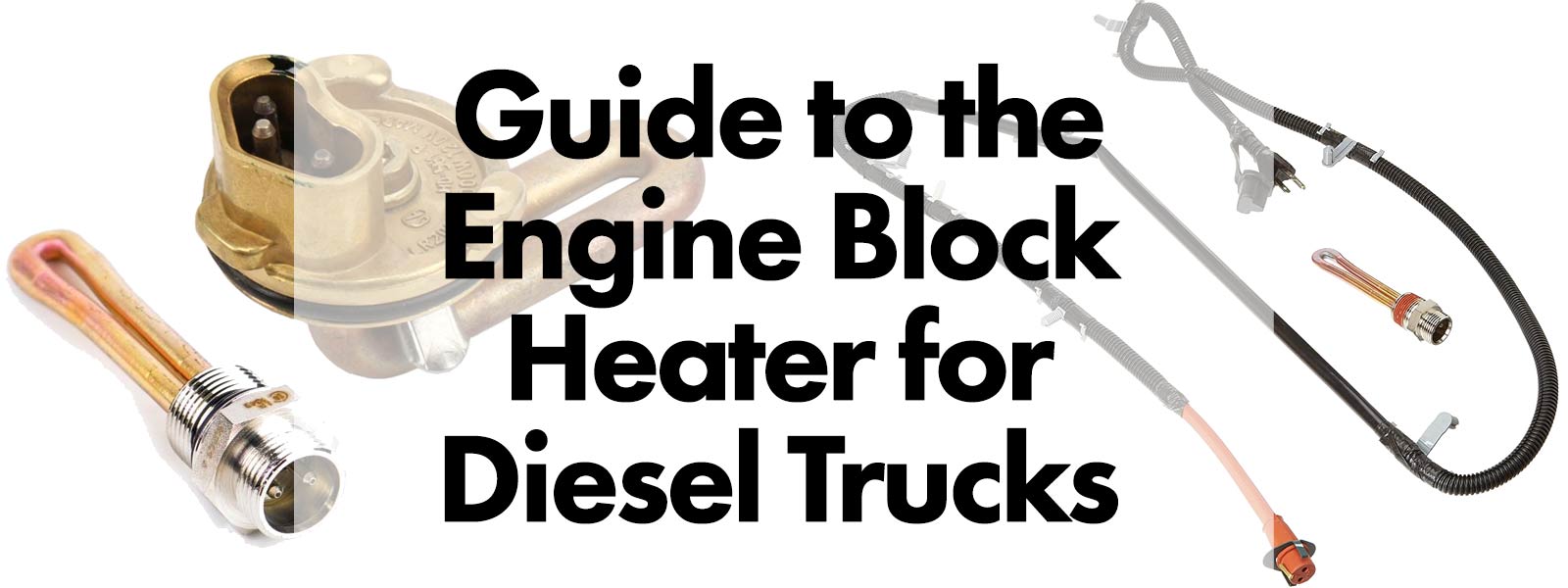

The global engine block heater market is experiencing steady growth, driven by increasing demand for improved cold-weather engine performance, especially in commercial diesel vehicles and heavy-duty machinery. According to Mordor Intelligence, the engine block heater market is projected to grow at a CAGR of approximately 4.8% from 2023 to 2028, fueled by colder climate regions’ reliance on pre-heating systems to ensure reliable engine starts and reduce wear. Diesel engines, in particular, benefit from block heaters due to their higher compression ratios and slower cold-start performance compared to gasoline engines. With rising adoption in North America and Northern Europe, and growing industrial activity in remote, low-temperature environments, the need for reliable, efficient engine block heaters has never been more critical. In this data-driven landscape, seven manufacturers have distinguished themselves through innovation, durability, and performance, setting the standard for diesel engine readiness in extreme conditions.

Top 7 Engine Block Heater For Diesel Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 In

Domain Est. 1997

Website: hotstart.com

Key Highlights: Hotstart’s line of In-Block heaters mount directly into the water jacket of the engine block, reducing engine wear due to cold starts by up to 50%….

