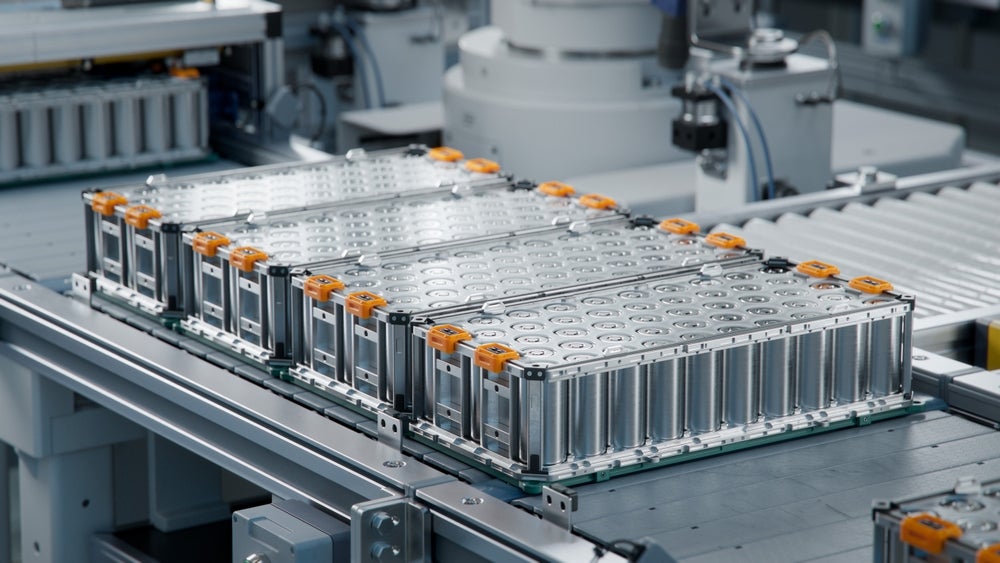

The global battery market is undergoing rapid expansion, driven by surging demand for electric vehicles (EVs), renewable energy storage, and consumer electronics. According to Grand View Research, the global battery market size was valued at USD 116.6 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 12.4% from 2024 to 2030. This growth is further fueled by government initiatives promoting clean energy and increasing investments in grid-scale energy storage solutions. As the world transitions toward electrification, a select group of manufacturers—often referred to as “battery empires”—have emerged as dominant players, leveraging advanced technology, vast production capacity, and global supply chains to lead the charge. These top-tier companies are not only shaping the future of energy storage but are also playing a pivotal role in decarbonizing transportation and power systems worldwide. Here are the top 7 battery manufacturers at the forefront of this transformative industry.

Top 7 Empire Battery Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Discover Battery

Domain Est. 2007

Website: discoverbattery.com

Key Highlights: Empire Batteries, Inc. We’ve been impressed with the performance and reliability of Discover batteries. We are keen for our customers in Europe and the rest ……

#2 Duracell: Batteries

Domain Est. 1995

Website: duracell.com

Key Highlights: Explore AA batteries, rechargeable batteries, chargers, coin button batteries and more from Duracell, the longer-lasting and #1 trusted battery brand….

#3 Empire Level

Domain Est. 1996

Website: empirelevel.com

Key Highlights: Empire delivers a broad range of layout tools for the construction trades….

#4 Empire State Development Announces Lithium Battery …

Domain Est. 2002

Website: esd.ny.gov

Key Highlights: Empire State Development Announces Lithium Battery Company Natrion to Build New Manufacturing Facility in Western New York. December 3, 2025….

#5 Empire

Domain Est. 2004

Website: batteryjunction.com

Key Highlights: Empire is one of the leading suppliers of unique batteries. Empire has a large manufacturing headquarters location in Deer Park, NY and thrives by providing ……

#6 Empire R11234 Battery Backup Pack for Electric Ignition

Domain Est. 2009

Website: fireplaceblowersonline.com

Key Highlights: Replacement Dexen battery pack with 6″ wire leads for gas log sets, fireplaces, stoves and inserts. Works with LP and NG gas models….

