The global embroidery machine market is experiencing robust growth, driven by rising demand for customized textiles and increasing automation in small-scale manufacturing. According to a 2023 report by Mordor Intelligence, the market is projected to grow at a CAGR of 6.8% from 2023 to 2028, fueled by advancements in digitalization and the expansion of e-commerce platforms that enable personalized apparel production. Grand View Research further supports this trend, estimating the market size to reach USD 6.2 billion by 2030, with small business manufacturers representing a significant share due to their agility and focus on niche, high-value products. As competition intensifies, selecting the right embroidery machine—balancing precision, speed, scalability, and cost—has become a critical strategic decision for small manufacturers aiming to capture market share. In this data-driven landscape, investing in high-performance equipment is no longer a luxury but a necessity for sustainable growth.

Top 10 Embroidery Machine For Small Business Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

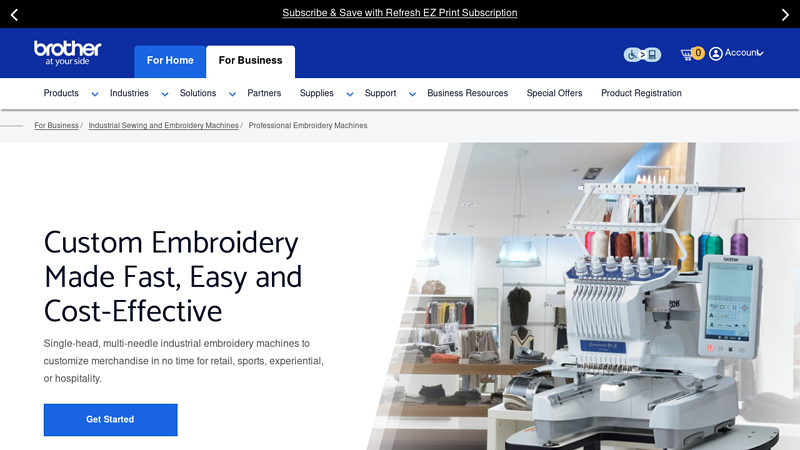

#1 Industrial Embroidery Machines

Domain Est. 2000

Website: brother-usa.com

Key Highlights: Free delivery over $50 · 30-day returnsSingle-head, multi-needle industrial embroidery machines to customize merchandise in no time for retail, sports, experiential, or hospitalit…

#2 Tajima Group|The World’s Favorite Embroidery machines

Domain Est. 2001

Website: tajima.com

Key Highlights: Tajima is a leading embroidery machine manufacturer. Made in Japan.| Learn more about our product information, case studies, tips and solutions for your…

#3 Tajima

Domain Est. 2002

Website: hsi.us

Key Highlights: The MOST TRUSTED commercial embroidery machine in the industry. Tajima machines have set the standard for advanced technology and proven efficiency in ……

#4 ColDesi, Inc. Make Your Own Customized Products

Domain Est. 2010

Website: coldesi.com

Key Highlights: Leading provider of customized products equipment. Including: commercial embroidery machines, direct-to-garment printers, and more….

