm (e.g., certain epoxy components).

Material Sourcing & Safety Data Sheets (SDS)

When sourcing epoxy resin:

– Only purchase from reputable suppliers who provide Safety Data Sheets (SDS) for each resin component.

– Verify that the resin is labeled as non-toxic, art/craft-grade, and suitable for jewelry making.

– Maintain SDS documentation for every batch; this may be required during customs clearance or compliance audits.

Ensure pigments and additives (e.g., mica powders, dyes) are also non-toxic and comply with cosmetic or consumer product safety standards if applicable.

Packaging & Labeling Requirements

Proper labeling enhances compliance and customer trust:

– Include manufacturer or brand name and contact information.

– Add a Proposition 65 warning if selling in California (e.g., “This product contains chemicals known to the State of California to cause cancer and birth defects”).

– Use caution labels if the jewelry contains small parts (choking hazard for children under 3).

– Avoid misleading claims such as “food-safe” or “body-safe” unless independently certified.

Shipping & Hazard Classification

Most cured epoxy resin jewelry is non-hazardous and can be shipped via standard courier services (e.g., USPS, UPS, FedEx). However:

– Uncured resin or liquid components are often classified as hazardous materials (ORM-D or UN3082) and subject to IATA/IMDG/ADR regulations for air, sea, and ground transport.

– Never ship uncured resin with finished jewelry unless properly classified, packaged, and labeled.

– For international shipments, declare the product accurately as “Handmade Jewelry – Epoxy Resin” and provide Harmonized System (HS) Code (typically 7117 for imitation jewelry).

Import/Export Compliance

When shipping internationally:

– Determine the correct HS Code for epoxy resin jewelry (e.g., 7117.19 for other imitation jewelry).

– Research import duties and restrictions in the destination country. Some countries restrict certain chemicals or require product certification.

– Complete commercial invoices with detailed descriptions, value, and country of origin.

– Consider using a customs broker for high-volume or complex international shipments.

Environmental & Disposal Considerations

- Educate customers on proper disposal: Cured epoxy is inert and can be discarded with regular waste.

- Provide guidelines for safe cleanup of uncured resin (e.g., use gloves, avoid drain disposal).

- Follow local regulations for disposing of mixing tools, gloves, and leftover resin.

Recordkeeping & Documentation

Maintain records for at least 5 years, including:

– SDS for all materials used

– Supplier certifications

– Product testing reports (if applicable)

– Shipping documentation and customs forms

This documentation supports compliance during audits or product liability inquiries.

Best Practices Summary

- Use only certified, low-hazard resin for jewelry.

- Label clearly and comply with regional regulations.

- Ship only finished, cured products via non-hazardous methods.

- Stay updated on chemical regulations (REACH, TSCA, Prop 65).

- Prioritize transparency with customers about materials used.

By following this guide, artisans and businesses can safely and legally produce and distribute epoxy resin jewelry across domestic and international markets.

In conclusion, sourcing epoxy resin for jewelry making requires careful consideration of quality, safety, clarity, and ease of use to ensure professional and durable results. It is essential to choose a high-quality, UV-resistant, and non-yellowing epoxy resin that offers excellent clarity and self-leveling properties. Whether purchasing from local craft stores, online retailers, or specialty suppliers, comparing product reviews, pricing, and shipping options can help identify reliable sources. Additionally, prioritizing health and safety by selecting resins that comply with industry standards and using proper ventilation and protective gear during application is crucial. By sourcing the right epoxy resin from trusted suppliers, jewelry artisans can enhance their craftsmanship, produce stunning pieces, and maintain consistency in their creative projects.