The global automotive lift market is experiencing steady expansion, driven by rising vehicle ownership, increased demand for vehicle maintenance and repair services, and technological advancements in lift systems. According to Mordor Intelligence, the automobile lifts market was valued at approximately USD 1.2 billion in 2023 and is projected to grow at a CAGR of over 4.5% from 2024 to 2029. This growth is further fueled by the expansion of automotive aftermarket services and the growing adoption of heavy-duty lifts in commercial repair facilities. As demand surges across North America, Europe, and the Asia-Pacific regions, manufacturers are innovating to deliver safer, more efficient, and smart-enabled lifting solutions. In this evolving landscape, identifying the top elevadores de autos (car lift) manufacturers becomes essential for distributors, repair shops, and OEMs seeking reliable, high-performance equipment. Based on market presence, product innovation, and global reach, the following ten companies stand out in the competitive automotive lift industry.

Top 10 Elevadores De Autos Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Manufacturer of elevators, escalators, & moving walkways …

Domain Est. 1993

Website: schindler.com

Key Highlights: We manufacture, install, maintain, repair, and modernize elevators, escalators, and moving walkways for almost every type of building/company requirement….

#2 Elevators, Escalators, Lifts & Moving Walks

Domain Est. 1994

Website: otis.com

Key Highlights: Otis is a leading manufacturer and maintainer of Elevators, Escalators, Moving Walkways with world class modernization tools & service packages for ……

#3 EAE

Domain Est. 2012

Website: en.eae-ae.com

Key Highlights: EAE, Professional vehicle lifts manufacturer, offers a wide range of car lifts for most of job, include of alignment lifts, scissor lifts, two post lifts, ……

#4 GAL Manufacturing

Domain Est. 1995

Website: gal.com

Key Highlights: For generations, GAL™ has served the elevator industry as the supplier of choice by offering robust, non-proprietary elevator solutions….

#5 Elevador Automotriz de Dos Postes 16K

Domain Est. 1996

Website: johnbean.com

Key Highlights: Diseñado para levantar cargas pesadas de forma rápida y segura, el elevador de dos postes 16K de John Bean® cuenta con características que aseguran una ……

#6 BendPak

Domain Est. 1997

Website: bendpak.com

Key Highlights: Our automotive lift offerings include two-post lifts, four-post lifts, parking lifts, alignment lifts and mobile column lifts….

#7 Challenger Lifts

Domain Est. 1997

Website: challengerlifts.com

Key Highlights: We are dedicated to designing, manufacturing and distributing the most advanced technological car lifts and accessories in the industry….

#8 Velyen

Domain Est. 2002

Website: velyen.com

Key Highlights: Equipamiento integral para talleres profesionales del automóvil. Fabricantes de elevadores para vehículos….

#9 Atlas Automotive Equipment

Domain Est. 2009

Website: atlasautoequipment.com

Key Highlights: Atlas Automotive Equipment has grown to become one of the most well-known and well-respected names in the automotive Industry for Car Lifts and Automotive ……

#10 Rotary Solutions

Domain Est. 2009 | Founded: 1925

Website: rotarysolutions.com

Key Highlights: Trusted source for automotive shop equipment since 1925. Industry-leading vehicle lifts, collision repair tools, and A/C service equipment….

Expert Sourcing Insights for Elevadores De Autos

H2: 2026 Market Trends for Elevadores De Autos (Car Lifts)

The global market for elevadores de autos, or car lifts, is expected to undergo significant transformation by 2026, driven by technological innovation, increasing demand in automotive service sectors, and evolving regulatory environments. Below is an analysis of key trends shaping the industry:

-

Increased Adoption of Hydraulic and Electric Dual-System Lifts

By 2026, dual-system car lifts that combine hydraulic power with electric efficiency are anticipated to dominate the market. These lifts offer enhanced safety, energy efficiency, and smoother operation, making them ideal for both independent garages and large-scale service centers in Latin America and beyond. -

Growth in Emerging Markets

Countries in Latin America, Southeast Asia, and parts of Africa are projected to see robust growth in the auto lift market. Expanding vehicle ownership, coupled with rising investments in automotive repair infrastructure, will fuel demand for reliable and affordable elevadores de autos. Regional manufacturers are expected to leverage cost-effective production to meet local needs. -

Smart and IoT-Integrated Lift Systems

Integration of Internet of Things (IoT) technology into car lifts is a key trend. By 2026, smart lifts with remote diagnostics, real-time maintenance alerts, and load-balancing sensors will become standard in professional workshops. These features enhance operational safety and reduce downtime, appealing to high-volume service providers. -