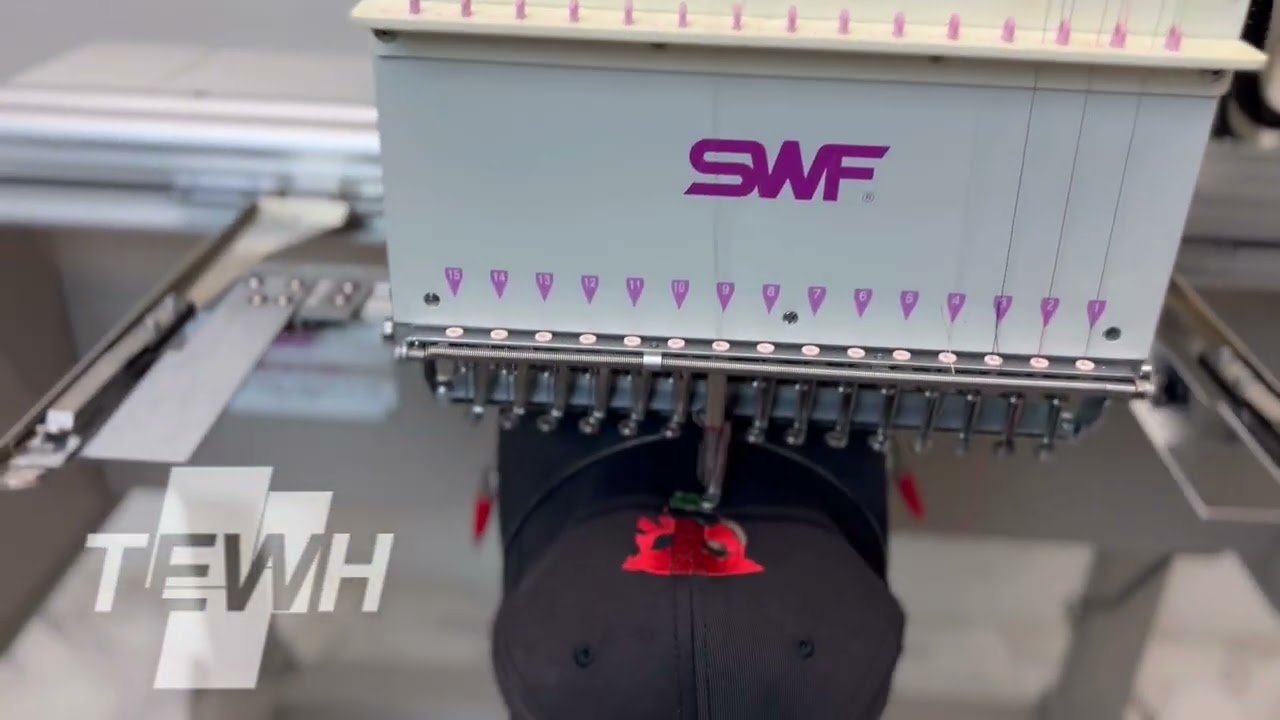

#5 SWF

Domain Est. 2019

Website: swfkorea.co.kr

Key Highlights: SWF offers industrial and commercial embroidery machines in a wide variety of styles and configurations to fit the embroidery equipment needs of small to large ……

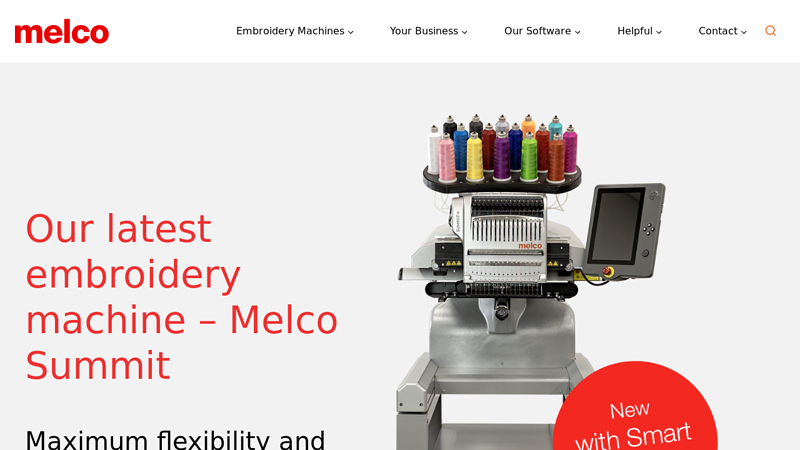

#6 Melco

Domain Est. 1993

Website: melco.com

Key Highlights: Melco has the solutions your business needs: innovative embroidery machines, DTG printers, digitizing software, and outstanding tech support….

#7 Baby Lock Aurora Sewing and Embroidery Machine

Domain Est. 1996

Website: babylock.com

Key Highlights: Free delivery over $100 30-day returnsCompact in size, it’s loaded with the features you need, like 303 built-in embroidery designs and 191 stitches. Get ready to step into the wor…

