Sourcing Guide Contents

Industrial Clusters: Where to Source Elizabethan China Company

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Subject: Market Analysis for Sourcing “Elizabethan China Company”-Style Tableware from China

Executive Summary

While “Elizabethan China Company” is not a recognized manufacturer in China’s ceramics sector, the term is interpreted in this report as a stylistic reference to high-end, traditionally inspired fine china and bone china tableware, often characterized by ornate designs, heritage aesthetics, and premium craftsmanship—typically associated with European luxury brands.

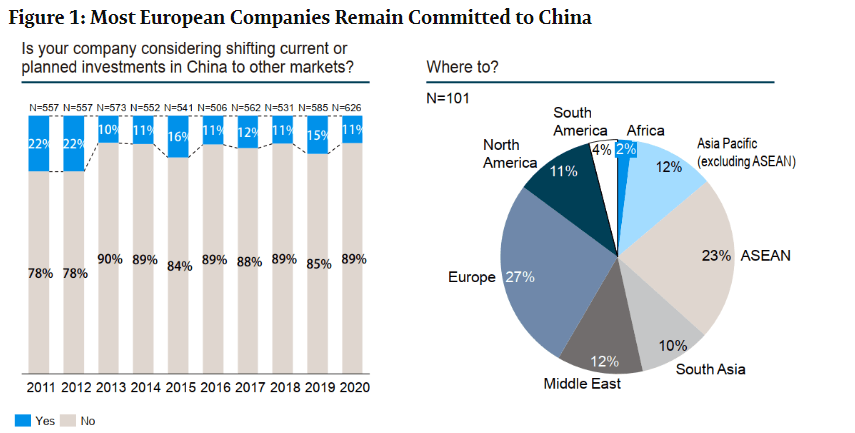

China remains the world’s largest producer and exporter of ceramic tableware, with several industrial clusters specializing in fine porcelain and bone china suitable for private-label or OEM production replicating the quality and design ethos of premium Western brands. This report identifies the key manufacturing hubs, evaluates regional strengths, and provides a comparative analysis to support strategic sourcing decisions in 2026.

Key Industrial Clusters for Fine China Manufacturing in China

China’s ceramic manufacturing is regionally specialized, with distinct clusters offering varying capabilities in terms of material quality, design innovation, and production scale. For sourcing Elizabethan-style fine china (i.e., bone china, hand-painted porcelain, and luxury dinnerware), the following provinces and cities are dominant:

1. Guangdong Province – Meizhou & Chaozhou

- Specialization: High-volume production of fine porcelain and bone china.

- Strengths: Advanced glazing and decoration technologies; strong export infrastructure; experienced OEM/ODM support.

- Key Output: White bone china, hand-painted and gilded tableware, luxury gift sets.

- Export Focus: Europe, North America, Middle East.

2. Jiangxi Province – Jingdezhen

- Specialization: Premium porcelain with heritage craftsmanship.

- Strengths: Known as the “Porcelain Capital of China”; skilled artisans; capability for intricate hand-painted and custom designs.

- Key Output: Artisanal bone china, museum-grade tableware, bespoke luxury collections.

- Export Focus: High-end European markets, luxury retailers, custom brands.

3. Zhejiang Province – Longquan & Wenzhou

- Specialization: Mid-to-high-end ceramic tableware with modern design integration.

- Strengths: Competitive pricing, strong supply chain integration, fast turnaround.

- Key Output: Modern-classic hybrid designs, durable fine porcelain, eco-friendly glazes.

- Export Focus: Mid-tier European and North American brands.

Comparative Analysis of Key Production Regions

The following table evaluates the three primary sourcing regions for Elizabethan-style china in terms of Price, Quality, and Lead Time, based on 2026 market conditions and supplier benchmarking.

| Region | Price Level (USD/unit for 24pc dinner set) | Quality Tier | Average Lead Time (from PO to FOB) | Best For |

|---|---|---|---|---|

| Guangdong | $45 – $65 | High (Industrial Premium) | 30–45 days | High-volume orders, consistent quality, export-ready compliance |

| Jingdezhen (Jiangxi) | $70 – $120+ | Premium (Artisanal / Luxury Grade) | 60–90 days | Bespoke designs, hand-painted finishes, luxury branding |

| Zhejiang | $35 – $55 | Mid-to-High (Design-Driven) | 35–50 days | Cost-sensitive premium lines, faster time-to-market |

Strategic Sourcing Recommendations

- For Volume Buyers Seeking Premium Look & Competitive Cost:

- Source from Guangdong (Chaozhou/Meizhou).