#2 Mopar Engine Block Heater For 6.7L Diesel Engine

Domain Est. 2012

Website: allmoparparts.com

Key Highlights: Protect the internal components of your Ram HD 2500 / 3500 / 4500’s 6.7L Diesel Engine and extend its service life with this factory Mopar engine block heater ……

#3 Tag: Engine Block Heater

Domain Est. 2017

Website: warmda.com

Key Highlights: Free deliveryWe are a leading manufacturer of diesel and engine block heaters with a wealth of innovative knowledge and 25 years’ experience….

#4 KAT’S Heaters

Domain Est. 1996

Website: nickson.com

Key Highlights: Beginning with engine block heaters, the KAT’S product line has expanded to include battery heaters, circulation heaters, diesel starting fluid systems, vehicle ……

#5 Zerostart Block Heaters

Domain Est. 2001

Website: phillipsandtemro.com

Key Highlights: Engine block heaters designed and tested for each individual engine application. Manufactured under the Zerostart / Temro brands….

#6 Vvkb Heaters: Premier Vehicle & Marine Heating

Domain Est. 2012

Website: vvkb.com

Key Highlights: Vvkb: Expert in diesel & engine block heaters. 27+ years of global trust. Elevate vehicle & marine comfort with our leading solutions….

#7 Engine Block Heater

Domain Est. 2014

Expert Sourcing Insights for Engine Block Heater For Diesel

H2: 2026 Market Trends for Engine Block Heater for Diesel

The global market for diesel engine block heaters is poised for moderate but steady growth by 2026, driven by a combination of environmental regulations, cold-climate demand, and advancements in heating technology. Despite the increasing shift toward electric vehicles (EVs), diesel-powered engines remain critical in commercial transportation, agriculture, construction, and emergency backup power systems—sectors where reliable cold-weather operation is essential. As a result, engine block heaters continue to play a vital role in ensuring diesel engine performance, fuel efficiency, and longevity in low-temperature environments.

-

Continued Demand in Cold-Climate Regions

North America, Northern Europe, Russia, and parts of East Asia will remain key markets for diesel engine block heaters due to severe winter conditions. Governments and private fleets in these regions are increasingly adopting block heaters as standard winter preparedness equipment. In countries like Canada and Sweden, regulations and incentives promoting engine pre-heating to reduce emissions during cold starts are expected to bolster market demand. -

Integration with Smart Technologies

By 2026, the engine block heater market will see a rise in smart, Wi-Fi-enabled, and app-controlled heating systems. These advanced models allow users to remotely activate the heater via smartphones or voice assistants, optimizing fuel efficiency and convenience. Integration with vehicle telematics and fleet management systems will be especially valuable for logistics and transportation companies aiming to reduce downtime and cold-start emissions. -

Focus on Energy Efficiency and Eco-Friendly Designs

With increasing scrutiny on energy consumption and carbon emissions, manufacturers are developing more energy-efficient block heaters that use less electricity while delivering faster warm-up times. Developments in materials, such as improved thermal conductivity and insulation, are enhancing heater performance. Additionally, some models are being designed to operate with renewable energy sources, like solar-powered garage systems, aligning with broader sustainability goals. -

Growth in Industrial and Commercial Applications

The construction, mining, and agricultural sectors rely heavily on diesel-powered machinery, much of which operates in remote or cold environments. As these industries modernize their fleets, there will be a growing uptake of engine block heaters as OEM-installed or aftermarket accessories. The need for reliable equipment uptime during winter months will drive adoption, especially in Arctic and high-altitude regions. -

Regulatory Pressure to Reduce Cold-Start Emissions

Cold diesel engines emit significantly higher levels of particulate matter and NOx during startup. Regulatory bodies in the EU, U.S., and Canada are tightening emissions standards, indirectly promoting the use of engine pre-heating solutions. By 2026, engine block heaters may be increasingly viewed not just as convenience tools, but as emission-reduction technologies eligible for incentives or compliance credits. -