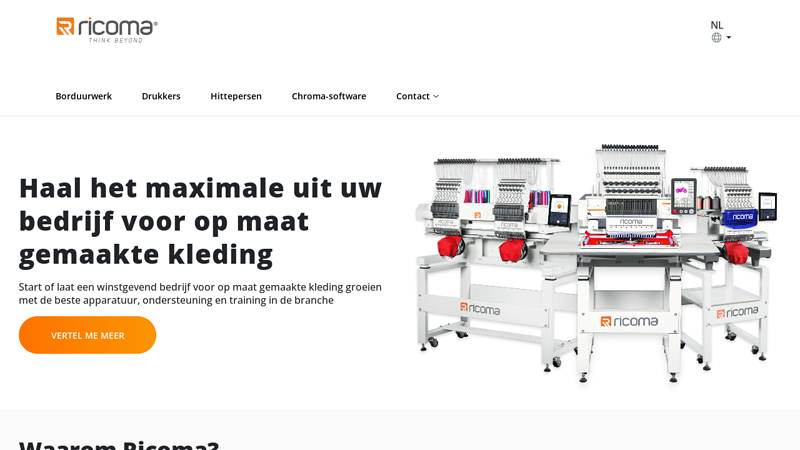

#8 to Ricoma

Domain Est. 2005

Website: staging.ricoma.com

Key Highlights: Our all-inclusive embroidery machines come equipped with all the accessories and tools you need to embroider flats and caps and get started on your first orders ……

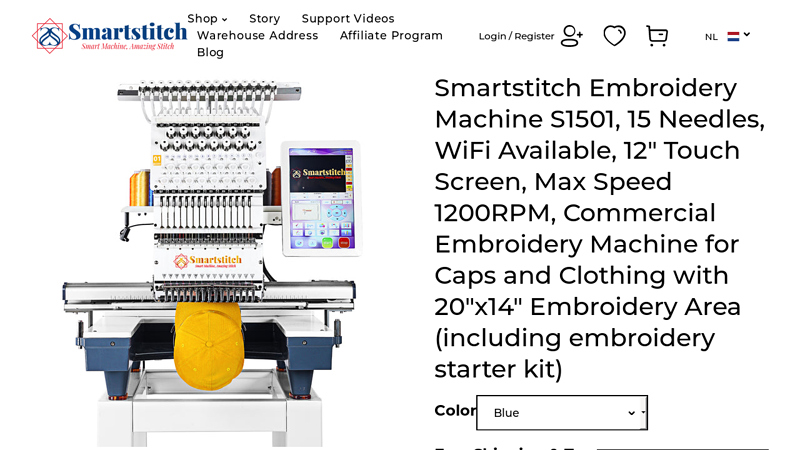

#9 Smartstitch Embroidery Machine S1501, 15 Needles, WiFi Available …

Domain Est. 2023

Website: smartstitch-official.com

Key Highlights: In stock Rating 5.0 (16) Featuring 15 needles, a blazing 1200SPM speed, a user-friendly 12″ touch screen, and WiFi connectivity, this classic machine offers a vast 14″x20″ embroi…

#10 Embroidery machines

Website: zsk.de

Key Highlights: ZSK embroidery machines are state of the art, efficient and can be easily integrated into automated workflow solutions….

Expert Sourcing Insights for Embroidery Machine For Small Business

2026 Market Trends for Embroidery Machines for Small Business

As the small business landscape evolves with technological advancements and shifting consumer preferences, the embroidery machine market is poised for significant transformation by 2026. For entrepreneurs in custom apparel, promotional products, and niche fashion, embroidery machines remain essential tools. This analysis explores key trends shaping the market for small businesses in the coming years.

Rising Demand for Customization and Personalization

Consumers increasingly value unique, personalized products—from monogrammed gifts to custom-branded workwear. By 2026, this demand will continue to drive small businesses toward versatile embroidery machines capable of handling small-batch, high-variety production. Digital platforms and e-commerce integration have lowered entry barriers, enabling micro-entrepreneurs to offer made-to-order services efficiently. As a result, compact, user-friendly embroidery machines with quick design-change capabilities will be in high demand.

Integration of Smart Technology and Automation

Smart embroidery machines equipped with IoT connectivity, automated thread trimming, and AI-assisted design optimization are expected to dominate the small business segment by 2026. These features reduce labor intensity, minimize errors, and increase throughput—critical advantages for resource-limited small operations. Cloud-based design libraries and mobile app control allow business owners to manage workflows remotely, improving operational flexibility. Expect major manufacturers to focus on intuitive interfaces and seamless integration with popular design software like Adobe Illustrator and CorelDRAW.

Growth in Home-Based and Micro-Entrepreneurship

The rise of the gig economy and remote work culture has fueled a surge in home-based embroidery businesses. By 2026, the market will see heightened demand for desktop and mid-range embroidery machines that are affordable, space-efficient, and quiet. Entry-level models with Wi-Fi, USB connectivity, and built-in tutorials will appeal to novice users. Subscription-based models for design content and machine maintenance may also emerge, lowering upfront costs and enabling broader adoption.