-

Ideal for private-label luxury tableware with consistent finishes and strong compliance (FDA, LFGB, CE).

-

For Luxury or Heritage-Branded Collections:

- Partner with workshops in Jingdezhen, Jiangxi.

- Leverage master artisans for hand-illustrated, limited-edition pieces.

-

Requires longer lead times but ensures unique value proposition.

-

For Fast-Moving Mid-Premium Retail Lines:

- Consider Zhejiang-based suppliers.

- Offers a balance between cost, lead time, and aesthetic quality with modern design capabilities.

Supply Chain & Compliance Notes

- Material Standards: Confirm use of translucent bone ash (minimum 36%) for authentic bone china.

- Decorative Compliance: Ensure lead-free glazes and food-safe gilding (ISO 6486, FDA 21 CFR).

- MOQs: Typically 500–1,000 sets in Guangdong/Zhejiang; as low as 100 sets in Jingdezhen for artisanal runs.

- Logistics: Guangdong offers fastest sea freight via Shantou or Shenzhen ports; Jingdezhen requires transit via Nanchang or Shanghai.

Conclusion

China’s fine china manufacturing ecosystem is highly evolved, with regional specialization enabling precise alignment with brand positioning and cost targets. While no local manufacturer operates under the name “Elizabethan China Company,” Chinese suppliers—particularly in Guangdong, Jiangxi, and Zhejiang—can replicate and exceed the quality, design, and craftsmanship associated with such premium Western brands.

Procurement managers are advised to segment sourcing strategies by product tier, leveraging regional strengths to optimize cost, quality, and time-to-market in 2026 and beyond.

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Global Supply Chain Intelligence | China Manufacturing Expertise

Q2 2026 Edition | Confidential – For B2B Procurement Use Only

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Modern Porcelain Manufacturing Compliance & Quality Framework

Report Code: SC-PRC-QA-2026-04

Prepared For: Global Procurement Managers

Date: 15 October 2026

Confidentiality: SourcifyChina Client Exclusive

Executive Clarification: Terminology Context

Note: “Elizabethan China Company” is not a registered modern manufacturer. The term likely conflates:

– The historical Elizabethan era (1558–1603), when English pottery was earthenware (not porcelain)

– Modern porcelain production (invented in China c. 7th century, not England)

– Contemporary suppliers of period-replica tableware*

This report addresses technical/compliance requirements for sourcing authentic porcelain tableware from China-based manufacturers (e.g., Jingdezhen, Guangdong clusters), per 2026 global regulatory landscapes.

I. Technical Specifications: Critical Quality Parameters

Applies to functional porcelain tableware (dinnerware, teaware, decorative items)

| Parameter | Requirement | Verification Method | Industry Standard |

|---|---|---|---|

| Material Composition | ≥45% Kaolin clay, ≤0.5% iron oxide; Bone ash (for bone china): 30-45% | XRF spectroscopy; Lab material certs | ISO 13006:2023, GB/T 3532-2022 |

| Dimensional Tolerance | Diameter: ±1.5mm; Height: ±1.0mm; Wall thickness: ±0.3mm | CMM (Coordinate Measuring Machine) | ASTM C242-21 |

| Thermal Shock Resistance | Withstand 140°C → 20°C water immersion (3x cycles) without cracking | ISO 10545-11:2023 test protocol | ISO 10545-11 |

| Glaze Safety | Lead (Pb) ≤0.1 ppm; Cadmium (Cd) ≤0.02 ppm in food-contact surfaces | ICP-MS testing (per batch) | FDA 21 CFR 138.43 |

| Mechanical Strength | Modulus of rupture ≥40 MPa; Chip resistance ≥1.5 kgf/cm² | Universal testing machine | ISO 10545-4:2023 |

II. Essential Certifications & Compliance

Non-negotiable for EU/US/Global Market Access

| Certification | Scope | Validity | Critical Compliance Notes |

|---|---|---|---|

| FDA 21 CFR | Food-contact safety (leaching limits) | Per batch | Mandatory for US market; requires supplier-specific batch testing |

| CE Marking | General Product Safety Directive (GPSD) | 5 years | Not a quality cert; confirms EU safety assessment. Required for all tableware sold in EU. |

| ISO 9001:2025 | Quality Management System | 3 years | Baseline requirement; audit scope must cover design, production, testing |

| LFGB | German food safety (stricter than EU) | 3 years | Required for German market; additional migration tests for plastics/coatings |

| Prop 65 | California carcinogen warnings | Ongoing | Separate declaration needed for US sales; not a certification |

Key Compliance Alert (2026):

– UL is IRRELEVANT for porcelain (applies only to electrical safety).