#7 Empire Batteries, Inc

Website: empirebatteriesor.net

Key Highlights: We are the Fleet Battery specialists and authorized distributors for Trojan, Crown, Odyssey, and Lifeline batteries. Deep cycle batteries for use in golf carts ……

Expert Sourcing Insights for Empire Battery

H2: 2026 Market Trends Analysis for Empire Battery

As the global energy storage and electric mobility sectors continue to evolve rapidly, Empire Battery is poised to navigate a dynamic market landscape in 2026. This analysis outlines key macroeconomic, technological, and industry-specific trends shaping the battery sector and their implications for Empire Battery’s strategic positioning.

1. Accelerated Growth in Electric Vehicles (EVs)

The EV market is projected to experience sustained expansion in 2026, with global EV sales expected to surpass 40 million units annually. This growth is driven by tightening emissions regulations, government incentives, and declining battery costs. For Empire Battery, this presents a significant opportunity to scale production of lithium-ion and next-generation batteries tailored for automotive applications. Strategic partnerships with EV OEMs will be critical to capturing market share.

2. Shift Toward Solid-State and Advanced Chemistries

In 2026, solid-state batteries are anticipated to move from pilot production to early commercialization. With higher energy density, improved safety, and faster charging capabilities, this technology represents a competitive frontier. Empire Battery must invest in R&D and pilot lines to remain competitive. Delays in adopting advanced chemistries could risk obsolescence against tech-forward rivals like CATL, LG Energy Solution, and Toyota-backed ventures.

3. Expansion of Stationary Energy Storage

Grid-scale and residential energy storage systems are expected to grow at a CAGR of over 15% through 2026. Renewables integration, demand for energy resilience, and supportive policies (e.g., U.S. Inflation Reduction Act, EU Green Deal) are fueling demand. Empire Battery can leverage its manufacturing base to offer cost-competitive solutions for utility and commercial customers, particularly in emerging markets with unreliable grids.

