The global engineered quartz stone countertops market is experiencing robust growth, driven by rising demand for durable, low-maintenance, and aesthetically versatile surfacing solutions in residential and commercial construction. According to Grand View Research, the global quartz market was valued at USD 5.3 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 7.8% from 2023 to 2030. This growth is fueled by increased urbanization, evolving consumer preferences for premium interior finishes, and the material’s non-porous, stain-resistant properties that outperform natural stone alternatives. As sustainability and design innovation become key differentiators, a select group of manufacturers are leading the way in technology, production capacity, and global distribution. Based on market presence, product innovation, and geographic reach, the following ten companies represent the forefront of the engineered quartz industry worldwide.

Top 10 Engineered Quartz Stone Countertops Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Avant Quartz Quartz Stone

Domain Est. 2015

Website: avant-quartz.com

Key Highlights: Buy Quartz Stone from Avant Manufacturer. Wide range of colors and collections. Durable, modern, and eco-friendly engineered stone. Certified products….

#2 HanStone Quartz Kitchen & Bathroom Countertop Manufacturer

Domain Est. 2018

Website: hyundailncusa.com

Key Highlights: HanStone Quartz is not only high-performance, but it’s also luxurious, durable, low maintenance and perfect for kitchens, baths or anywhere you use every day….

#3 Surfaces for Life

Domain Est. 1997 | Founded: 1987

Website: caesarstone.com

Key Highlights: Durable surfaces in timeless designs, by Caesarstone U.S.A, the quartz countertop pioneer redefining surface innovation since 1987….

#4 Our Collection of Engineered Quartz Slabs

Domain Est. 2007

Website: omnisurfaces.com

Key Highlights: Omni Surfaces has over 20000 slabs of marble, granite, quartz, and porcelain, and more than 300 colors to choose from. We have built a hard-working team ……

#5 Quartz Countertops

Domain Est. 2012

Website: msisurfaces.com

Key Highlights: Q Premium Natural Quartz from MSI offers over 125 quartz styles in a wide range of patterns, including marble-looks, concrete-looks, and nature-inspired ……

#6 Vadara Quartz Surfaces

Domain Est. 2014

Website: vadara.com

Key Highlights: NEW AND EXCITING DESIGNS. Discover Vadara’s latest and greatest innovations — stunning quartz designs that bring nature’s beauty to every space….

#7 Madhav Surfaces

Domain Est. 2018

Website: madhavquartz.com

Key Highlights: Discover premium quartz countertops and engineered stone surfaces from Madhav Quartz. Luxury collections for kitchens, bathrooms, and commercial spaces….

#8 PentalQuartz® Countertop Collections Online

Domain Est. 2019

Website: arcsurfaces.com

Key Highlights: Unmatched beauty of PentalQuartz® countertops, a remarkable blend of natural stone elegance and exceptional durability available at Architectural Surfaces….

#9 Premium Engineered Quartz Countertops and Slabs

Domain Est. 2021

Website: grandquartztech.com

Key Highlights: Discover premium engineered quartz countertops and slabs from Grand Quartz Tech. We manufacture high-quality quartz surfaces with superior durability, ……

#10 VICOSTONE Quartz Surfaces®

Domain Est. 2005

Website: vicostone.com

Key Highlights: Vicostone is the world’s leading manufacture of quality QUARTZ stone products for residential and commercial applications. WHERE TO BUY. LOCATE YOUR NEAREST….

Expert Sourcing Insights for Engineered Quartz Stone Countertops

H2: 2026 Market Trends for Engineered Quartz Stone Countertops

The engineered quartz stone countertops market is poised for significant evolution by 2026, shaped by shifts in consumer preferences, technological advancements, sustainability demands, and global economic dynamics. As a leading surface material in residential and commercial construction, engineered quartz continues to gain traction due to its durability, aesthetic versatility, and low maintenance. Below are the key trends expected to influence the market through 2026:

1. Rising Demand in Emerging Economies

By 2026, rapid urbanization and a growing middle class in regions such as Southeast Asia, India, and Latin America are expected to drive increased demand for engineered quartz. Rising disposable incomes and expanding construction sectors will boost adoption in both new builds and renovation projects, expanding beyond traditional strongholds in North America and Western Europe.