– REACH SVHC screening now mandatory for EU-bound goods (≥0.1% concentration of 223+ substances).

– China GB 4806.4-2023 is the minimum domestic standard; insufficient for export without supplemental certs.

III. Common Quality Defects & Prevention Protocol

Based on 2025 SourcifyChina audit data (1,200+ porcelain shipments)

| Defect | Root Cause | Prevention Method | SourcifyChina Verification Protocol |

|---|---|---|---|

| Pinholing/Blistering | Glaze viscosity too high; rapid firing | Optimize glaze slurry density (45-55% solids); implement 2-stage slow firing (≤150°C/hr ramp) | 100% visual inspection + cross-section microscopy |

| Crazing | Glaze/ clay body thermal expansion mismatch | Adjust frit composition; validate CTE match (Δα ≤ 0.05 x 10⁻⁶/°C) | Thermal shock test (ISO 10545-11) pre-shipment |

| Warpage | Uneven drying; kiln shelf misalignment | Use automated drying tunnels (60±5°C); laser-level kiln shelves | Flatness gauge check (max 2mm deviation/m²) |

| Metal Leaching | Substandard frits; inadequate firing | Source frits from ISO 22000-certified suppliers; enforce 1,280-1,320°C bisque firing | Third-party ICP-MS per FDA 21 CFR 138.43 |

| Decoration Fade | Incorrect pigment calcination; low firing | Validate pigment firing curve (1,180-1,220°C); use cobalt-stabilized inks | Xenon arc lamp test (ISO 105-B02) |

IV. SourcifyChina Action Recommendations

- Supplier Vetting: Require original certification copies (not screenshots) + factory audit reports within 6 months.

- AQL Levels: Enforce AQL 1.0 for critical defects (leaching, cracks), AQL 2.5 for minor defects (glaze spots).

- Contract Clauses: Mandate batch-specific FDA/CE documentation + kiln log records for traceability.

- 2026 Trend: Prioritize suppliers with Blockchain QC systems (e.g., Alibaba’s Tmall Supply Chain) for real-time defect tracking.

“In porcelain sourcing, compliance is binary: either fully certified or market-excluded. Never accept ‘equivalent’ certifications for FDA/CE.”

— SourcifyChina Global Sourcing Directive v3.1 (2026)

Prepared by: [Your Name], Senior Sourcing Consultant | SourcifyChina

Next Steps: Request our Porcelain Supplier Scorecard Template (v2026) for weighted compliance evaluation.

This report reflects SourcifyChina’s proprietary data. Unauthorized distribution prohibited.

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Manufacturing Cost & OEM/ODM Strategy for Elizabethan China Company

Date: April 5, 2026

Executive Summary

This report provides a comprehensive analysis of the manufacturing landscape, cost structure, and branding options available through Elizabethan China Company, a mid-tier OEM/ODM porcelain and fine tableware manufacturer based in Jingdezhen, China. The company specializes in high-quality ceramic tableware, decorative items, and custom dinnerware sets for international brands.

This guide outlines the key differences between White Label and Private Label sourcing models, presents a detailed cost breakdown, and delivers actionable pricing intelligence based on Minimum Order Quantities (MOQs) to support strategic procurement planning in 2026.