Sustainability and Eco-Friendly Materials

Environmental consciousness is influencing purchasing decisions across industries. By 2026, small embroidery businesses will increasingly prioritize machines that support sustainable practices—such as reduced energy consumption, low-waste stitching patterns, and compatibility with organic or recycled fabrics. Manufacturers may respond by offering energy-efficient motors, recyclable machine components, and partnerships with eco-conscious thread suppliers.

Expansion of Niche Markets

Specialty embroidery applications—such as pet apparel, eco-friendly wedding goods, and adaptive clothing for people with disabilities—are gaining traction. Small businesses that cater to these niches require machines with high precision, multi-needle capabilities, and strong software support for intricate designs. As these markets grow, so will the demand for customizable embroidery solutions that support creative differentiation and brand authenticity.

Competitive Pricing and Financing Innovations

With increased competition among manufacturers like Brother, Janome, and Singer, price points for entry- and mid-level embroidery machines are expected to remain competitive in 2026. Additionally, financing options such as rent-to-own programs, leasing, and bundled packages (machine + software + training) will make advanced equipment more accessible to startups and side-hustle entrepreneurs.

Conclusion

By 2026, the embroidery machine market for small businesses will be defined by personalization, smart technology, accessibility, and sustainability. Small business owners who adopt agile, tech-integrated machines will be better positioned to meet evolving customer demands and scale efficiently. As innovation continues, the line between industrial and small-business equipment will blur, democratizing high-quality embroidery for a new generation of entrepreneurs.

Common Pitfalls When Sourcing an Embroidery Machine for Small Business (Quality and Intellectual Property)

Starting or expanding a small embroidery business requires careful investment in equipment. Choosing the right machine is critical, but many entrepreneurs encounter pitfalls—especially concerning machine quality and intellectual property risks. Avoiding these common mistakes can save time, money, and legal headaches down the line.

Overlooking Machine Build Quality and Long-Term Durability

One of the most frequent mistakes is selecting an embroidery machine based solely on upfront cost without assessing build quality. Low-cost machines may use plastic components, weaker motors, or inferior stitching mechanisms that wear out quickly under regular use. This leads to frequent breakdowns, inconsistent stitch quality, and higher long-term costs due to repairs and downtime. Small businesses need reliable machines designed for consistent production—prioritizing durability over initial savings is essential.

Ignoring Brand Reputation and After-Sales Support

Choosing an unknown or unverified brand—especially from overseas suppliers—can result in poor customer service, lack of technical support, and difficulty sourcing replacement parts. Reputable brands like Brother, Tajima, and Melco offer proven reliability, firmware updates, and accessible service networks. Skimping on support infrastructure can leave a small business stranded when issues arise, affecting customer delivery timelines and reputation.

Falling for Misleading Specifications or “Too Good to Be True” Deals

Some suppliers exaggerate machine capabilities—such as stitch speed, needle count, or compatibility—to attract buyers. Others sell rebranded or refurbished machines as new. These practices mislead small business owners into thinking they’re getting professional-grade equipment at a bargain price. Always verify technical specs through independent reviews and request proof of authenticity and warranty terms.

Purchasing Machines with Embedded or Preloaded Copyrighted Designs

A serious but often overlooked IP risk is buying a machine that comes with preinstalled embroidery designs. Many low-cost or gray-market machines include design libraries that infringe on copyrighted or trademarked artwork (e.g., sports logos, character designs, or brand emblems). Using these designs—even unknowingly—in commercial production can lead to cease-and-desist letters, fines, or lawsuits. Small businesses must ensure all designs are properly licensed or created in-house.

Failing to Secure Proper Licensing for Design Files

Even if you purchase designs separately, not all files come with commercial-use rights. Some marketplaces sell embroidery digitized files for personal use only. Using such designs in a for-profit business violates intellectual property laws. Always confirm licensing terms before purchasing or using third-party designs, and maintain records of licenses to protect your business.

Neglecting Software Compatibility and Ownership Rights

Embroidery machines often require proprietary software for design editing and machine control. Some suppliers lock users into closed ecosystems or charge recurring fees for updates and support. Additionally, businesses may not realize they don’t own the digital files they create if the software terms restrict usage rights. Ensure you retain ownership of your designs and that the software integrates smoothly with your workflow.