4. Supply Chain Resilience and Localization

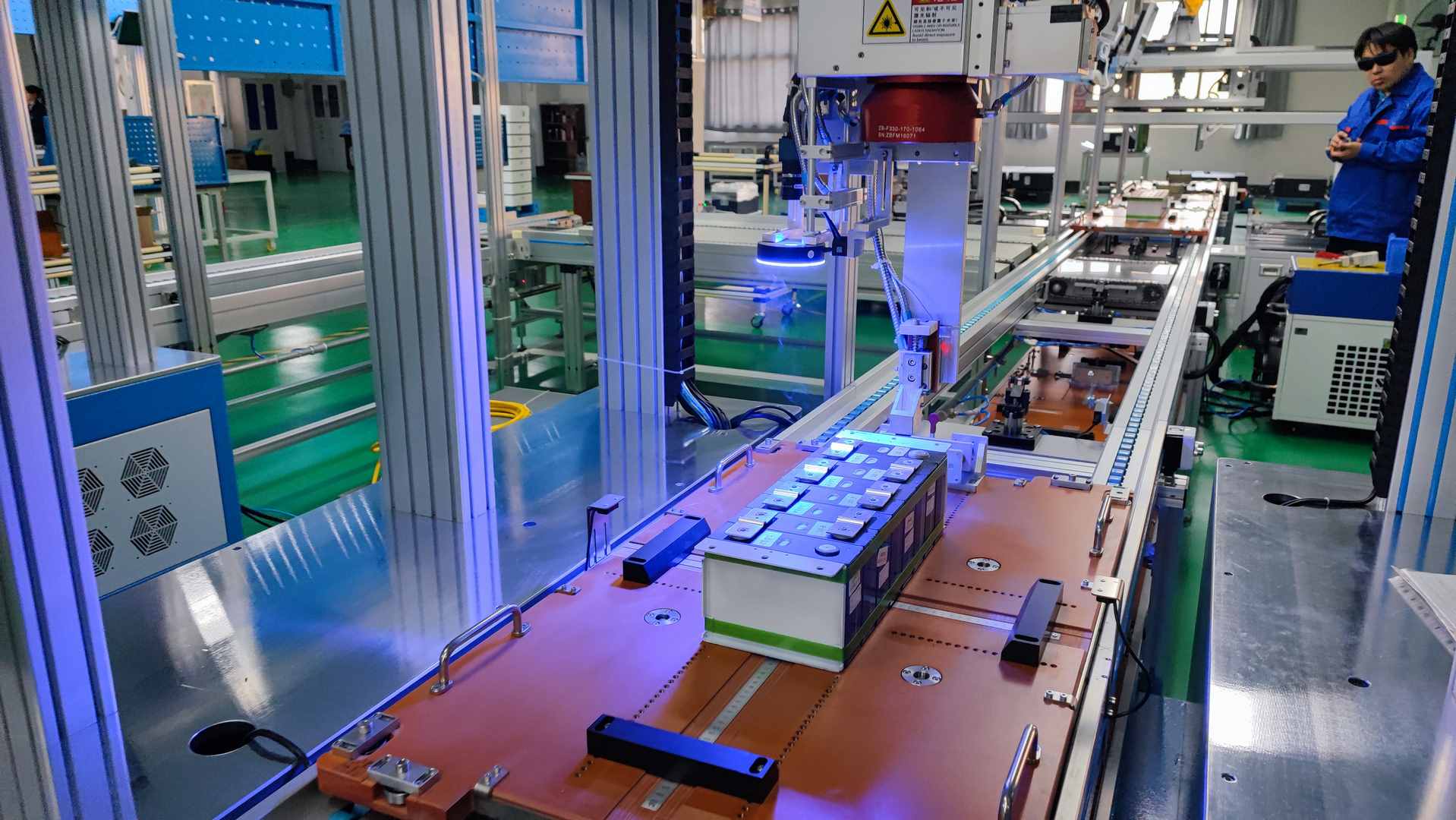

Geopolitical tensions and trade policies are pushing automakers and governments to localize battery supply chains. In North America and Europe, “onshoring” mandates favor domestic battery production. Empire Battery should consider expanding manufacturing facilities in key regions to qualify for tax credits and reduce logistics risks. Securing long-term contracts for critical raw materials—especially lithium, nickel, and cobalt—will be vital to mitigate price volatility.

5. Sustainability and Circular Economy Pressures

Regulatory bodies and consumers are demanding greater transparency in battery lifecycle management. The EU’s Battery Regulation, effective in 2026, mandates carbon footprint labeling, recycled content requirements, and extended producer responsibility. Empire Battery must strengthen its recycling infrastructure and invest in closed-loop systems to comply and enhance brand reputation.

6. Competitive Intensification and Price Pressure

The battery market remains highly competitive, with pricing continuing to decline due to economies of scale and technological improvements. Average lithium-ion battery pack prices are projected to fall below $70/kWh by 2026. To maintain margins, Empire Battery must focus on operational efficiency, vertical integration, and differentiation through performance or service offerings.

Conclusion

In 2026, Empire Battery operates in a high-growth yet fiercely competitive environment. Success will depend on its ability to innovate rapidly, adapt to regulatory shifts, secure supply chains, and deliver sustainable, cost-effective energy storage solutions. A proactive strategy focused on technology leadership, geographic diversification, and circularity will position Empire Battery for long-term resilience and market relevance.

Common Pitfalls Sourcing Empire Battery (Quality, IP)

When sourcing batteries—especially from suppliers or manufacturers associated with or resembling names like “Empire Battery”—buyers often encounter significant risks related to quality control and intellectual property (IP) infringement. Being aware of these pitfalls is essential to avoid supply chain disruptions, legal liabilities, and reputational damage.