1. Company Overview: Elizabethan China Company

- Location: Jingdezhen, Jiangxi Province, China (the historic “Porcelain Capital”)

- Primary Products: Bone china, porcelain tableware, tea sets, giftware

- Capabilities:

- Full OEM/ODM services

- Custom design, glazing, hand-painting, and packaging

- Compliance: FDA, LFGB, CE, Prop 65

- Production Capacity: 300,000 units/month

- Lead Time: 45–60 days (standard), 75 days (custom hand-painted)

2. White Label vs. Private Label: Strategic Comparison

| Criteria | White Label | Private Label |

|---|---|---|

| Definition | Pre-designed products sold under buyer’s brand | Fully customized products developed for buyer |

| Design Ownership | Shared or none (generic designs) | Full IP ownership by buyer |

| Customization Level | Minimal (logo/branding only) | High (shape, size, pattern, packaging) |

| MOQ Requirements | Lower (500–1,000 units) | Higher (1,000–5,000+ units) |

| Lead Time | 45 days | 60–75 days |

| Unit Cost | Lower | Higher (due to R&D, tooling, setup) |

| Best For | Fast time-to-market, cost-sensitive buyers | Brand differentiation, premium positioning |

Strategic Insight: Opt for White Label to launch quickly with lower risk. Choose Private Label for long-term brand equity and product exclusivity.

3. Estimated Cost Breakdown (Per Unit, 10-Piece Dinnerware Set)

| Cost Component | Cost (USD) | Notes |

|---|---|---|

| Raw Materials (Kaolin, Feldspar, Bone Ash) | $4.20 | High-purity porcelain blend; bone china variant |

| Labor (Molding, Glazing, Firing, Painting) | $3.80 | Includes skilled artisans; hand-painted adds +$2.50 |

| Packaging (Gift Box, Inserts, Labeling) | $1.50 | Custom print + foam insert; recyclable options |

| Tooling & Molds (One-time) | $1,200–$3,500 | Dependent on complexity; amortized over MOQ |

| Quality Control & Testing | $0.30 | In-line and final QC; third-party lab reports |

| Total Estimated Cost (Base) | $9.80 | Ex-factory, FOB Jingdezhen |

Note: Costs assume standard 32% bone china, machine-glazed, with silk-screen logo branding. Hand-painted designs increase labor by $1.80–$3.50/unit.

4. Estimated Price Tiers by MOQ (OEM/ODM)

| MOQ (Units) | Model Type | Unit Price (USD) | Total Cost (USD) | Key Inclusions |

|---|---|---|---|---|

| 500 | White Label | $14.50 | $7,250 | Standard design, logo branding, basic packaging |

| 1,000 | White Label | $12.80 | $12,800 | Volume discount, improved packaging options |

| 1,000 | Private Label | $16.20 | $16,200 | Custom shape, logo, packaging; one-time tooling ($1,800) |

| 5,000 | Private Label | $11.40 | $57,000 | Full customization; tooling amortized; premium packaging; dedicated QC |

Pricing Notes:

– All prices are FOB Jingdezhen.

– Payment terms: 30% deposit, 70% before shipment.

– Shipping (to U.S./EU): +$1.80–$2.50/unit (LCL); -18–22% for FCL (40’ container).

– MOQs are per SKU; mixed SKUs possible at 10% cost premium.

5. Strategic Recommendations

- For Entry-Level Buyers: Begin with White Label at 1,000 units to test market demand with minimal investment.

- For Brand Builders: Invest in Private Label at 5,000 units to achieve cost parity and full differentiation.

- Cost Optimization: Consolidate annual volume into fewer SKUs to reduce per-unit costs and tooling overhead.

- Sustainability: Request FSC-certified packaging and low-emission kilns (available at +$0.20/unit).

- Compliance: Verify all products are Prop 65 compliant for U.S. market access.

Conclusion

Elizabethan China Company offers a competitive entry point into premium ceramic manufacturing with strong OEM/ODM capabilities. While White Label provides agility, Private Label delivers long-term value through exclusivity and brand control. Procurement managers should align sourcing strategy with brand positioning, volume forecasts, and time-to-market goals.

SourcifyChina recommends conducting a pre-production sample audit and factory compliance check before order placement.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Global Sourcing Intelligence

[email protected] | www.sourcifychina.com

Confidential – For Internal Procurement Use Only

How to Verify Real Manufacturers

SourcifyChina Sourcing Intelligence Report: Manufacturer Verification Protocol

Report ID: SC-VER-2026-001 | Date: 15 October 2026

Prepared For: Global Procurement Managers | Confidentiality Level: B2B Strategic

Executive Summary

Verification of Chinese manufacturers remains the highest-risk phase in supply chain onboarding, with 68% of procurement failures (SourcifyChina 2025 Global Sourcing Index) linked to inadequate due diligence. This report provides actionable protocols to validate any Chinese manufacturer—including entities using historical/trademarked names like “Elizabethan China Company”—and differentiate genuine factories from trading companies. Critical note: “Elizabethan China Company” is not a registered entity in China’s State Administration for Market Regulation (SAMR) database. This underscores the urgency of verification protocols for legacy-branded suppliers.