2. Emphasis on Sustainability and Eco-Friendly Production

Environmental concerns will play a pivotal role in shaping market trends. Manufacturers are anticipated to invest in sustainable practices, such as reducing water and energy use, incorporating recycled content (including post-consumer glass and quartz waste), and achieving third-party certifications like NSF, Greenguard, and EPDs. Demand for transparent supply chains and low-carbon footprint products will grow, influencing consumer and contractor choices.

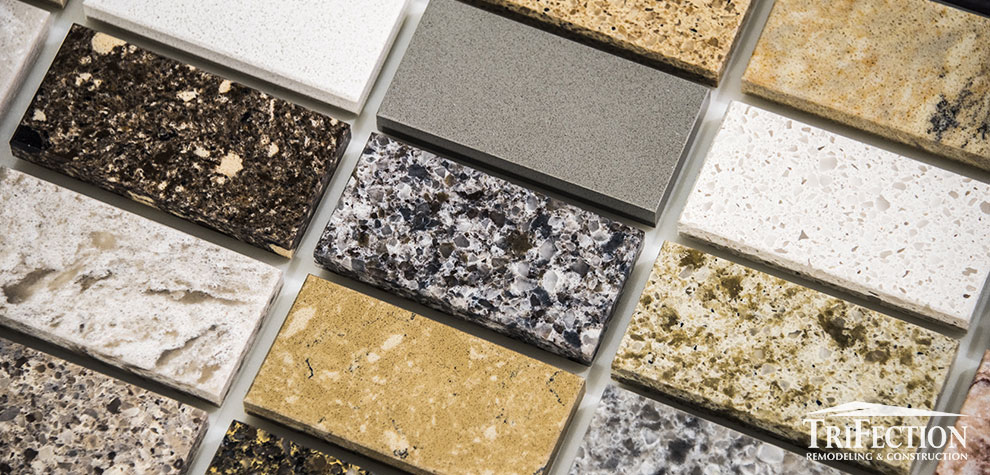

3. Innovation in Design and Surface Finishes

Consumers are increasingly seeking personalized and aesthetically sophisticated interiors. In response, producers will expand their design portfolios to include ultra-realistic marble and natural stone patterns, bold colors, matte finishes, and textured surfaces. By 2026, digital printing and AI-assisted design tools are expected to allow for greater customization, enabling homeowners and designers to create unique countertop solutions.

4. Growth in Thin Quartz and Large-Format Slabs

The adoption of thin quartz (6–12 mm) will accelerate, particularly in renovation projects and lightweight applications such as wall cladding and furniture. These thinner slabs reduce shipping costs and material use while maintaining durability. Concurrently, large-format slabs (up to 3200×1600 mm or larger) will gain popularity for seamless installations in kitchens and bathrooms, minimizing visible joints and enhancing visual continuity.

5. Smart Integration and Functional Surfaces

While still in early stages, the integration of smart technology into countertops—such as embedded wireless charging, antimicrobial surfaces, and self-cleaning properties—will begin to emerge by 2026. R&D investments may yield quartz composites with enhanced functionality, including heat resistance, improved scratch resistance, and UV stability for outdoor applications.

6. Competitive Pricing and Market Consolidation

Increased production capacity, particularly in China, Turkey, and India, will contribute to competitive pricing, making engineered quartz more accessible. However, this may lead to consolidation among smaller manufacturers unable to scale efficiently or meet evolving regulatory and quality standards. Leading brands like Caesarstone, Silestone (Cosentino), and Cambria will likely strengthen their market positions through innovation and global distribution.

7. Influence of E-Commerce and Digital Showrooms

The purchasing journey for quartz countertops will become increasingly digital. By 2026, augmented reality (AR) tools, 3D visualization platforms, and online configurators will enable consumers to preview countertops in their own spaces virtually. E-commerce partnerships with home improvement retailers and direct-to-consumer models will expand, especially in markets with high internet penetration.

Conclusion

By 2026, the engineered quartz stone countertop market will be characterized by innovation, sustainability, and global expansion. As consumers prioritize both style and performance, manufacturers that adapt to these evolving demands—through eco-conscious production, design leadership, and digital engagement—will be best positioned for long-term success.

Common Pitfalls When Sourcing Engineered Quartz Stone Countertops (Quality and Intellectual Property)

Sourcing engineered quartz stone countertops can be challenging, especially when balancing cost, quality, and compliance. Below are key pitfalls to avoid, particularly concerning quality assurance and intellectual property (IP) concerns.