Buying from Unauthorized or Gray-Market Distributors

Purchasing machines from unauthorized resellers or overseas suppliers may void manufacturer warranties and support. These machines might not meet regional safety or electrical standards and can lack essential language support or service documentation. Moreover, gray-market machines sometimes lack IP-compliant software or include unauthorized modifications that expose the buyer to legal risk.

By recognizing these quality and intellectual property pitfalls, small business owners can make informed decisions, protect their operations, and build a sustainable embroidery venture on solid, compliant foundations.

Logistics & Compliance Guide for Embroidery Machine for Small Business

Understanding Import Regulations and Tariffs

Before purchasing an embroidery machine from overseas, small businesses must research import regulations and applicable tariffs in their country. Check the Harmonized System (HS) code for embroidery machines (typically under 8447.20 or similar) to determine duty rates. Contact your local customs authority or use online tariff databases to verify current rates and any trade agreements that may reduce costs. Some countries require import licenses or certifications for industrial machinery—ensure your business meets these requirements to avoid delays or penalties.

Shipping and Freight Options

Choose the appropriate shipping method based on cost, speed, and machine size. Small embroidery machines may ship via express courier (e.g., DHL, FedEx) for faster delivery, while larger multi-head models often require air or sea freight. Request a detailed quote from freight forwarders that includes insurance, handling fees, and delivery to your doorstep (DDP—Delivered Duty Paid). Always confirm packaging standards to prevent damage during transit, and ensure the machine is crated securely for international shipping.

Customs Clearance and Documentation

Proper documentation is essential for smooth customs clearance. Required documents typically include a commercial invoice, bill of lading or air waybill, packing list, and certificate of origin. The commercial invoice must detail the machine’s value, model number, and intended use. For some countries, an import declaration form or conformity certificate (e.g., CE, FCC) may be necessary. Assign a customs broker if needed to handle submissions and resolve any hold-ups promptly.

Compliance with Safety and Electrical Standards

Ensure the embroidery machine meets your country’s electrical and safety standards. Machines designed for 110V/60Hz (North America) may not work safely in 220V/50Hz regions without a voltage converter. Look for certifications such as UL (U.S.), CE (Europe), or CCC (China) to confirm compliance. Non-compliant machines can pose safety hazards and may be confiscated at customs or prohibited from use in commercial settings.

Warranty and After-Sales Support Considerations

Verify whether the manufacturer or supplier offers an international warranty and technical support. Machines purchased overseas may void warranties if serviced locally. Confirm availability of spare parts, software updates, and technician support in your region. Consider purchasing an extended service agreement or partnering with a local dealer who can provide maintenance and repairs.

Inventory and Installation Logistics

Plan for secure storage upon arrival and schedule installation during non-peak business hours. Ensure your workspace has adequate power supply, ventilation, and space for the machine and operator. Train staff on safe operation and maintenance procedures. Keep all compliance documents, manuals, and warranty information in a central digital and physical file for audits or insurance claims.

Environmental and Disposal Compliance

Be aware of environmental regulations related to electronic waste. When upgrading or retiring the machine, dispose of it through certified e-waste recyclers to comply with local laws (e.g., WEEE in the EU). Some manufacturers offer take-back programs—leverage these to ensure responsible disposal and potential tax benefits.

Conclusion:

Sourcing an embroidery machine for a small business requires careful consideration of several key factors, including budget, production needs, machine type (single-head vs. multi-head), embroidery quality, ease of use, and available technical support. For most small businesses just starting out or operating on a limited scale, a reliable single-head embroidery machine offers the ideal balance of affordability, flexibility, and functionality. It allows for customization, quick setup, and the ability to fulfill small to medium-sized orders efficiently.

When selecting a machine, prioritize reputable brands known for durability and strong customer service, such as Brother, Tajima, or Melco. Also, evaluate software compatibility, hoop sizes, stitch speed, and maintenance requirements to ensure long-term operational efficiency. Additionally, purchasing from authorized dealers or suppliers that offer warranties, training, and technical assistance can significantly reduce downtime and improve productivity.

Ultimately, investing in the right embroidery machine is a strategic decision that can enhance product quality, improve turnaround time, and support business growth. By aligning the machine’s capabilities with your business goals and production volume, you set a strong foundation for long-term success in the competitive custom apparel and embroidery market.