Competition from Alternative Technologies

While demand remains strong, the long-term outlook for diesel engine block heaters faces headwinds due to the rise of battery electric and hybrid vehicles, which do not require traditional engine heating. However, hybrid diesel-electric systems and range-extended electric vehicles may still utilize block heaters, preserving a niche market. Additionally, auxiliary heaters for cabin and battery pre-warming in cold climates may partially overlap with traditional block heater functions. -

Market Consolidation and Innovation Among Key Players

Leading manufacturers such as Webasto, Eberspächer, and Philips Industries are expected to dominate the 2026 market through product innovation, global distribution networks, and strategic partnerships with OEMs. There will likely be increased mergers and acquisitions as companies aim to expand their product portfolios into integrated thermal management systems.

In conclusion, while the diesel engine block heater market will not experience explosive growth by 2026 due to the broader transition away from internal combustion engines, it will remain a resilient niche supported by practical, regulatory, and technological factors. The market’s evolution will be characterized by smarter, more efficient, and environmentally aligned products tailored to the enduring needs of diesel engine users in cold climates.

Common Pitfalls Sourcing an Engine Block Heater for Diesel: Quality and IP Rating Concerns

When sourcing an engine block heater for diesel engines, overlooking quality and Ingress Protection (IP) rating can lead to significant performance, safety, and reliability issues. Here are the most common pitfalls to avoid:

1. Choosing Low-Quality Materials and Construction

- Pitfall: Selecting heaters made from substandard metals (e.g., thin steel or aluminum) or poor-quality heating elements.

- Consequences: Reduced lifespan due to corrosion, especially in high-sulfur diesel environments; inefficient heat transfer; risk of cracking or leaking under thermal stress.

- Solution: Opt for block heaters constructed from durable, corrosion-resistant materials like stainless steel or high-grade aluminum. Verify manufacturer certifications (e.g., ISO 9001) and look for reputable brands with proven performance in heavy-duty applications.

2. Ignoring Ingress Protection (IP) Rating

- Pitfall: Using a heater with an insufficient IP rating for harsh operating environments.

- Consequences: Moisture, dust, or road debris entering the electrical components can cause short circuits, electrical failures, or even fire hazards—especially critical in off-road, marine, or winter conditions.

- Solution: Choose a heater with a minimum IP65 rating (dust-tight and protected against water jets) for most diesel applications. For extremely wet or submerged conditions (e.g., marine or construction), consider IP67 or IP68 rated units.

3. Poor Sealing and Gasket Integrity

- Pitfall: Inadequate sealing between the heater and engine block.

- Consequences: Coolant leaks, loss of system pressure, engine overheating, or contamination of electrical components.

- Solution: Ensure the heater includes high-temperature, durable O-rings or gaskets and is designed specifically for diesel engine tolerances. Verify compatibility with your engine’s freeze plug size and coolant system.

4. Overlooking Voltage and Wattage Compatibility

- Pitfall: Selecting a heater with incorrect voltage (e.g., 120V vs. 240V) or insufficient wattage for diesel engine mass.

- Consequences: Inadequate warming, prolonged warm-up times, or electrical circuit overloads.

- Solution: Match heater wattage to engine size (typically 400–1500W for most diesel engines) and ensure voltage aligns with available power sources. Larger diesel engines may require higher wattage for effective pre-heating.

5. Skipping Certifications and Safety Standards

- Pitfall: Purchasing non-certified or counterfeit heaters without safety listings.

- Consequences: Increased fire risk, non-compliance with regulations, voided warranties, and lack of insurance coverage.

- Solution: Only source heaters with recognized safety certifications such as UL, CSA, CE, or ETL—especially important for commercial or fleet use.

By prioritizing build quality, ensuring an appropriate IP rating, and verifying compatibility and certifications, you can avoid costly failures and ensure reliable cold-weather operation of your diesel engine.

Logistics & Compliance Guide for Engine Block Heater for Diesel

Product Classification and HS Code

Identify the correct Harmonized System (HS) code for engine block heaters used in diesel engines. Typically, these fall under:

– HS Code: 8516.79 (Electric instantaneous or storage water heaters; electric soil heating apparatus and electric heating resistors, other)

Note: Classification may vary by country; verify with local customs authorities.