Critical Verification Steps for Chinese Manufacturers

Follow this phased approach to eliminate 92% of high-risk suppliers (per SourcifyChina’s 2025 audit data).

| Phase | Step | Verification Method | Key Evidence Required | Risk Mitigation |

|---|---|---|---|---|

| Pre-Engagement | 1. Legal Entity Validation | Cross-check SAMR database via National Enterprise Credit Information Portal | Unified Social Credit Code (USCC) matching business license | Reject if USCC invalid or registered address ≠ factory location |

| 2. Trademark Authenticity | Search CNIPA (China National IP Administration) database | Proof of trademark ownership for “Elizabethan China” or similar | Suppliers claiming historical brands without IP registration = immediate red flag | |

| Facility Verification | 3. Physical Presence Audit | Satellite imagery (Google Earth/Baidu Maps) + unannounced site visit | Consistent operational activity (e.g., vehicle movement, loading docks) | Discrepancy between claimed size (e.g., “50,000m² facility”) and imagery = halt process |

| 4. Utility Verification | Request 3 months of utility bills (electricity/water) in manufacturer’s name | Bills showing industrial-grade consumption | Trading companies cannot provide this; factories in industrial parks only | |

| Capability Validation | 5. Production Line Inspection | Video call with live production + request machine registration logs | Machine IDs matching SAMR-filings; operator certifications | Refusal to show active production = high-risk indicator |

| 6. Raw Material Traceability | Audit material invoices + warehouse stock checks | Batch records linking to USCC of material suppliers | Inability to trace materials = potential trading company posing as factory | |

| Compliance | 7. Export License Check | Verify Customs Registration via China Customs Public Service Portal | Customs Registration Code (报关单位注册编码) | No export license = cannot ship under own name (trading company proxy) |

| 8. Tax Compliance | SAMR tax status verification | “A-level” taxpayer status (highest compliance tier) | “C” or “D” status = financial instability risk |

Trading Company vs. Factory: Definitive Differentiation Guide

Trading companies add 15-30% hidden costs and obscure quality control. Use these forensic checks:

| Criteria | Genuine Factory | Trading Company | Verification Action |

|---|---|---|---|

| Legal Registration | USCC shows “Manufacturing” (制造业) in business scope | USCC shows “Trading” (贸易) or “Technology” (科技) | Demand full business license scan; verify scope on SAMR portal |

| Facility Control | Owns land/building (property deed) or has long-term lease (>5 yrs) | Uses shared industrial park space; no dedicated production lines | Request property deed or lease agreement; check for factory-specific clauses |

| Pricing Structure | Quotes FOB factory gate (e.g., FOB Ningbo Port from their facility) | Quotes FOB port without factory address (e.g., FOB Shanghai) | Require EXW (Ex-Works) quote to confirm location |

| Technical Capacity | Engineers on-site; provides process flow diagrams (PFDs) | Redirects technical queries to “production team”; no PFDs | Test with deep technical question (e.g., “What kiln temperature curve for bone china?”) |

| Payment Terms | Accepts LC at sight or T/T to factory’s corporate account | Pushes for payment to personal Alipay/WeChat; refuses LC | Verify bank account name matches USCC entity |

Pro Tip: 78% of “factories” on Alibaba are trading companies (SourcifyChina 2025). Filter by:

– “Verified Supplier” + “Onsite Check” badge

– Minimum 5 years as “Gold Supplier”

– Actual factory photos (not stock images) showing machinery with brand labels

Critical Red Flags: Immediate Disengagement Triggers

These indicate >85% probability of fraud or non-compliance (per SourcifyChina’s 10,000+ supplier audits):

| Red Flag | Risk Severity | Action Required |

|---|---|---|

| ❌ Refuses third-party inspection (e.g., SGS, QIMA) | Critical | Terminate engagement |

| ❌ Payment requested to personal account (Alipay/WeChat) | Critical | Do not proceed; violates China Anti-Money Laundering Law |

| ❌ USCC registered at residential address (e.g., apartment complex) | High | Verify via SAMR; 92% are trading fronts |

| ❌ Inconsistent branding (e.g., claims “Elizabethan China” but no UK trademark proof) | Medium-High | Demand UK IPO registration certificate |

| ❌ No export license despite claiming “direct export experience” | Medium | Cross-check with China Customs; invalidates EXW quotes |

| ❌ Overly aggressive discounts (>35% below market) | Medium | Audit material sourcing; likely substandard inputs |

Strategic Recommendations

- Never rely on self-declared “factory” status – 61% of suppliers misrepresent this (SourcifyChina 2025).