Focus on Safety and Regulatory Compliance

Governments and industry bodies are expected to enforce stricter safety standards for automotive lifting equipment. Manufacturers will need to comply with certifications such as CE, ANSI/ALI ALCTV, and ISO 3157. As a result, there will be increased demand for lifts equipped with automatic locking mechanisms, overload protection, and emergency descent functions. -

Rise in Electric Vehicle (EV) Service Infrastructure

With the global shift toward electric vehicles, car lifts designed specifically for EV maintenance—featuring wider clearance, non-conductive materials, and underbody access—are gaining traction. By 2026, EV-compatible elevadores de autos will represent a growing segment, particularly in markets with strong EV adoption like Europe and China. -

Sustainability and Eco-Friendly Manufacturing

Environmental concerns are pushing manufacturers to adopt sustainable practices. Recyclable materials, energy-efficient production processes, and reduced hydraulic fluid leakage are becoming competitive advantages. Companies emphasizing ESG (Environmental, Social, and Governance) principles are likely to gain market share. -

E-Commerce Expansion and Direct-to-Consumer Sales

Online platforms are playing a larger role in the distribution of car lifts. By 2026, more consumers and small businesses are expected to purchase elevadores de autos through e-commerce channels, supported by detailed product comparisons, virtual installation guides, and financing options. -

Consolidation and Strategic Partnerships

The market may witness increased mergers and acquisitions as larger players seek to expand their global footprint. Strategic partnerships between lift manufacturers and automotive tool distributors will enhance market penetration, particularly in underserved regions.

In conclusion, the 2026 landscape for elevadores de autos will be defined by technological advancement, regulatory adaptation, and geographic expansion. Companies that innovate sustainably and align with emerging service needs—particularly in EV maintenance and digital integration—will be best positioned for growth.

Common Pitfalls Sourcing Elevadores De Autos (Quality, IP)

Sourcing auto lifts (elevadores de autos) from international suppliers—especially from regions like Asia—can offer cost advantages, but it also comes with significant risks related to quality and intellectual property (IP). Understanding and avoiding these common pitfalls is essential for businesses looking to maintain reliability, safety, and legal compliance.

1. Compromised Build Quality and Safety Standards

One of the most frequent issues when sourcing elevadores de autos is receiving units that do not meet required safety and durability standards. Inferior materials, poor welding, and inadequate hydraulic systems can lead to equipment failure, posing serious safety risks in automotive workshops.

- Substandard Materials: Suppliers may use lower-grade steel or components to cut costs, reducing the lift’s lifting capacity and lifespan.

- Lack of Certifications: Many low-cost suppliers do not provide or obtain recognized certifications (e.g., CE, ANSI/ALI ALCTV, or ISO), making compliance with local regulations difficult.

- Inconsistent Manufacturing: Poor quality control processes result in inconsistent product performance across units.

2. Misrepresentation of Technical Specifications

Suppliers may exaggerate or falsify technical claims such as lifting capacity, platform dimensions, or hydraulic pressure ratings. This misrepresentation can lead to mismatched equipment that fails under expected workloads.

- Always request third-party test reports or conduct on-site inspections.

- Verify published data through independent engineering assessments.

3. Intellectual Property Infringement

Many low-cost elevadores de autos are reverse-engineered copies of well-known branded models, leading to potential IP violations.

- Design and Patent Infringement: Copying patented lifting mechanisms, safety locks, or structural designs can expose importers to legal action, especially in markets with strong IP enforcement (e.g., the U.S. or EU).

- Trademark Violations: Using logos, branding, or model names similar to established brands can result in customs seizures or lawsuits.

Importers are often held liable even if they were unaware of the infringement, making due diligence critical.

4. Lack of After-Sales Support and Spare Parts

Low-cost suppliers often lack the infrastructure to provide technical support, maintenance guidance, or readily available spare parts.

- Extended downtime occurs when components fail and replacements take weeks to arrive.

- Absence of manuals or bilingual documentation complicates installation and servicing.

5. Inadequate Compliance with Local Regulations

Different countries have specific requirements for workplace equipment, including electrical systems, emergency stop functions, and load testing.

- Imported lifts may not comply with local electrical codes or safety protocols.

- Non-compliant units may be rejected by regulators or insurers, creating operational and financial liabilities.

