The global concrete sealers market is experiencing robust growth, driven by rising infrastructure development and increasing demand for durable, low-maintenance flooring solutions across industrial, commercial, and residential sectors. According to a report by Grand View Research, the global concrete sealers market was valued at USD 2.49 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.5% from 2023 to 2030. Epoxy-based sealers, in particular, are gaining traction due to their superior adhesion, chemical resistance, and long-term performance. With the construction and renovation sectors scaling up worldwide—especially in North America, Europe, and parts of Asia-Pacific—the need for high-performance epoxy concrete sealers has become critical. This growing demand has positioned several manufacturers at the forefront of innovation and market share. Based on market presence, product portfolio, and technological advancements, here are the top 8 epoxy concrete sealers manufacturers shaping the industry landscape.

Top 8 Epoxy Concrete Sealers Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

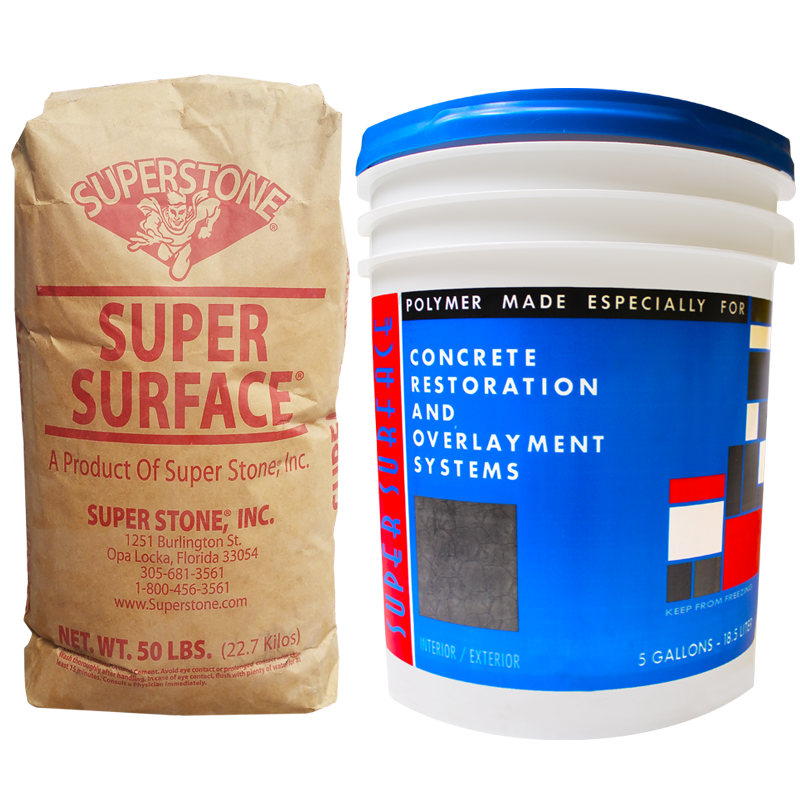

#1 Super Stone, Inc.

Domain Est. 1997

Website: superstone.com

Key Highlights: SEALERS. Our sealers are designed to enhance and protect stamped concrete & masonry surfaces. EPOXY. Use our epoxy in your projects for versatile options that ……

#2 Devcon Industrial Epoxy Adhesive

Domain Est. 2017

Website: itwperformancepolymers.com

Key Highlights: Devcon® is the best metal epoxy manufacturer & coating solutions provider. You can use the epoxy adhesives as metal bonding filler, epoxy plastic filler, ……

#3 APF Polymer Flooring

Domain Est. 1998

Website: apfepoxy.com

Key Highlights: APF Polymer Surfaces is a respected name in the concrete surfacing industry, known for our experience, technology and integrity….

#4 SureCrete Decorative Concrete Products

Domain Est. 1999

Website: surecretedesign.com

Key Highlights: Concrete Coatings, Inc. has been proudly leading the industry for over 20 years, manufacturing overlays, stains & dyes and other products for your concrete ……

#5 Sealers / Topcoats Archives

Domain Est. 2005

Website: duraamen.com

Key Highlights: 10-day returnsIf you’re looking for a durable and long-lasting solution to protect your concrete surfaces, epoxy coatings are a great choice. Our line of high-performance ……

#6 Water Based Concrete Sealers

Domain Est. 2016

Website: spartanepoxies.com

Key Highlights: 3–5 day delivery 5-day returnsSpartan Epoxies delivers professional-grade epoxy flooring and waterproofing solutions for residential, commercial, and industrial projects….

#7 Classic Coating Systems

Domain Est. 2011

Website: classiccoatingssystems.com

Key Highlights: Classic Coatings Systems products enable you to craft stunning, multi-toned finishes on various concrete and masonry surfaces….

#8 Convergent Epoxy Resin Adhesives & Concrete Technologies

Domain Est. 2013

Website: atcepoxy.com

Key Highlights: Convergent Concrete Technologies is the leading concrete densifiers, cures, sealers, coatings, cleaners and other specialty formulations. Learn more with ATC!…

Expert Sourcing Insights for Epoxy Concrete Sealers

H2: Projected Market Trends for Epoxy Concrete Sealers in 2026

The global market for epoxy concrete sealers is expected to experience steady growth through 2026, driven by increasing demand across construction, industrial, and residential sectors. Key trends shaping the industry include technological advancements, sustainability initiatives, regional expansion, and evolving consumer preferences.