Overlooking Manufacturer Certifications and Testing Standards

Many suppliers claim high quality but lack third-party certifications such as NSF, CE, or GREENGUARD. Without proper testing for durability, stain resistance, and chemical safety, buyers risk receiving subpar slabs that degrade quickly or emit harmful VOCs. Always verify compliance with international standards like ISO 9001 and request test reports for flexural strength, water absorption, and abrasion resistance.

Ignoring Slab Consistency and Batch Variability

Engineered quartz involves pigments and resins, and inconsistent manufacturing can lead to visible color, pattern, or thickness variations between slabs—even within the same batch. Buyers may face mismatched seams or an unprofessional finish during installation. Request full-size samples and ensure the supplier guarantees batch consistency for your entire project.

Falling for IP-Infringing “Copycat” Brands

Many low-cost suppliers replicate popular designs from premium brands (e.g., mimicking Caesarstone, Silestone, or Cambria patterns) without licensing. These knockoffs may infringe on intellectual property rights, exposing buyers—especially commercial developers or designers—to legal risks. Always confirm that the supplier owns or legally licenses the designs they offer and request IP compliance documentation.

Underestimating Resin Content and UV Sensitivity

Lower-quality quartz often uses excessive polyester resin (above 12%), which can lead to chipping, yellowing, or reduced heat resistance. Some formulations also degrade under UV exposure, making them unsuitable for sunlit areas. Verify the resin type and percentage, and ask for UV stability test results if the countertops will be near windows or in outdoor applications.

Relying Solely on Visual Samples Without Performance Testing

A polished sample may look premium but fail under real-world conditions. Without testing for thermal shock, scratch resistance, or impact strength, buyers risk premature damage. Conduct or request independent performance tests, especially for high-traffic or commercial installations.

Choosing Suppliers Without Traceability or Transparency

Opaque supply chains make it difficult to verify material origins, labor practices, or environmental compliance. Ethical and legal risks increase when sourcing from manufacturers that don’t disclose their production processes. Prioritize suppliers that provide full traceability, including raw material sourcing and factory audit reports.

Assuming All “Branded” Quartz is Authentic

Some intermediaries rebrand generic quartz as premium names or create lookalike brand names to mislead buyers. This not only affects quality but may also void warranties. Verify the brand’s official distributor network and cross-check with the original manufacturer before purchasing.

Avoiding these pitfalls requires due diligence, clear specifications, and partnerships with reputable, transparent suppliers who respect both quality standards and intellectual property rights.

Logistics & Compliance Guide for Engineered Quartz Stone Countertops

Overview

Engineered quartz stone countertops, composed of approximately 90–95% ground quartz mixed with polymer resins and pigments, are popular in residential and commercial construction due to their durability, aesthetic appeal, and low maintenance. This guide outlines key logistics considerations and compliance requirements for the import, export, transportation, and handling of engineered quartz stone countertops across global markets.

International Trade Regulations

Harmonized System (HS) Code Classification

Engineered quartz slabs and countertops are typically classified under the following HS codes:

– 6810.11: “Artificial stone, inedible, whether or not reinforced: Slabs, tiles, and similar articles, simply cut or sawn, of a kind used for building or industrial purposes”

– 6810.19: “Other artificial stone articles”

Accurate classification is essential for determining import duties, taxes, and regulatory requirements. Classification may vary by country; consult local customs authorities for precise codes.

Import/Export Documentation

Required documentation includes:

– Commercial Invoice

– Packing List

– Bill of Lading (B/L) or Air Waybill (AWB)

– Certificate of Origin

– Material Safety Data Sheet (MSDS)

– Product Conformity Certificate (e.g., CE, NSF, or GreenGuard)

– Phytosanitary Certificate (if wooden packaging is used – ISPM 15 compliant)

Ensure all documents are accurate and consistent to avoid customs delays.

Transportation & Handling

Packaging Requirements

- Slabs must be securely packed vertically in wooden crates or metal racks with edge protection.

- Use moisture-resistant wrapping and desiccants to prevent staining and condensation during transit.

- Wooden packaging must comply with ISPM 15 standards (heat-treated and stamped) to prevent the spread of pests.

Loading & Securing Cargo

- Slabs must be loaded vertically to prevent breakage; never stack horizontally.