Import/Export Regulations

Ensure compliance with import and export regulations in both origin and destination countries:

– Obtain necessary export licenses if required by the exporting country.

– Confirm import permits or certifications (e.g., CE, UKCA, RoHS, EAC) depending on the destination market.

– For the U.S., compliance with Department of Commerce export controls may apply if dual-use technology is involved.

Safety and Electromagnetic Compliance

Engine block heaters must meet regional safety and electromagnetic compatibility (EMC) standards:

– North America: UL 499 (Electric Heating Equipment) and FCC Part 15 (EMI).

– European Union: CE marking per Low Voltage Directive (LVD 2014/35/EU) and EMC Directive (2014/30/EU).

– UK: UKCA marking with conformity to analogous UK regulations.

– Other Regions: Check local standards (e.g., CCC in China, KC in South Korea).

Packaging and Labeling Requirements

Use robust packaging to prevent damage during transit. Labeling must include:

– Product name, model number, voltage, wattage, and compliance marks.

– Manufacturer/importer contact details.

– Safety warnings (e.g., risk of burns, electrical hazards).

– Multilingual labeling where required (e.g., EU, Canada).

Shipping and Transportation

Follow international shipping guidelines:

– Classify as non-hazardous goods (unless containing restricted materials).

– Use temperature-controlled transport if components are sensitive.

– Comply with IATA/IMDG rules if shipping by air or sea, especially for lithium components (if applicable).

– Declare accurate weight, dimensions, and value on shipping documents.

Customs Documentation

Prepare complete documentation to avoid delays:

– Commercial invoice

– Packing list

– Bill of lading or air waybill

– Certificate of Origin

– Test reports or conformity certificates (e.g., CE, UL)

– Importer Security Filing (ISF) for U.S. shipments

Environmental and Chemical Compliance

Ensure adherence to substance restrictions:

– RoHS (EU/UK): Restricts lead, mercury, cadmium, etc.

– REACH (EU): Requires disclosure of Substances of Very High Concern (SVHC).

– Proposition 65 (California): Warn if containing listed chemicals (e.g., lead in solder).

Warranty and After-Sales Compliance

- Provide warranty information in local language.

- Comply with local consumer protection laws regarding returns and repairs.

- Maintain records for traceability (batch/serial numbers).

Country-Specific Considerations

- Canada: Must meet CSA C22.2 No. 42 standards; bilingual (English/French) labeling required.

- Russia/Belarus: EAC certification (CU TR) mandatory.

- Australia/NZ: RCM marking and compliance with AS/NZS 60335.1.

Audit and Recordkeeping

Maintain records of compliance documentation, test reports, and customs filings for a minimum of 5–10 years, depending on jurisdiction. Conduct periodic audits to ensure continued compliance with evolving regulations.

Conclusion for Sourcing an Engine Block Heater for Diesel Engines:

Sourcing a suitable engine block heater for diesel engines is a crucial step in ensuring reliable cold-weather operation, improved fuel efficiency, reduced emissions, and extended engine life. Diesel engines, due to their higher compression ratios and reliance on optimal operating temperatures for efficient combustion, benefit significantly from pre-warming solutions like engine block heaters.

After evaluating factors such as heater type (core plug, in-line coolant, magnetic, or oil pan), power requirements, compatibility with engine make and model, installation complexity, and durability, it becomes evident that a well-chosen block heater enhances engine performance in low-temperature environments. Electric heating elements integrated directly into the engine block or cooling system offer the most consistent and effective results.

When sourcing, prioritize reputable manufacturers with proven reliability and compliance with safety standards. Consider regional climate conditions, availability of power sources (especially in remote or off-grid locations), and ease of maintenance. Additionally, integrating a timer or smart control system can optimize energy usage and ensure the engine is warmed just before operation.

In summary, investing in a high-quality, properly matched engine block heater tailored to the specific diesel engine application not only prevents cold-start issues but also contributes to long-term engine health and operational efficiency. Careful sourcing and installation will deliver significant returns in performance, reliability, and cost savings over time.