6. Hidden Costs from Poor Quality

While initial prices may be attractive, hidden costs can erode savings:

- Frequent repairs and maintenance

- Increased risk of workplace accidents and liability claims

- Costs associated with equipment downtime

7. Supplier Reliability and Communication Gaps

Many overseas suppliers lack experience with international logistics, warranties, or post-sale accountability.

- Poor communication can delay resolution of quality issues.

- Some suppliers may disappear after payment, leaving buyers with no recourse.

Best Practices to Avoid Pitfalls

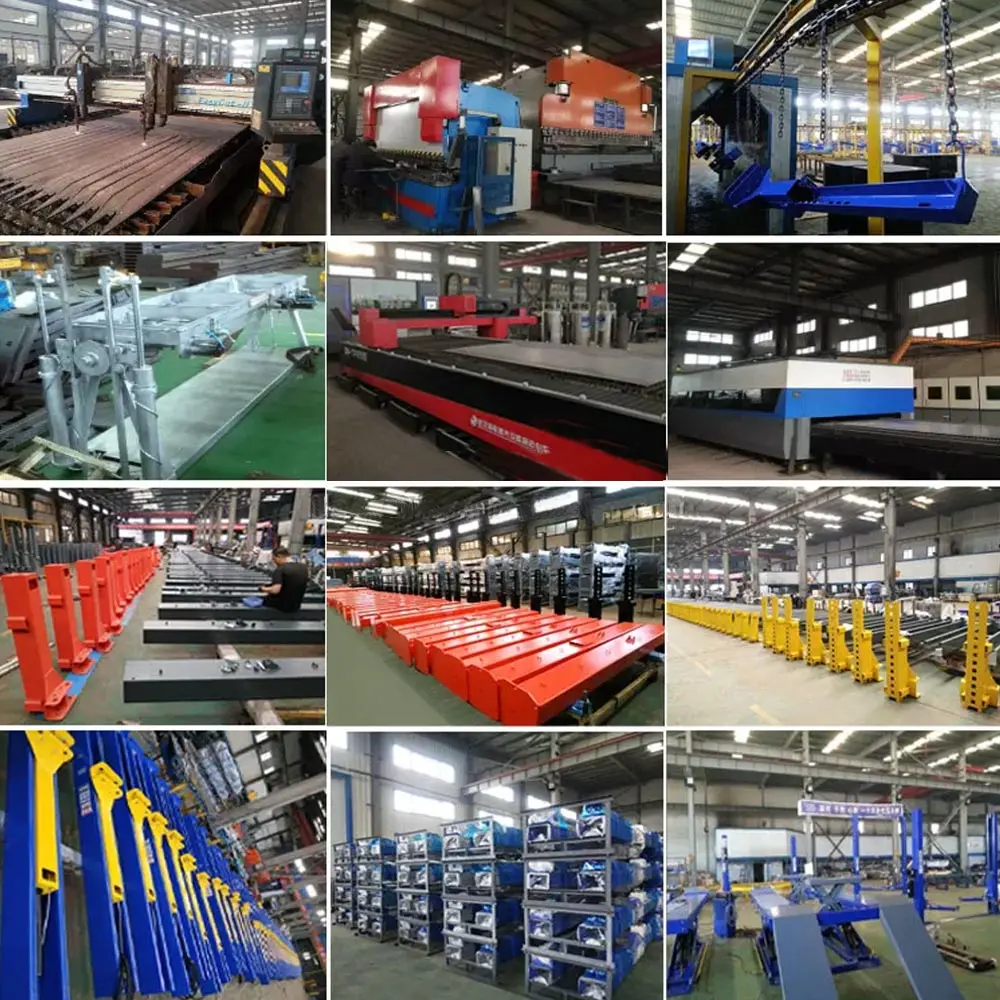

- Conduct Factory Audits: Visit or hire third parties to inspect manufacturing facilities and quality control processes.

- Demand Certifications: Require proof of compliance with international safety standards.

- Verify IP Status: Ensure designs do not infringe on existing patents or trademarks; consider legal review.

- Start with a Sample Order: Test the product thoroughly before committing to large volumes.

- Use Escrow or LC Payments: Protect payments until quality and compliance are confirmed.

- Partner with Reputable Distributors: Work with suppliers who offer warranties, technical support, and spare parts.

By proactively addressing quality and IP concerns, businesses can source elevadores de autos effectively while minimizing risk and ensuring long-term value.