- Use dunnage and straps to prevent shifting during shipping.

- For container shipments, ensure even weight distribution and avoid overloading.

Modes of Transport

- Maritime (FCL/LCL): Most cost-effective for large shipments. Containers should be weatherproof and secured against moisture.

- Air Freight: Used for urgent or high-value shipments; higher cost and weight restrictions apply.

- Overland (Trucking): Required for domestic and regional distribution. Use suspension-equipped vehicles to minimize vibration damage.

Safety & Material Compliance

Material Safety Data Sheet (MSDS/SDS)

- Required under OSHA’s Hazard Communication Standard (29 CFR 1910.1200) in the U.S. and REACH/GHS in the EU.

- Must detail chemical composition, health hazards (e.g., silica dust), safe handling, and disposal procedures.

- Note: While engineered quartz contains minimal free silica, cutting or grinding generates respirable crystalline silica (RCS), a known carcinogen.

Regulatory Standards & Certifications

- NSF/ANSI 51: Certification for food zone surfaces in kitchens and food prep areas.

- GREENGUARD Gold: Ensures low chemical emissions, critical for indoor air quality compliance in schools and healthcare facilities.

- CE Marking (EU): Required for construction products under the Construction Products Regulation (CPR) 305/2011/EU, indicating conformity with health, safety, and environmental standards.

- CARB Phase 2 (California): Regulates formaldehyde emissions from composite wood products used in packaging or cabinetry; relevant if quartz is part of a larger assembly.

Environmental & Sustainability Compliance

VOC Emissions

- Engineered quartz must meet low volatile organic compound (VOC) standards in jurisdictions such as California (CA 01350) and the EU (EMICODE EC1 PLUS).

- Use low-emission resins during manufacturing to comply with green building standards (e.g., LEED, BREEAM).

Waste & Recycling

- Off-cuts and damaged slabs should be recycled through approved stone recyclers.

- Follow local regulations for disposal of resin-contaminated waste.

- Some manufacturers offer take-back programs for production waste.

Installation & End-User Compliance

Workplace Safety (Installation Phase)

- Installers must follow OSHA (U.S.) or equivalent local regulations when cutting or grinding quartz.

- Required controls include:

- Wet-cutting methods to suppress dust

- Local exhaust ventilation (LEV) systems

- NIOSH-approved respirators (N95 or higher)

- Training on silica exposure risks (per OSHA 29 CFR 1926.1153)

Building Code Compliance

- Countertops must meet structural requirements if used in load-bearing applications (rare, but possible in commercial designs).

- Verify fire resistance ratings when used near cooking appliances (most quartz is heat-resistant up to 150°C/300°F but can be damaged by sudden temperature changes).

Regional Compliance Highlights

United States

- Compliance with OSHA silica rule, CARB, and NSF standards is mandatory.

- Customs clearance via U.S. CBP using accurate HS code 6810.11.

European Union

- Must comply with REACH, RoHS (for any electronic components in smart countertops), and CPR.

- CE marking required; technical documentation must be available upon request.

Canada

- Adhere to Health Canada’s Consumer Chemicals and Containers Regulations (CCCR) if resins contain hazardous substances.

- Use of CSA B51.1 for stone countertop installation standards.

Australia & New Zealand

- Comply with AS/NZS 4020 for water contact surfaces and AS/NZS ISO 14001 for environmental management.

- Import permits may be required depending on resin composition.

Conclusion

Successfully managing the logistics and compliance of engineered quartz stone countertops requires attention to international trade rules, safe handling practices, regional regulatory standards, and environmental considerations. Proactive documentation, adherence to safety protocols, and engagement with certified suppliers ensure smooth supply chain operations and legal compliance across markets.

In conclusion, sourcing engineered quartz stone countertops offers a reliable, durable, and aesthetically versatile solution for both residential and commercial projects. With its non-porous surface, low maintenance requirements, and resistance to stains, scratches, and heat, engineered quartz provides a practical alternative to natural stone. When sourcing, it is essential to partner with reputable suppliers and manufacturers that adhere to quality standards, offer consistent color and pattern availability, and provide comprehensive warranties. Evaluating factors such as price, lead times, sustainability practices, and customization options will ensure a successful procurement process. Ultimately, investing in high-quality engineered quartz countertops enhances the long-term value, functionality, and appeal of any space.