Poor Quality Control and Inconsistent Performance

One of the most frequent issues when sourcing batteries from less-regulated or ambiguous suppliers is inconsistent quality. Empire Battery, or similarly named entities, may lack standardized manufacturing processes, resulting in:

- Variable cell performance, including reduced cycle life, lower energy density, or inconsistent charge retention.

- Lack of proper testing for safety standards such as overcharge, short-circuit, and thermal runaway.

- Use of recycled or substandard materials, which increase the risk of premature failure or safety hazards like swelling or leakage.

These quality issues can lead to product returns, warranty claims, and safety incidents—especially critical in applications like medical devices, electric vehicles, or consumer electronics.

Intellectual Property (IP) Infringement Risks

Another major concern is the potential for IP violations. Some manufacturers operating under names like Empire Battery may:

- Clone or reverse-engineer patented battery designs, chemistries, or management systems without authorization.

- Use counterfeit branding or mimic well-known battery trademarks, leading to customs seizures or legal action.

- Supply batteries integrated with infringing circuitry or firmware, implicating the buyer in IP disputes even if unintentional.

Sourcing from such suppliers exposes companies to litigation, import bans, and damage to brand integrity, particularly in markets with strict IP enforcement like the U.S., EU, or Japan.

Lack of Certification and Compliance Documentation

Many problematic suppliers fail to provide authentic certifications (e.g., UL, CE, UN38.3, IEC 62133), or supply falsified documentation. This creates compliance risks, especially for regulated industries or international shipments. Without verifiable proof of compliance, companies may face:

- Rejected shipments at customs.

- Liability in case of product failure or safety incidents.

- Ineligibility for insurance or regulatory approvals.

Supply Chain Opacity and Traceability Gaps

Empire Battery-like suppliers may operate through opaque supply chains, making it difficult to trace raw materials or verify ethical sourcing (e.g., conflict-free minerals). This lack of transparency increases exposure to:

- Reputational risk from association with unethical labor or environmental practices.

- Regulatory non-compliance with laws like the U.S. Uyghur Forced Labor Prevention Act (UFLPA).

Mitigation Strategies

To avoid these pitfalls:

- Conduct thorough due diligence, including on-site audits and third-party testing.

- Require complete and verifiable certification packages.

- Include IP indemnification clauses in supplier contracts.

- Work with legally registered, transparent manufacturers with a verifiable track record.

Sourcing batteries requires caution—prioritizing low cost over quality and IP compliance can lead to far greater expenses down the line.

Logistics & Compliance Guide for Empire Battery

This guide outlines the essential logistics and compliance protocols for Empire Battery to ensure safe, efficient, and legally compliant handling, transportation, storage, and disposal of battery products.

Regulatory Compliance

Empire Battery must adhere to all applicable local, national, and international regulations governing the transportation and handling of batteries, particularly lithium-ion and lead-acid types. Key regulatory frameworks include:

- DOT (Department of Transportation) – 49 CFR: Governs safe transportation of hazardous materials in the U.S., including classification, packaging, labeling, and documentation.

- IATA Dangerous Goods Regulations (DGR): Applies to air transport of batteries; requires proper classification, packaging, marking, labeling, and shipper training.

- IMDG Code: Required for international sea freight shipments; outlines safety standards for maritime transport.

- EPA and RCRA (Resource Conservation and Recovery Act): Regulates proper disposal and recycling of spent batteries to prevent environmental contamination.

- REACH and RoHS (EU Regulations): Applies to products sold in the European Union; restricts hazardous substances and ensures chemical safety.

All personnel involved in logistics operations must be trained and certified in relevant regulations and maintain up-to-date documentation.