-

Growing Infrastructure Development

Ongoing urbanization and public and private investment in infrastructure—particularly in North America, Europe, and Asia-Pacific—are fueling demand for durable flooring solutions. Epoxy concrete sealers are favored for their strength, chemical resistance, and low maintenance, making them ideal for use in commercial buildings, parking garages, warehouses, and transportation hubs. -

Shift Toward Sustainable and Low-VOC Products

Environmental regulations and consumer demand for eco-friendly building materials are pushing manufacturers to develop water-based epoxy formulations and low-VOC (volatile organic compound) sealers. By 2026, companies that prioritize sustainable production methods and green certifications are expected to gain a competitive edge. -

Innovation in Product Performance

Advancements in epoxy resin technology are leading to sealers with enhanced features such as UV resistance, faster curing times, improved flexibility, and antimicrobial properties. These innovations are expanding applications into high-moisture environments like food processing plants and healthcare facilities. -

Rise in DIY and Residential Applications

The home improvement sector is a growing market for epoxy concrete sealers, especially in garage floor coatings and basement renovations. Online retail platforms and easy-to-apply kits are empowering homeowners, contributing to increased market penetration in residential spaces. -

Regional Market Dynamics

Asia-Pacific is anticipated to be the fastest-growing region due to rapid industrialization and urban development in countries like China, India, and Vietnam. Meanwhile, North America will remain a dominant market, supported by stringent building codes and a strong commercial construction sector. -

Consolidation and Strategic Partnerships

Market players are likely to engage in mergers, acquisitions, and R&D collaborations to expand product portfolios and geographic reach. Companies such as PPG Industries, Sherwin-Williams, and BASF are expected to strengthen their foothold through innovation and customer-centric solutions.

In summary, the epoxy concrete sealer market in 2026 will be shaped by sustainability, performance innovation, and expanding applications. Businesses that align with these trends and adapt to regulatory and consumer demands will be well-positioned for long-term growth.

Common Pitfalls When Sourcing Epoxy Concrete Sealers: Quality and Intellectual Property Risks

Sourcing epoxy concrete sealers can be complex, with several potential pitfalls that impact product performance, compliance, and long-term value. Two critical areas where issues commonly arise are quality consistency and intellectual property (IP) protection. Being aware of these challenges helps buyers make informed decisions and avoid costly mistakes.

Quality-Related Pitfalls

-

Inconsistent Formulation and Raw Material Sourcing

Many suppliers—especially lower-cost or unverified manufacturers—may alter formulations or use substandard raw materials to cut costs. This inconsistency leads to unpredictable performance, such as reduced adhesion, poor chemical resistance, or premature coating failure. -

Lack of Third-Party Testing and Certification

Reputable epoxy sealers should come with verifiable test reports (e.g., ASTM, ISO standards) for properties like compressive strength, abrasion resistance, VOC content, and chemical resistance. Sourcing from suppliers who cannot provide these documents increases the risk of receiving non-compliant or underperforming products. -

Misrepresentation of Product Specifications

Some suppliers exaggerate technical claims (e.g., thickness coverage, pot life, cure time) without real-world validation. This can lead to application issues, increased material costs, or structural vulnerabilities in demanding environments like industrial floors or parking garages. -

Inadequate Technical Support and Documentation

Poor supplier guidance on surface preparation, mixing ratios, application conditions, and curing procedures often results in improper installation—even with high-quality materials—compromising the final outcome.

Intellectual Property (IP) Risks

-

Counterfeit or “Knock-Off” Products

The epoxy sealer market is prone to counterfeit goods that mimic leading brands. These products may copy packaging and branding but use inferior chemistry, posing safety, durability, and compliance risks. Buyers may unknowingly violate IP laws by specifying or installing such products. -

Unauthorized Use of Technology or Patents

Some manufacturers replicate patented resin systems or curing agents without licensing. Using such products exposes end users and specifiers to potential legal liability, especially in regulated industries or public infrastructure projects. -

Lack of Transparency in Formulation Ownership

Suppliers may claim proprietary technology without clear evidence of R&D investment or patent protection. This opacity makes it difficult to assess innovation legitimacy and increases dependency on suppliers who may not protect their own IP, risking supply chain instability. -

Gray Market Imports

Sourcing from unauthorized distributors or gray market channels may result in genuine products being sold outside intended regions—often bypassing warranties, technical support, and compliance certifications. This can also breach the IP holder’s distribution agreements.

Mitigation Strategies

To avoid these pitfalls, buyers should:

– Conduct supplier audits and request full technical data sheets (TDS) and safety data sheets (SDS).

– Verify certifications and request independent lab test results.

– Work with authorized distributors and branded manufacturers with transparent IP practices.

– Include quality assurance clauses and IP indemnification in procurement contracts.

By focusing on both quality assurance and IP due diligence, organizations can ensure long-term performance, compliance, and legal safety in their epoxy concrete sealer sourcing.