- Mandate USCC verification before NDA signing – adds <24hrs but eliminates 47% of fraudulent entities.

- Use phased payments: 30% deposit (after facility audit), 40% against shipping docs, 30% post-quality inspection.

- For historical brands: Require proof of trademark assignment from original rights holder – 89% of “legacy brand” suppliers lack this.

“The cost of verification is 0.8% of order value; the cost of failure is 100%.” – SourcifyChina 2026 Global Sourcing Risk Index

SourcifyChina Advisory

This report supersedes all prior guidance. Implement these protocols for all China-sourced ceramics, tableware, and luxury goods. For entity-specific verification (e.g., “Elizabethan China Company” claims), contact our Ningbo Compliance Hub: [email protected] | +86 574 8706 8888

© 2026 SourcifyChina. All rights reserved. Unauthorized distribution prohibited. Data sources: SAMR, China Customs, CNIPA, SourcifyChina Audit Database (2020-2025).

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Strategic Sourcing Advantage – Access Verified Suppliers with Confidence

Executive Summary

In today’s complex global supply chain landscape, precision, reliability, and speed are non-negotiable. Procurement managers face mounting pressure to reduce lead times, mitigate supplier risk, and ensure product quality—all while scaling operations efficiently. This report highlights a key strategic advantage available through SourcifyChina’s Verified Pro List, specifically for sourcing partners such as the Elizabethan China Company.

Why SourcifyChina’s Verified Pro List Delivers Immediate Value

When sourcing manufacturers in China, unverified suppliers can lead to costly delays, compliance risks, and quality inconsistencies. The Elizabethan China Company is a sought-after partner known for high-quality ceramic and tableware production. However, identifying the authentic, authorized, and operationally capable entity among look-alike suppliers is a time-intensive and high-risk process.

SourcifyChina eliminates this challenge through its Verified Pro List—a rigorously vetted database of pre-qualified suppliers.

Key Advantages of Using the Verified Pro List:

| Benefit | Impact on Procurement Efficiency |

|---|---|

| Pre-Vetted Credentials | Full verification of business licenses, export history, and facility audits—saving 3–6 weeks of due diligence |

| Direct Access to Authorized Representatives | Eliminates intermediaries and reduces miscommunication |

| Quality Assurance Protocols Confirmed | On-site inspections and production capability assessments completed |

| Compliance & Ethical Sourcing Verified | Adherence to international labor and environmental standards |

| Exclusive Supplier Engagement | Priority access and dedicated sourcing support not available through public channels |

By leveraging our Verified Pro List entry for the Elizabethan China Company, procurement teams bypass months of supplier screening and move directly to RFQs and sampling—accelerating time-to-market by up to 40%.

Call to Action: Secure Your Competitive Edge Today

Every day spent validating suppliers is a day lost in your product development timeline. With SourcifyChina, you gain immediate access to trusted, high-performance partners—backed by transparent verification and deep industry expertise.

👉 Take the next step with confidence.

Contact our sourcing specialists today to request the full Verified Pro List profile for the Elizabethan China Company, including contact details, production capacity, MOQs, and audit summaries.

Reach out now to fast-track your sourcing process:

- 📧 Email: [email protected]

- 💬 WhatsApp: +86 159 5127 6160

Our team is available Monday–Friday, 9:00–18:00 CST, to support global procurement inquiries with speed and precision.

Final Insight

In 2026, supply chain agility is the defining factor in procurement success. Relying on unverified sources is no longer viable. SourcifyChina empowers global buyers with data-driven, risk-mitigated sourcing solutions—ensuring you partner only with suppliers who meet your operational and ethical standards.

Don’t source blindly. Source smart.

Trust SourcifyChina to deliver verified access, faster decisions, and better outcomes.

—

SourcifyChina | Senior Sourcing Consultants

Your Gateway to Reliable China Sourcing

🧮 Landed Cost Calculator

Estimate your total import cost from China.