Packaging & Labeling Standards

Proper packaging and labeling are critical for safety and regulatory compliance:

- Batteries must be packed to prevent short circuits, physical damage, and unintended activation.

- Use non-conductive inner packaging (e.g., individual plastic bags or separators) for loose batteries.

- Outer packaging must be strong enough to withstand normal handling and meet UN-certified standards when required.

- Clearly label packages with:

- Proper shipping name (e.g., “Lithium Ion Batteries, UN3480”)

- UN number

- Hazard Class 9 label for lithium batteries

- Orientation arrows (if required)

- “Lithium Battery Mark” for air shipments per IATA

- Include required documentation such as Safety Data Sheets (SDS) and shipper’s declarations for dangerous goods.

Transportation & Carrier Coordination

Empire Battery must partner with certified carriers experienced in handling hazardous materials:

- Pre-qualify all freight carriers for DOT, IATA, or IMDG compliance.

- Ensure accurate classification of battery shipments (e.g., excepted, limited, or full regulation quantities).

- Maintain real-time shipment tracking and communicate handling requirements to carriers.

- Avoid mixing incompatible goods during transport.

- Implement incident response procedures for spills, leaks, or damage during transit.

Storage & Handling Procedures

Safe storage and handling practices reduce risks of fire, chemical exposure, and damage:

- Store batteries in a dry, temperature-controlled environment away from direct sunlight and heat sources.

- Keep batteries in original packaging until use; separate by chemistry type (e.g., lithium, lead-acid).

- Use non-conductive shelving and avoid stacking unless designed for battery storage.

- Prohibit smoking, open flames, and use of metal tools near battery storage areas.

- Train staff in emergency response (e.g., using fire extinguishers rated for electrical/chemical fires).

Reverse Logistics & Recycling

Empire Battery supports sustainable practices through responsible end-of-life management:

- Establish a take-back program for used or defective batteries.

- Partner with certified recyclers compliant with EPA, R2, or e-Stewards standards.

- Ensure proper documentation (e.g., manifests) for battery returns and recycling.

- Label and package returned batteries according to hazardous material regulations.

- Maintain records of recycling and disposal activities for audit and compliance purposes.

Documentation & Recordkeeping

Accurate documentation is essential for regulatory audits and traceability:

- Retain shipping manifests, SDS, training records, and compliance certifications for a minimum of three years.

- Maintain an internal compliance log for audits and inspections.

- Use digital tracking systems to monitor battery movement from origin to destination and through reverse logistics.

Training & Accountability

All employees and contractors involved in logistics must undergo regular training:

- Initial and annual refresher training on hazardous materials handling.

- Certification for personnel preparing dangerous goods shipments.

- Clear assignment of compliance responsibilities within the logistics team.

- Internal audits to verify adherence to procedures and regulations.

Failure to comply with logistics and safety regulations may result in fines, shipment delays, environmental harm, or safety incidents. Empire Battery is committed to the highest standards in compliance and operational excellence.

Conclusion for Sourcing Empire Battery:

Sourcing batteries from Empire Battery presents a strategic opportunity to secure reliable, high-quality power solutions for various applications, including automotive, industrial, and renewable energy systems. Empire Battery’s strong reputation for durability, consistent performance, and technical support makes it a trusted supplier in the market. Their extensive product range, competitive pricing, and commitment to innovation align well with the needs of distributors, OEMs, and end-users seeking dependable energy storage solutions.

However, as with any supplier, due diligence is essential. Considerations such as supply chain stability, warranty terms, and after-sales service should be evaluated to ensure long-term satisfaction. Additionally, comparing Empire Battery’s offerings with alternative brands can help confirm that it is the optimal choice based on cost, performance, and compatibility with specific requirements.

In conclusion, Empire Battery is a credible and capable supplier worth considering in your procurement strategy. With proper vendor assessment and ongoing performance monitoring, sourcing from Empire Battery can contribute to improved operational efficiency and customer satisfaction.