Logistics & Compliance Guide for Epoxy Concrete Sealers

Product Classification and Regulatory Overview

Epoxy concrete sealers are typically classified as industrial coatings containing reactive chemicals. They may fall under regulations governing hazardous materials, volatile organic compounds (VOCs), and workplace safety. Key regulatory frameworks include OSHA (Occupational Safety and Health Administration) in the U.S., REACH and CLP in the EU, and local environmental protection standards. Proper classification ensures compliance with transport, storage, and handling requirements.

Hazard Communication (HazCom) and Safety Data Sheets (SDS)

Suppliers must provide a current Safety Data Sheet (SDS) compliant with the Globally Harmonized System (GHS). The SDS must include hazard identification, composition, first-aid measures, fire-fighting procedures, accidental release measures, handling and storage instructions, exposure controls, and toxicological information. Employers are responsible for ensuring SDS availability and training personnel on chemical hazards and protective measures.

Transportation and Shipping Requirements

Epoxy sealers often contain flammable or hazardous components, requiring adherence to transportation regulations such as DOT (U.S. Department of Transportation), IATA (air), or IMDG (maritime). Proper labeling, packaging, and documentation—including a hazardous materials declaration—are mandatory. Containers must be UN-rated, tightly sealed, and compatible with epoxy resins and solvents. Shipments must be marked with appropriate hazard class labels (e.g., Class 3 Flammable Liquid).

Storage Guidelines

Store epoxy concrete sealers in a cool, dry, well-ventilated area away from direct sunlight, heat sources, and ignition hazards. Maintain temperatures between 50°F and 80°F (10°C–27°C) to prevent premature curing or degradation. Keep containers closed when not in use and store away from oxidizers and strong acids. Segregate hardeners from base resins if shipped separately. Use secondary containment to prevent environmental contamination in case of leaks.

Environmental Compliance

Ensure VOC content complies with regional limits (e.g., EPA, SCAQMD, or EU Directive 2004/42/EC). Dispose of waste materials, including empty containers and spill residues, in accordance with local, state, and federal environmental regulations. Never pour unused sealer or rinse water down drains. Use licensed hazardous waste disposal services where applicable.

Worker Safety and Personal Protective Equipment (PPE)

Personnel handling epoxy sealers must use appropriate PPE, including chemical-resistant gloves (nitrile or neoprene), safety goggles, respiratory protection (when ventilation is inadequate), and protective clothing. Ensure adequate ventilation in application and mixing areas. Monitor for potential sensitization or respiratory irritation with prolonged exposure. Train staff on emergency procedures and spill response.

Spill Response and Emergency Procedures

In the event of a spill, contain the area immediately using absorbent materials compatible with organic solvents (e.g., spill socks, vermiculite). Avoid water runoff into storm drains. Clean up residue with appropriate solvents and dispose of contaminated materials as hazardous waste. Evacuate area if vapors are present and ventilate thoroughly. Maintain spill kits on-site and ensure personnel are trained in their use.

Import/Export Considerations

For international shipments, verify compliance with destination country regulations, including import permits, labeling in local language, and restrictions on chemical ingredients. Obtain necessary export licenses if required. Use customs brokers familiar with chemical product classifications to avoid delays. Ensure all documentation (commercial invoice, packing list, SDS, certificates of analysis) is accurate and complete.

Recordkeeping and Audit Readiness

Maintain records of SDS, shipping manifests, training logs, spill reports, waste disposal receipts, and regulatory correspondence for a minimum of three to five years, or as required by jurisdiction. Conduct periodic internal audits to ensure ongoing compliance with safety, environmental, and transportation standards.

Supplier and Contractor Compliance

Require vendors and contractors to adhere to the same compliance standards. Verify that subcontractors using epoxy sealers are trained, equipped with proper PPE, and follow site-specific safety plans. Include compliance requirements in contracts and service agreements.

Conclusion for Sourcing Epoxy Concrete Sealers

Sourcing high-quality epoxy concrete sealers is a critical step in ensuring the longevity, durability, and aesthetic appeal of concrete surfaces across various applications—ranging from industrial floors to commercial and residential spaces. After evaluating key factors such as performance characteristics, environmental resistance, application requirements, and supplier reliability, it becomes evident that selecting the right epoxy sealer involves a balanced approach between product quality, cost-efficiency, and technical support.

Priority should be given to suppliers offering proven, ASTM-compliant products with strong adhesion, chemical resistance, abrasion resistance, and UV stability when needed. Additionally, considering the environmental impact and compliance with VOC regulations is increasingly important due to stricter environmental standards.

Establishing partnerships with reputable manufacturers or distributors who provide consistent product quality, technical guidance, and responsive customer service ensures smooth implementation and long-term satisfaction. Bulk purchasing, regional availability, and lead times should also be factored into the sourcing strategy to maintain project timelines and reduce costs.

In conclusion, a strategic and informed sourcing approach—grounded in product performance, supplier reliability, and lifecycle value—will maximize the effectiveness of epoxy concrete sealers and contribute to the successful protection and enhancement of concrete infrastructure.