Logistics & Compliance Guide for Elevadores De Autos (Automotive Lifts)

Understanding Product Classification and Regulations

When importing or distributing elevadores de autos (automotive lifts) internationally, it is crucial to understand the correct product classification codes (such as HS or HTS codes) and applicable safety and technical standards. In most countries, automotive lifts fall under industrial machinery and are subject to strict regulations to ensure structural integrity and operational safety. Identify the correct Harmonized System (HS) code—commonly 8428.10 or similar, depending on the type (two-post, four-post, scissor, etc.)—to determine import duties, taxes, and regulatory requirements. Always consult local customs authorities for precise classification.

Compliance with Safety and Technical Standards

Automotive lifts must comply with recognized safety standards to be legally sold and operated. In the United States, lifts must meet ANSI/ALI ALCTV (formerly ALI AALTV) standards, certified by organizations like the Automotive Lift Institute (ALI). In the European Union, compliance with the Machinery Directive (2006/42/EC) and CE marking is mandatory. Key requirements include load capacity labeling, emergency stop mechanisms, structural stability testing, and clear user manuals in the local language. Non-compliant lifts may be rejected at customs or recalled after sale.

Packaging and Shipping Requirements

Proper packaging is essential to prevent damage during transit, especially for heavy and sensitive components like hydraulic systems and lift arms. Use robust wooden crates or strong pallets with corner protectors and waterproof wrapping. Clearly label packages with handling instructions (e.g., “Fragile,” “This Side Up”) and include product identification, model number, and weight. For international shipping, ensure compliance with ISPM 15 regulations for wooden packaging materials, which require heat treatment and certification to prevent the spread of pests.

Import and Customs Clearance Procedures

Prepare complete documentation for customs clearance, including a commercial invoice, packing list, bill of lading or air waybill, certificate of origin, and product compliance certificates (e.g., ALI certification, CE Declaration of Conformity). Accurate valuation and declared country of origin are critical to avoid delays or penalties. Some countries may require additional inspections or approvals from local technical or safety agencies before the lifts are released. Work with a customs broker familiar with industrial equipment imports to streamline the process.

Storage and Handling at Destination

Upon arrival, store automotive lifts in a dry, level environment protected from moisture and extreme temperatures to prevent rust and component degradation. Use forklifts or cranes with appropriate capacity when handling lifts—never drag or drop units. Keep original packaging until installation to protect parts. Train warehouse personnel on safe handling procedures, especially for heavy counterweights and hydraulic components.

Installation and End-User Compliance

Ensure that installation is performed by qualified technicians according to manufacturer guidelines and local building codes. Anchoring lifts to a properly rated concrete floor (typically 4–6 inches thick with rebar) is mandatory. Provide end-users with comprehensive installation manuals, maintenance schedules, and safety warnings in the local language. Offer training or certification programs where possible, especially in commercial repair shops, to promote safe operation and reduce liability.

Environmental and Disposal Considerations

Automotive lifts may contain hydraulic oil, metal components, and electronic parts requiring proper disposal at end-of-life. Follow local environmental regulations (e.g., EPA in the U.S. or WEEE in the EU) for recycling and hazardous waste handling. Encourage dealers and customers to recycle steel frames and dispose of hydraulic fluids through certified facilities. Manufacturers should consider designing for disassembly and recyclability to meet growing sustainability expectations.

Record Keeping and Documentation Retention

Maintain detailed records of compliance certifications, test reports, import documentation, and customer warranties for a minimum of 5–10 years, depending on regional requirements. These records support traceability in case of recalls, audits, or liability claims. Digital archives with secure backups are recommended for efficient access and compliance with data protection laws.

Conclusion for Sourcing Auto Lifts (Elevadores de Autos):

Sourcing auto lifts requires a thorough evaluation of quality, safety standards, supplier reliability, and total cost of ownership. Whether purchasing for a repair shop, dealership, or industrial facility, it is essential to consider factors such as lift type (2-post, 4-post, scissor, etc.), weight capacity, certifications (e.g., CE, ALI), and after-sales support including installation and warranty. While domestic suppliers may offer faster delivery and easier communication, international suppliers—particularly from regions like China—can provide cost-effective options if due diligence is performed on product compliance and long-term serviceability.

In conclusion, the most successful sourcing strategy balances upfront cost with durability, safety, and support. Establishing relationships with reputable suppliers, conducting product inspections, and staying informed about industry standards will ensure the acquisition of reliable auto lifts that enhance workshop efficiency and operator safety over the long term.